- The principle of operation of the heat plinth as a heating device

- The principle of operation of the heating skirting board

- Types of baseboard heating

- Installation of a water warm skirting board system

- Calculation of baseboard heating

- How to act

- Kinds

- Water

- Electric

- What is the system of warm skirting boards

- Varieties of warm skirting boards

- With water coolant

- Electrical Models

- Types of heating skirting boards

- Electric heating

- Water warm plinth

- Heating element length calculation

- What and how to connect

- System features

- 6. Do-it-yourself installation of a warm plinth

- Self-installation of a warm water skirting board

- Self-installation of electric warm plinth

- Characteristics of the heating water circuit in the plinth

- Rating of the best models with a water coolant

- TurboTech TP1 - water

- Mr.Tektum water, brown RAL 8019

- Charley Standard water, white RAL9003

- The principle of operation of warm skirting boards

- Electric warm plinth

- Installation of electric plinth

The principle of operation of the heat plinth as a heating device

Obviously, this heating device got its name due to its location. They fix a warm plinth in the same place as a regular one - around the perimeter of the room. The main advantage of such a heating system is that the device heats up not only the air surrounding it, but also the walls with which it comes into contact.Such a system allows you to better retain heat and reduce heat loss.

The positive effect is the fact that air convection is reduced, and the heat is evenly distributed throughout the room, not concentrating in one place, as is often the case with traditional radiators. A considerable advantage is that due to the slow movement of air from the baseboard to the ceiling, dust from the floor practically does not rise. And this not only greatly facilitates cleaning, but also has a positive effect on the health of residents.

An electric warm plinth was used to heat the room.

An electric warm plinth was used to heat the room.

The temperature limits in which the device operates are 40-70 degrees and with the help of a thermostat you can set the indicator within these limits. According to the reviews of the owners, a warm baseboard never allows the air temperature to drop below 20 degrees, and this can be considered quite a comfortable temperature for living. Of course, this applies to cases where the calculations of the required number of elements and their power were carried out correctly.

If we are talking about installing an electric baseboard, then it is worth noting the fact that, like one section of any traditional radiator, one segment of a warm baseboard emits 190 W of heat. At the same time, the energy consumption for its production is 3 times less, and this is a considerable saving for the entire heating season.

As a heating device, a warm skirting board can be installed in almost any room. Neither the size nor any location of the room can serve as a contraindication to its installation. It is generally accepted that this design option is ideal for rooms with panoramic windows, where conventional radiators under the windows simply do not fit.

A warm baseboard is an ideal solution for installation in a room with panoramic windows. Note! A warm baseboard is an ideal solution for rooms with high ceilings where an additional or main source of heating is required. The main thing is to take care of the proper power of the device.

A warm baseboard is an ideal solution for installation in a room with panoramic windows. Note! A warm baseboard is an ideal solution for rooms with high ceilings where an additional or main source of heating is required. The main thing is to take care of the proper power of the device.

The principle of operation of the heating skirting board

As for the principle of operation of baseboard heating, here everything is the same as with radiators. Cold air streams enter the plinth ventilation grille and heat up, after which they rise up, giving off heat to the room.

There are pros and cons to this air heating scheme. So, for example, hot air from a warm baseboard rises along the walls, noticeably heating their surface. The advantage is that the walls accumulate heat, and then give it to the room. The downside is that this happens noticeably longer than with classic radiator heating. Also, not every finishing material is able to withstand the temperature load.

Types of baseboard heating

There are several types of baseboard heating: water and electric. To heat the air in the electric warm plinth, heating elements are used, and in the water one - the boiler coolant.

Therefore, a warm baseboard powered by electricity is the easiest to install. All that needs to be done is to fix it along the walls, and then connect it to the mains of the house.

In the case of a water heating baseboard, you will have to lay pipes to the installation site, hide them in the screed, and then connect them to the heating boiler. At the same time, baseboard heating in the house will work from a common system, so it becomes difficult to manage each of its elements individually.

In addition, today you can find a combined warm plinth, which can work both from a water heating system and from electricity. The cost of such baseboard heating will cost an order of magnitude higher, but it will be possible to combine different energy sources to heat housing.

Installation of a water warm skirting board system

Mounting electric warm skirting board very simple: we fix it on the wall. Everything, the system is ready for operation. It remains to plug in the sockets. The main thing is that the wire cross-section is correctly calculated, there are circuit breakers of the correct rating. This is the main problem in the case of using an electric warm plinth. Water is much more difficult to mount. Everything must be assembled into a single system, and this is not easy.

Installation of a heating skirting board: you need to know the nuances

Calculation of baseboard heating

A complete heat engineering calculation of heating is a long and complicated matter.

The size and geometry of the room, the material of the walls, floor, ceiling are taken into account, the degree of insulation of all structural elements, including windows and doors, is taken into account. In general, the calculation is quite difficult

Therefore, most often they take the average figure, which is derived from the analysis of many calculations.

