- Inset with overlay

- Preparatory stage and necessary tools

- Tips

- Structural features and application

- Mounting methods

- Adhesive connection

- Connection using a rubber ring

- Assembly with cement

- Socket welding of pipes

- Cast iron pipes for sewerage

- Technical characteristics of cast iron pipes

- Types and classification of cast iron pipes

- Dimensions and prices of cast iron pipes

- Pros and cons of operating cast iron pipes at the present time

- Disadvantages of cast iron systems

- Advantages of cast iron products in our time

- Inner and outer diameters of a cast-iron sewer pipe: assortment

- Range of pipe products made of cast iron

- Advantages of cast iron pipe products

- Installation of a sewerage system made of cast iron

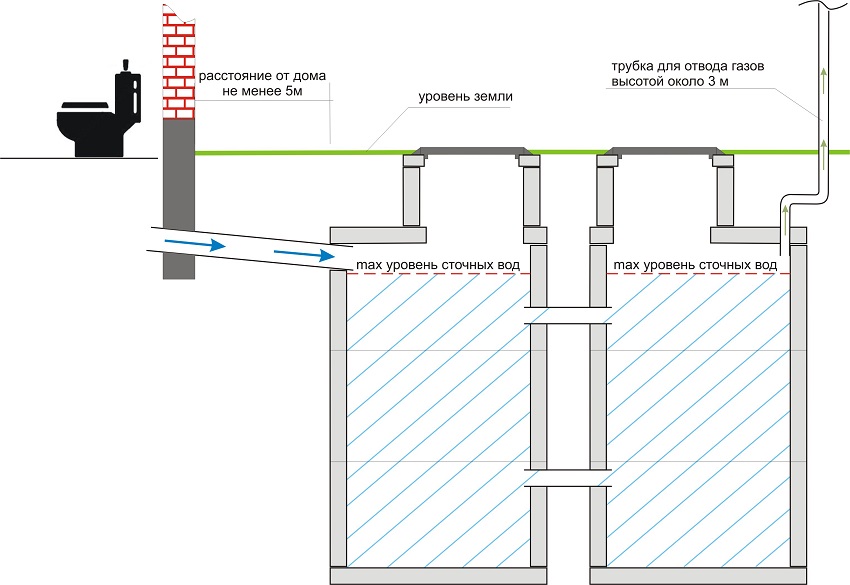

- The dimensions of the external sewage system are determined by the Sanitary Norms and Rules (SNiP)

- Advantages of cast iron pipes

- Sewer fittings

- Dimensions

Inset with overlay

Such an operation is carried out without removing the riser segment. To do this, it is necessary to accurately determine the tie-in point, drill or

cut a hole and install an adapter with an outlet of the desired size. Installation of the lining can be carried out on pipes of different diameters.The size of the hole being made will depend on their size, which should not be more than half the diameter of the pipe.

The lining can be purchased at the store or made by yourself. To do this, take a shaped part with the removal of the necessary

size and cut it out, leaving part of the wall of the product. This is necessary to seal the installation site. To ensure sufficient density, the pipe is cleaned, burrs and casting defects are removed. The installation site of the lining is lubricated with sealant. The device is fixed with clamps. Excess paste is removed.

The industrial adapter is installed in the same way, only it is attached with bolts. The tightness of the site is ensured by rubber sealing rings. Insertion using welding on cast iron pipes is not carried out, since it is impossible to achieve the required tightness.

Preparatory stage and necessary tools

Before you make a tie-in, you need to perform a number of preparatory work. In apartment buildings, sewer pipes run in technological shafts. To get to them, it is necessary to dismantle part of the wall masonry and prepare a place for work. The better this step is done, the easier it will be to work. To arrange the tie-in, you will need the following tools and materials:

- grinder with a cutting wheel for metal;

- a set of locksmith tools;

- perforator or drill;

- fittings, tees, bends, adapters;

- sealing mastics, clamps.

Before starting work, it is necessary to prepare a drawing (diagram) of the area to be installed, indicating the exact dimensions. Any inaccuracies made during installation may lead to the fact that the volume of operations performed may increase.In multi-storey buildings, it would be useful to notify the neighbors about the work being done and ask them not to use the sewer during this period.

