- 6 Fuel used

- Design and principle of operation

- What should be the heating in the garage

- Step-by-step instructions for making an oven

- Video - Homemade potbelly stove for the garage

- Solar heater - principle of operation

- Ignition

- Cons of using boilers

- high cost

- Strict requirements for fuel quality

- Bad smell and noise

- Constant checks

- Installing and testing the device

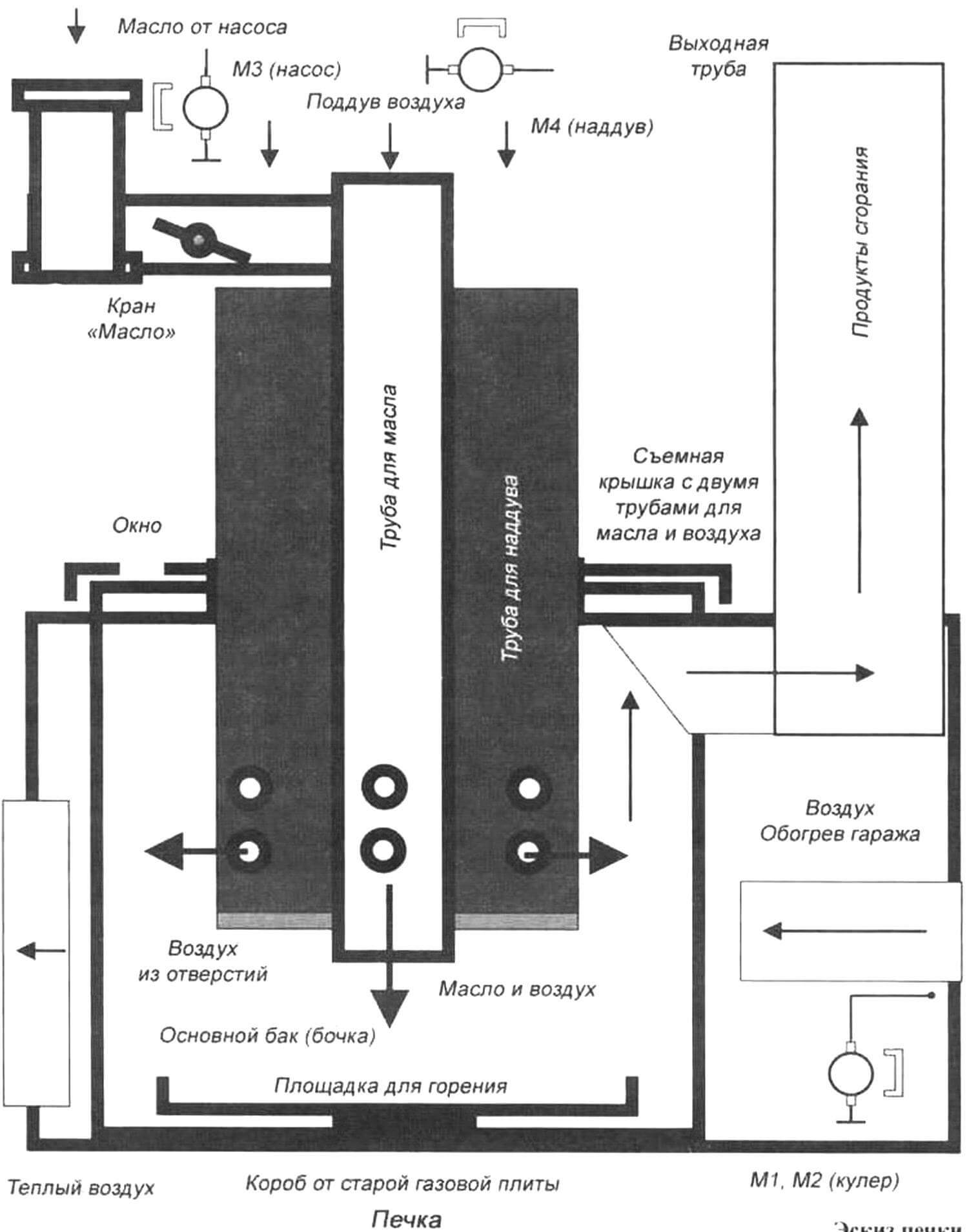

- Do it yourself

- Do-it-yourself step-by-step oven manufacturing technology

- What is a miracle oven in diesel fuel: types and subtleties of operation

- About diesel heat guns

- Application area

6 Fuel used

The water heater uses either kerosene or diesel fuel. Kerosene is slightly more expensive than diesel fuel, it can only be purchased at hardware stores. Diesel can be bought at any gas station, which is easier and cheaper. Here it is worth considering that with the onset of severe frosts, the diesel engine will begin to become cloudy and crystallize, this can lead to clogging of the valve installed in the tank and burner.

In such a case, it is good to have a small amount of kerosene. Alternatively, you can dilute diesel fuel with kerosene in a 1: 1 ratio, which will certainly prevent the fuel from thickening.

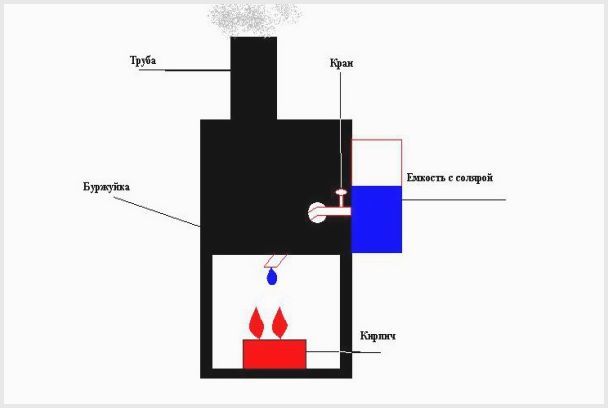

Design and principle of operation

The miracle oven can work not only on diesel fuel, but also on kerosene.Some people prefer the second option, since the performance of the unit is increased, and the emission of potentially hazardous substances is reduced.

Today, there are many models that differ in power, and this indicator affects the duration of continuous operation of the furnace: it can be from 6 to 28 hours.

The principle of operation is discussed in more detail below:

- Through the pipeline, the fuel flows by gravity into a special combustion chamber.

- The furnace is equipped with shut-off valves, which, if necessary, allows you to regulate the process of supplying diesel fuel to the chamber.

- The hole designed to supply air into the unit is also used for ignition.

- The temperature regime inside the furnace gradually increases and gradually reaches a point at which the combustion process of diesel fuel is stable.