It is believed that 100 W of thermal energy is needed to heat one square meter of a room with medium insulation. That is, to calculate the power of a warm baseboard, you need to multiply the area of \u200b\u200bthe room by 100. Get the required figure. That is how much (and preferably more by about 20-25%) should give in total all the elements of a warm plinth.

An example of the technical characteristics of the Best Board warm plinth for different operating modes of the system

For example, the area of the room is 18 square meters. For its heating, 1800 watts will be needed. Next, we look at how much heat is emitted by one meter of heating. A water heating skirting board can work in different modes, depending on the mode it emits a different amount of heat. The table above shows data for one of the systems. For example, let's take the heat output of one meter of warm plinth from this table (other manufacturers may have significant differences).

For example, the system will operate with a supply temperature of 50 °C. Then one running meter produces 132 watts of heat. To heat this room, you will need 1800/132 = 13.6 m of warm plinth. When ordering, it is better to add a margin of 20-25%. This reserve is necessary so that the system does not work all the time at the limit. This time. And also in case of abnormal cold weather. This is two. So, with a margin we take 17 meters.

Once again, we draw your attention: these are average data for some average house. And here even the height of the ceilings is not taken into account

It is again taken as an average - 2.5 meters. If you have better insulation, you will need less heat; if worse than "average" - more. In general, this method gives only approximate calculations.

How to act

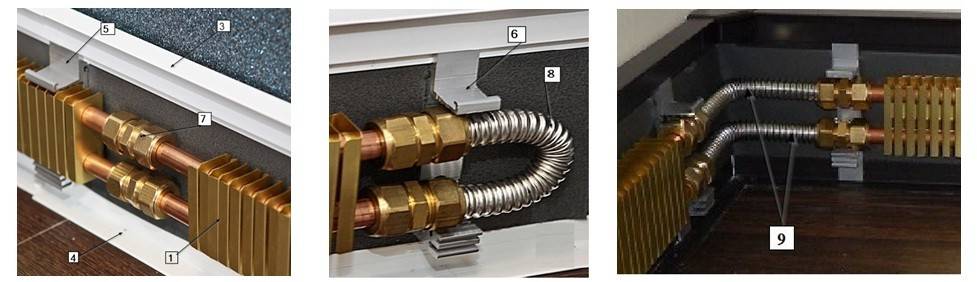

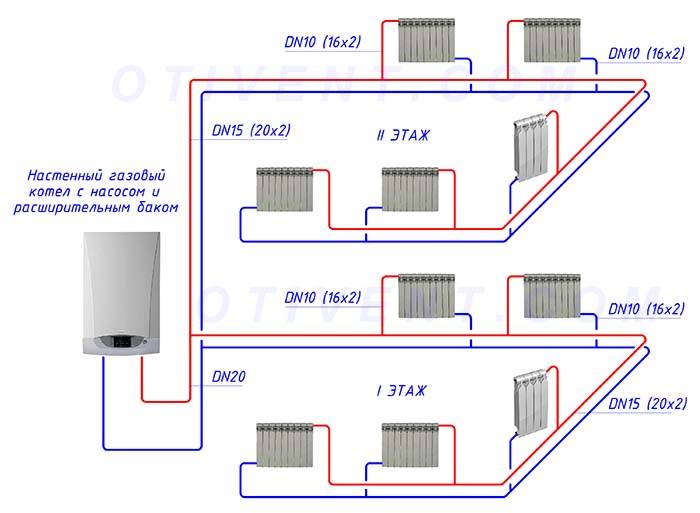

The first thing to do is to draw a plan on which to indicate the length of each heater, the length of the connecting tubes. After all, the length of a warm baseboard is not always equal to the perimeter of the room. In this case, the segments of heating devices are interconnected by copper or polymer pipes. It is undesirable to use steel, as they chemically interact with copper (it is gradually destroyed).

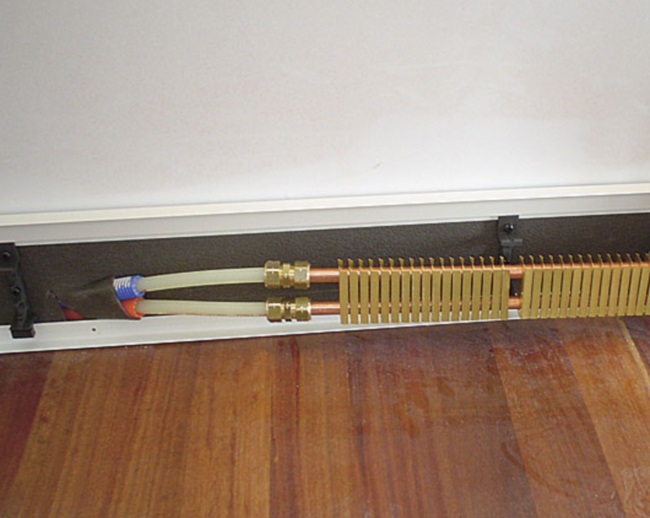

Preparation for installation takes place long before its actual start. At the very beginning of the repair, even before the leveling of the floor, pipes are pulled from the boiler or collector unit to the connection point of the warm baseboard. Pipes are laid, tested for integrity, filled with a screed in a filled state under pressure (working pressure in a private house is 2-3 atm, in a multi-storey building you need to find out in the housing office). Then all repairs are carried out and only after the finishing of the walls and floor does the installation of a warm baseboard begin. Here is its order:

- A heat-reflecting tape is attached along the perimeter of the walls. It prevents the consumption of heat for heating the wall.

