- We calculate the power of a cast-iron radiator

- Video instructions for assembling sections

- About the design and types of cast iron radiators

- Calculation of the actual weight of heating appliances

- Technical characteristics of cast iron radiators

- Features of the choice of cast iron radiators

- Modern market

- Let's talk about the difference in the price of radiators

- Main materials used for production

- Cast iron radiators

- Steel heat exchangers

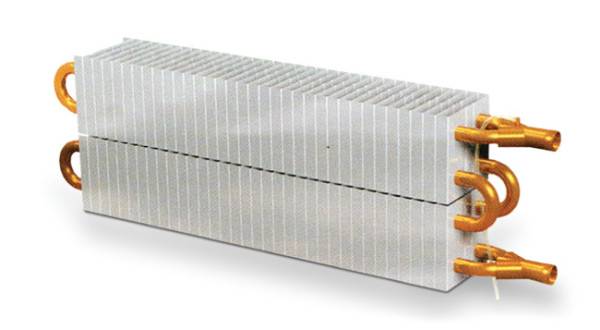

- Aluminum radiators

- Bimetallic batteries

- Panel heating systems

- Types of heating radiators for a private house

- Cast iron radiators

- Steel heating appliances

- Bimetal radiators

- Aluminum radiators

- Copper radiators

- plastic radiators

- Types of aluminum radiators

- Casting technology

- Extrusion Technology

- Anodized heatsinks

- Ability to hold pressure

- Features of decorative radiators

- TOP-4 steel heating radiators

- Axis Classic 22 500×1000

- Buderus Logatrend K-Profil 22 500×1000

- Kermi FKO 22 500×1000

- Arbonia 2180 1800 270

- Characteristics of cast iron radiators of various manufacturers and models

We calculate the power of a cast-iron radiator

You can calculate the number of sections for cast iron heaters using a variety of methods.In specialized books, there are methods that include a large number of factors, including the area of \u200b\u200bthe room, the location of windows and doorways, the material and structure of the walls, technical indicators of batteries, etc.

However, you can get the desired value using a simpler formula: multiply the area of \u200b\u200bthe room by 100 and divide by the power of one section.

The result obtained should be corrected as follows:

- In rooms with a height of more than 3 m, 1-2 sections are added to compensate for heat losses

- It is necessary to add several sections for rooms in which two walls border the street

- In rooms with two window openings, radiators are installed under each of them, dividing the number of sections found equally. This is necessary in order to form air barriers under the windows for cold through flows from outside.

- A fractional value is always increased in a positive direction

Design

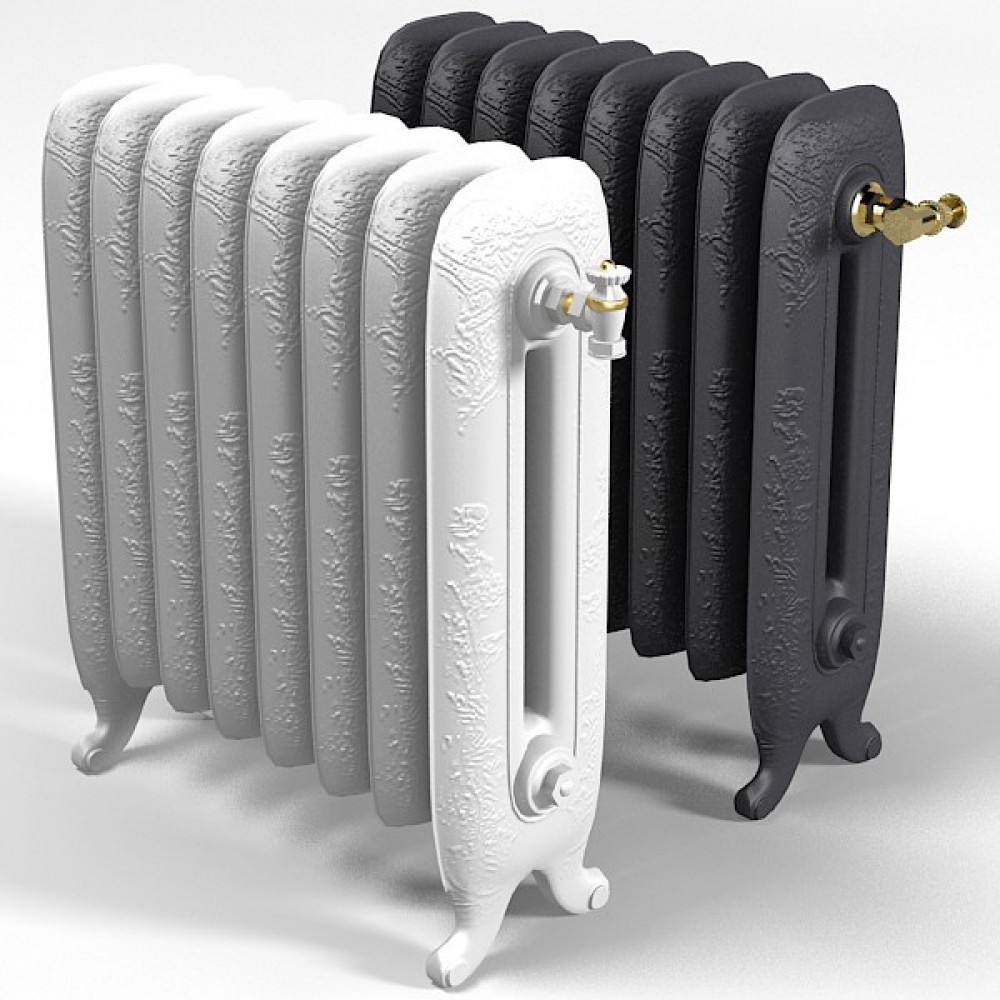

Classic cast-iron radiators differ little in appearance. However, the development of the market for heating appliances and the constant change in the style features of the interior forced manufacturers to come up with something new, more elegant and extravagant.