- Immediately after the stabilization of combustion, a very stable thrust appears.

- During combustion, solar vapors arise, which are mixed with air: this reaction proceeds under the node where the fuel is burned.

- Until the fuel burns out completely, the room in which the miracle furnace is located is heated.

The classic design of most types of such furnaces, working on solar, as follows:

- Removable fuel tank. It must be equipped with a valve.

- The adjusting screw allows you to manually adjust the fuel consumption and select the room heating temperature.

- Block equipped with a wick. If necessary, it is replaced.

- Protective grid.

- Frame. Most models have a modern design and can fit into the design of any room.

- Reflector, which is specially painted with powder paint, which allows you to effectively warm up the heated room.

- The burner is located in the center of the unit. Diesel fuel enters it from the fuel tank by gravity.

Special types of steel with heat-resistant characteristics are used as the main material for the manufacture of a miracle furnace. The equipment has small dimensions and weighs an average of about 10 kg, which ensures high mobility and allows it to be moved by one adult.

The hole designed to supply air into the unit is also used for ignition.

What should be the heating in the garage

For many motorists, a garage is almost a second home. Here they delve into their hobby, take a break from the hustle and bustle and take care of the car. Therefore, first of all, you should think about the comfort of the person who is in the room for hours.

For the car, heating is also necessary, because. low temperatures adversely affect its technical condition and significantly reduce the service life.

When it gets cold, the garage gets too humid. Condensation forms on metal parts, which provokes corrosion processes. In a cold room, the car body quickly rusts and becomes unusable.

To keep the garage dry, you should take care of good waterproofing and ensure the normal operation of the ventilation system. However, moisture still gets into the room on the wheels of the car. It evaporates and drops of water settle on surfaces. If there is no heating, moisture accumulates, which causes fungus, mold, and rust to appear. To prevent this from happening, heating is necessary.

Low temperatures cause the oil to thicken and reduce battery capacity. Because of this, there are difficulties with starting the engine, and fuel consumption increases. Therefore, it makes sense to spend time and effort on assembling a miracle stove.

Features of the operation of the garage determine the requirements that apply to heating systems:

- Efficiency. The oven must quickly warm up the air and maintain the desired temperature for several hours.

- Ease of operation. Coming to the garage, its owner should spend a minimum of time and effort on heating the room.

- Ease of maintenance. The furnace needs to be inspected, cleaned, repaired in a timely manner, so its design should be simple and understandable, and parts should be easily replaceable.

- Availability of an energy source. When choosing a heating system, the availability of fuel is of fundamental importance. For a garage, a diesel, diesel or waste oil stove is well suited.

- Safety. There is always a certain amount of combustibles in the garage. Since these rooms often serve as workshops and sheds, flammable materials are often found here. Therefore, heating must comply with all fire safety standards.

- Cheapness. The cost of maintaining a car and arranging a garage is already high, so saving on heating without compromising its quality is an urgent issue.

When choosing a suitable heater, you should prioritize, because. the ideal is unattainable. The easiest to use are electric heaters. This source of energy is available in almost any locality. However, the price of heating with electricity is too high, so it is worth considering other options.

Image gallery

Photo from

This method of heating is chosen by people who are ready to invest in an infrared heater and pay electricity bills. Although the devices are very economical, they are still not cheap. The main advantage of infrared heating: objects are heated, not air (it warms up indirectly, in contact with warm surfaces). This allows you to create local thermal zones.

Garage owners, who have the opportunity to buy solid fuel inexpensively, make good old potbelly stoves. Such heating is reliable, and its effectiveness has been proven by time. There are also disadvantages: you will have to install a chimney, and keep a supply of fuel in the garage, which takes up a lot of space

To heat garages, workshops, utility rooms, heat guns are often bought. There are many models that run on gas cylinders, electricity or diesel fuel. Every garage owner is sure to find a suitable option. The only negative is the high price of the device

Models of industrial production are compact, beautiful, easy to use, but not cheap. If you make a miracle stove yourself, you get a completely functional and inexpensive design. The only negative: in terms of design, it will not be able to compete with aesthetic industrial models.

Heating with infrared heater

Homemade solid fuel stove

Gas heater in the garage

Wonderful solar oven

Step-by-step instructions for making an oven

Step 1. In our example, a simple 250-liter barrel with thick walls is used - ideal for making an oven. Cut off the top of the barrel, but don't throw it away.

The top of the barrel is cut off

Step 2. Make a kind of cover from the top - a "pancake" for supplying oxygen. Adjust it to the size of the barrel - as a result, when installed, 2 mm should remain between it and the walls around the entire circumference. Seal the neck of the lid. In its center, make a hole for installing a pipe through which air will be supplied. Also weld 4 channels, as in the photo below.

"Pancake" for air supplyAnother photo of the element

Step 3 Stepping back a little from the top edge, cut another hole in the wall of the barrel - for mounting the chimney. In our example, a pipe with a diameter of 140 mm will serve as a chimney.

Hole for installing a chimney

Step 4. Start making the lid. Make it from sheet metal 4 mm thick, and weld a sealing ring on the bottom that matches the diameter of the barrel. In the center of the cover, make a hole for the pipe that was welded to the "pancake".

Cover for the ovenIn the middle of the cover there is a hole for the air duct from the "pancake"

Step 5. At the bottom of the barrel, make simple legs so that the structure is stable. The legs must be metal, as well as all other elements.

Making oven legsLegs must be metal

Step 6 Install the stove in the right place and start creating the chimney. In our example, it is of a prefabricated type. First of all, make a clamp, through which the chimney will be attached to the body.

A clamp that will allow you to attach the chimney to the stove

Step 7. Make guides in the chimney, thanks to which it will be easily fixed to the body.

Guides in the chimney

Step 8. Dock the barrel with the pipe, without fail laying all the joints with asbestos cloth. Put a collar over the fabric, tighten it.

Asbestos fabric Tightening the clamp over the fabric Finished joint between the pipe and the barrel

Step 9. That's it, the design is assembled, you can check its performance. Load sawdust or firewood inside.

Furnace loaded with fuel

Step 10 Pour used oil into the fuel, then install the cap. As for the "pancake", then do not use it yet. After the fuel flares up, remove the lid and put the "pancake". For a full warm-up of such a design, it takes about 10 minutes, in the future, firewood will burn for a long time. Although how long the burning will last depends largely on the quality of the fuel.

Photo of the finished oven for the garage

Video - Homemade potbelly stove for the garage

If you wish, you can modify the design described above, although it will already do its job perfectly. For example, to increase efficiency, you can increase the surface and thereby improve heat transfer. To this end, weld metal plates on the sides of the case.

In addition, you can make a grate with an ash pan: cut a circle from a sheet of metal along the inner diameter of the body, drill holes with a diameter of 60-80 cm and install from below. After that, the ash will fall down through the holes - to where the ash pan is equipped. It is believed that the fuel will burn faster because of this, remember this moment and make sure that the ash pan is sealed as much as possible.

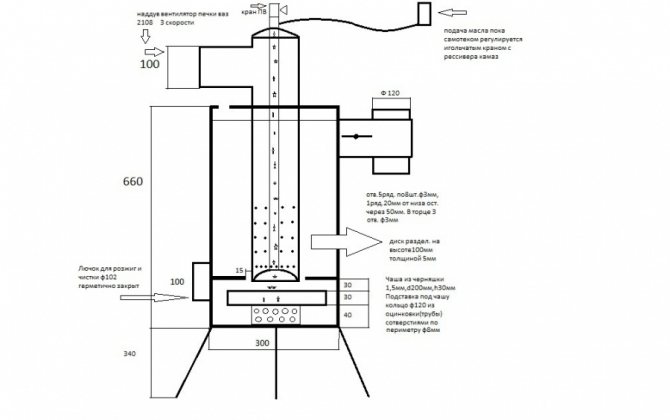

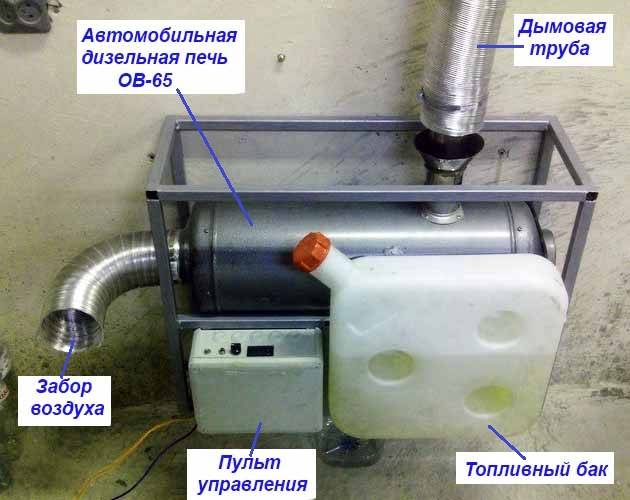

Solar heater - principle of operation

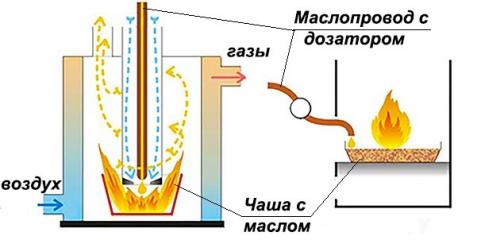

To manufacture a high-quality and efficient miracle furnace for a garage that will run on diesel fuel or mining, you must clearly understand and represent the principle of operation and design of the device. To avoid smoke and soot during operation, it is better to make the furnace tank with a volume of 2 liters.The fact is that the products that stand out at the time of ignition can hardly be called harmless, much less useful.

If it is possible to move the stove, it is better to relocate this process to the street. The garage in which the device is planned to be placed must be well ventilated. The design of such a furnace and the principle of its operation are quite simple. The main procedure is to ignite the fuel, then the temperature of the diesel fuel rises, which leads to the ignition of vapors in the combustion chamber.

acquires a gaseous state, which burn further, a temperature of 800 degrees, a side chimney is used, its price is more acceptable.

Ignition

It is better to ignite on the street, and only then bring the working device into the house (this will avoid unpleasant odors in the room).

If the stove has not been used for a long time, it must be cleaned before starting the ignition. The grate, burner, tank on the back wall are removed, the entire fuel assembly is pulled out. All parts are cleaned, the reflective screen is rubbed.

It is very important to install the device strictly horizontally, otherwise it will be difficult to achieve uniform burning of the wick along its entire length. Then ignition:

Then ignition:

- Fuel is poured into the removable tank.

- A new wick is installed in the burner (it is twisted into a ring at the bottom of the burner).

- The burner and grate return to their original place.

- The valve is slightly unscrewed, which gives fuel access to the wick.

- The front panel opens and acts as a door.

- The edge of the twisted paper is lit and brought to the burner from below.

- When the fuel flares up well, and the flame rises above the grate, the valve is completely twisted (the bottom of the burner, red-hot to red, will indicate that sufficient heating has occurred).

- After waiting until the flame starts to go out, unscrew it again, but already to the intensity that I would like to achieve.

When you need to turn off the stove, its valve is twisted all the way.

Until the user has little experience with the stove, it is very difficult to achieve even burning of the wick (this can take more than half an hour).

But if there is experience of ignition, but still it is not possible to get a blue flame all over the wick, this may be one of the following problems:

- Uneven surface, oven slope.

- The burner cylinder has not yet fully warmed up.

- The wick is worn out (it burns slightly every time and the more it is used, the more damaged it is).

You can try to extend the life of a worn wick by simply turning it over, or cutting off the burnt edge with scissors. To make the wick last longer, it can be periodically washed in kerosene.

Cons of using boilers

These include:

- the high cost of heating with diesel fuel;

- stringent requirements for fuel quality;

- unpleasant smell and noise;

- regular boiler checks.

high cost

The price of diesel fuel and diesel fuel is constantly changing, more often upwards.

With an average cost of 38 rubles per liter purchase of a ton fuel will cost 38 thousand rubles, which, with a long heating season, will amount to a large amount.

Heating with diesel fuel is more expensive than heating with liquefied gas, coal or wood.

But these costs are less than the cost of heating with electrical appliances and an electric boiler.

Strict requirements for fuel quality

With a low quality of diesel fuel, the presence of foreign hydrocarbons, water, mechanical suspensions in the fuel, the equipment quickly deteriorates.Burners emit soot, which clogs the nozzles, is deposited on the heat exchangers and the walls of the combustion chamber, in the chimney.

As a result, the efficiency of the device is greatly reduced, it is necessary to carry out unscheduled cleaning of the boiler with the involvement of a specialist. Therefore, it is better to purchase a large batch of high-quality fuel from a trusted supplier.

Bad smell and noise

The smell of diesel comes from the fuel tank. With poor ventilation of the boiler room, it also penetrates into living rooms. Solar fumes create a fire hazard.

To eliminate the smell in the technical room, supply and exhaust ventilation is done.

The noise from the burners is quite strong. To reduce the hum of fans and flames, use burners with a noise-absorbing casing or close the boiler room with a tight door.

Constant checks

The device must not be left unattended for a long time. Automation turns off the device in case of any malfunction. If this happens in winter, the water in the heating system will quickly freeze.

The heater equipment needs constant checks. A complete inspection is done at the beginning and at the end of the heating season, for which a specialist is invited. Unscheduled inspections are carried out with frequent spontaneous shutdown of burners and breakdowns.

Installing and testing the device

The stove is installed in a fireproof place, not on a wooden (linoleum) floor. It is advisable to provide a container with sand in the garage in case of fire. Drafts, installation in cramped conditions (under hinged shelves, racks) are excluded. Pour oil into the bottom tank. It is advisable to clean it before use, let it stand.