A heat-insulating tape is attached, and fasteners on top of it - Fasteners are installed on top of the tape with a step of 50-60 cm. They are fixed to the wall with dowels or self-tapping screws (depending on the material of the walls).

- In fasteners, according to the plan, sections of the heating plinth are fixed, connected to each other by copper or polymer pipes.

We install the pieces and connect them into a single whole - The tightness of the system is checked by pressure testing.

- If everything is fine, pipes are connected from the collector unit or from the boiler, the system is filled with coolant and tested.

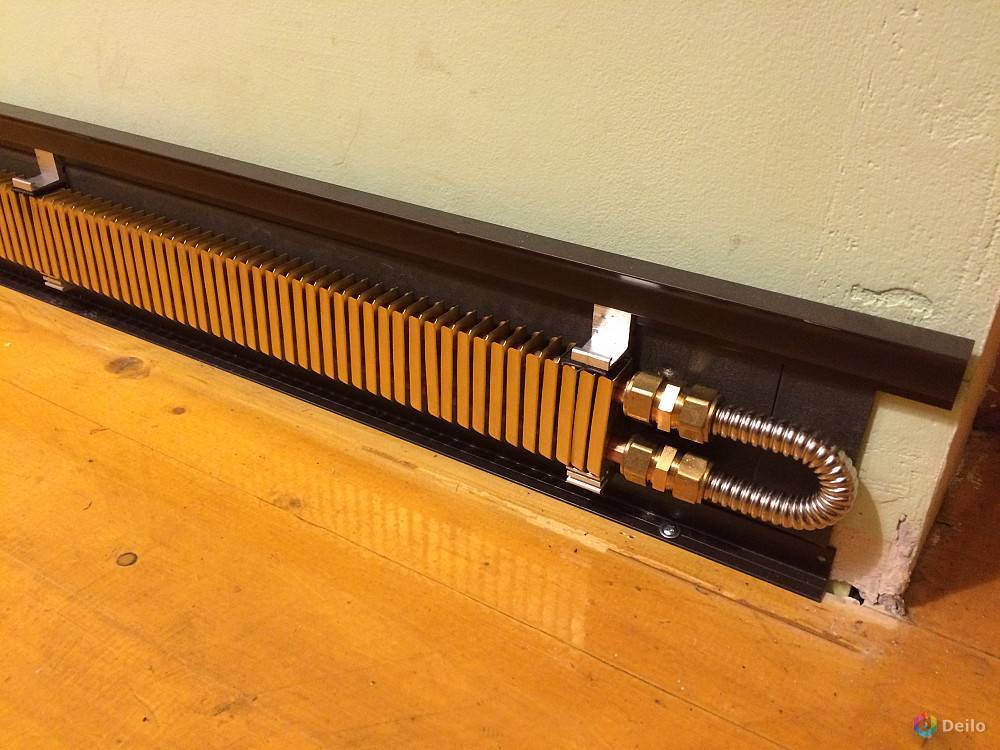

This is what it looks like when it's done - After successful tests, decorative covers are installed, the baseboard heating system is ready for operation.

Actually, the installation of warm baseboards is not too complicated.

But the tightness of the joints is important and special attention must be paid to this.

Kinds

Today, only two types of warm plinth are common - water and electric. Each of them is used in specific conditions for arranging rooms and furnishing the apartment itself.It is worth considering each of the types in detail.

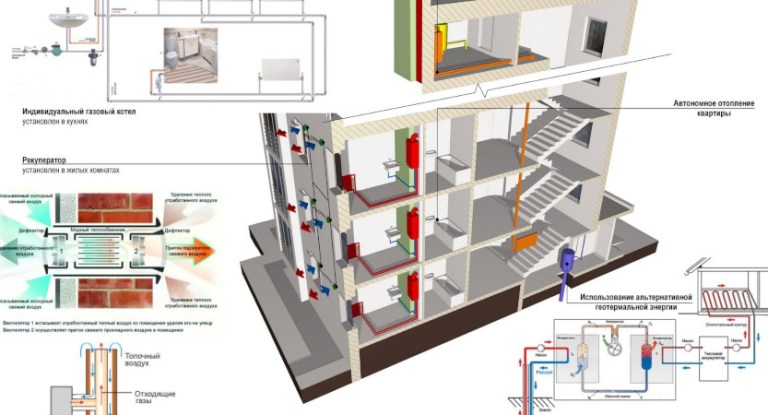

Water

This installation option is quite common - it can be seen in the interior of some modern residential buildings, office buildings, even shopping centers. It is worth noting that the water type of warm plinth is widespread in many Western countries. Such interest is due to such factors as: ease of use and low maintenance requirements. A warm water plinth is an externally metal panel or box, inside of which a heating or heating module with mini-tubes for water supply and heating is placed. The outer or back side of the device is also equipped with a metal panel, which is already designed to protect the wall itself from high temperatures.