Tips

Pipelines are installed for decades, the comfort of people and the efficiency of the life support systems of residential and commercial premises largely depend on their functionality.

That is why it is very important to choose good quality goods

The first thing you should pay attention to is the offered assortment. A reliable seller always has a wide selection of both the pipes themselves and related fasteners and fittings (nurses, etc.

P. ). It is quite convenient if the pipes themselves, and the tow, and other materials used to create hermetic joints are sold in one place.

This is not only convenient, but also profitable, since purchasing goods in several places significantly increases transportation costs.

It is very important to check all the proposed terms of payment and delivery of pipes, as well as the seller's warranty obligations and the possibility of returning defective goods with subsequent reimbursement of costs. And, of course, you need to make sure that the cast-iron pipes are of the proper quality.

- It is necessary to make an external inspection and make sure that there are no external defects: deformations, chips, cracks, metal influxes and slag layers. These defects must be absent both outside and inside.

- The dimensions of the products must exactly correspond to the existing GOST. The deviation should not exceed 2 mm, and the largest length error should be 0.9% of the nominal value in those. conditions.

Even in the production of cast iron pipes, they are coated with a special mixture based on bitumen, which determines the threshold for converting a hard layer into a softer one at a temperature of at least 60 degrees. It is not possible to measure the change in the required plasticity outside the laboratory, however, it is quite easy to verify the absence of cracks, blisters and other defects.

For this, several methods are used:

- At a temperature of at least 15 degrees Celsius, a white sheet of paper must be pressed against the outer surface of the pipe tightly, but without excessive pressure. After the sheet is separated, no traces should remain on it.

- The second method allows evaluating the reliability of the anti-corrosion coating. To do this, it is cut in the form of a grid so that a distance of 40-45 mm remains between the lines. If the coating remains intact, then the layer is of high quality, but if it begins to peel off, it is worth purchasing the product from another seller.

For information on how cast iron pipes are made, see the following video.

Structural features and application

The main feature of cast iron pipes from the TML classifier group is the purpose for installation underground at a depth of 0.8 to 6 meters. Designed specifically as elements of TML outdoor systems, pipes are distinguished by an increased degree of strength and anti-corrosion protection.

The operational parameters of the compression resistance make it possible to lay sewer lines without fear of damage, for example, under the roadway with large weight loads. But during installation, it is required to comply with DIN EN 877, 1610, GOST standards, which provide for the creation of an appropriate supporting foundation and ceilings.

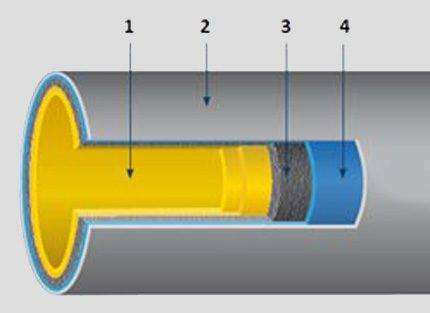

The structure of a modern socketless cast iron pipe consists of a two-layer internal coating with epoxy resin (1), an external coating with epoxy varnish (2), a working layer of cast iron with lamellar or spheroidal graphite (3), a protective zinc coating (4)

Among the features of a high-strength cast iron pipe, the presence of an effective coating (external and internal), including on shaped parts, should also be highlighted. The coating is carried out with the introduction of zinc and epoxy resins, which ensures high reliability of corrosion protection even in conditions of a pronounced aggressive environment.

These pipes can be successfully used for laying in soils with a high pH level (0-10). The internal lacquer epoxy coating of cast iron sewer pipes has a smooth (sliding) structure, which minimizes the coefficient of resistance to the movement of drains.

The structure of modern TML cast iron pipe:

- Coating with modified epoxy resin in two layers (layer thickness 120 µm).

- Protective coating with epoxy varnish (layer thickness 60 µm).

- Cast iron base layer with high carbon content.

- Protective coating with zinc powder (spraying density 130 g/m2).

The standard pipe length (3000 mm) can be easily shortened to the required size if necessary, for example with an electric pipe cutter. When cutting a cast-iron pipe, you need to ensure an accurate, even cut. This approach guarantees reliable sealing when assembling drain lines.

In addition, the cut edges are usually painted with a special paint and covered with Pro-Cut type insulating tape. Special seals are used for aggressive media. These measures further increase and negate the risk of leaks.