A chimney must be installed, otherwise the stove in the garage cannot be used. Water impurities are not allowed in the oil.First, pour a small portion, a couple of liters. Then, with the help of a paper wick, the oil in the tank is ignited. By opening or closing the damper, stable traction is achieved. After 2-3 minutes, the stove goes into operation, the oil boils. The unit is ready for use.

Do it yourself

It is not at all necessary to purchase a miracle furnace that runs on diesel fuel in a store, since such a heating device can be made independently.

To do this, you do not need to have any specific knowledge or experience with metal, you just need to have basic skills and read the instructions, so virtually anyone can master this technology.

A detailed algorithm of actions is given below:

Initially, it is necessary to prepare all the drawings of the entire body parts, mark them on the selected material and cut them out.

The previous step can be skipped if a barrel made of steel with suitable physical and technical properties is taken as the basis. In this case, it will be necessary to make a small hole in the lower part, which will be designed to ignite diesel fuel and ensure air exchange inside the furnace.

The barrel or self-made body is equipped with a removable lid

She needs to pay special attention, since this part must provide tightness, without which it will not be possible to achieve stable combustion and operation of the heater. When assembling the hull from various parts, all internal seams should be abundantly impregnated with kerosene, and external joints should be covered with chalk.

After that, you can observe the reaction: the darkening of the metal will indicate the presence of defects, since kerosene has the ability to penetrate even the most microscopic holes

When assembling the hull from various parts, all internal seams should be abundantly impregnated with kerosene, and external joints should be covered with chalk. After that, you can observe the reaction: the darkening of the metal will indicate the presence of defects, since kerosene has the ability to penetrate even the most microscopic holes

In this case, you will need to look for the gaps left, and improve the quality of the existing seams.

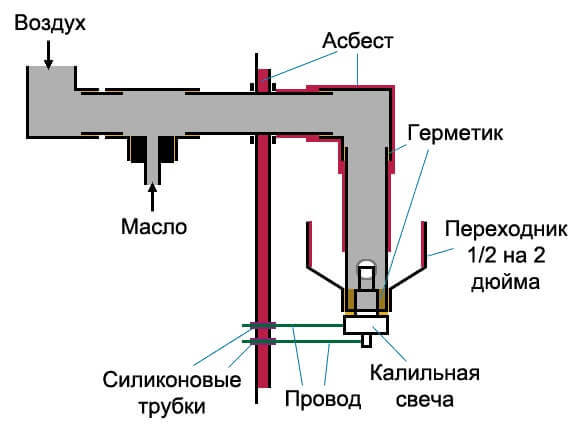

A non-pressure type burner is made separately, it will consist of two different parts that are joined to each other. The optimum burner diameter is 21.5cm.

The upper part of the burner is equipped with a lid, in the center of which a small cutout is made.

Small holes are made in all side surfaces of the burner, it is better to arrange them in 5 rows.

Near the surface of the bottom of the burner, it is necessary to cut out the exhaust pipe and the assembly that will provide oxygen to the inside, since without it the combustion process will not be supported.

All individually manufactured parts are assembled into a single unit. Even in the absence of experience, all the described processes usually take no more than 2-3 days.

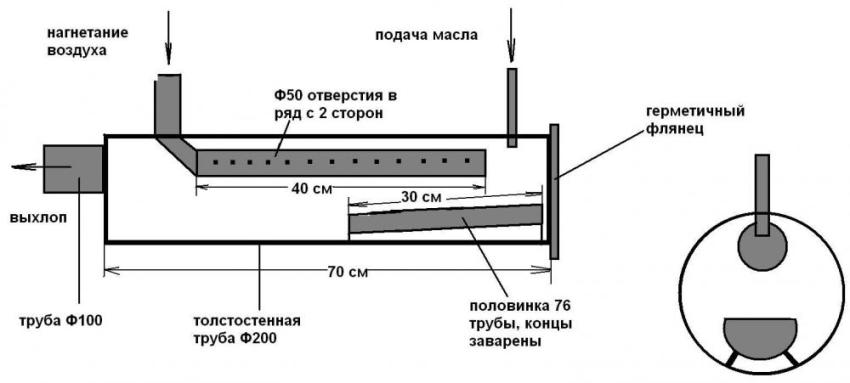

Do-it-yourself step-by-step oven manufacturing technology

Start by choosing a material. Preference is given not to rusty, but to metal in a normal state, without defects, shells and cracks. The algorithm for further actions is as follows:

Cut blanks for the furnace tanks. They are similar, just different caps. The lower bottom is solid, a branch pipe emerges from the upper end. At the other, respectively, an afterburner is welded in at the bottom in the center, at the top - the chimney outlet (with an offset from the center).

Choose a piece of pipe for the afterburner. Holes are drilled in the walls for air intake.

Tanks are going

The lower bottom is solid, it is important not to confuse it. An afterburner pipe is welded into the upper tank at the bottom, and a pipe for the furnace chimney at the top

At the bottom, a damper is provided, as in an ordinary potbelly stove (you can do it later).

The seams are checked for quality, the slag is beaten and cleaned. The cooled furnace is ready for testing.

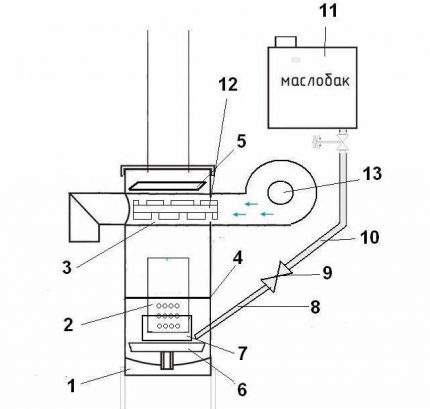

What is a miracle oven in diesel fuel: types and subtleties of operation

The question of what to use in the absence of heating of a garage, house, dwelling or temporary building, each owner decides differently. Some choose liquid fuel appliances, others are satisfied with a stove design, such as a fireplace or a wood-burning potbelly stove, someone has a home-made stove or a mini heating gasoline system, and someone prefers a kerosene stove (kerosene stove) such as Bumblebee or plans make a boiler, the principle of operation of which is based on water or diesel fuel. But still there is one time-tested device called a miracle furnace. This is a heating unit, the fuel for which is a solarium or kerosene.

In fact, there is nothing miraculous in such units, because it is an improved design of the well-known kerogas. Such a diesel stove, to the delight of the owner, has a low solarium consumption. For example, one of the manufacturers gives the following data: a heater with a power of 2.5 kW consumes approximately 0.2 liters of diesel fuel per hour.

Types of miracle stove in diesel fuel:

- Small liquid fuel stove. It is a small fuel tank and a tank connected to it according to the principle of communicating vessels, plus a simple diesel burner.They are used as camp stoves for cooking and heating, and can act as an automotive option.

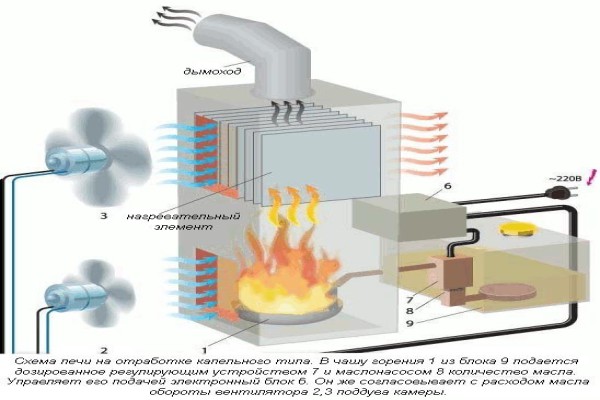

- Diesel heat gun. It is used for fast heating of large rooms with an area of more than 20 m2. Good for a garage or cottage. The air flow heated by the gun is driven through it with the help of a fan, which significantly accelerates its flow and propagation speed.

- Homemade ovens. As you may have guessed, these are do-it-yourself thermal units, and instructions for such inventions are not included in the kit, but they are in no way inferior, and sometimes even superior to their official competitors.

- Drip oven. From the name of the unit it becomes clear that it has a drip system for supplying diesel fuel to the combustion chamber. This oven is easy to use and ready for use within minutes of being unpacked.

It is impossible to ignore such an integral component in the operation of the furnace as air supply. Of course, natural draft in the chimney is fine, but you can achieve a greater effect if you install a blower with a capacity control function. In this case, the fuel will burn much more efficiently, and the performance adjustment will make it possible to flexibly adjust the heat transfer.

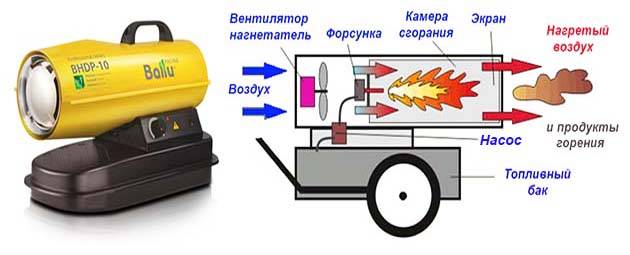

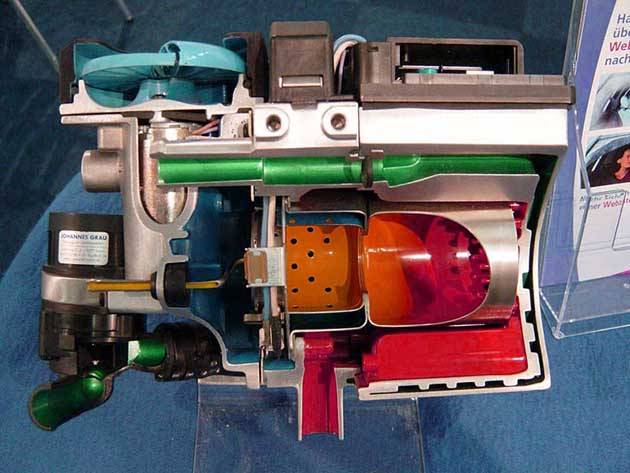

About diesel heat guns

Heating units of this type are designed to heat large areas (from 30 m²) in all weather conditions. The diesel oven is a hot air blower in the form of a pipe mounted on wheels for ease of movement. A turbine built into the end of this pipe is responsible for creating the air flow.The burner for the furnace, which burns diesel fuel, is placed inside the combustion chamber and is washed by air from all sides. There are 2 types of heat guns:

- With direct heating. This means that the air passing through the pipe is heated by the walls of the chamber and mixed with the combustion products coming out of there, and then the mixture of gases enters the room. The heater is very efficient, but not suitable for working in confined spaces.

- With indirect heating. The design is similar to the first one, but the exhaust gases do not mix with the air flow and are sent through a separate channel to the chimney, as shown in the diagram. The heater loses its efficiency, since part of the heat goes away with the combustion products, but it is absolutely safe and able to heat residential premises.

Scheme of operation of a diesel gun with direct heating of the air flow

We list the main advantages of solar-powered air ovens:

- the ability to heat large areas, for which models with a capacity of 10 to 100 kW are produced;

- acceptable diesel consumption;

- mobility;

- maintaining the required air temperature in the room;

- safety automatics that turn off the pump and fuel supply to the nozzle in case of overheating, power outage and other emergencies;

- high speed of heating the entire volume of the room.

The principle of operation of an air heater on diesel fuel with a chimney

The main disadvantage of powerful diesel heaters is their high cost. Take the products of the same brand Ballu, which is included in the middle price category: a direct heating installation with a capacity of 10 kW will cost 270 USD. e., and indirect by 20 kW - as much as 590 c.u. e.

Diesel stove with air injection - inside view

The second important disadvantage applies to direct heating units that emit flue gases along with air. This feature greatly limits the scope of air heaters of this type. It is safe to use a heat gun only in industrial or technical rooms with forced ventilation or at construction sites for local heating.

Application area

Installing a miracle furnace on diesel fuel will be the best solution for heating greenhouses, country houses, basements, utility rooms, workshops, tents, garage buildings erected in places where there is no possibility of connecting to centralized heat sources.

It can be used as a permanent or additional device for heating, as well as heat tea or other food on it. A kerosene stove is more suitable for heating summer cottages. Its efficiency is higher than that of diesel analogues, no harmful substances are emitted into the atmosphere during operation, there is no unpleasant odor.