This method of connection by technicians is called beam. The difference between this type of warm plinth and electric is a wide range of possible installations in the interior. Water warm plinth can be mounted on attics, loggias, even on a balcony, while the heating efficiency does not decrease, and energy costs remain relatively small. Another feature of the water type is the speed of heating the air, since the physical properties of water make it possible to freely transfer even the hottest streams through pipes. However, it is necessary to constantly monitor the temperature level in boiler rooms.

Electric

If the water version of the warm baseboard is valued for its quick heating and ease of maintenance, the electric type is common due to the following characteristics:

- ease of installation work - unlike the water type, the electric one is installed on site, the installation process is simple and fast, because it is enough to fix the heating panels to the wall;

- the presence of more advanced heat regulation systems - most models of water skirting boards are not equipped with special devices for measuring temperature - for this it is enough to monitor the average water level in boiler rooms. The electric type is often equipped with specialized thermostats that look like conventional thermometers. Thermostats can work both automatically and can be adjusted manually, and their work is aimed at optimizing energy costs.

Here it is worth noting the negative aspects of using such a plinth:

- high energy consumption - when using any equipment with power supply, the question arises of cash costs. The electric type, unfortunately, even with thermostats consumes a large amount of energy;

- installation of the electric type is much simpler, however, the connection process itself can cause some difficulties - this is the preparation of a dedicated line with the correct rating;

- one potential downside for many buyers is the availability of power. The probability of wiring damage and fire is extremely small, however, for some this is a determining factor under certain operating conditions.

If the buyer liked the aquatic variety more, then do not despair and think that these species differ in appearance.

In addition to the presence of terminals or wire attachments to the electrical supply, these varieties are outwardly absolutely similar.It is worth noting such a type of plinth equipment as an infrared warm plinth. The peculiarity of this type is the use of a special film tape, which, under the influence of high temperatures, heats up and becomes a kind of source of infrared radiation, which provides additional and high-quality heating of the room.

What is the system of warm skirting boards

Heating baseboards or baseboard heating are not new in the field of heating. The idea was proposed at the beginning of the last century, but due to the complexity of implementation and high price, it was almost forgotten. With the development of technology, the complexity has become lower, but the price is still high. This is basically what deters potential users.

This is what heating with a warm baseboard might look like

The main difference of this system is the non-standard form of heating devices and their unusual location. Heaters are long and low, located along the perimeter of the room at floor level. The heaters are covered with a long decorative strip that looks very much like a plinth. When installed, they replace the usual plinth. Therefore, such a system is very often called a "warm plinth". This system is very good for panoramic glazing - it can be no higher than the frames, so it is completely invisible. She is no worse in ordinary rooms - she is not visible at all.

Varieties of warm skirting boards

There are only two types of convectors in stores. Some run on electrical energy, while others require liquid

To understand which option is suitable for installation, it is important to know the features of each device.

With water coolant

This option is most popular for indoor installations.It can be found both in residential apartments and in office buildings, shopping centers. Almost most of the European countries prefer to use such models, since their installation takes less time. In addition, it is not necessary to carry out constant maintenance. Good and uniform heating will be throughout the entire period of operation.

The device with a water coolant is a small metal panel. Inside there are small tubes into which liquid enters, then it heats up to operating temperature. The front and back sides are equipped with insulating material. The main task of the element is to protect the walls from high temperatures, which avoids the risk of damage and increases the efficiency of the device.

Another feature of the device is a large selection, which makes it available for installation in modern interiors. The equipment is installed not only in living rooms, but also on a balcony or attic. The quality of heating remains at a high level, while the cost of electrical energy is minimal.

Warm skirting boards with a water coolant are characterized by a high heating rate. Because water can easily transfer hot streams

The only thing that is important to consider is that constant temperature control is required. Otherwise, there is a risk of damage to the entire heating system.

Electrical Models

While water-heated skirting boards are popular due to their easy maintenance and wide design options, electric skirting boards are valued for other reasons:

- Ease of installation.The electric version does not require complex connections, the entire installation process takes place on site. It takes a minimum of time, you only need to attach the heating elements to the wall.

- Control. Most convectors with water do not have special regulators, which makes temperature control difficult. Therefore, a person needs to look for these values in boiler rooms. In electrical systems, everything is simpler, since a special thermostat is installed there, which displays the current readings.

