- Design and characteristics

- Key components of the device

- 4 How an anemostat is installed

- Varieties

- Floor diffusers

- Types of diffusers

- Place of use

- materials

- Location

- Anemostat: what is it?

- Purpose of the product

- Rating of reliable metal anemostats

- VENTS AM 150 VRF N

- Airone DVS-100

- EUROPLAST DM 100mm

- Era Anemostat universal detachable

- Classification: types and differences

- By purpose (direction of air flow)

- Supply and exhaust models

- By material

- By device (hole design)

- By place of installation

- Models and approximate prices

- Do-it-yourself anemostat installation

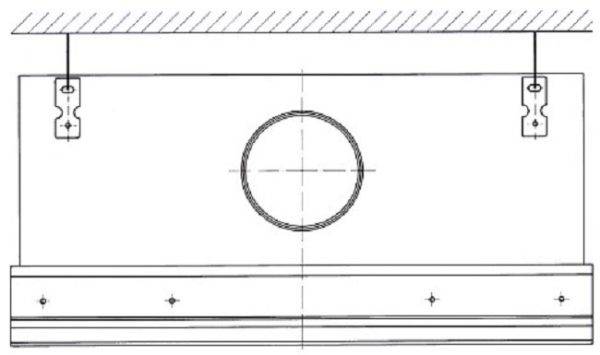

- Concealed installation

- Other installation methods

- Tips of the masters

- Ceiling diffuser: installation

- If the shape and dimensions of the ceiling diffusers and ventilation pipes match

- Using Adapters

Design and characteristics

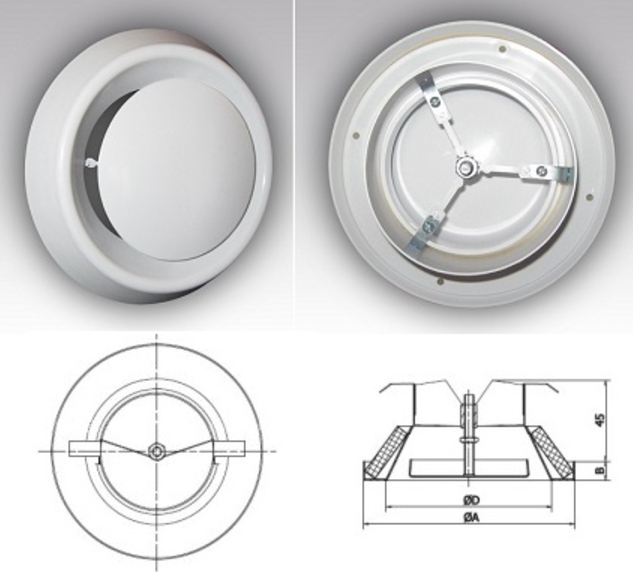

Anemostat design

So, an anemostat - what is it in terms of design? These air separators are round, white or silver. The diameter of the products varies from 10 to 13 cm. A distinctive feature of the devices is their compact form, the use of light materials - galvanized steel, plastic, aluminum alloys.

Key components of the device

The adjustable unit consists of several components and functional elements:

- A protective case that performs not only a functional, but also a decorative role.

- Mounting coupling.

- Hanging fixture.

- Decorative adjustable partitions (have the form of flanges).

- A valve with which you can adjust the direction of the air.

- End cap.

Anemostat internal design

The outlet ends of the product consist of a metal or plastic frame and horizontally arranged lamellae. This design is considered optimal in terms of supplying oxygen from the ventilation system to the room. A centering screw is used to install or dismantle the frame. Pipes are fastened using connecting cabinets with a rounded shape of the horizontal neck.

4 How an anemostat is installed

There is nothing complicated in installing a control device. Installation can be carried out both in a brick wall and a plasterboard structure. Specialists prefer to work with a flexible duct connected to the ventilation system and covered with a decorative material, drywall.

It is optimal to carry out activities in the process of building a house or repairing an apartment, when there is unhindered and full access to the plasterboard structure. All work is carried out in 7 stages:

- 1. A flexible duct system is laid in the direction from the main duct to the selected area on the ceiling or wall.