In this way, a joint is created at the edge of a cut cast iron pipe when Pro-Cut tape is used as a protective and sealing element.

The list of features of cast iron sewer pipes is impressive. Compared with the same polymer products, which are rapidly gaining popularity due to low cost, cast iron products have a lot of advantages.

Cast iron is not afraid of fire and high temperatures, while plastic pipes soften already at T = 100º, and at higher temperatures they begin to deform and may melt.

Cast iron pipelines are characterized by a low noise level during system operation and do not require the installation of expansion joints. They can be laid in the thickness of concrete without fear of rupture from compression / expansion of materials.

Thus, the acquisition costs are very soon compensated for by the economical operation of cast iron pipes. Their use does not require the creation of fire and noise insulation, the overhaul period is several times longer than the same period for plastic communications. The duration of operation is not limited even to 100 years.

Mounting methods

It may seem that the socket technology for connecting pipeline sections is the only option that ensures the tightness of the system. However, there are other methods as well. They are selected taking into account the type of material from which communications are made. If this factor is not taken into account, the reliability of installing a socket sewer pipe will decrease significantly. You will have to regularly repair the system, eliminating the leak.Such problems can be avoided if the installation is carried out in accordance with the instructions.

Adhesive connection

This option can only be used when laying polymer pipes, in particular, PVC products. This is due to the fact that such a material has a structure different from metal analogues. When performing installation, it is necessary to use a special adhesive for polymer communications

It is necessary to work with such a composition carefully, because. it instantly glues the elements

After installation, water cannot be supplied to the system for 1 day.

Work instructions:

- To increase adhesion, the smooth end of the pipe is treated with sandpaper.

- At a distance of at least 2 cm from the end, a special glue is applied.

- It is necessary to immediately connect 2 parts, because. composition sets quickly.

- It is necessary to hold a section of the pipeline for several seconds, pressing 2 pipes tightly against each other.

- The glue sets in 1.5 minutes.

If the system is tested immediately after gluing communications, the quality of the connection will decrease. Soon, a leak may appear in this area.

Connection using a rubber ring

The use of products with a socket implies the need to ensure tightness. This condition is difficult to fulfill if a sealing rubber ring is not used during installation. Thanks to it, the required level of reliability is ensured, and the service life of the structure is extended. The rubber ring is in most cases offered together with communications. If you purchased an understaffed product, you can purchase the seal separately.

A groove is provided for installing the rubber ring. It runs along the entire circumference of communications. The seal must be placed in the groove.Moreover, you should carefully check the quality of installation: the ring should fit snugly against the walls of communications; if waves form, then an unsuitable element was purchased. After installing the seal, it is possible to connect sections of the pipeline - a smooth end is inserted into the socket. Additionally, it is recommended to apply silicone sealant from above along the entire circumference of the mounting joint.

Assembly with cement

This method is called - chasing; it is suitable for steel, cast iron, ceramic, asbestos concrete, reinforced concrete products. This technology is used when the gap between the walls of the socket and the smooth section of communications is large enough. In addition, chasing is used to connect products from different materials.

Operating procedure:

- Prepare the linen sealer. Prepare a solution of cement and water. The components are taken in a ratio of 9:1.

- Then you need to fill the gap between the socket and the smooth end with a linen sealant. It is rammed using a screwdriver, a narrow spatula. Leakage is filled to 2/3 of the length.

- At the last stage, the seam is sealed with cement mortar.

The system is tested no earlier than after 1 day.

Socket welding of pipes

This technology is considered an auxiliary measure. It is used for mounting cast iron products, but only after caulking. First, the gap at the junction of the sewer pipe and the socket is sealed with linen material, then cemented according to the previously discussed method. And you need to leave 1-2 cm from the edge of the socket free. Welding takes place in this area.

Cast iron pipes for sewerage

Plastic pipes, due to their low cost and other advantages, have almost completely replaced cast-iron counterparts in sewer systems. However, due to certain technical characteristics, the cast-iron pipe still remains in demand for sewerage. They can be found not only in old systems, but also in new ones.

Of course, cast iron pipes cannot be called an ideal material for arranging pipelines, but nevertheless they are quite reliable products with a number of advantages. Although cast iron is a brittle material, it can crack when subjected to mechanical impact: impact or fall, but with careful installation it will last for decades.

Technical characteristics of cast iron pipes

Most often, cast iron pipes are used for sewerage in multi-storey buildings and industrial premises. The sewerage of a private house is less subject to heavy loads, so they are rarely used there.

They are mainly used when laying external sewerage, that is, where the pipeline passes outside the house and is subject to heavy loads. Cast iron pipes withstand the load from the soil pressing on them.

Performance characteristics of cast iron pipe:

- high strength and wear resistance - according to statistics, they have the smallest percentage of pipeline accidents;

- resistant to hydraulic shocks - withstand loads up to 550 N / mm²;

- good sound insulation;

- stacked to a depth of 10 m;

- withstand low temperatures - up to minus 60 ° C;

- can be laid in an "arc" without using connecting elements;

- service life of 80 years.

The warranty period for a cast iron pipe is 80 years, with high-quality installation and proper operation, this period increases to 100 years or more.

Types and classification of cast iron pipes

Depending on the scope of application, cast iron pipes are classified into:

- pressure - VSHCHG (high-strength cast iron with nodular graphite);

- non-pressure - CHK (cast iron sewer);

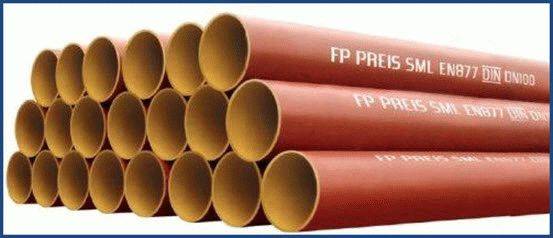

- socketless - SML;

- pressure socket - ChNR (pig-iron pressure socket).

Let's consider these varieties in more detail.

The main scope of pressure pipes made of cast iron is industrial production. By adding spherical graphite to cast iron, it becomes ductile and viscous. That allows it to replace products from simple cast iron and cast or forged steel. Pressure pipes successfully compete with steel pipes, this is due to their high corrosion resistance and service life, which is 3 to 8 times longer.

They can be used in aggressive environments and at low temperatures, have high strength, therefore they are used for sewerage at great depths and under highways. They are produced both with a socket connection and with the use of rubber sealing cuffs.

Non-pressure

This type of cast iron pipe is not as strong as the previous one. Lamellar graphite is used for their production. Therefore, non-pressure cast iron pipes are used only in systems without high loads, for example when laying internal sewerage. The advantage of these products is the possibility of combining with plastic pipes (rubber adapters are used for this) and reuse (with careful dismantling).

Socketless

For the manufacture of socketless products, cast iron with the addition of a large amount of graphite is used. Inside they are coated with special compounds based on epoxy resin, which helps to reduce the formation of layers.Also, this coating protects the pipe from corrosion, which allows it to be used in aggressive environments.

The advantage of SML pipes is: no need for additional fire and sound insulation, high strength and resistance to high temperatures. Since they do not have a socket, they are connected using special clamps. The main scope of application is the device of water disposal systems.

bell-shaped

For many years of use, a cast-iron pipe with a socket has not lost its relevance and is still a sought-after material. Their advantage is considered to be durability, when compared with metal products that rust very quickly.

The disadvantage is fragility, which makes the installation process a little more difficult. To protect against corrosion, the inner and outer surfaces are coated with bituminous compounds.

Dimensions and prices of cast iron pipes

- inner diameter - conditional patency, for home use, the value of 50, 100 and 150 mm is mainly used .;

- construction length - the size of the pipe, excluding the socket, can be from 750 to 2200 mm.

Pros and cons of operating cast iron pipes at the present time

There are several disadvantages and advantages of operating systems made of cast iron. Below is a list of the main ones.

Disadvantages of cast iron systems

- Heavy. It is necessary to use special equipment in order to transport;

- Cost and complexity of installation. Highly skilled craftsmen are required to install the system correctly.

Advantages of cast iron products in our time

- Cast iron products are practically not subject to corrosion, since the level of resistance to it is much higher than that of steel products;

- Good soundproofing. The sounds of flowing water are practically inaudible during use;

- Pipes do not burn because cast iron is a fire resistant material;

- Durable, less often cracks appear under mechanical stress and pressure drops;

- Cast iron is environmentally friendly, does not emit toxic and toxic fumes and substances.

Many people believe that cast iron is brittle and not flexible, and even with light blows it will crack. In fact, this only applies to gray and some other types of cast iron. The fact is that scientists have long developed a formula for a new, high-strength cast iron. This is a special ductile iron with nodular graphite (VCSHG). The secret is that it contains inclusions of graphite in the form of spheres. It is because of them that the crystal lattice of cast iron does not collapse upon impact and mechanical damage, as happens in gray cast iron, where graphite is contained in the form of plates.

Due to the fact that in apartments with old systems that have served their time and were laid at the beginning of the twentieth century, accidents often occur and the help of a repairman is required, it is also believed that cast-iron pipes have a high accident rate. However, ductile iron, with proper care and timely prevention, are able to withstand heavy loads, such as erosion and movement of soils, destabilization of the base, strong temperature changes, and so on. All these loads of the system are more often transferred without any pipe breaks, seal failures and cracks.

When choosing a material for pipes, the cast-iron version is most often abandoned due to the fact that they believe that pipes are mounted only by caulking. This is a complex process that includes sealing the gap with a hemp strand, and then sealing the joint with a cement mixture.Such connections cannot be flexible, and the slightest movement can lead to leaks, which leads to the need for repairs later.

However, at present, instead of chasing, much more modern methods of connection are used, the most durable and resistant to movement. One of the most common methods is "Titon". With this method, the tightness of the pipe connection is achieved due to the fact that a sealing ring is included in the socket. This connection withstands high pressure. It is used for complex laying of pipelines in mountainous areas, in a vertical position, or when the ground is unstable.

In ductile iron, the specific resistance to electric current is much greater than that of steel, and when using rubber cuffs in the joints, the pipes do not allow the current to move through the water supply.

Since the cuffs are made of rubber - a rather short-lived material, the question arises: will the cuff become a stumbling block? Over time, cuffs made of rubber change their mechanical properties, which gradually leads to an increase in the deformation of the cuffs.

However, when using flare connections, sealing is achieved by pressure between the pipe and collar. Due to this, the deformation of the ring is almost constant, which means relaxation is the only thing that affects the cuff. This is also one of the features due to which the service life of cast iron systems reaches 100 years.

Inner and outer diameters of a cast-iron sewer pipe: assortment

Pipe products made of cast iron are used in the installation of internal and external (channelless and channel) pipelines for sewerage. Their service life sometimes reaches a hundred years.The assortment of cast-iron sewer pipes and connecting elements is determined by GOST 6942-98, and quite strictly.

Range of pipe products made of cast iron

There are only three units of assortment, which differ in the size of the cross section. Two main types: SMU - with smooth ends and SME - one end is smooth, the other is with a socket. Pipe products made of cast iron are marked according to the nominal section.

The first part of the inscription is the grade of the material, the second part is the nominal section (for example, if the marking indicates DN 100, then the inner diameter of the cast-iron sewer pipe is 100 mm, the outer diameter is Ø110 mm). Products with a socket are divided into 3 classes - A, B, LA (depending on the wall thickness).

The weight completely depends on the dimensions, for example, a cast-iron sewer pipe DN50 - 11 kg, DN100 - 25 kg, DN150 - 40 kg, DN 1000 - 620 kg. But this is just an estimated mass, which may differ significantly from the real one. Due to the large weight, cast iron tubular products are sold in lengths of 0.75-7 m.

When choosing, it should be borne in mind that you should not purchase materials with a thick wall if the pressure in the system is low. This will reduce the cost of purchase, transportation and installation.

Advantages of cast iron pipe products

- designed for 80-100 years of operation without losing their qualities;

- resistance to the formation of a corrosive layer;

- resistance to mechanical damage;

- ability to withstand frost down to -60 ° C;

- plastic;

- low operating costs (rarely requires repairs);

- easy disposal and recycling;

- environmental Safety;

- wide operating temperature range;

- the ability to dig to a depth of 10 meters;

- during installation, welding, socket connections and fittings can be used.

The disadvantages include heavy weight, roughness of the inner surface and the need for special materials for mounting hermetic joints.

Installation of a sewerage system made of cast iron

For internal sewerage, a cast-iron pipe 50 (du) and 100 (du) is used.

Mounting is done with fittings.

- knees (bell-shaped, socket-smooth end, flanged);

- bends (socket, 10°, 15°, 30°, 45°, 60°, socket-smooth end 10°, 15°, 30°, 45°, 60°0;

- double sockets;

- branch pipes (flange-bell, socket-smooth end, with the transition to steel);

- plugs;

- releases;

- tees;

- crosses;

- transitions.

To ensure tightness, the use of a sealing gasket is mandatory. When laying vertically (for example, a riser - a sewer pipe Ø 110), the pipeline is hung on supports and attached to the wall with brackets and clamps. This method of installation is due to the weight of cast iron products, for example, cast iron Ø100 weight 20.8 kg.

Tubular products of all manufacturers are made according to the same dimensions. For example, a cast-iron pipe 150 is the same in Russia as in Ukraine, so they are completely interchangeable.

But this condition is not valid if the old sewage system is installed from material made before 1974. In this case, adapters are needed.

The dimensions of the external sewage system are determined by the Sanitary Norms and Rules (SNiP)

- intra-quarter network - the diameter of the cast-iron sewer pipe is 150 mm;

- street network - 200 mm;

- street storm network - 250 mm.

External networks are mounted mainly in a bell-shaped way:

- the smooth end of one segment is placed in the socket of the other;

- the free space is filled with tow and minted with a special tool and a hammer;

- tow should fill 2/3 of the volume of the socket;

- the remaining third is filled with cement mortar or silicone sealant.

To properly arrange the sewerage system, it is necessary to correctly calculate the diameter of the cast-iron pipe and fittings. The dimensions vary in a fairly wide range, allowing you to install a pipeline of almost any configuration.

Advantages of cast iron pipes

The main operational qualities of pipes are determined by the characteristics of the material used in their manufacture. The advantages of cast iron pipes include the following points:

Strength. There is a fairly large number of loads that can be placed on the pipeline. Among all, it should be noted the pressure arising inside the system from water, vapors or gases, as well as outside - the soil, elevated buildings, groundwater, and so on. Cast iron pipes differ from the rest in that they can withstand fairly high pressure. Therefore, they are used when laying central highways, which are laid to a great depth.

Corrosion resistance not only to water, but also to domestic, technological wastewater. Water causes corrosion on metal pipes, which leads to a decrease in strength and service life. In addition, we note the various chemicals that affect both galvanized metal and plastic. Cast iron is less susceptible to chemicals. Therefore, pipes from this material are quite common in industry.

Durability.High corrosion resistance and strength determine that the type of pipe in question can last for several decades: the main thing is to exclude the possibility of impact point loading.

Preservation of properties over a long period. If the plastic may lose rigidity over time, the shape of the pipe will change under the influence of pressure, then the cast-iron version remains unchanged for a long period.

Wear resistance. When designing a pipeline, the throughput indicator is taken into account. Water and runoff over a long period of exposure can affect the material like sandpaper. Such a process of surface abrasion is long, but with the active operation of the system for several years, it will be noticeable. Modern casting methods can reduce the surface roughness index, increasing wear resistance.

Low coefficient of thermal expansion. Plastic pipes are quite popular, but are not applicable in many industrial premises due to the loss of rigidity when the ambient or internal temperature rises. If you need to organize the supply of hot water or steam, it is cast-iron pipes that are suitable: even when exposed to high temperatures, the plasticity index does not change.

Fire safety when using cast iron pipes is at the highest level: the material in question does not ignite or melt.

Variety when choosing. Today, you can purchase pipes of the type in question of almost any length, since such material is extremely difficult to process.

In addition, we pay attention to the fact that when searching for sections with a very large diametrical size, attention should be paid to the particular type of pipes under consideration.

In addition, we note the relatively low cost in comparison with galvanized and aluminum pipes. Of course, in terms of price, they are significantly inferior to plastic pipes (their use alone when creating a central highway or pipelines in industrial premises is always in question).

Sewer fittings

There are a lot of types of connections for pipelines, they are used in certain cases. For example, when installing a non-pressure system, the connection element "in the socket" is more often used. It is used in such pipelines because it is simple and easy to install, and also does not require the use of additional sealing equipment.

In other cases, various seals are used for the tightness of the structure. Previously, ordinary tow was taken as sealants, today elastic rubber seals are used.

The main connecting parts of the pipeline are fittings. They are designed to seal, attach branches and give bends to the system.

Among other things, to connect pipelines used:

- Adapters - parts that connect branches of different sizes.

- Couplings. Connect individual elements of the pipeline.

- Elbows are fittings connecting vertical and horizontal branches. Can have an angle of 22.5, 45, 90°.

- Tees - connecting three branches. They are produced in the form of "Y" and "T".

- Revisions are fittings designed to clear blockages and maintain the system.

- Crosses - fittings connecting several branches located in different planes.

Dimensions

Plastic sewer pipe elements are produced in accordance with GOST 51613-2000. The dimensions of PVC pipes are determined by such indicators as length, outer diameter, inner diameter of the socket, through diameter, wall thickness. The outer diameter refers to the nominal size of the product. The throughput depends on the bore diameter.

The wall thickness determines the strength of the pipeline, what load the pipe structure can withstand.

According to the class of strength classify:

- lightweight SN2 structures with a wall thickness of less than 2.3 mm are capable of withstanding loads up to 630 Pa;

- medium-heavy SN4 with walls from 2.5 to 12.3 mm depending on the diameter, cope with pressure from 600 to 800 Pa;

- heavy pipes SN8 with wall thickness from 3.2 to 15.3 mm, varying with diameter, endure pressure from 800 to 1000 Pa.

A sewer pipeline capable of withstanding pressure up to 1.6 MPa is made of non-plasticized PVC with a wall thickness of 0.5 to 1.9 cm. It is used for laying to great depths, under highways, in pressurized sewer systems.

Sewer pipes are divided depending on the installation site. There is an external and internal sewage system. For the arrangement of internal sewerage, gray pipes are used. Standard diameter sizes are 32, 40, 50, 75, 110 and 160mm. The wall thickness is not designed for high loads, varies from 1 to 3.2 mm. The length can be 0.3, 0.5, 1, 1.5, 2 and 3 meters.

Pipes for external drain are orange. Depending on the amount of wastewater, diameters of 110, 125, 160, 200, 250, 300, 400 and 500 mm are produced. The wall size starts from 3 mm, the length varies from 1.2 to 3 m.For the arrangement of urban sewer systems, a diameter of 200 mm or more is used.

Depending on the pressure to which the walls of the pipeline are subjected, a pressure and non-pressure sewer system is distinguished. For internal gravity sewerage, pipes with a wall thickness of 1.8 to 3 mm are taken. For a street pipeline with a free-flow drain, products are produced with a wall size from 3.2 mm with a diameter of 11 cm to 1.2 cm with an outer diameter of 50 cm.

A pressure sewer system with pumping equipment requires increased strength characteristics. Plastic pressure pipes are made of unplasticized PVC with a greater thickness. The table shows the possible wall parameters depending on the test pressure from 800 Pa to 1.6 MPa.

| Diameter, mm | Wall thickness, mm |

| 90 | 2,2–6,6 |

| 110 | 2,7–8,6 |

| 160 | 4,0–9,5 |

| 225 | 5,5–13,4 |

| 315 | 7,7–18,7 |

| 400 | 9,8–23,7 |

| 500 | 12,3–23,9 |

In addition to the smooth-walled PVC pipeline, a corrugated pipe is produced. It differs in the increased rigidity and different diameter. Gray corrugation of small diameter, used to drain waste from a washing machine, dryer, dishwasher. Two-layer corrugated pipe structures of large diameter from 11 to 120 cm are used for laying to a depth of up to 15 m with high mechanical impact. The table represents the dimensional form of the release of corrugated pipes.

| Outer diameter, mm | Inner diameter, mm | Corrugation protrusion pitch, mm |

| 110 | 91 | 12,6 |

| 160 | 139 | 12,6 |

| 200 | 176 | 16,5 |

| 250 | 216 | 37 |

| 315 | 271 | 42 |

| 400 | 343 | 49 |

| 500 | 427 | 58 |

| 630 | 535 | 75 |

| 800 | 678 | 89 |

| 1000 | 851 | 98 |

| 1200 | 1030 | 110 |