- Possibility of adjustment. In most devices there is a special regulator. It allows you to change the temperature up or down. This solution reduces energy costs.

Despite the positive aspects, there are also disadvantages that affect comfortable use:

- High consumption. Even with a thermostat installed, such equipment consumes a large amount of electricity. Of course, with minimal settings, the costs will be small, but there will be no good warm-up either. Therefore, some users refuse such a performance.

- Installation nuances. When compared with water thermal skirting boards, the installation process is less expensive. However, there are a number of features that do not allow it to be carried out quickly.

Types of heating skirting boards

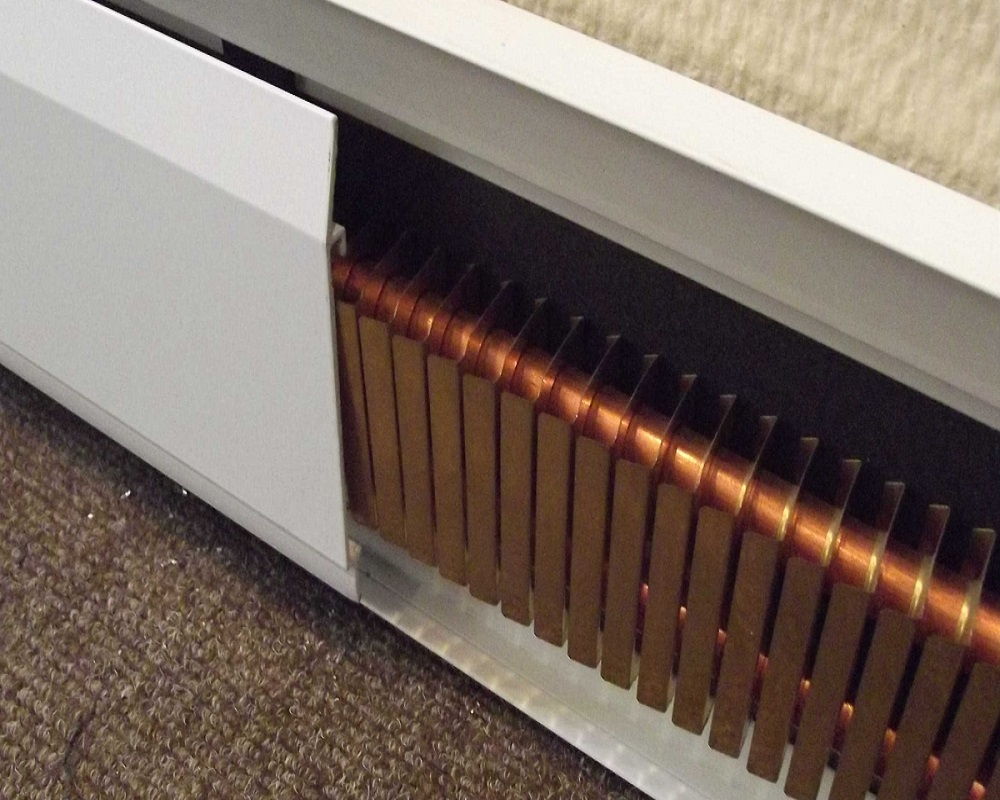

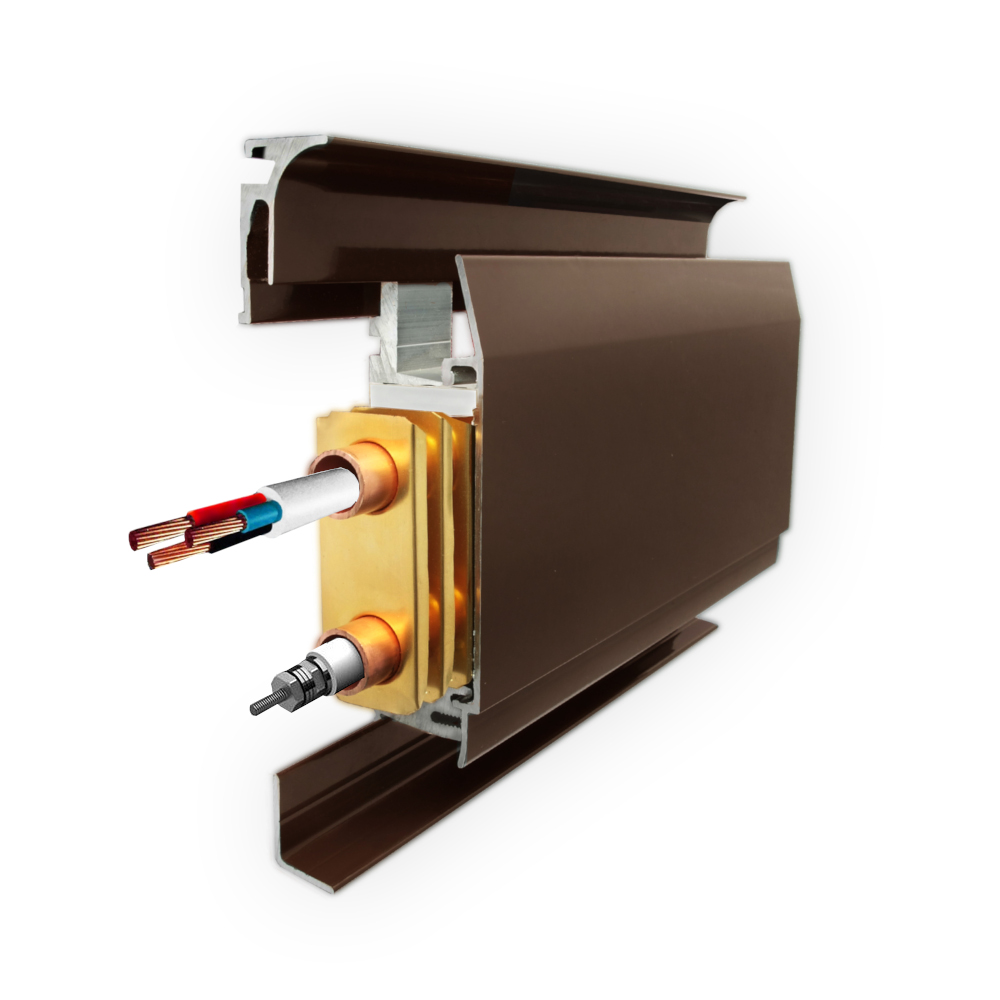

Structurally baseboard heating system consists of a heating module covered with a decorative aluminum strip. The heating module consists of two copper tubes on which aluminum plates are put on. Copper is known to have high heat dissipation and high corrosion resistance, but it comes at a high price. Aluminum also transfers heat well, and is much cheaper.This combination of copper + aluminum is used in many heating devices and has proven its effectiveness.

Read about copper and copper-aluminum radiators here.

This is a baseboard heating design

There are two ways to heat the heat transfer module: using a coolant (water or antifreeze) and an electric heater element. On this basis, they differ.

Electric heating