- 2. A round hole is made, the diameter of which corresponds to the duct. What is a special nozzle used for, if it is not there, then you can use a jigsaw.

-

3. A suitable anemostat model is selected.

- 4. The tubular structure of the device is mounted in the hole.

- 5.The outer part of the circle is fixed with self-tapping screws and sealed with carpentry tape until the repair work is completed.

- 6. A support structure is placed in the unit body (it has a screw with a plate on it). It is connected to a round decorative panel and placed in the grooves inside the pipe.

- 7. A plate is screwed to the support installation.

The adjusting screw adjusts the volume of air flow entering the room (by turning the screw clockwise and counterclockwise).

Varieties

There are a huge number of diffusers on the modern construction market. They are made of two materials: plastic and metal (steel or aluminum). Metal products are covered with paint with a variety of colors and are usually an order of magnitude more expensive than models made of plastic. It is very rare to find wooden diffusers for sale, they are usually made to order. Wooden models will perfectly fit into the interior of a country house, as well as saunas and baths.

Diffusers are classified according to:

- shape - round, rectangular and square;

- purpose - ceiling, floor, wall;

- principle of operation - displacing or mixing;

- device - external and internal.

It is also customary to distinguish diffusers by the size and shape of the ventilation holes.

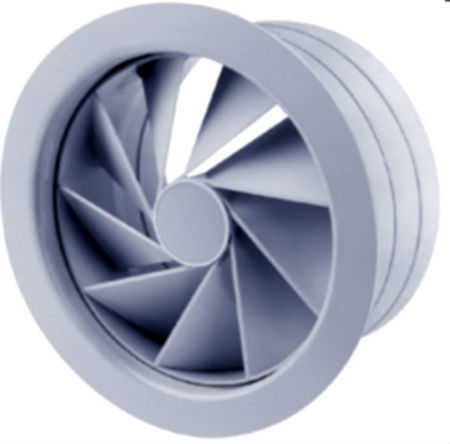

Slotted. Usually has a rectangular shape with long and narrow holes. The slats can be placed directly or at an angle, which allows you to adjust the air flow, directing it straight or in a certain direction. The lamellas are adjusted independently, some slot diffusers have the ability to adjust each blade individually. It is used both for supplying fresh air and for removing old air.Slotted models can be installed both on the wall and on the ceiling of the room.

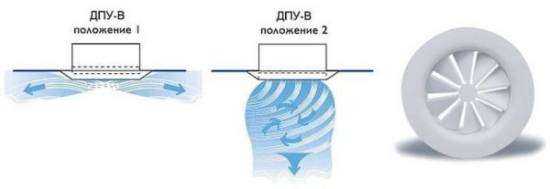

- Disc-shaped. These are round diffusers. They are a frame with a circle fixed around. Air supply is carried out due to the gap between the frame and the circle.

- Vortex. Equipped with blades that rotate like a fan and perfectly mix the air masses. The air, passing through the vortex diffuser, twists into a spiral and significantly increases the speed of its movement. Are established in rooms where fast change of air is necessary (for example, a bathroom or a toilet). In order to avoid drafts, all vortex models are equipped with a static pressure chamber

- Fan. Represented by a whole complex of diffusers, which are combined into one system.

Low-velocity diffusers stand apart. They work on the principle of expelling old air from the room. Clean air enters at a low speed, which means that the risk of drafts is minimal. In addition, the fresh air temperature differs by only a few degrees, which makes these diffusers one of the most comfortable. They can be both wall-mounted and floor-mounted, as well as built-in. Widely used in museums, sports complexes, concert halls, cinemas. Very often mounted in flights of stairs and steps.

Ceiling diffusers are the most popular model, widely used in various conditions, including industrial ones. Floor types of air mass distributors are usually used in combination with radiators or entire heating systems that are mounted on the floor.

Wall models are used very rarely, since usually ordinary ventilation grilles are installed on these planes.

