- Regulatory requirements for apartment pressure regulators

- How to calculate loss?

- Calculation on straight sections

- In places

- Types of water pressure regulators

- Piston

- Membrane

- Flowing

- Automatic

- Electronic

- Installation

- Kinds

- Mechanical

- flowing

- Electric

- Auto

- Domestic

- Membrane

- Piston

- Electronic

- Which type and when to choose?

- Dependence of speed on pressure

- Step by step installation instructions

- Installation

- Instrument adjustment

- Selection Tips

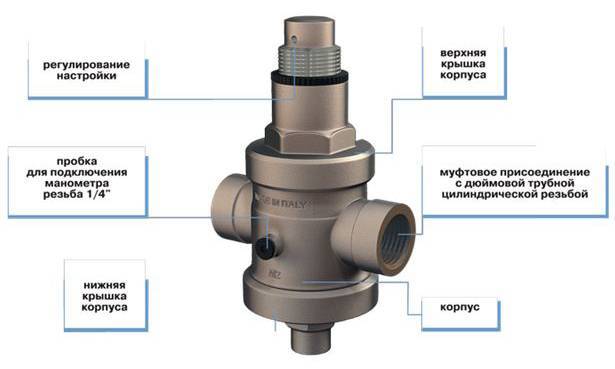

- Types of regulators and design features

- Flanged lever regulator

- Household products

- Electronic variety

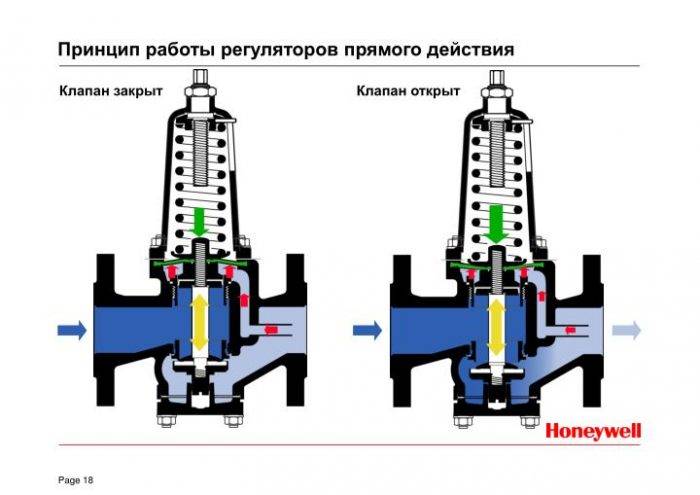

- Direct action device

- Regulator Honeywell

- Apartment regulators

- Purpose and scope of the device

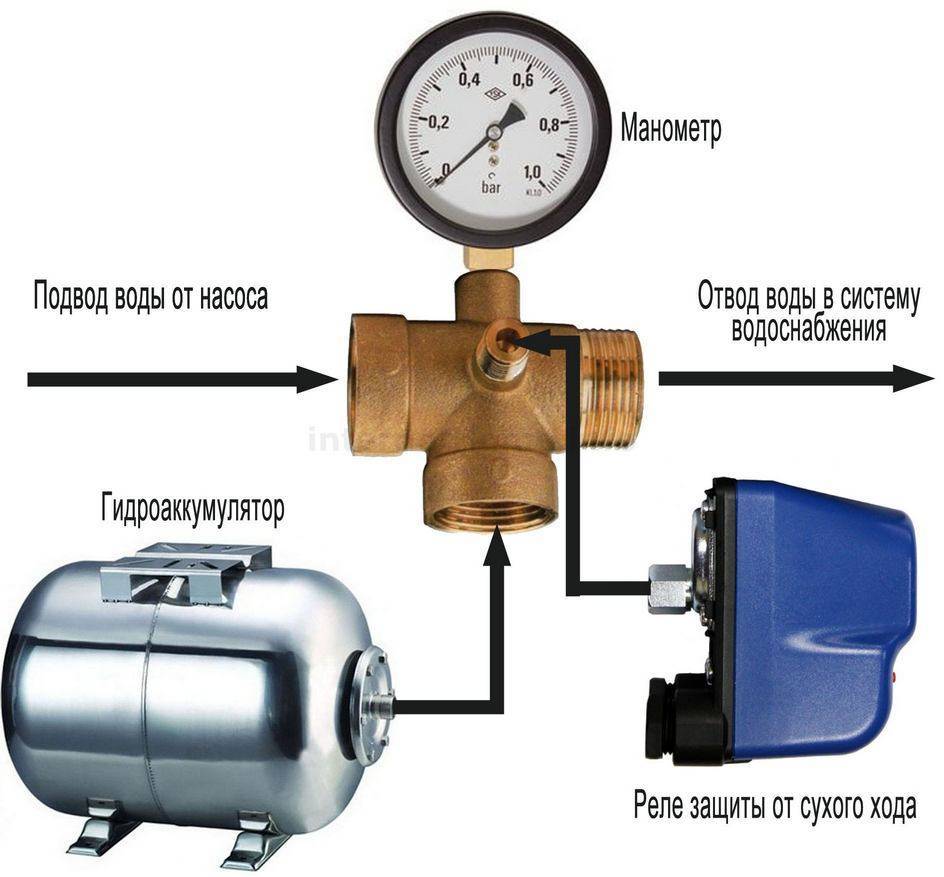

- Air pressure in the accumulator.

- So what specific air pressure should be in the accumulator?

- Method for monitoring and adjusting air pressure in a hydraulic accumulator.

Regulatory requirements for apartment pressure regulators

Unbalanced pressure drops in the hot and cold water risers lead to a change in the mixed water temperature setting at the mixer spout.Many have probably come across such a fact when the comfortable temperature of the water in the mixer suddenly began to change dramatically either towards boiling water or to absolutely cold water.

The presence of pressure regulators on the apartment inputs will make it possible to get rid of such an unpleasant phenomenon. The domestic regulatory framework governing the requirements for household water pressure regulators is currently represented by the following main documents:

- GOST 55023 Apartment pressure regulators. General specifications

- GOST 12678 Direct acting pressure regulators. Main parameters.

- Guidelines for the selection and use of apartment pressure regulators in residential and public buildings (Research Institute of Sanitary Engineering).

The main requirements for gearboxes set out in the listed documents are presented in the table:

| № | Characteristic name | Unit. | Meaning |

| Conditional throughput, not less than | m3/h | 1.6 (GOST R 55023) 2.5 (GOST 12678) 1.1 (Research Institute of Sanitary Engineering) | |

| Throughput in the operating range of inlet pressures, not less than | m3/h | 1,8 | |

| Throughput at inlet pressures below the operating range, not less than | m3/h | 0,72 | |

| Inlet pressure operating range | bar | 3–10 | |

| Operating range of expenses | m3/h | 0,18÷1,8 | |

| Maximum output pressure in the operating range of flow rates, no more | bar | 2,7±0,2 | |

| Maximum output pressure in non-flow mode, no more | bar | 3,5 | |

| Change in pressure when the flow rate changes by 0.05 l/s in the operating range of flow rates, no more | bar | 0,04 | |

| Full resource | thousand cycles | ||

| Noise level at a distance of 2 m from the device | dBA | ||

| Bending moment on the body, not less than | N m | ||

| Ambient temperature range | ºС | 5–90 | |

| Permissible ambient humidity | % | ||

| Medium temperature range | ºС | 5–90 |

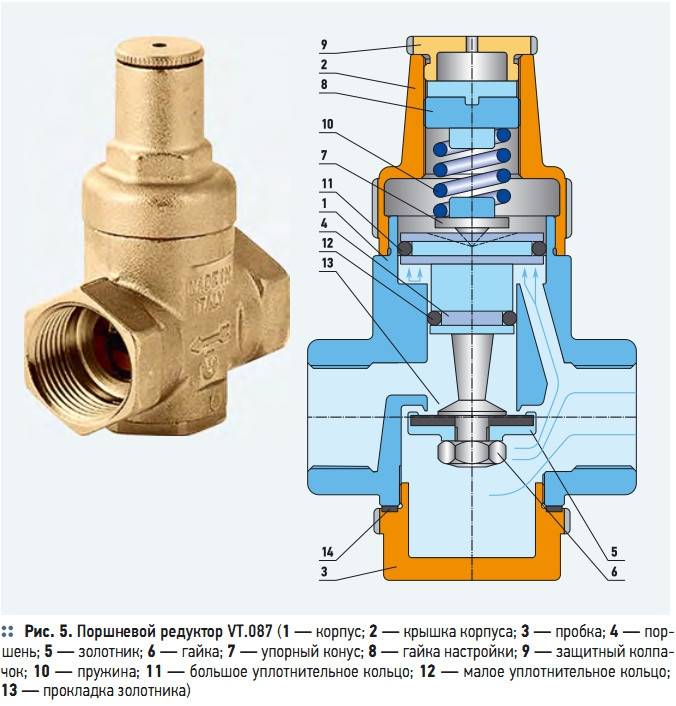

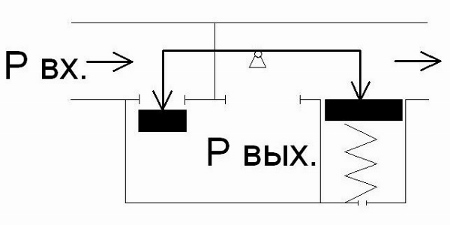

The principle of operation of apartment pressure regulators is based on balancing the forces created by the pressures at the inlet and outlet due to the ratio of the areas affected by these pressures.

The pressure at the inlet Рin acts on the small piston, trying to open it. Due to the throttling in the spool associated with the small piston, the pressure is reduced to Pout. This reduced pressure acts on the large piston to close the spool.

The large piston spring keeps the spool open when the inlet pressure is below the set pressure. A diaphragm can be used instead of a large piston.

How to calculate loss?

The loss of pressure in the water supply network occurs for the following reasons (blockages and rust of pipes are not considered):

- Pipe resistance in straight sections.

- Local resistance (bends, valves, etc.).

For the convenience of calculations, there are online calculators that in a matter of seconds allow you to find out the level of pressure drop in the pipeline. Also, to solve this problem, you can use special tabular data.

Calculation on straight sections

To calculate losses, you need to find out:

- water consumption;

- pipeline material, its diameter and length.

By selecting the desired value in the table and find out the amount of pressure reduction.

Tabular data for polypropylene pipes - for metal pipes, a correction factor of 1.5 must be added to the calculations. If the pipe length is less than 100 meters, then the result is multiplied by the length factor. So for a metal pipe with a diameter of 50 mm, a length of 35 meters and a water flow rate of 6.0 m³ / h, the following result will be obtained: 1.6 * 0.35 * 1.5 \u003d 0.84 mvs.

In places

Also, losses occur at the turns and bends of the pipeline, as well as at the locations of valves and filters.

For calculations, there is a special table, in order to use it, you need to find out the flow rate of water in the pipe - this is calculated as follows: the flow rate must be divided by the cross-sectional area of \u200b\u200bthe pipe.

Types of water pressure regulators

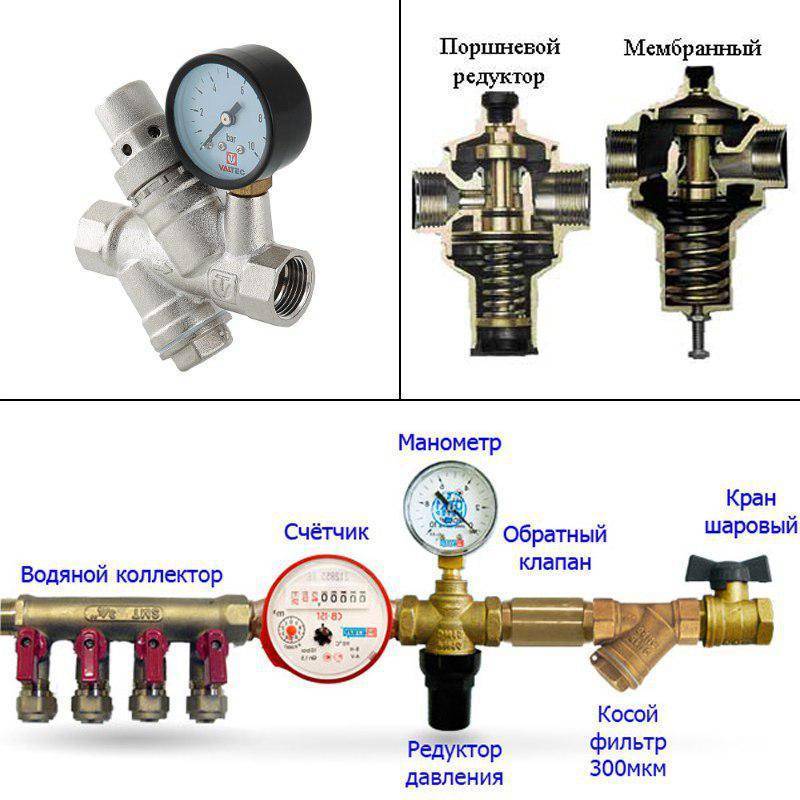

By type, pressure regulators can be divided into piston, membrane, flow, automatic and electronic. Let's consider each separately.

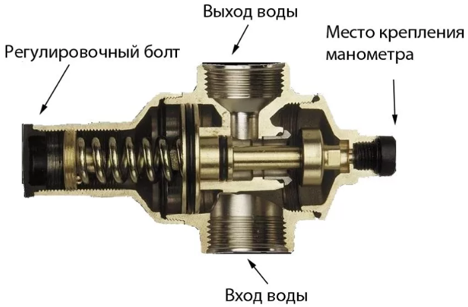

Piston

Piston regulator

Structurally, the simplest pressure regulator, also called mechanical. Due to the fact that the principle of its operation is based on the work of a spring-loaded piston. Which regulates the incoming pressure from the pipeline and sets it with an adjusting screw. By reducing or increasing the capacity of the reducer, according to the requirements of the user. The outlet pressure in the system is indicated by the installed outlet pressure gauge.

The disadvantages of this device include the sensitivity of the piston to various types of debris in the water supply. As a result, it quickly falls into disrepair. This problem is solved by installing a filter in front of the pressure regulator inlet. The throughput of such an RFE is from one to five atmospheres.

Membrane

Membrane

A pressure regulator that has earned the reputation of a reliable and unpretentious household appliance in use with a throughput from 0.5 m3 to 3 m3 per hour. Having a fairly high price due to the reliability of the design. Due to its high cost, it is better to entrust the replacement or installation of this unit to an experienced specialist.

The basis of its work is a membrane with a spring, located in a sealed chamber.Therefore, it is completely protected from various types of blockages. The spring transmits force to a small valve, which in turn regulates the size of the outlet water flow into the domestic plumbing system.

Flowing

Flow water reducer

The reliability and unpretentiousness of the flow-through WFD is ensured by the complete absence of moving parts in it. Which affects its durability.

Stabilization of the outlet pressure occurs due to the many narrow internal channels. Distributed over which, the chaotic incoming water pressure is first extinguished by passing through many turns. Comes to the given parameter, and then merges into one output channel.

The use of a flow-through pressure regulator, as a rule, is reduced to irrigation systems of personal plots.

Automatic

The automatic pressure regulator is structurally analogous to a membrane high-pressure hose. The presence of two screws for changing the operating pressure range in the plumbing system distinguishes it from the membrane.

The operation of the device is provided by a membrane and two springs, the compression force of which is regulated by special nuts. With a weak incoming water pressure, the membrane weakens. With an increase in inlet pressure, the membrane is compressed, leading to a decrease in the outlet channel.

Included with the automatic RFE is an automatic pressure regulator that actuates the springs on the membrane. With low pressure, the springs close the contacts, driving the pump. The task of which is to maintain the pressure in the system at a given level.

Electronic

Electronic water pressure regulator

This is a sophisticated device of a fully automatic type with silent operation, providing complete protection of the system against water hammer.

The electronic display shows current information about the characteristics of the flow of water in the home plumbing. The electronic mechanism continuously monitors the water pressure in the pipeline using a motion sensor.

The pumping station included in the set of the device turns on automatically when a signal is received from the tracking sensors. With dry water supply, the electronics will not allow the pump to turn on.

Thanks to a well-thought-out electronic mechanism, this device will fully satisfy all the needs of the user in automatic mode.

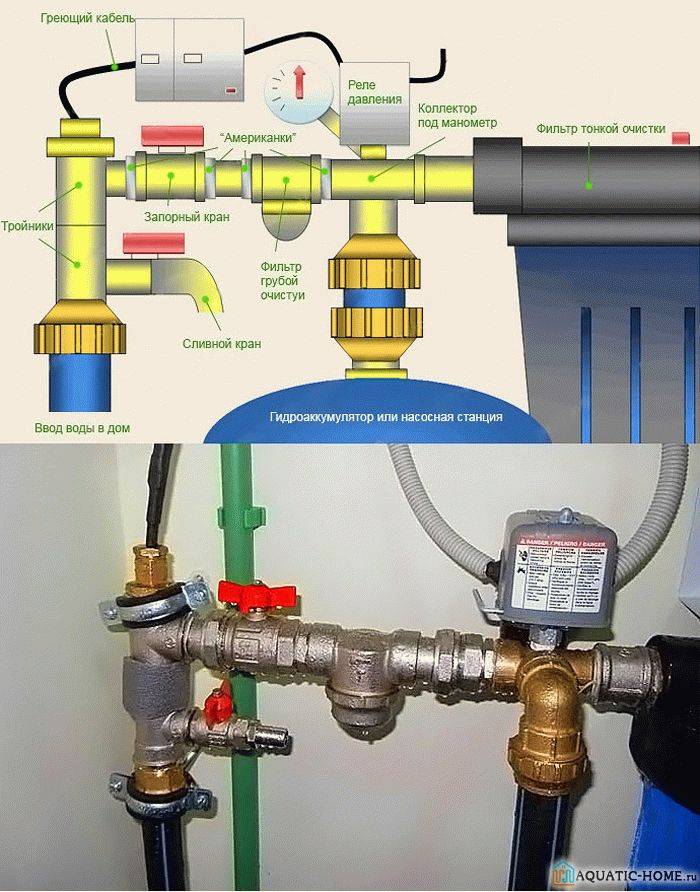

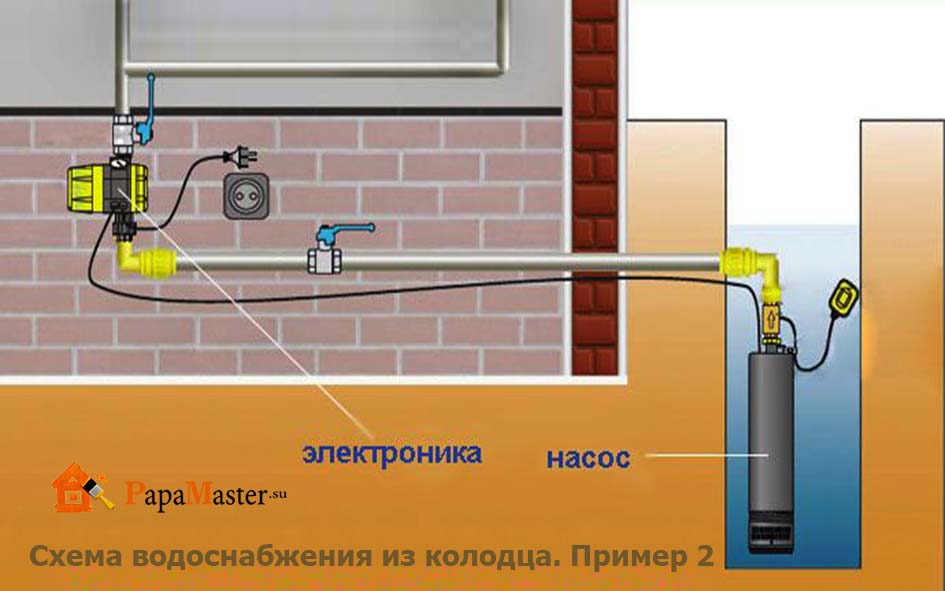

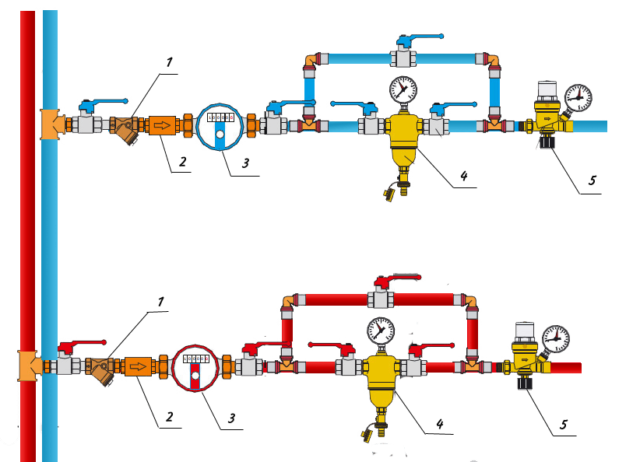

Installation

It is not recommended to install pressure regulators on your own, as it requires certain knowledge and skills. Consider the connection diagram of pressure reducers in the water supply system of the apartment.

Explanation:

- mechanical coarse filter;

- check valve;

- hot water and cold water meters;

- washing filter;

- Pressure reducer.

Installation of reducers is carried out in the main cold and hot water supply of the apartment. It is preferable to install pressure reducers on a horizontal section of the pipeline, but installation on a vertical one is also allowed. To ensure trouble-free operation of the gearbox, it is necessary to install a mechanical filter before it.

Usually the reducer is mounted behind the water meter. Behind the reducer, a pipeline of the same diameter with a length of 5xDn must be provided. To ensure the possibility of adjustment and maintenance of the gearbox, shut-off valves are installed behind it. If safety valves are provided in the system, the set outlet pressure of the reducer must be 20% lower than the opening pressure of the safety valves.

The set of rules for water supply and sewerage states that the installation of pressure regulators should be carried out immediately after the shut-off valves at the inlet, that is, before the metering devices.

This sounds sensible, because in this case the gearbox will protect all hydraulic devices, including the meter and the filtration unit.

But when installed up to the metering station, any possibility of water intake should be excluded, which means that the technical plugs for washing the filter and the stem will be sealed, and the gearbox itself will lose the possibility of maintenance.

This can be neglected, but even in this case it is very difficult to provide for different hydrodynamic resistance and achieve pressure equalization in the cold and hot water collectors. It is necessary either to install additional pressure gauges in them for more accurate adjustment, or to place pressure regulators immediately in front of the manifolds, as most experienced plumbers do.

Example of water distribution with a reducer

If it is not possible to install at the inlet of the system, but some components require protection against overpressure, local installation is also possible. There are quite a few primitive models of gearboxes for 20 mm pipe threads, and even without fine tuning, they do their job well with their protective function.

Kinds

There are many designs and sizes of such devices on the market that are designed to work in various networks or systems.

When choosing, you need to pay attention to the main parameters of the gearbox:

- Connecting dimensions. This is an important characteristic, since all household networks have a standard size of threaded connections - 1/2 inch.

As a rule, gearboxes are installed as part of an assembly - a ball valve filter and a coarse cleaning counter.

All of these devices have a 1/2 inch thread and are connected in series with each other.

If the gearbox has a different thread, you will have to complicate the assembly, look for adapters. In addition, extra connections will appear, which will increase the risk of leaks.

- The maximum allowable temperature. This characteristic will help determine whether the reducer is suitable for a hot or cold line.

- Device design.

Mechanical

The pressure is adjusted using a special valve that changes the size of the passage for the water flow. A spring acts on the valve, the force of which balances the water pressure.

As soon as it changes, the spring will either stretch or compress in response to the jump that has occurred. Mechanical devices are simple, easy to install and adjust. In addition, devices of this type are inexpensive, which increases their popularity among users.

flowing

This is a specific design designed to reduce excess water pressure while reducing flow. There are no moving parts inside such a device, which makes it almost eternal.

The water pressure is reduced due to the branching of the flow into a network of small channels. At the output, they are again combined into a single stream, but with changed parameters.

Note! The only problem with such devices is the dependence on water quality. Small particles gradually clog the channels, gradually putting the gearbox out of action.

Electric

This is a group of devices that provide precise and instantaneous adjustment of flow parameters.They have a different design, from fairly simple mechanisms with a servo pushing a stem with a valve, to complex devices with pressure sensors, actuators and a host of additional functions.

Despite their capabilities, electric gearboxes are not in high demand. They require power, maintenance and frequent adjustments. The price of these devices is much higher than that of mechanical models.

Auto

All gearboxes operate on an automatic principle. Therefore, absolutely any device can be attributed to this category, regardless of its design and technical parameters. This is precisely the value of the device - an automatic change in pressure that does not require human intervention.

However, there are also automatic gearboxes with a circulation start function. When the pressure increases, they stop the pump, and when it decreases, they start it, ensuring the nominal operation of the system.

Important! Are used in autonomous systems of water supply and heating.

Domestic

Household reducers are designed to work with flows of a certain pressure and temperature. Unlike industrial models, they are able to regulate pressure only up to 15 atmospheres. In residential buildings, apartment buildings or private houses, this is quite enough, and household appliances and plumbing require even less.

Membrane

The role of the valve is played by an elastic membrane, which is balanced by a spring. Diaphragm reducers are less dependent on water quality, so the demand for them is higher.

For a full specification of membrane regulators, click here.

Piston

Piston devices are a classic type of mechanical gearboxes.The functions of the valve are performed by a piston that closes the passage for the flow of water.

The force is balanced by a spring, the tension of which is regulated by a screw. The simplest, cheapest and most popular design.

Electronic

Electronic gearboxes are the most expensive and complex devices. They have high accuracy, but are rather capricious and require the creation of good working conditions.

Reference! Used in conjunction with expensive imported plumbing or household appliances.

Full information about electronic water pressure regulators in our article.

Which type and when to choose?

The choice of gearbox depends on the conditions of its operation, the features of plumbing and other factors. If the house has a lot of imported plumbing fixtures, dishwashers, washing machines, showers, etc., you need a high-quality and accurate gearbox with a guarantee of performance.

For a simple reduction in drops and cutoff of water hammer, a simpler mechanical model is suitable.

Dependence of speed on pressure

In water supply, there is one very important relationship - the dependence of pressure on the speed of water in the pipeline. This property is described in detail in Bernoulli's physical law. We will not consider it in detail, but we will only point out its essence - with an increase in the speed of the flow of water, its pressure in the pipe decreases.

It so happened that not all plumbing fixtures are designed for operation at high pressure, in most cases they are limited to 5-6 atmospheres, otherwise increased wear and premature failure.

In the central highways, this figure is much higher - it can reach 15 atmospheres, and therefore, to reduce it, when connecting internal systems, pipes of a smaller diameter are used.

Important. With a decrease in the cross section of the pipe, the speed of the flow of water increases, but its pressure decreases

Therefore, with a chronically low pressure in the apartment, it is necessary to consider the possibility of increasing the diameter of the internal pipeline.

Step by step installation instructions

Simplicity of design and ease of regulation allow you to perform work on embedding the device in a plumbing system without having professional skills.

Installation

Assembly procedure:

- Determine the installation position of the device. An arrow image is found on the device body and combined with the direction of the water flow in the system.

- The installation of the pressure regulator in the pipeline system is carried out with the help of two half-strings (at both ends).

The common name for this compound is "American". Usually these spare parts are included with the product, if they are not available, they are easily selected in any specialized store.

Depending on the material of the water pipes (polypropylene, metal-plastic, metal), the corresponding half-strings are bought. In some cases, the purchase of adapters is required.

In the polypropylene version of pipelines, connecting products are soldered to the ends of the pipes using a welding soldering iron. Then the regulator itself is installed by tightening the nuts of the half-wheels on both sides of the device. With a metal version of the pipeline, the connection is made using flax and sanitary sealant

To install polusgonov in this way, you will need a gas or adjustable wrench.

These same tools are used to tighten the nuts on the threaded ends of the regulator when it is connected to the plumbing system.

If the gearbox being installed is equipped with a pressure gauge, during installation pay attention to the visual availability of the readings on the dial of the device.

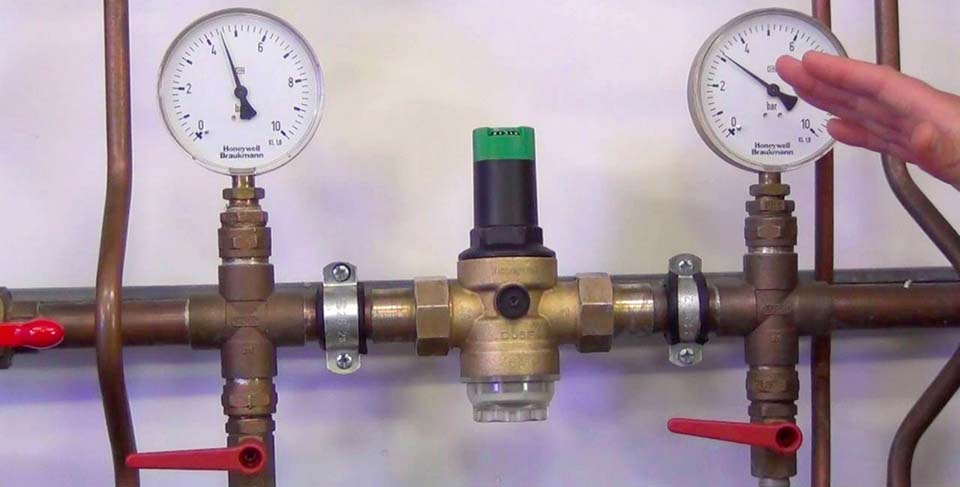

Instrument adjustment

The standard pressure in the water system is 2-4 atm, the real one is always higher. The factory preset pressure regulators correspond on average to 3 atm. For a longer service life of the gearbox, the difference in water pressure after the device should not exceed 1.5 atm in continuous operation.

To obtain the desired pressure, the gearbox is adjusted:

- with the help of shut-off valves (ball valve, valve) they shut off the water in the home plumbing system;

- using a flat or curly screwdriver, turn the adjustment screw to the desired angle;

- open the inlet tap and at the same time the valve of the sink or bath faucet, monitor the setting readings on the pressure gauge;

- the process is repeated until the desired results are achieved.

In modern models, a knob and a pressure scale are provided to adjust the pressure. Depending on the direction of turning the knob, the water flow at the outlet of the device decreases or increases.

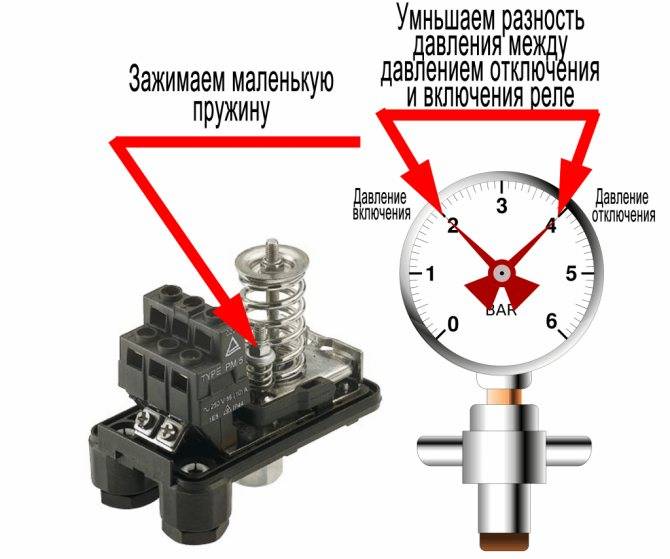

Selection Tips

Mechanical relays are simple, inexpensive and very popular. As a rule, they are made by domestic manufacturers. Models of foreign companies are both more expensive and equipped with a large number of devices. They have a scale for adjustment, a built-in pressure gauge and other useful devices.

Mechanical relays are very popular with owners of country houses. This can be explained by the following factors:

- these devices are quite simple in design, which determines the reliability of their work;

- their huge advantage is their independence from the power supply - and they do not need a separate outlet for connection;

- the price of such a product will be significantly lower than for electronic counterparts.

As for electronic pressure sensors, these units are very sensitive to any, even the slightest fluctuations and deviations from the specified parameters, and protection against dry running is also provided. There are also models on the market for which automatic start-up of the system after an emergency shutdown is provided. Such systems even notify the owner of problems by sending him warnings on his mobile phone. There are also many other useful additional features.

You can group pressure sensors based on their useful features and cost. Three main groups should be distinguished, such as:

- simple pressure controller;

- additional relay for protection against dry running (supplied in tandem with a conventional controller);

- a complex pressure sensor (an expensive device with a pressure gauge and a lot of functions).

Obviously, expensive electronic relays are no more complicated than mechanical ones, but the tasks that these devices cope with are much more extensive. So, electronic sensors have an additional regulator that prevents sharp fluctuations in water pressure in the system. As a result, uniform water pressure is ensured, regardless of whether the pump is on or off at the moment. Such controllers are usually installed together with hydraulic accumulators. This device controls the continuous measurement of pressure in the system and the comparison of the obtained readings with the given ones.

Thus, the choice of device is determined, first of all, based on the tasks assigned to the water supply system. If the complex is needed to provide water supply, for example, in a country house or in a small village house, then there is no need to spend money on purchasing a complex and expensive system. It is better to buy simple mechanical sensors of domestic production. If we are talking about a large-scale country house and life support, for example, for a large family with children, then, obviously, it is still worth spending more money and purchasing solid imported equipment with a large resource and productivity.

Types of regulators and design features

There are several varieties of such products. To choose a suitable device, you need to understand the purpose, design and characteristics of each variety.

Flanged lever regulator

This model is designed to contain too much head before and after the installed equipment. With its help, you can regulate the flow of fluid.

The device consists of the following parts:

- housings made of steel or cast iron;

- lever with supporting elements;

- membrane mechanism;

- covers;

- stems and valves;

- weights.

As a result of the impact of the weights of the valve open access to water

In this case, it is important to correctly adjust the device, taking into account the weights and fluid flow.

Household products

The household regulator is produced by the domestic company Pascal. These products extend the life of the pipeline and the valve mechanism. They reduce pressure, reduce noise and vibration in the network. Household structures differ in configuration.After their installation, energy consumption and water consumption are reduced.

Electronic variety

The electronic water pressure regulator in the water supply system includes a low-power pump that draws water from the water supply network. The operation of the unit is completely silent. Installed sensors protect against water hammer and idle operation of pumping equipment. They are part of an automated water supply system.

The device consists of a diaphragm, a housing, a sleeve with which it is connected to the cable, and a board. The unit is installed up to the first liquid intake point. It is equipped with incoming branch pipes, which allows it to be mounted in the main line. Before starting, the pump is filled with water.

The optimum pressure value is set by the manufacturer and is equal to 1.5 bar. In this case, the nominal value must exceed the starting value by no more than 0.8 bar. To adjust the starting value, use a special screwdriver.

Direct action device

Industrial products have a different flange valve. The price of such a device starts at $ 500. The network settings are used to adjust the value.

The unit consists of the following parts:

- bushings;

- boxes with flanges (outgoing and incoming);

- impulse pipes;

- big valve;

- membranes;

- pilot crane accessories.

When the threshold value is exceeded, the liquid penetrates into the valve container, and the membrane blocks the through hole in the device. As soon as the pressure is reduced, the membrane releases the passage.

Regulator Honeywell

This is one of the varieties of household models, which provides economical water consumption and maintains a constant pressure in the network. On sale there are combined models that include a filter and a regulator. They are easy to use and have an attractive design. Thanks to filters, water is purified from contaminants and impurities, extending the life of the water supply system. The filter is flushed without turning off the water.

Apartment regulators

To improve the quality of the fluid supply in the water supply system, a regulating mechanism is installed. Typically, products with a throughput of 3 cubic meters per hour are used.

Such units are installed in compliance with certain rules:

- The control device is installed in a heated room. The item must be freely accessible.

- The part must be protected from mechanical stress.

- The device is mounted so that the arrow on the body points in the direction of the water flow.

- Before installation, the main pipeline must be cleaned.

- It is recommended to use the regulator in combination with a strainer.

- To facilitate the maintenance of the device, a special valve is installed.

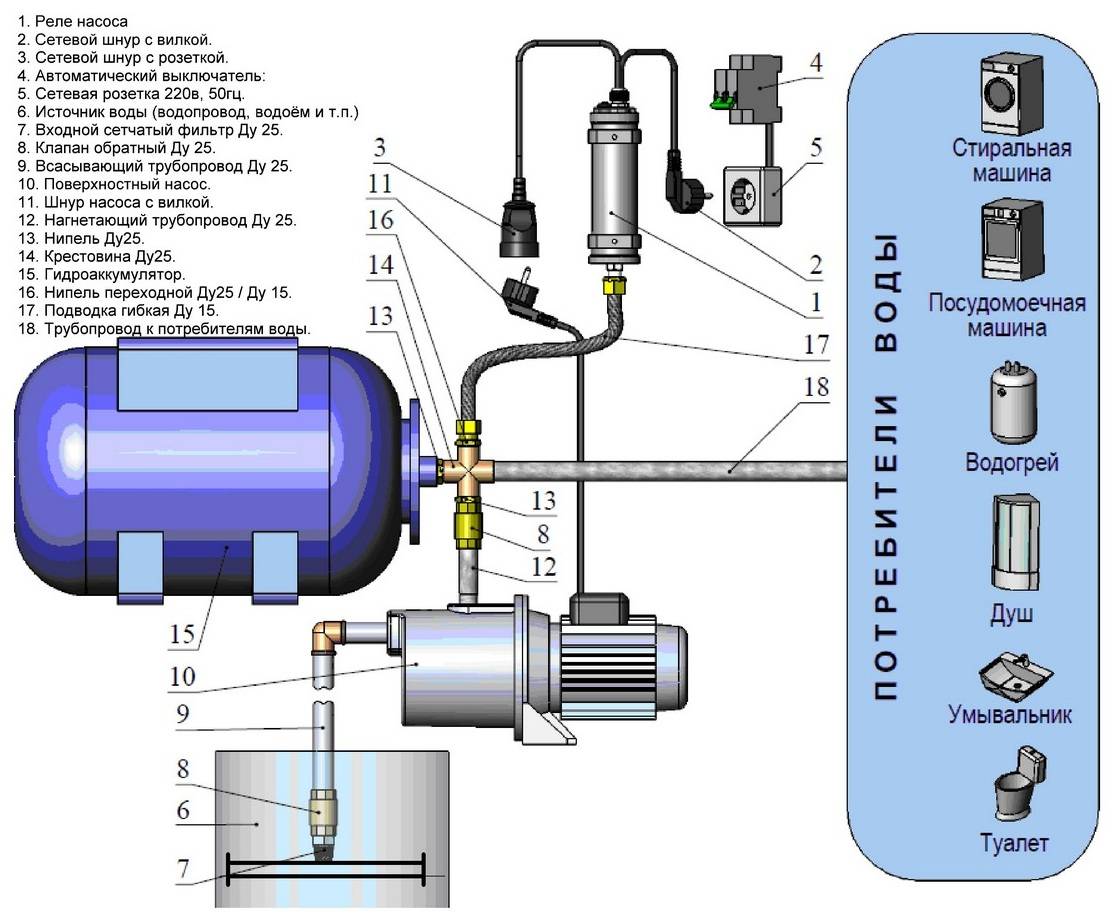

Purpose and scope of the device

Issues that many residents of large cities are not even aware of, after acquiring suburban real estate, immediately become relevant. Among them is a personal water supply device, one of the important elements of which is a pressure sensor.

Living in the open air is doubly pleasant if you can take a bath, use the washing machine, or turn on the automatic watering of beds planted with home-made vegetables, strawberries and herbs.To satisfy all the needs of the residents of a particular private household, a well-functioning water supply system is required.

To automate the process of water intake into autonomous water pipes, pressure sensors are installed, the following selection introduces the specifics of their use:

The owners of dachas and cottages use water from wells and wells. For its intake, modern equipment is used, the heart of which is a pump. It pumps water as needed. To extend the service life, a special sensor is installed that monitors the water pressure in the pipeline.

To water at the cottage did not end at the most inopportune moment, for example, while washing dishes or in the midst of swimming, auto control for turning on the pump will help

The second name of this device is a pressure switch. In some models of pumping stations, it is included. The sensor has the settings set by the manufacturer. Its purpose is to ensure the optimal frequency of switching on and off the pump.

If the relay does an excellent job with the function assigned to it, then the heart of an individual water supply system will work for a long time. Otherwise, the pump may overheat and burn out quickly.

When 5-6 households live permanently in the house, they turn on the taps to wash their hands, use the toilet, wash the dishes, take a bath, use the water to wash the car or water the garden. It is difficult to imagine how long a pump would last if the sensor does not control its operation. It would turn on every time users need water.

A regular drop in pressure and, as a result, a weak pressure of water, is fraught with frequent switching on of the pump.This may be due to an incorrect setting of the water pressure sensor.

Air pressure in the accumulator.

Those who already have a good idea of the hydraulic accumulator device know that water is under pressure inside the membrane, and air is pumped outside the membrane.

The water pressure inside the membrane is created by the pump and only by the pump, and with the help of a pressure switch or automation units, a pressure range is set (R on and R off) in which the entire water supply system functions.

The maximum water pressure for which the accumulator is designed is indicated on its nameplate. As a rule, this pressure is 10 bar, which is quite sufficient for any domestic water supply system. The water pressure in the accumulator depends on the hydraulic characteristics of the pump and the system settings, but the air pressure between the membrane and the housing is a characteristic of the accumulator itself.

Factory air pressure:

Each accumulator comes from the factory pre-aired. As an example, we give the values of the factory air injection for hydraulic accumulators of the Italian company Aquasystem:

| Hydraulic accumulator volume: | Air pre-injection pressure: |

|---|---|

| 24-150 l | 1.5 bar |

| 200-500 l | 2 bar |

| The indicated values may differ from manufacturer to manufacturer. |

The actual pre-charge pressure is also indicated on the accumulator label (pre-charge pressure).

So what specific air pressure should be in the accumulator?

For water supply systems with a pressure switch:

Pressure air in the accumulator be 10% lower than the pump cut-in pressure.

Compliance with this requirement guarantees the presence of a minimum amount of water in the accumulator at the moment the pump is turned on, ensuring the continuity of the flow.

For example, if the pump starts at 1.6 bar, the accumulator air pressure should be around 1.4 bar. If the pump starts at 3 bar, the air pressure should be around 2.7 bar.

For water supply systems with a frequency converter:

The air pressure in the accumulator must be 30% lower than the constant pressure maintained by the frequency converter.

It turns out that the factory air injection pressure is not universal for all systems, because the pump on pressure can be adjusted individually by the user and the tank manufacturer cannot predict it. Therefore, the air pressure must be adjusted in each specific system in accordance with the above recommendations.

Method for monitoring and adjusting air pressure in a hydraulic accumulator.

You can control and pump up air pressure with a standard car pump or compressor by connecting it to a nipple, which is usually located under a plastic protective cap.

All measurements must be made in a system without water pressure. Those. the pump must be disconnected from the power supply, open the lowest tap and wait for the water to drain completely.

The larger the tank, the longer it takes to fill it up. For accumulators with a volume of 50 liters or more, we strongly recommend using a compressor.

When changing (increasing or decreasing) the pump activation pressure, do not forget to also change the air pressure in the accumulator. And do not confuse this procedure with setting the pressure switch.

Over time, the pressure in the air cavity of the accumulator may decrease, so it is recommended to check it regularly.

Air pressure monitoring intervals:

- If you use the water supply system only during the warm season, then it is recommended to check it before the start of each new season.

- If you use the water supply system year-round, then it is recommended to check it 2-3 times a year.

You can treat this simple procedure as a planned maintenance. maintenance, which quite realistically extend the life of the membrane.

If you notice any oddities in the operation of the water supply system, it makes sense to make an unscheduled control of the air pressure in the hydraulic tank, as well as the pressure on and off the pump (controlled by a water pressure gauge).

By the way, the stability of the air pressure in the accumulator over a long time is one of the important indicators of its quality.