Special low-temperature heating elements are inserted into the electric skirting boards. They heat up to a maximum of 60 oC. At the same time, their power is more than enough: one linear meter produces about 180-280 watts. Electric heaters are inserted into the lower tube, and a cable in a special sheath is laid in the upper one. With its help, voltage is applied to all sections of the heating element. The length of one is from 70 cm to 2.5 m, and the power necessary for heating the room is collected from different lengths of the heaters.

A special heating element is inserted inside the copper tube. This is how an electric warm baseboard is obtained

Water warm plinth

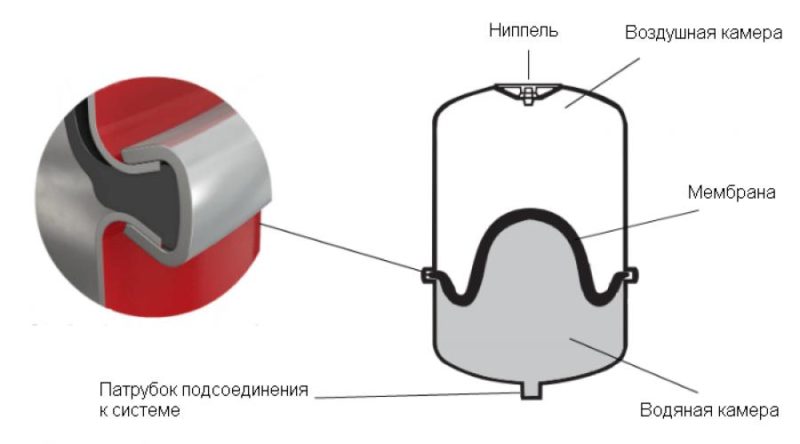

When using water or antifreeze for heat transfer, the same modules are connected into a single heating circuit. There is only one limitation: for maximum heating efficiency, the length of one circuit should not exceed 12.5-15 m (different lengths from different manufacturers).

If there are several circuits for installing a warm water plinth system, it is convenient to connect a collector (comb). You can use the most common model or with flow meters - this is your choice. Heating modules with a water heating method are recruited based on the required power for a specific thermal head of the system.

Heating element length calculation

Table of dependence of the power of a warm baseboard on the temperature delta (thermal pressure)

For example, at ΔT = 37.5 oC to compensate for the heat loss of a room of 1500 W, the heat output (according to this table) is 162 W. So, you need 1500/162 = 9.25 m of the heating element.

What and how to connect

Having collected the required length in total, distribute it around the perimeter of the room, combining it into closed contours. Between themselves, the segments of the heaters are connected in several ways:

- flexible pipes made of stainless steel with union nuts or under a press;

- copper pipes and fittings for soldering;

- copper or brass threaded fittings.