Floor diffusers

Floor ventilation grilles deserve special attention. They are installed in places where they are least subject to mechanical stress, and are also made exclusively of metal. It is forbidden to place floor diffusers directly under the workplace. The ventilation device must be located at least 40 cm from it. Air supply is carried out due to excess static pressure, which is formed in the underground space, or in a chamber specially designed for this. The advantages of this type include: extremely low noise level, uniform temperature distribution throughout the serviced area. Most often, this type of diffuser is used for ventilation of premises in theaters, auditoriums, concert halls, etc.

Types of diffusers

In a store or company selling ventilation equipment, you will be offered a choice of a large number of diffusers of different appearance and materials. It is more or less easy to decide on materials - choose what you like best or what is best suited for operating conditions. If the ventilation ducts are made of metal, it is logical (although not necessary) to use metal grilles. They are galvanized, stainless steel, there are ordinary steel, but painted with powder paint.

If the ventilation ducts are made of plastic pipes, they fit better with plastic diffusers. Here, it seems, everything is clear. With the rest of the parameters a little more complicated, let's figure it out.

These are all diffusers.

Place of use

According to their purpose, diffusers are divided into:

- supply;

- exhaust;

- universal (supply and exhaust);

- combined.

The names speak for themselves: they are used in different parts of the ventilation system. Supply and exhaust differ in the direction and position of the lamellas and partitions. There is not too much difference, just some work better for air output, others for input. In principle, you can put the supply air on the hood or vice versa. The catastrophe will not happen, but the performance of the ventilation system may drop slightly. In private houses and apartments, the difference, due to low productivity, cannot be noticed. Tangible changes can only be in high-performance ventilation.

Universal diffusers pass air in both directions equally. So you can install them without hesitation. But, as usual, "station wagons" work a little worse than specially designed models.

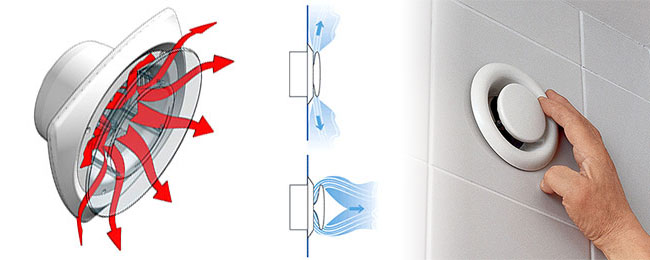

This is how an adjustable supply diffuser works - it changes the direction and shape of the air flow

Explanations are needed only, perhaps, with combined models. They differ in that part of the device works for inflow, part for outflow. Accordingly, they are connected to different parts of the ventilation system. That is, you can install only one universal diffuser on the ceiling, and you will need to connect it to two branches - supply and exhaust. The connection method is described in each specific model, in general it makes no sense to talk about it.

materials

Diffusers are made from:

- plastics;

- aluminum;

- steel (plain or stainless).

In private houses and apartments, plastic is most often used. For this situation, this is the best option. At a relatively low price, they have excellent performance, long service life, easy maintenance, and are not subject to corrosion.They fit seamlessly with plastic air ducts, which are used more and more often in private homes.

Ceiling diffuser can be made of plastic, metal, with wooden elements

Metal diffusers are used in industrial premises where only non-combustible materials can be used. They cost significantly more, weigh more, which complicates installation.

There are also diffusers, the outer part of which (grille) is made of wood. Such devices will ideally fit into the interior of a wooden house.

Location

By location, diffusers are:

- ceiling;

- wall;

- floor.

According to the installation method, diffusers are ceiling (most), wall and floor

Most often you can see a ceiling diffuser. They are used in 95% of ventilation systems, both in supply and exhaust systems. Mainly because the air is mixed in the upper part of the room, without causing much discomfort to a person. And also because with the device of false ceilings it is easier to make a ventilation system, if it simply did not exist before. Most often, the devices are attached to the main ceiling, and a hole is cut out in the stretch / suspended ceiling, which is covered by the grille.

Sometimes forced ventilation is done through the basement. Then install floor diffusers. This phenomenon is very rare.

Wall diffusers are used even less often. There are not many situations. For example, in apartments after replacing windows with plastic ones. In this case, an influx of fresh air is needed and it can only be provided by making a hole in the wall and installing a diffuser. Or with a lack of fresh air inflow and unwillingness to build / reconstruct the supply system.

Further, he will talk about ceiling diffusers, since they are the majority, and all the others still need to be looked for - they are usually delivered to order.

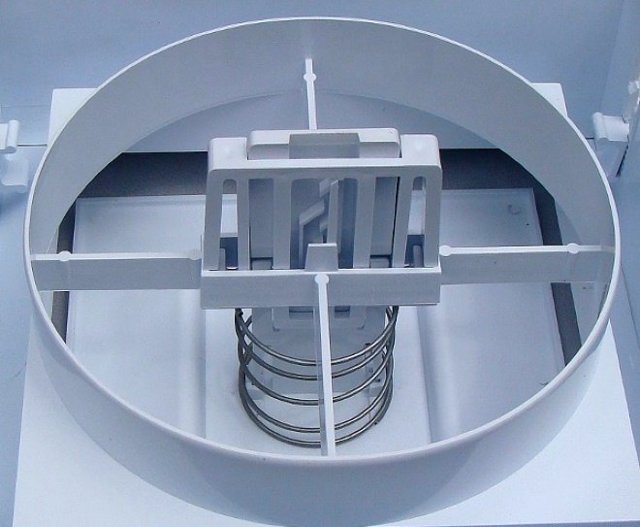

Anemostat: what is it?

Essentially, an anemostat is analogue of a ventilation adjustable grilledone in a different way.

A spacer is inserted inside the pipe, on which the adjusting screw is held.

At the end of the screw is a plate: a round shield that can move perpendicular to the surface into which the anemostat is built. The plate is movable (since it is mounted on a screw), and can move back and forth along the anemostat pipe.

Anemostat device (rear view)

When the shield extends (that is, when a person rotates the plate counterclockwise), the slot between it and the pipe walls increases, and the inflow (or outflow) of air increases. When the shield moves in (the plate spins clockwise), the hole decreases, and the air permeability through the anemostat also decreases.

Some supply models may have not 1, but 2 plates. In this case, one of them has a larger diameter, and is made in the form of a concave circle. The second - has a standard shape (plate), and is located inside the circle. Such a device will better distribute air throughout the room, but this cannot be called a too serious advantage.

The main difference between anemostat and diffuser - the ability of the anemostat to regulate the amount of passing air (this cannot be done in diffusers). Also, diffusers can be both round and square, while anemostats have only a round body.

Indoors, the product practically does not catch the eye, since it is located in the upper parts of the room.Most often this is the ceiling, less often - the upper part of the wall. On the surface (after installation and finishing work is completed), it looks like a small plastic (or metal) circle.

Anemostat in the ceiling in the room

The color of the product can be any. Most often, white (or metallic) anemostats are offered in stores. If desired, you can apply paint of any color to the product so that it matches the color of the interior.

Purpose of the product

The product can be used in systems:

-

ventilation;

-

conditioning;

-

air heating.

The anemostat can be used in premises of any purpose - both in residential and industrial, public, or sanitary facilities.

In the systems mentioned above, the anemostat performs the following functions:

-

Air flow distribution.

-

Smooth adjustment of the amount of passing air.

-

Decorative function: covering the opening of the ventilation duct.

The first point is relevant in supply systems: the shape of the "plate" contributes to the fact that the air is not directed in one direction, in a continuous stream. Flowing around the shield (plate), it spreads along the surface. This ensures a more even mixing of air and does not create strong air currents in the room.

This is interesting: Ventilation in the cellar, garage - how to do it do-it-yourself hood with one or two pipes

Rating of reliable metal anemostats

VENTS AM 150 VRF N

An excellent device with a living area of 0.009 square meters. m. Provides good air circulation indoors. The product can be installed on the ceiling, which simplifies operation. Due to the good shape, the air is distributed evenly throughout the room.The case is made of durable stainless steel, which makes it possible to place the equipment in a room where there is little humidity, for example, in the kitchen.

Adjustment is smooth and does not take time. For greater convenience, the design includes a round branch pipe of various diameters, which provides a good and durable connection to the air ducts. Fixation occurs thanks to spacer legs and self-tapping screws.

The average cost is 950 rubles.

ventilation anemostat VENTS AM 150 VRF N

Advantages:

- Strength characteristics;

- Corrosion resistance;

- Uniform distribution;

- Provides high-quality circulation;

- High service life.

Flaws:

- Weight;

- Price.

Airone DVS-100

A high-quality device that contributes to the effective distribution of air masses over the entire area. The product is easily mounted in the ceiling or fixed on the wall, while the adjustment is smooth and does not take time. The shape of the product is universal, which is suitable for most interiors. On top there is a special paint.

The case is made of steel, which is covered with a protective powder on top. This reduces the chance of corrosion and prevents rapid deterioration of products. To ensure that the installation does not take time, the manufacturer equipped the device with a coupling, which ensures a tight and secure fit to the duct.

Average cost: from 270 rubles.

ventilation anemostat Airone DVS-100

Advantages:

- Easy adjustment;

- Strength;

- Low cost;

- Efficiency;

- High service life;

- Reliability;

- Easy to install.

Flaws:

EUROPLAST DM 100mm

Exhaust anemostat, which is distinguished by reliability and durability. It is made of steel, which is covered with a special protective layer, which increases the strength characteristics and reliability. It can be installed in living rooms, as well as in bathrooms and sanitary facilities. For greater convenience, the manufacturer has equipped the product with airflow adjustment. Installation can be carried out on almost any surface.

The installation diameter is 100 mm. Sold in white. Steel does not deteriorate from prolonged use and can withstand sudden changes in temperature.

ventilation anemostat EUROPLAST DM 100mm

Advantages:

- Suitable for any interior;

- Low price;

- High service life;

- Strength indicators;

- Efficiency.

Flaws:

Era Anemostat universal detachable

A reliable device that guarantees a good distribution of air masses. Installation will take a minimum of time, as the manufacturer has equipped the device with high-quality spacer legs. The product can be installed not only in residential premises, but also in places where there is heated air. Therefore, the product is ideal for public, industrial and domestic use.

The outer part is made of solid steel and covered with polymer enamel, which increases strength.

Average cost: from 320 rubles.

ventilation Era Anemostat universal detachable

Advantages:

- External execution;

- Universal application;

- Small price;

- Suitable for use in places with heated air;

- Durability;

- Efficiency.

Flaws:

Classification: types and differences

Products may differ in a number of features and characteristics.

Let's take a look at the available options below.

By purpose (direction of air flow)

Diffusers are:

-

Supply.

-

Exhaust.

-

Universal.

The difference between them lies in the angle of inclination of the blades.

It should be noted that the products are mainly used in supply ventilation systems, less often in exhaust systems.

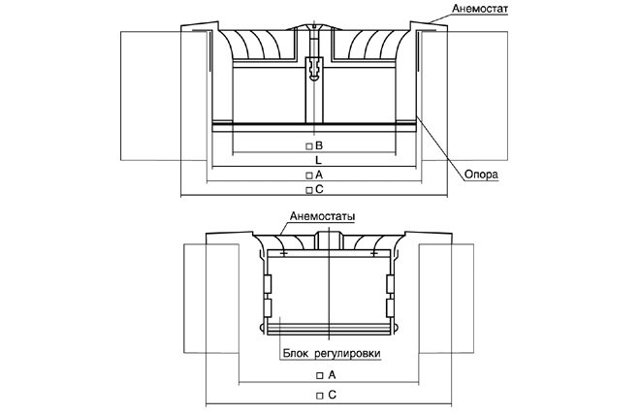

Supply and exhaust models

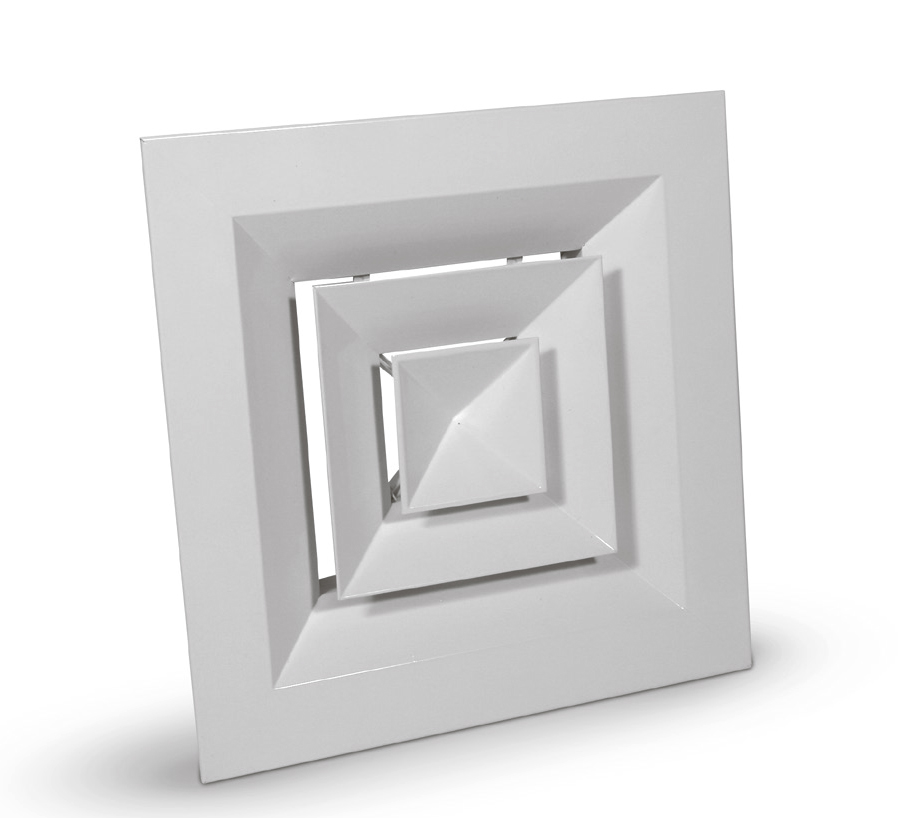

Separately, it should be said about the supply and exhaust diffusers, which can be installed simultaneously to both exhaust and supply ventilation. Such models are located on the ceilings, and have a rectangular or square shape.

On the sides - there are slots directed away from the center of the diffuser. Through them, air enters the room.

In the center - there are holes for removing air (exhaust).

Due to the different direction of air flows (air is drawn vertically, in the center, and supplied - on the sides, and directed to the sides), they do not mix with each other.

By material

The ventilation diffuser can be made of the following materials:

-

Plastic. A plastic diffuser is cheaper and lighter.

-

Metal. Metal products are usually either steel or aluminum. To extend the service life and improve the “appearance”, the surface of the products is coated with paint. Compared to PVC, metal models are more expensive.

By device (hole design)

According to the type of holes, the diffuser happens:

-

slotted. It has a rectangular frame in which several long narrow holes are cut. In this case, the slats can have an inclination (then the air will be directed in a certain direction), or be located at a right angle with respect to the frame (then the air will flow in a straight stream from the diffuser). They are good for their invisibility - such products fit well into the interior and do not catch the eye.For some models, the slope of the slats can be adjusted, both for all the blinds at once, and for each individually.

-

Nozzle (jet). Provides air with a continuous jet, due to which it passes further. It is usually used in the ceilings of large premises (concert halls, gyms, industrial premises, theaters, galleries, warehouses, shopping malls). For some products, the inclination and direction of the nozzle can be adjusted.

-

Dish-shaped (in fact - the same anemostat). It has a round frame, at a small distance from which a flat (or convex, or concave) circle is fixed. The air passes between the circle and the frame and is distributed along the surface (ceiling).

-

Vortex. The shape of the products can be round or square. The location of the shutters resembles the blades of a fan. This design allows you to more effectively mix the air in the room.

-

Fan. A round product, which is several diffusers of different diameters, connected into one.

Universal plastic diffuser

The shape of the body (frame) can be:

-

Round.

-

Rectangular.

-

Square.

By place of installation

According to the location of the product, there are

-

Ceiling. Ceiling mounting is the most common option.

-

Floor. They are usually used for heating appliances that are laid under the floor.

-

Wall. They are used extremely rarely, since ordinary ventilation grilles are usually mounted on the walls.

Slot ceiling diffuser

Models and approximate prices

For reference, here are the approximate prices at which you can buy products:

-

Round, aluminum, supply and exhaust, diameter - 10 / 200 mm: about 110 / 220 rubles.

-

Round, plastic, supply and exhaust, diameter - 200 mm: about 180 rubles.

-

Round, stainless steel, supply and exhaust, diameter - 100 mm: 700-800 rubles.

-

Nozzle, aluminum, diameter - 100 mm: about 1500 rubles.

-

Square, plastic, 150x150 mm: about 600 rubles.

-

Square, plastic, 600x600 mm: about 2200 rubles.

-

Slotted (rectangular), plastic, 500x100 mm: about 1200 rubles.

Popular manufacturers present on the Russian market:

-

Arktos (RF).

- Europlast (Latvia).

- Airone (RF).

-

Era (RF).

- Systemair (Sweden).

-

Vents (Ukraine).

-

Vanvent (RF).

Do-it-yourself anemostat installation

Installation of equipment is most often carried out in ventilation systems hidden behind suspended or stretch ceilings. If the rigid air duct is brought to the top of the wall, then the installation is carried out on the wall. The efficiency of air distribution does not depend on the installation method of the anemostat.

Concealed installation

When performing installation, it is necessary that the structural elements of the anemostat are located parallel to the ventilation duct in which it is installed. It is better to do this during the construction of a house or during a major overhaul, so that access to the ventilation system is convenient.

Work order:

- From the ventilation duct (if installation is not carried out directly into it), a flexible air duct is carried out to the installation site of the anemostat.

- A round hole is made in the ceiling. If it is made of drywall, then it is done with a jigsaw, if it is suspended, a special mounting ring is used.

- Once again, check that the landing diameter of the device matches the hole in which it is installed. Then connect the anemostat tube and the ventilation duct.

- The outer part of the circle is fixed with glue or self-tapping screws.

- When installing devices with electrical control, lay the wire and mount the switch.

- The last stage is passed after all the finishing work is completed. The support part of the device is placed in the pipe and fixed on a decorative circle.

- Install the plate and fix the adjusting screw.

Other installation methods

If the device has special mounting flanges, then its installation is carried out in a different way. In this case, it is enough to dock the anemostat flanges with the air duct pipe and fix the device with bolts.

Tips of the masters

If the anemostat will be controlled by electricity, a power line is laid before finishing work to provide it with power. At the final installation of the device, do not forget to connect electricity to it.

If the device first needs to be fixed on the duct, then the main body is installed. Then the hole is closed so that the dust generated during the repair does not get there. After finishing the finishing work, a plate with a control mechanism and decorative elements are mounted.

Despite a relatively simple device, an anemostat is a highly functional device that improves the performance of any ventilation system. Regardless of the type, it makes it easy and simple to regulate the air flow and ensures the required temperature and ventilation in individual rooms. The device helps to effectively remove polluted air in areas intended for smoking, as well as where there is a lot of smoke and pungent odors.

Ceiling diffuser: installation

There are two ways to connect diffusers to ventilation ducts: directly or through an adapter (plenum).The second option is more correct, but it requires a larger gap between the base and decorative ceiling.

If the shape and dimensions of the ceiling diffusers and ventilation pipes match

To connect the ceiling diffuser directly to the ventilation pipes (bends), a tee/splitter is placed in the ventilation pipe at the installation site. In the free - third - exit and put the device.