Today, the market offers models of various color palettes (gilding, silver, copper, bronze, etc.). There are radiators with artistic casting, on which ornaments are applied.

However, the external design significantly affects the cost. Decorative models are much more expensive than classic, modern aluminum, steel or bimetallic ones.

Video instructions for assembling sections

Summing up

Having considered in more detail the features and technical characteristics of cast-iron heating radiators, you can get your own idea of \u200b\u200bthese heaters. However, it is impossible to assert their great superiority over other models. The reason is that each of the proposed options has its pros and cons.

Due attention should be paid to cast iron models when designing a heating system. They can be purchased for savings in a used condition and do not worry that they will soon fail.

About the design and types of cast iron radiators

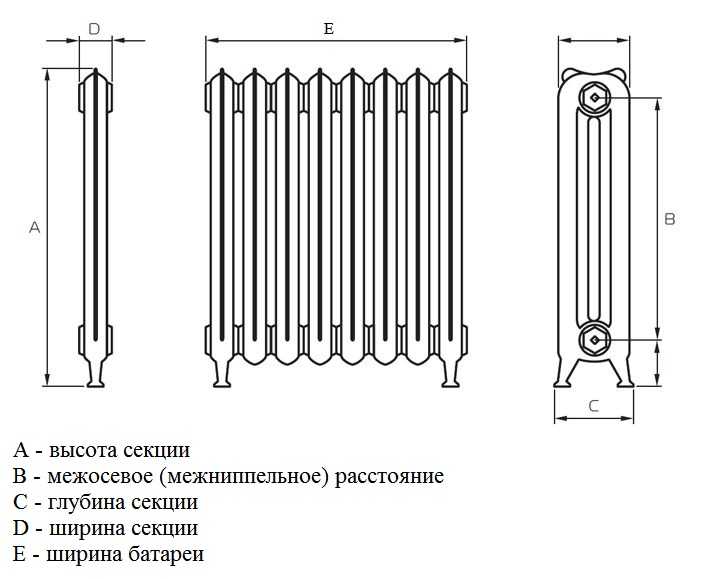

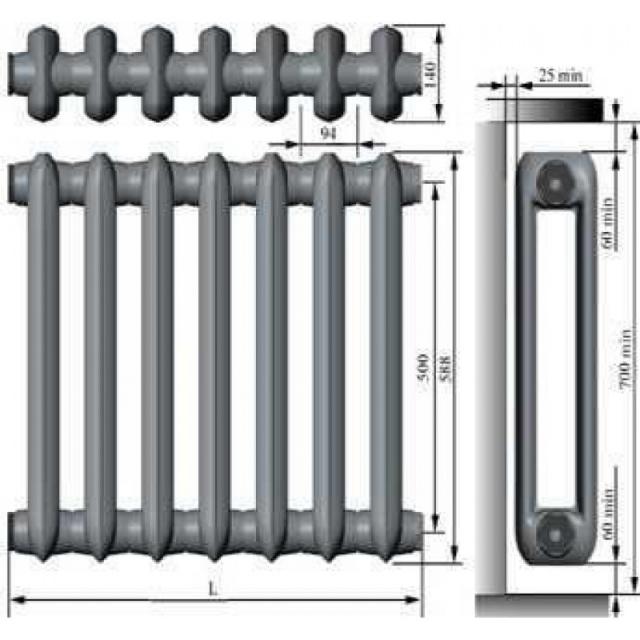

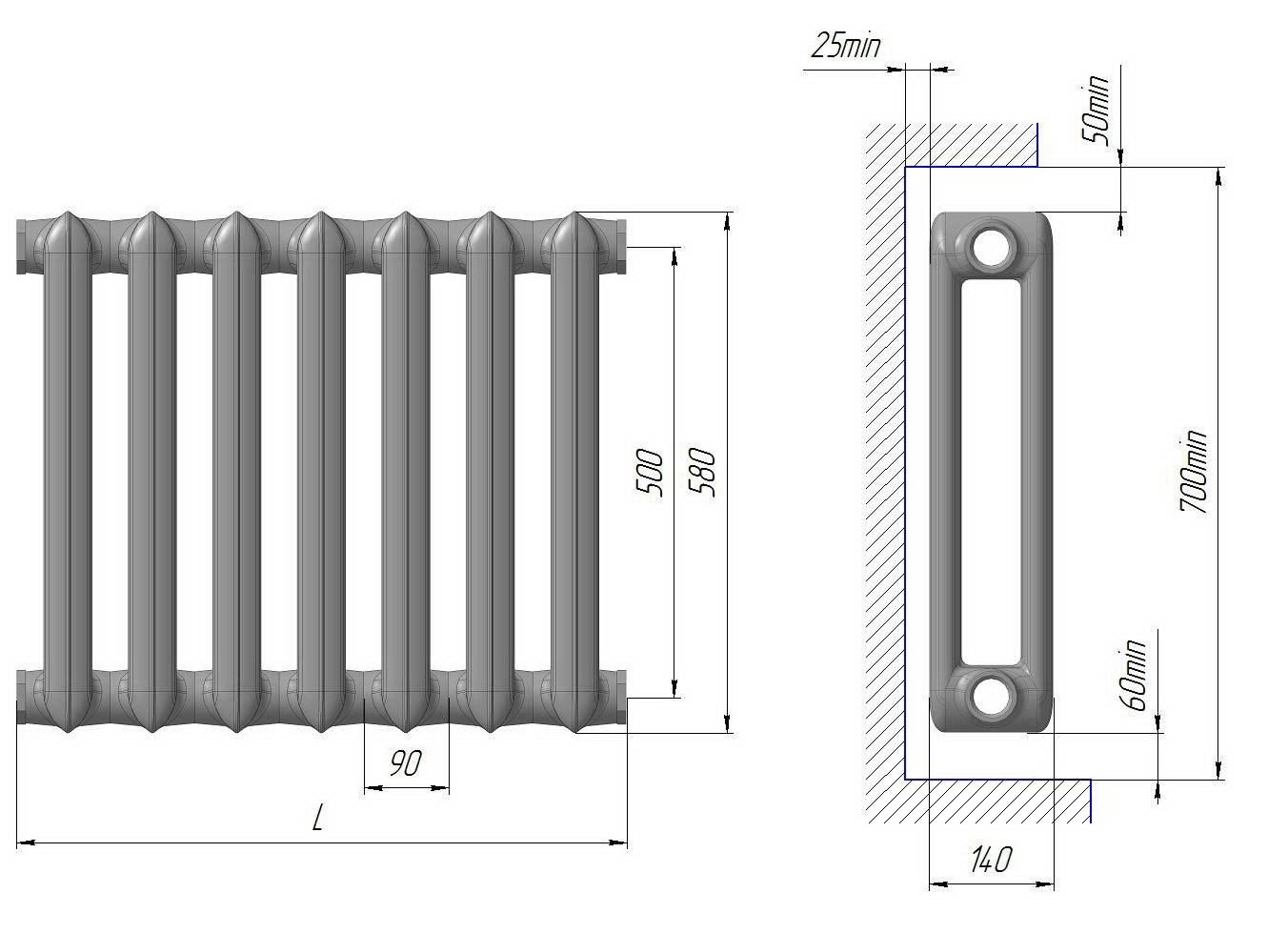

Each radiator, like a designer, is made up of several identical sections. They are cast in the factory from gray cast iron. Channels through which hot water flows can be round or elliptical. At the assembly stage, the sections are connected to one another using nipples, and the joints are additionally sealed. To do this, take heat-resistant rubber or paronite gaskets.

By the number of channels in one section, they can be:

- single-channel;

- two-channel.

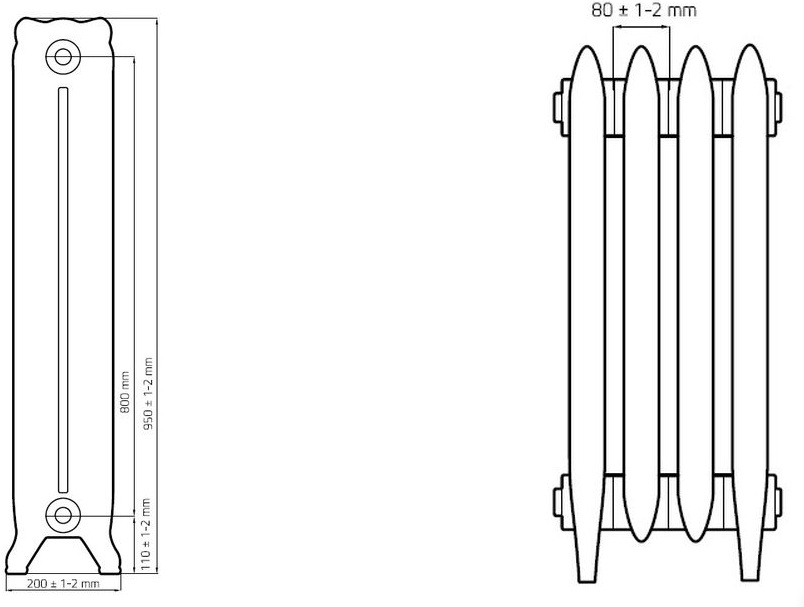

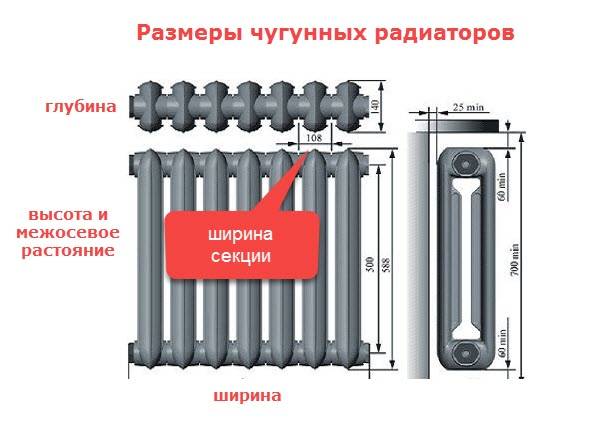

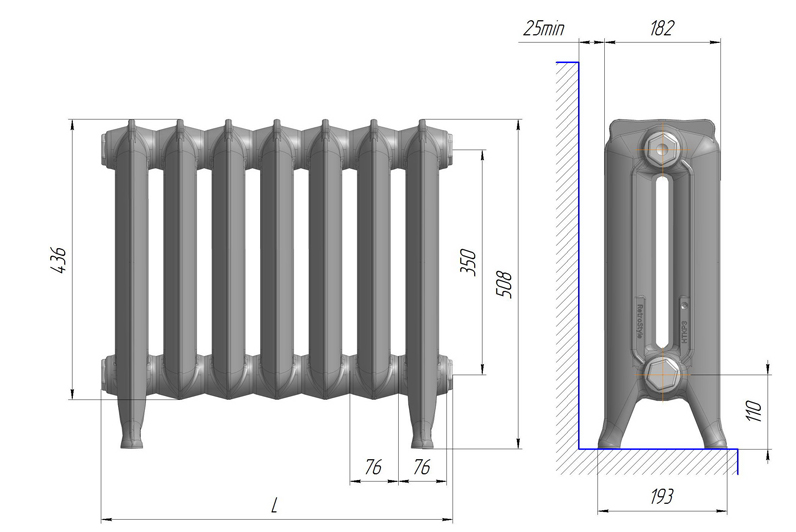

Cast iron radiators can have different widths (which depend on the number of sections) and heights. The width of the radiator depends on the volume of the heated room, the number of windows in it, the thickness of the outer walls. After all, the more sections are used, the more heat the radiator will give off. As for the height, it can range from 35 centimeters to one and a half meters. Let's not forget to look at such an indicator as the depth of the radiator. After all, it depends on her how these cast-iron products fit into the design of the room. Depth can also matter from 50 to 140 centimeters or more.

For installation, you will need special strong brackets that must be securely fixed to the wall.After all, usually heavy batteries are hung under the window opening on these brackets, positioning them so that the battery recedes some distance from the wall. However, now there are new models of the floor type, which come with legs.

Calculation of the actual weight of heating appliances

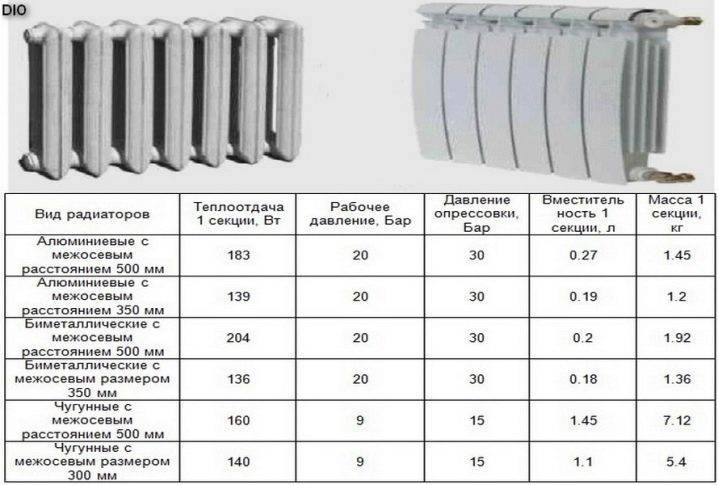

Now let's calculate the weight and number of sections for cast-iron heating batteries that provide a heat transfer of 2 kW. Let's start with the old model - MS-140, whose power is 160 W from one fin. To dial 2000 W, you need to divide them by 160 W, we get 12.5 sections, rounded 13 pcs. The total weight of the finished batteries will be 13 x 7.12 = 92.6 kg, and with water - 112 kg. That is, for every kilowatt of heat transfer, there are 112 / 2 = 56 kg of the mass of the radiator filled with coolant.

In the same way, we calculate the specific gravity of the cast iron batteries presented above and find out how far the technology for manufacturing such heaters has gone ahead. Let's put the results in the table:

| Radiator brand and model | Power of 1 fin, W | Number of sections providing 2 kW of heat | Weight with water, kg | What is the weight for heat transfer of 1 kW, kg | The price of a radiator for 2 kW, c.u. e. |

| Viadrus KALOR 500/70 | 70.3 | 29 | 139 | 69.5 | 582 |

| Viadrus Bohemia 450/220 | 110 | 19 | 234 | 117 | 1487 |

| Demir Dokum Nostalgia 500/200 | 163 | 13 | 155 | 77.5 | 679 |

| Retro Style Anerli 560/230 | 189 | 11 | 223 | 111.5 | 2526 |

| EXEMET Modern 600/100 | 102 | 20 | 100 | 50 | 640 |

| EXEMET Classica 500/176 | 145 | 14 | 158 | 79 | 1076 |

Based on the analysis carried out, the following conclusions can be drawn:

- The thermal power of the heating device practically does not depend on its mass, only on the surface area.

- Manufacturers make both massive and lighter models of cast-iron batteries that are attached to the walls.

- The heaviest cast iron radiators are made in the retro style, while the lighter ones are made in the modern style.

- If we compare new heaters from different brands with “accordions” in terms of coolant volume, it becomes clear that this indicator has not changed much.

- Massiveness is ensured by the thickness of the cast-iron walls. This means that the thinnest walls are from products from the Turkish brands EXEMET and Demir Dokum, and the thickest from the Russian manufacturer Retro Style.

- Note that the weight of cast iron affects the final price of the product. The heavier the product, the more expensive it is.

Technical characteristics of cast iron radiators

The technical parameters of cast iron batteries are related to their reliability and endurance. The main characteristics of a cast iron radiator, like any heating device, are heat transfer and power. As a rule, manufacturers indicate the power of cast-iron heating radiators for one section. The number of sections may vary. As a rule, from 3 to 6. But sometimes it can reach 12. The required number of sections is calculated separately for each apartment.

The number of sections depends on a number of factors:

- area of the room;

- room height;

- number of windows;

- floor;

- the presence of installed double-glazed windows;

- corner apartment.

The price per section is given for cast-iron heating radiators, and may vary depending on the manufacturer. The heat dissipation of batteries depends on what material they are made of. In this regard, cast iron is inferior to aluminum and steel.

Other technical parameters include:

- maximum working pressure - 9-12 bar;

- maximum coolant temperature - 150 degrees;

- one section holds about 1.4 liters of water;

- the weight of one section is approximately 6 kg;

- section width 9.8 cm.

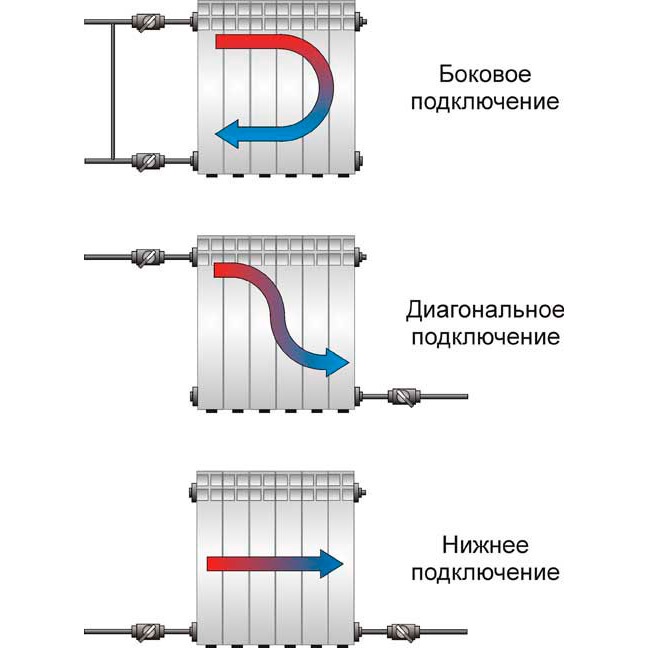

Such batteries should be installed with a distance between the radiator and the wall from 2 to 5 cm. The installation height above the floor should be at least 10 cm. If there are several windows in the room, install Batteries are needed under every window. If the apartment is angular, then it is recommended to carry out external wall insulation or increase the number of sections.

It should be noted that cast iron batteries are often sold unpainted. In this regard, after purchase, they must be covered with a heat-resistant decorative composition, it must first be stretched.

Among domestic radiators, the ms 140 model can be distinguished. For cast-iron heating radiators ms 140, the technical characteristics are given below:

-

- heat transfer of the MS section 140 - 175 W;

- height - 59 cm;

- the radiator weighs 7 kg;

- capacity of one section - 1.4 l;

- section depth is 14 cm;

- section power reaches 160 W;

- section width is 9.3 cm;

- the maximum temperature of the coolant is 130 degrees;

- maximum working pressure - 9 bar;

- the radiator has a sectional design;

- pressing pressure is 15 bar;

- the volume of water in one section is 1.35 liters;

- heat-resistant rubber is used as a material for intersectional gaskets.

It should be noted that cast iron radiators ms 140 are reliable and durable. Yes, and the price is quite affordable. Which determines their demand in the domestic market.

Features of the choice of cast iron radiators

To choose cast iron which radiators are better all suitable for your conditions, it is necessary to take into account the following technical parameters:

- heat transfer. Choose based on the size of the room;

- radiator weight;

- power;

- dimensions: width, height, depth.

To calculate the thermal power of a cast-iron battery, one must be guided by the following rule: for a room with 1 outer wall and 1 window, you need 1 kW power per 10 kV.m area of the premises; for a room with 2 outer walls and 1 window - 1.2 kW .; for heating a room with 2 external walls and 2 windows - 1.3 kW.

If you decide to buy cast-iron heating radiators, you should consider the following nuances:

- if the ceiling is higher than 3 m, the required power will increase proportionally;

- if the room has windows with double-glazed windows, then the battery power can be reduced by 15%;

- if there are several windows in the apartment, then a radiator must be installed under each of them.

Modern market

Imported batteries have a perfectly smooth surface, they are of better quality and look more aesthetically pleasing. True, their cost is high.

Among domestic analogues, konner cast-iron radiators, which are in good demand today, can be distinguished. They are distinguished by a long service life, reliability, and fit perfectly into a modern interior. Cast iron radiators konner heating are produced in any configuration.

- How to pour water into an open and closed heating system?

- Popular Russian-made outdoor gas boiler

- How to correctly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes in case of malfunction

Recommended reading

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement entails legal liability. Contacts

Let's talk about the difference in the price of radiators

Cast iron is undoubtedly cheaper, especially domestic production. So, the cheapest section of the MS model, for example, costs only about 300 rubles. However, only classic models will have such a “tasty” price. But radiators in the "retro" style, made by the method of artistic casting, are several times more expensive. Similar models of the Konner brand cost from 2000 rubles (for one section).

Sectional models of bimetallic radiators will be somewhat more expensive than similar cast iron ones. For example, one radiator section from Rifar (Russia) will cost at least 500 rubles. The price of a section of the same Italian radiator starts from 600-700 rubles.

Price: Cast iron + | Bimetallic -

Main materials used for production

Currently, the main criterion that separates all models of low radiators available on the market is the material from which they are made. Along with the traditional ones, which were used in the last century, new types appear that have better performance properties.

Cast iron radiators

The elements made of cast iron stand out with the longest history of use. They are distinguished by high heat transfer, prolonged cooling and heating, large mass and their low resistance to shock loads.

The increased roughness of the inner surface of the cast sections of the cast-iron battery contributes to the accumulation of dirt and rust deposits on its walls, which significantly reduces heat transfer over time.

Note! Despite the fluidity of cast irons, the manufacturer manufactures heat exchangers with a height of at least 390 mm. This is due to the disadvantages mentioned above.There are batteries made at a sufficient artistic level, which allows you to decorate the interior of rooms.

There are batteries made at a sufficient artistic level, which allows you to decorate the interior of rooms.

Here is a decoration you can install at home

Steel heat exchangers

Products from this iron-carbon alloy may be smaller than cast iron. They are a lamellar structure, the basis of which are metal pipelines. This aspect significantly reduces the required amount of coolant in the system and, as a result, increases its output.

In the photo - steel panel batteries

Heat exchangers made of steel have a number of positive and negative aspects. Their mass is much lower than cast iron, they are more compact and have a greater heat transfer. The disadvantages include susceptibility to corrosion and poor resistance to water hammer.

Steel heating radiators low in height have poor repairability. If one of the sections is damaged in a cast-iron battery, it is easy to replace or eliminate it.

The steel product will have to be replaced entirely, which will lead to additional costs. The price of such units is one of the most significant in the segment.

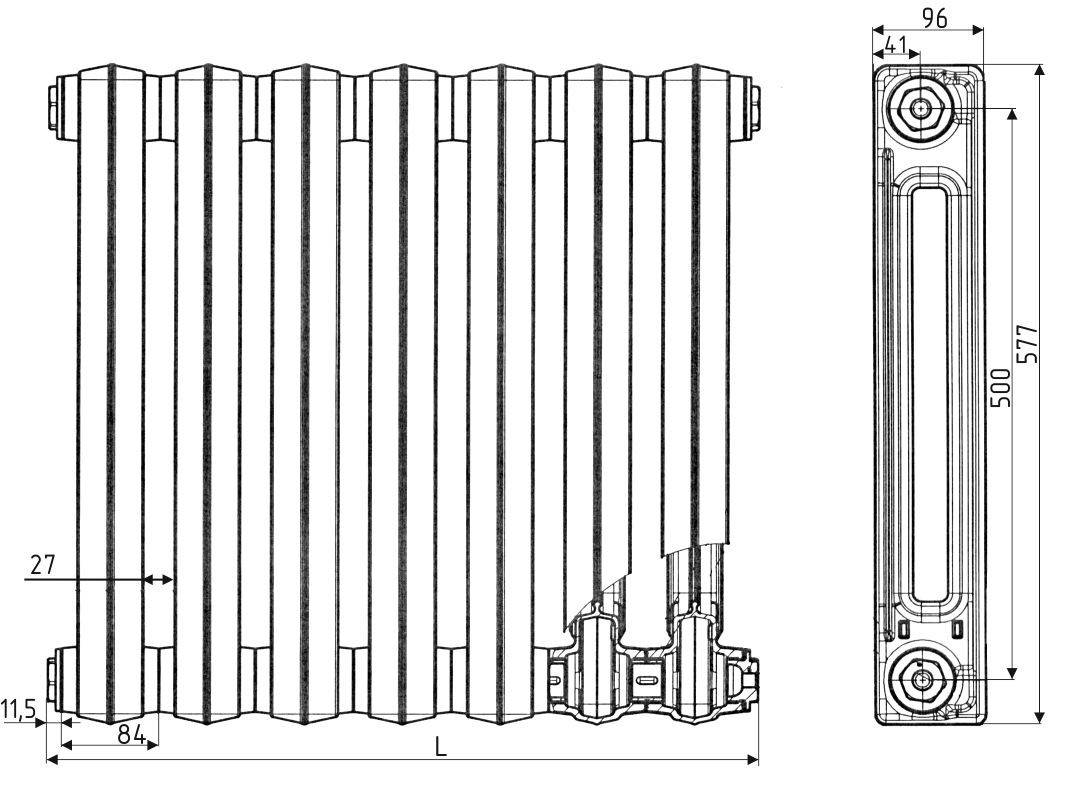

Aluminum radiators

Low aluminum heating radiators have a set of advantages over their competitors.

- the minimum mass of all such products;

- good heat dissipation;

- and the plasticity of the metal makes it possible to obtain products of elegant shapes.

The size of the devices does not affect their characteristics.

Note! Aluminum does not have high strength characteristics, which can lead to the formation of leaks due to water hammer in the system, formed during filling or draining. The average service life of such products does not exceed 12-15 years. The cost of radiators made of aluminum is low

The cost of radiators made of aluminum is low.

Bimetallic batteries

One of the last types of heating devices recommended for use in individual heating systems of private houses are the so-called bimetallic batteries. They are made on the basis of steel or copper pipelines equipped with aluminum plates.

Reliable strength of two metals in bimetallic devices

Their advantages include the following:

- sufficient corrosion resistance;

- significant (up to 100 atm.) working pressure that they are able to withstand;

- low volume of coolant required for heating.

Such structures also have disadvantages:

- lower heat transfer compared to aluminum products;

- the highest cost among all low radiators.

Panel heating systems

In the event that you decide to get your home's heating system completely devoid of visible elements, panel heaters can come to the rescue. These are really low horizontal heating radiators. Their height from the floor does not exceed 20 cm with a thickness of 30 mm.

Such products are located along the walls and are closed with decorative overlays (panels). Using a similar option, you can get a heating system with a height of 100 mm, working as a standard with high batteries.Significant disadvantages of this heating option are high cost and complete unsuitability for repair.

Types of heating radiators for a private house

Only in the last few decades, heating batteries have evolved from simple bulky cast-iron sections to efficient convection devices, where control is carried out by complex electronic systems. Considering household appliances, it is convenient to divide them according to the materials from which the heat transfer surfaces are made into the following types:

- Cast iron multi-section batteries;

- Heaters made of welded steel sheets of various thicknesses;

- Bimetallic devices using two types of metals, one of which is aluminum;

- Devices made of aluminum alloys;

- Copper heaters;

- Plastic elements for systems where the temperature of the heat transfer fluid does not exceed 80 degrees.

Structurally, radiators are divided into:

- sectional;

- tubular;

- panel;

- lamellar.

For special conditions, corner appliances, skirting radiators or convection devices are developed for installation in interior details (window sills, doorways, stairs, floors). Each type of device has its pros and cons.

Cast iron radiators

Cast iron sections have long been included in the interiors of both most private houses and apartments in high-rise buildings. They are resistant to corrosion and withstand pressures up to 18 atmospheres, are compatible with other materials and have a service life of up to 30 years.

The disadvantages include bulkiness and a large internal volume of the coolant.Many homeowners, however, with the right paint job, give a second life to cast iron radiators, creating interesting retro options.

Steel heating appliances

Steel radiators, as a rule, are not expensive to manufacture, have low inertia and light weight. Most often, manufacturers produce steel radiators of certain sizes, allowing you to select the required parameters for performance and the number of elements.

All surfaces are painted using innovative technologies that reduce the thickness of the paint to increase heat transfer, while maintaining high protective properties. The main disadvantage of steel devices is low corrosion resistance, leading to a relatively short service life of about ten years.

Bimetal radiators

Bimetallic devices are a technological design that combines the excellent heat-conducting properties of aluminum and the strength of steel. They are able to withstand pressure from 18 to 40 atmospheres, which is more than enough in individual heating systems.

There are two types of bimetallic batteries: with an all-steel inner core, or with only steel vertical channels. In the first case, the radiators are more durable, in the second they heat up faster and are cheaper. The main disadvantage is only the high price of the device.

Aluminum radiators

Aluminum alloy batteries have excellent thermal conductivity and light weight. They serve up to 15 years, and perfectly heat the premises both by thermal radiation and convection.On sale you can devices produced by casting, or by combining vertical aluminum panels with a silumin (alloy of aluminum and silicon) collector. In the second case, the devices are cheaper, however, the sections are connected without the possibility of adding. For cast radiators, you can dial any number of sections.

Copper radiators

Copper thermoblocks are much less common due to their high price. However, those who find funds for copper products receive excellent heat transfer with high resistance to aggressive environments. Due to the formation of a stable oxide film, they practically do not corrode and serve up to 50 years.

plastic radiators

Plastic radiators are the most budgetary type of devices. They are fairly easy to install and light weight. Despite their low price, they are not widely used in individual heating systems due to the low heat transfer coefficient, and, as a result, low efficiency.

Which batteries to choose for a private house can be decided only after all the calculations have been made, and also based on financial capabilities. When choosing purely technical parameters, their appearance is of great importance. For modern interiors, various models of vertical devices have been developed, and the range of shapes, sizes and colors is truly great. Convectors with forced air circulation have become quite popular, providing rapid heating of buildings with a large glazing area, or installed on the verandas of private houses.

You can learn more about choosing radiators from the video:

Types of aluminum radiators

Aluminum batteries differ in manufacturing technology:

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery across all territory of the Russian Federation and the CIS countries.

Casting technology

This production method means that each section will be designed separately. They are cast from silumin (composition of aluminum and silicon additives). The amount of silicon in this mixture is no more than 12%. This amount is enough to ensure that the device is strong enough and reliable.

The manufacturing process is carried out as follows:

- The mold for casting the battery section is two equal parts. Before pouring the composition, both parts are joined under high pressure in the injection molding unit.

- At the next stage, the finished alloy enters the finished mold through special channels.

- The molten composition spreads through all channels of the mold, where it cools and crystallizes.

- After the crystallization process is completed, the mold must be opened and left until it cools.

- As soon as the composition has cooled down, a neck is welded to the blanks of the sections.

- The next stage: in a special bath, under the influence of high pressure, the sections are checked for tightness.

- Then the inner and outer aluminum walls are coated with an anti-corrosion compound, and then they are cooled and dried.

- After the above manipulations, the sections are painted with powder enamel.

- At the final stage, the sections are assembled into radiators and tested for strength and tightness.

A similar method of manufacturing radiators allows you to create batteries of absolutely any shape.

Extrusion Technology

The extrusion process is based on forcing a softened metal melt through a special molding extruder.In this way, a detail of the required profile is obtained.

This method of production does not imply instant production of radiator parts with a closed volume. Initially, the front and back parts are formed, which are subsequently interconnected by thermal pressing.

Using the extrusion method, both individual sections and integral manifolds are manufactured.

Technical indicators for devices made by extrusion are lower than for batteries made by casting technology. First of all, this is due to a smaller surface area, and therefore, lower heat transfer. Another disadvantage is that the press joints are usually not able to withstand high pressure and quickly begin to rust under the influence of an aggressive coolant environment.

Anodized heatsinks

Such batteries are made of an alloy in which aluminum has undergone high-quality cleaning. Its amount in the composition is 90% or more. Both internal and external surfaces of the product are subjected to anodic oxidation (anodizing).

The standard anodizing process for aluminum heatsinks is as follows:

- Initially, the batteries are well washed, for this the radiator is placed in a bath with an alkaline solution and there its surface is cleaned of all kinds of contaminants.

- Then "chemical milling" is carried out. The aluminum surface is cleaned of the oxide film, and a thin top layer of metal is also removed.

- The next step is lighting. Heavy metals are removed from the outer sides of aluminum.

- Further, the radiators are lowered into a bath with an electrolyte, under the influence of this negative charge, an electrochemical reaction is carried out, as a result of which a protective oxide film AL203 is formed.

- At the final stage, the layers are compacted by clogging the pores.

External dry couplings are used to connect all parts of the anodized radiator to each other. Due to this, the inside of the batteries remains smooth. Such a connection contributes to the fact that the device is protected from stagnant processes and the coolant circulation process occurs with minimal hydraulic resistance.

The only drawback of this type of aluminum radiators is the high price.

Ability to hold pressure

In a traditional central heating system, typical for multi-storey buildings, the pressure is by no means stable. Sometimes there are even water hammers. After all, the cranes of circulation pumps, according to the rules, should turn on smoothly, but often workers do not follow these rules. And with a sharp shutdown of hot water, its pressure in the entire system jumps so that many batteries burst. Therefore, residents of apartments should definitely choose radiators with a good pressure margin.

Cast iron radiators can withstand 9-12 atmospheres of pressure. This may be enough until a strong water hammer occurs. If it does happen, then brittle cast iron, unfortunately, can burst. Therefore, when viewed from this point of view, better cast iron radiators or bimetallic, then of course it is better to play it safe and take a bimetal.

After all, a bimetallic radiator is not afraid of any pressure surges - in the passport it has indicators for this parameter up to 20-50 atmospheres (depending on the model). So even powerful water hammers are not capable of breaking a high-quality bimetal product.And let's also mention models with a monolithic steel core - they can easily withstand up to 100 atmospheres. Examples of such radiators are Russian-made radiators Rifar Monolit, you can see its technical features in the photo below.

Ability to hold pressure: Cast iron - | Bimetal +

Features of decorative radiators

Designer products do not have such good technical performance:

- The heat transfer is somewhat lower, which is associated with an additional layer of paint, in some cases - with an ornament.

- The average power is less, because the dimensions are often cut. This helps to create an interior, but interferes with the direct purpose of the battery.

- The hydraulic resistance drops as the pipes are made small, neat.

- Unlike simple radiators, decorative ones are much more expensive.

These features look negative, but beauty requires sacrifice. Problems can be easily solved by minor design changes or by combining radiator heating with another.

TOP-4 steel heating radiators

Steel radiators are distinguished by reliability, high heat transfer. Of the minuses, it is worth highlighting the instability to water hammer, susceptibility to corrosion. Some manufacturers use special coatings to protect against it. Most steel radiators have a panel view, i.e. it is impossible to dial the required number of sections, as in aluminum and bimetallic ones. The exception is tubular steel radiators.

Axis Classic 22 500×1000

The steel radiator consists of two water-conducting panels and two convection rows. The outer grille is removable: you can clean the internal parts.It differs from the standard dimensions characteristic of all models of the rating (50 × 100 × 10 cm) by a slightly larger thickness - 11 cm. Almost all radiators weigh about 28 kg. The capacity of water is 5.63 liters. Steel radiators differ from bimetallic radiators with a lower working pressure - 9 bar (13.5 - during pressure testing). Side connection ½ inch. The center distance is non-standard - 449 mm. Designed for coolant temperatures up to 120 °C. The model has increased power - 2188 watts.

Advantages:

- Nice view. Simple design.

- Quality build. Russian production on Italian equipment.

- The kit includes everything you need for installation.

- Heats well.

- Inexpensive.

Flaw

- Non-standard center connection. There are no problems if the eyeliner is made of polypropylene pipes.

Axis Classic 22 500 1000 costs 3700 rubles. The model is superior all kinds of steel radiatorsincluded in the rating, by power. Provides rapid heating of the room. The quality of the metal, reliability satisfied demanding users, so the vast majority of them recommend the product for purchase.

Buderus Logatrend K-Profil 22 500×1000

It features a large volume of water - 6.3 liters. The working pressure in the system is higher - up to 10 bar, but less power - 1826 watts. According to the manufacturer's calculations, one radiator is enough to heat a room of about 18 square meters. m. The model undergoes anti-corrosion treatment by phosphating and hot powder spraying. Center distance - 450 mm.

Advantages:

- Laconic design.

- Good painted. Does not turn yellow over time.

- They heat well.

- Build quality is ok.

Flaw:

- One radiator is not enough for the declared area (but it depends on the coolant temperature).

Price Buderus Logatrend K-Profil 22 500 1000 - 4270 rubles. The model is somewhat inferior to Axis Classic 22 in terms of power, but it has a better anti-corrosion coating. Customers are satisfied with the quality of workmanship and the operation of the radiator.

Kermi FKO 22 500×1000

Differs in the smallest volume - 5.4 liters. But it loses in power to the first two models - 1808 watts. Designed for system pressure up to 10 bar (13 bar - pressure test). Provides operation at a coolant temperature up to 110 °C. Center distance - 446 mm. The manufacturer has applied Therm X2 technology, which increases the energy efficiency of the equipment. The outer coating is made of two layers of powder paint, which increases the resistance to mechanical damage.

Advantages:

- Beautiful view.

- Quality made.

- Ease of care.

- Good heat dissipation.

Flaw:

There are cases of leakage after several years of use (in an apartment building where the system is drained for the summer).

Kermi FKO 22 500 1000 for 6200 rubles provide a normal level of heat. Due to the small volume of coolant, the heating of the radiator and the room is faster. Recommended for installation in a closed system without draining the coolant for a long period.

Arbonia 2180 1800 270

The only representative of tubular steel radiators in the review. It differs from panel models in non-standard dimensions. This is a narrow model (65 mm) with a very high height (1800 mm). The width of one section (tube) is 45 mm. Center distance - 1730 mm. One section weighs 2.61 kg, but it includes a much larger volume than aluminum and bimetallic radiators - 1.56 liters. In terms of heat transfer, the six-section Arbonia is expectedly inferior to other models in the rating - 1730 W. Power - 990 watts.

Advantages:

- Interesting view.

- Normal heat dissipation. Heats up well.

- Quality build.

Flaw:

- It is necessary to take into account the place for installation, the possibility of piping. If there are windows in the room, they will blow (you cannot place such a radiator under them).

The price of Arbonia 2180 1800 270 is 9950 rubles. You can choose the number of sections, unlike other steel samples. Non-standard sizes significantly increase heat transfer due to the larger radiator area. Can become part of the interior. Customers have no complaints about the quality.

Characteristics of cast iron radiators of various manufacturers and models

In Soviet times, there were countless factories for the production of cast-iron radiators - after all, there was no alternative. Here, for example, are just a few of their types: NM-140, NM-150, Minsk-110, R-90, RKSH. Almost all of them are no longer produced. Long lives, perhaps, only one tested model - MS-140, classic and solid.

The new models look prettier, for example, the MS-110 of the Santehlit plant has a shallow depth (only 11 centimeters) and fits well under narrow plastic window sills.

Radiator MS - 110.

In Cheboksary they make FM radiators with one, two and three channels. Their outer side is flat, which looks quite aesthetically pleasing, and it is easier to wipe the dust.

Models of radiators ChM.

Beautiful two-channel radiators are produced in Minsk, about 10 models in total.

An example is the radiators 2K60P, 2K60PP, 2KP100-90-500, 2K60P-300.

Sectional batteries made of cast iron are also brought to us from abroad. Foreign products are smoother both outside and inside, so their heat transfer is higher. Let's note the Chinese company Konner (the models "Hit", "Modern" and "Fort" are especially good).

Konner radiators, Moder model.

The Czech plant Viadrus, the Turkish company DemirDöküm and the Spanish concern Roca also make good radiators. European manufacturers make very elegant batteries with cast iron patterns. True, such radiators are much more expensive than domestic ones.