The most reliable connection method is soldered copper pipes. This option is also suitable for central heating systems, since such connections can withstand up to 30 bar. The most difficult thing is assembly with threaded fittings: the dimensions and distances between the tubes and from the wall are small, it is very inconvenient to work. Flexible pipes must be chosen reliable: heating and hot water require good quality.

Connect the heating elements of the heating skirting boards with hoses, copper pipes

The piping from the boiler or the floor comb must be made of materials compatible with copper: polymer (polyethylene and reinforced polypropylene), metal-plastic or copper pipes.

System features

The system is compatible with boilers of any type on any fuel. But there is one feature: for normal heat transfer, a high speed of the coolant is required. With natural it will simply be ineffective

Therefore, it is important to choose the right pump.

6. Do-it-yourself installation of a warm plinth

In addition to the high cost of the system itself, you still have to pay a tangible amount for its installation. In this case, the calculation is made for each running meter. Based on this, many people have a question - is it possible to install a warm baseboard system on your own? We can say that if you have the skills to work with electrical wiring and plastic pipes, as well as with due attention and legibility, this is not so difficult to do.

Self-installation of a warm water skirting board

To carry out the work you will need the following materials:

- metal-plastic pipes;

- Thermal insulation material;

- Collector equipped with taps;

- Metal and plastic adapters;

- Set of tools.

Installation should begin with the installation of the collector. It is necessary to bring a pipe to it, which will provide its power. A boiler operating on any type of fuel can be used as a source of heat carrier. The only condition is that for the correct operation of the system, it is necessary to provide a pressure of at least 3 atm. After you calculate the required length of the plinth according to the recommendations from paragraph 6, you can start laying pipes.

It must be remembered that the maximum length of the circuit should not exceed 12.5 or 15 m, depending on the manufacturer

And that there should be two pipes in the system - one for supply, the other for the intake of coolant;

It is also important not to forget about thermal insulation in order to reduce heat loss. To do this, special material must be laid along the perimeter of the room between the wall and the pipes;

Now you need to screw the base to which the heat exchangers will be attached.

The plank is fixed with self-tapping screws

Please note that when finished, the plinth should not fit closely to the floor.Leave a gap of about 1 cm to prevent the appliance from overheating;

Now fix the modules and connect them together using compression fittings;

When the structure is assembled, you need to connect it to a common line by mounting a collector;

Be sure to check the system for leaks before final assembly.

To do this, a trial run is performed, which at the same time will show the correct operation;

If the system works reliably, fix the front panel to the plinth. It is very easy to do this by following the instructions in the instructions.

Self-installation of electric warm plinth

Installing an electric skirting board requires very different skills and attention to slightly different factors. It is recommended to connect the system directly to the shield and equip it with a separate machine. How many contours will be in your apartment or house, there should be so many separate lines. Choose wires with a large cross sectionthat can definitely withstand the load (at least 2.5 mm). Do not forget about the need to connect a thermostat for each circuit and a temperature sensor for each room. This will help set the most optimal temperature for each room.

- The beginning of the installation should begin with the laying of thermal insulation material;

- Then screw the base of the plinth;

- Fix heat exchangers on it;

- Make a parallel connection of wires;

- Perform a thorough visual inspection for the absence of non-insulated areas;

- Close the structure with a front panel;

- Connect the heating circuit to the thermostat and connect to the switchboard;

- Perform a test run of the system.

The gap from the floor to the baseboard should be at least 1 cm, and the distance from the wall should be at least 1.5 cm. This will ensure proper convection and protect the system from overheating.

Characteristics of the heating water circuit in the plinth

The heating circuit is located at the junction of the walls and the floor, it is an aluminum box, inside of which the heating elements are fixed. The system consists of a direct and return pipe, heating radiators, side and swivel plugs.

Efficient heat transfer is ensured by a copper-aluminum construction and a slot in the duct for air exchange. Heating of the room occurs in a few minutes, thanks to the law of thermodynamics.

Heating copper pipes are assembled around the perimeter of the room into several batteries connected in a circuit. Plinth heating can be main and auxiliary. Do-it-yourself installation of water or electric warm skirting boards is less expensive, but a specialist will do better.

Rating of the best models with a water coolant

TurboTech TP1 - water

A high-quality device that makes it possible to create a compact heating system for any room. Air flows are evenly distributed, which creates an optimal microclimate. The box is made of durable aluminum, it prevents the negative impact on the walls. The heat exchanger is made of durable stainless steel.

The main advantage of the device is the ability to withstand pressure up to 16 atm. The positive side is simple installation, which takes a minimum of time and allows you to install the product in every room.

TurboTech TP1 - water

Advantages:

- Uniform distribution of heat;

- High-quality insulating material;

- Sold in several colors;

- Strength characteristics;

- Small cost.