Cutting a hole directly in the pipe for its installation is the wrong decision. The body protrudes beyond the pipe, impeding the movement of air, the performance of the system drops, over time a dust plug is still formed, which can generally block the lumen. In general, this should be avoided.

It is necessary to select bends from the main pipe so that they can be conveniently connected to diffusers. It will not be difficult to connect a round diffuser to a round outlet from the duct, and a rectangular diffuser to a rectangular outlet

It is also important that their sizes match. This simple truth must be remembered when creating a system, choosing tees or making bends with the appropriate parameters.

If the shape and size match, installing a ceiling diffuser is not a problem

Diffusers of the same size are installed in the ventilation ducts by simply inserting them. Models that are small in size and weight can be fixed to the box with a sealant (silicone neutral). This is how models with a round base are usually attached.

For suspended ceilings of various types (plasterboard, plastic, Armstrong) developed a special fixation system - Clip in. It consists of spacers of the type that can be seen on recessed ceiling lights.

More massive square / rectangular models are attached to the walls of the box with self-tapping screws or suspended from the ceiling. The first option is simpler, but it is better not to use it, since dust collects on the protruding screw of the self-tapping screw. Unless the design provides for special protrusions for fasteners. Otherwise, over time, in the place where the self-tapping screw sticks out, a solid plug is formed that interferes with the passage of air.

Example of using an adapter - a round ceiling diffuser is connected to a rectangular ventilation duct

If the outlet is made of corrugated material or there is a desire to do everything “correctly”, heavy cases are suspended from the ceiling on studs or hangers.

Using Adapters

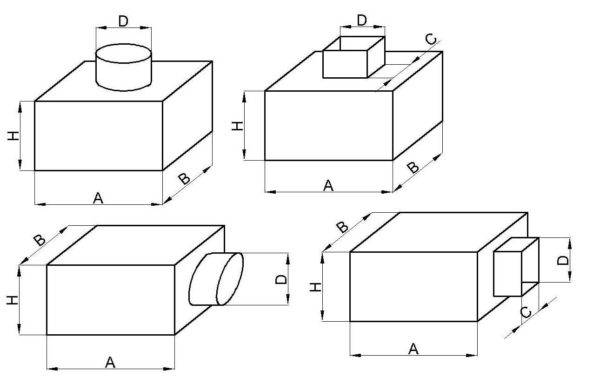

Adapters or plenums help to avoid such an unpleasant phenomenon as drafts. In this tank, there is a uniform redistribution of air, which flows evenly over the entire surface of the grate. But these devices have a significant drawback - they "steal" the height of the ceiling. Side connection models are smaller, but they still take up enough space.

Types of adapters for ventilation ceiling diffusers

Most often, a static pressure chamber is a parallelepiped, to the bottom of which a diffuser is attached. From above or side there is an exit for connection of a ventkanal. It can be of any required shape: circle, square, rectangle, oval.

There are adapters:

- With integrated rotary valve. If the diffuser model does not provide for adjustment, this can be done using an adapter.

- With removable filter. They also allow you to clean the incoming air.

- With airflow divider. This is a sheet of metal with a small cell.Mounted on powerful supply systems, it allows you to evenly distribute the air flow over the entire surface of the grille. .

Static pressure chambers for ventilation diffusers are made most often from galvanized steel. Sheet thickness - 0.5-0.8 mm. There are companies that will make the device according to your parameters. Also on sale there are standard adapters - for standard solutions. They can be made of steel (galvanized, stainless) or plastic.

Plastic adapters fit into corrugations or plastic air ducts

If necessary, the static pressure chamber is sheathed with insulation. This is necessary so that when the warm surface of the adapter and cold air interact, condensation does not fall on it.

One way to install an adapter for a ventilation diffuser

If the diffuser is connected via an adapter, the main task is to secure this device. If it is a suspended ceiling, you can mount the camera to the profiles. In the case of a stretch ceiling, you will have to hang it from the main ceiling. The methods are known: studs or perforated hangers.