Flaws:

Mr.Tektum water, brown RAL 8019

A reliable device that guarantees a healthy microclimate in the house. The product is suitable for installation on the floor with any coating, including parquet and carpet. Due to the good air flow, no cold spots are formed. The risk of condensation is minimal, which will prevent the development of mold.

During operation of the device, the air is not burdened with dust and does not dry out. Therefore, it becomes easier to breathe. For installation it is not required to open the floor, everything happens on the spot. It can be used not as the main, but as an auxiliary heating system.

The average cost is 5,500 rubles per meter.

Mr.Tektum water, brown RAL 8019

Advantages:

- Uniform temperature;

- Strength;

- Does not burden the air with dust;

- Ensuring a healthy microclimate;

- Does not form mold.

Flaws:

Charley Standard water, white RAL9003

Efficient heating system, which can be installed as auxiliary or main. Heating is carried out from the coolant, which comes from an external source, which is the best solution and is suitable for most rooms. The walls are heated evenly, eliminating the formation of cold spots and condensation. The device is suitable for installation in old and modern houses.

The outer casing is made of aluminum and PVC. The heat exchanger is made of copper, which guarantees long-term operation. The maximum length of one circuit is 20 meters. Inside the tubes is placed up to 520 ml of water. The warranty period is 5 years.

Charley Standard water, white RAL9003

Advantages:

- Long warranty;

- Efficiency;

- Fast heating;

- High service life;

- Equipment.

Flaws:

The principle of operation of warm skirting boards

The essence of the very idea of \u200b\u200bheating with warm baseboards is that the heating system is located around the perimeter of the room near the floor. The heated air in the convector slowly rises along the walls. Due to this, the entire volume of the room warms up.

Heat from convectors will not affect furniture

Warm baseboards practically do not take up much space. Despite the high power ratings, furniture and other interior items can be safely placed near the convectors. The surface of the convectors does not heat up to a dangerous temperature level that causes burns.

The trading network offers for sale systems of warm skirting boards of two types. This is an electric skirting board and a warm water skirting board. Consider each heater.

Electric warm plinth

How to make a warm plinth with your own hands, powered by the mains? Having skills in working with electrical engineering, you can assemble an electric warm plinth quite independently.

The heater consists of two horizontal copper tubes. The power cable, covered with silicone insulation, passes through the top tube. A tubular electric heater is threaded into the lower copper tube. The whole system is controlled via an air temperature sensor by a thermoregulation unit.

Heating element - conventional heating element

When the temperature inside the room falls or rises, the heaters periodically turn on and off, thus ensuring a constant temperature regime.

They purchase a set of warm skirting boards based on the calculation of the length of the heaters, rotation angles and other related elements.The heating element itself is a tubular electric heater (TEH), enclosed in a copper sheath.

In turn, a copper pipe is threaded through a body of finned thermal reflectors (radiator). Electric heating modules are produced in several standard sizes. Depending on the length of the electric heater, its power changes, as can be seen from the table:

| № | Heating element length mm | Power, W |

|---|---|---|

| 1 | 700 | 140 |

| 2 | 1000 | 200 |

| 3 | 1500 | 300 |

| 4 | 2500 | 500 |

Installation of electric plinth

Install the heating element 3 cm from the wall

Only a person with extensive experience in electrical work can assemble his floor electric heater by hand. Calculating the dimensions of heating elements, making radiator nozzles, installing connecting cables is a very difficult and responsible job. Therefore, it is easier to buy ready-made heating elements for warm skirting boards.

When a heating set of skirting boards has already been purchased, they begin preparatory work.

Mount the electric heater in several stages:

- I install the mounting box at a height of 4 - 6 cm from the floor. Lead the power wires to the junction box.

- At a convenient height, a switch with a thermostat is mounted on the wall.

- A protective tape 3 mm thick is glued to the walls over the entire height of the plinth.

- Markings are applied to the walls for mounting under heated skirting boards.

- Drill holes for dowels in places where fasteners should be installed.

- Screws are screwed into the dowel through the technological holes in the brackets.

- A thermal heating module is hung on the installed brackets.

- Connect the modules with electrical wires in parallel.

- A residual current device (RCD) is connected to the system.

- Connect the air temperature sensor.

- Make control inclusion of an electroplinth.If a malfunction is found, fix it immediately.

- Install the skirting board.

The lining of the plinth is made of enameled metal panels or plastic. The cladding should not reach the floor surface by 20 - 30 mm. There are horizontal slots on the top of the panels. This design provides a constant movement of air masses from the bottom up. The lining of the plinth, in addition to its function as an air duct, plays a protective role against accidental mechanical influences.

Work related to the supply of electricity to the plinth, connection to the electric meter, installation of a thermoregulation system is best entrusted to a specialist.

Installation of a warm plinth provides complete electrical safety. The places where the wires are connected to the contacts of the modules are closed with heat shrink tubes. The tubes protect the contact surface from moisture. For more information on installing a warm skirting board, see this video: