- Shut-off valve recovery technique

- Device and principle of operation

- Welding instructions

- Problems with the operation of the ball mixer

- Types of ball valves

- Repair of a single-lever mixer with a ball block

- Disassembly order

- Typical Ball Mixer Valve Gear Problems

- Assembling a single-lever mixer with a ball mechanism

- Problems with the swivel spout

- Crack in the hull

- Clogged aerator

- Helpful Hints

- If necessary, close and remove the radiator

- How to choose a ball valve

Shut-off valve recovery technique

When planning to restore the performance of a ball valve, it is necessary to ensure not only the availability of the necessary tools, but also good lighting.

When restoring the operation of the crane, first of all, unscrew the self-locking nut (in some cases, simply unscrew the screw that holds the rotary knob). You can easily do all this with a ring wrench of size 8 or 10, and an open-end wrench also helps in this matter (it all initially depends on the crane model).

There are symptoms, no antibodies: scientists named three inexplicable facts about coronavirus

Remove the hose and water in the morning. Secrets of July watering carrots

Australia - a country of thousands of cosmic landscapes on the sea and in the mountains (photo)

Next, you need to carefully remove the faucet handle. This, as a rule, is not easy, only after its gradual rocking, performed by alternately pressing on one or the other side of the structure

In this case, it is important not to knock on it - this will lead to a violation of the integrity of the flags and their breakage

Now you should choose the most suitable key, and then try to turn it, alternately changing direction: first you can try to do this clockwiseand then against it

Carrying out the described actions, it is important to monitor their amplitude - it should be low, because, with great effort, there is always a risk of breaking the stem or breaking the edges

As soon as movement is noticed, it is possible to increase the amplitude of movements and their scope.

When doing this work, it is very important to ensure that one of your hands holds the head on the stem, and the other turns it.

Teach your child to talk to himself, and he will be able to fend for himself after the holidays

Why Ilya Naishuller changed his mind about shooting Tyler Rake and chose another project

What a beauty the granddaughter of her beloved film grandmother Galina Makarova grew up (photo)

As soon as the stroke of the rod becomes as free as possible, at this moment you can put on the handle, and then fix it with a screw (or nut). Now you should continue the swinging process until the water supply is completely blocked.

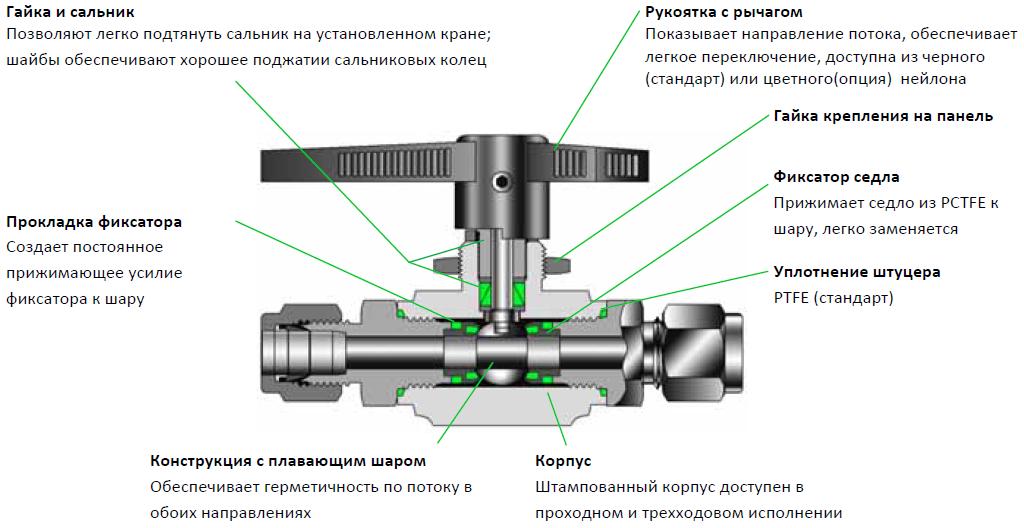

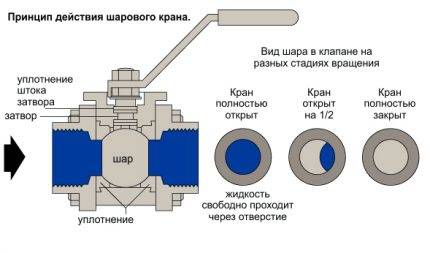

Device and principle of operation

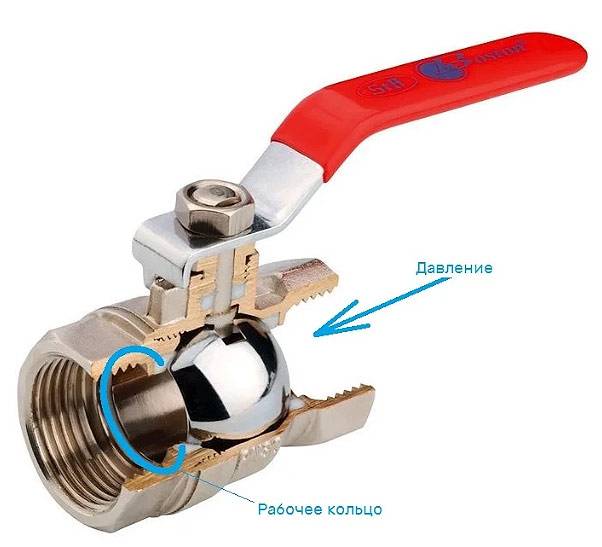

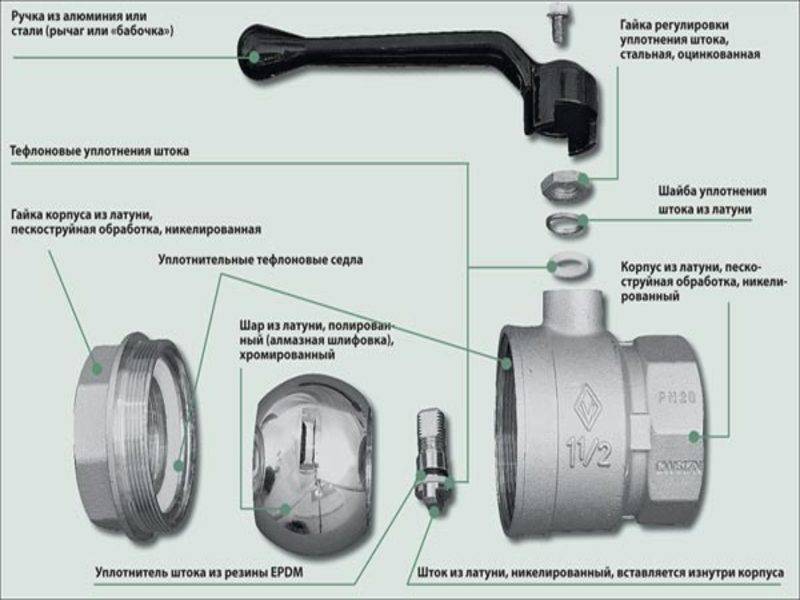

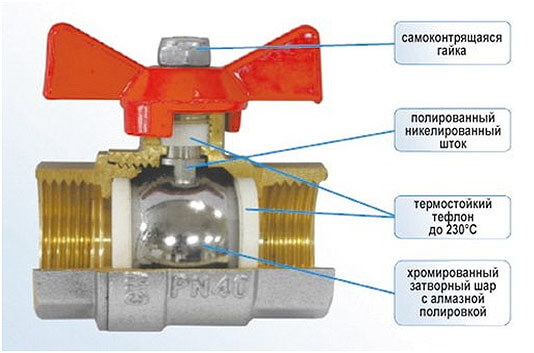

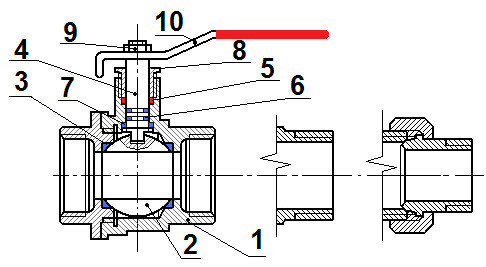

The body of the locking device is a piece of pipe, expanded in the middle part. In the extension, a seat made of sealing material is installed, inside of which is the main element - a ball, also known as a shutter or plug.

The ball can rotate freely inside the seat.It has only one through hole in the shut-off valve.

Regulating devices and valves that redirect the flow may have 2 or 3 holes. If the tap is used to regulate the pressure of hot or cold water, then there are two holes, if the device is a mixer, then there are three holes.

A ball valve is actuated by turning a lever to which a ball valve with a hole is connected through a stem. By turning the hole relative to the axis of the pipeline, we open / close the passage to the medium or pass it partially

A ball valve is actuated by turning a lever to which a ball valve with a hole is connected through a stem. By turning the hole relative to the axis of the pipeline, we open / close the passage to the medium or pass it partially

The principle of operation is very simple: when the axis of the hole in the ball is aligned with the axis of the faucet body, water will begin to flow from it.

Those. when the plug is turned so that its opening coincides with the direction of the pipeline, as if continuing it. In this position, the flow of liquid, steam, gas passes through the pipeline, including through the valve, freely.

When the ball valve is rotated 90º, the passage for water, steam, gas is blocked by the side on which there are no holes. In this position, the flow of the medium stops completely, because it rests against the solid wall of the shutter.

However, this simple device can also regulate the flow parameters. When turning 45º, for example, the flow will be blocked only half.

To control the ball, a rod connected to a lever is used. O-rings are located on both sides of the stem. The hole in the body through which the stem passes is also equipped with a washer and an o-ring.

The ball single-lever mixer is equipped with a shutter with two holes for passing cold and hot water and another hole for the outlet of the mixed jet

The ball single-lever mixer is equipped with a shutter with two holes for passing cold and hot water and another hole for the outlet of the mixed jet

Ball valves are made of brass or various steel grades.Brass devices are considered more reliable, their service life exceeds 10 years. Steel products are very rarely used in everyday life, mainly used for industrial piping systems.

More recently, manufacturers began to produce cranes, the body of which is made of high-strength plastic. Unlike brass, such devices not subject to corrosionare much cheaper.

The only drawback of plastic products is that they cannot be used for hot water.

All o-rings are made of high density rubber, these are the “weakest” points of the faucet that cause leaks, but are easily replaced with a regular repair kit

These taps are the most widely used in everyday life. A feature of their design is that the ball is not rigidly connected to the stem and can move under the action of water, pressing against the sealing ring, thus sealing the valve.

The floating ball is used in mechanisms whose nominal size does not exceed 20 cm. Such devices are installed in internal water and heat supply systems. Practically in all household mixers of domestic and foreign production, a floating ball mechanism is also installed.

Execution of the body of cranes with a floating ball can be either welded or collapsible. Sealing elements can be of different hardness. Small household appliances are usually collapsible and have soft seals.

Floating gate valves are installed on lines with a diameter of up to 200 mm with a constant movement of the working medium. The ball under the pressure of the medium is pressed against the sealing rings, sealing the fittings

Floating gate valves are installed on lines with a diameter of up to 200 mm with a constant movement of the working medium. The ball under the pressure of the medium is pressed against the sealing rings, sealing the fittings

There are valves in which the locking element is fixed on the stem axis, and the seals are pressed against the ball with the help of tie bolts or springs. To facilitate closing/opening, the trunnion is equipped with bearings.

This design is the most reliable, but due to the high cost it is rarely used in everyday life and usually in the most critical sections of the water supply system.

Welding instructions

The installation of ball valves in the production line must be carried out exclusively taking into account the requirements of the project, as well as common standards. The main recommendations are listed below:

At the time of work, it is strictly forbidden to fix the device by the handle or other technological elements. This is due to the fact that the load exerted can lead to very serious consequences. Even a slight deformation of the stem causes a decrease in the tightness of the entire device.

Welding work can only be carried out in the open position of the device. At the same time, you need to make sure that there will be no various contaminants inside that can get inside during transportation.

At the time of welding, it is recommended to remove the handle. Often, in its manufacture, a material is used that can suffer from falling drops of hot material.

When mounting in a vertical position, welding of the top seam is carried out in the fully open position. The bottom seam is obtained in a fully closed position, which eliminates the possibility of the effect of reverse draft of warm air.

With a diameter in the range from 10 to 125 millimeters, it is recommended to use electric welding, with a larger indicator this condition is mandatory.

The bevel of the pipe must ideally fit the locking element

That is why, in the case of poor surface quality, the end is cut off and carefully prepared.

When welding directly, care must be taken to ensure that the valve body does not heat up. This is due to the fact that too high a temperature can lead to very disastrous consequences. It is considered overheating to heat the body to a temperature of 100 degrees Celsius in the seat area.

It should be borne in mind that in most cases a special coolant and a moistened cloth are used. Welding can be carried out in several stages to reduce the likelihood of surface overheating. An increase in plasticity causes deformation of the surface and loss of tightness of the entire structure.

It is considered overheating to heat the body to a temperature of 100 degrees Celsius in the seat area. It should be borne in mind that in most cases a special coolant and a moistened cloth are used. Welding can be carried out in several stages to reduce the likelihood of surface overheating. An increase in plasticity causes deformation of the surface and loss of tightness of the entire structure.

After receiving the seam for a long period, it is forbidden to open and close the reinforcement. This can only be done after the surface has completely cooled down. Otherwise, the internal elements may be damaged.

The construction length of the nozzles must not be shortened. This is due to the fact that it is selected taking into account the probability of heating the main structure.

After completion of the work, the quality of the seam is checked in accordance with the established requirements. To protect the surface, a paint coating is applied. The final stage is the flushing of the crane to remove debris that could get inside the structure at the time of welding.

Problems with the operation of the ball mixer

What are the most common problems when using a ball type mixer?

Except for those cases where the cause of the breakdown is mechanical damage, that is crack in the hull or there is a problem with the water supply, for example, water is constantly flowing with rust, the following problems are the most common.

The most common problems:

- weakened pressure, provided that the pressure in the water supply system has not decreased;

- water leak;

- heavy temperature regulation (impossible to set warm water).

The most common problem is a mixer leak. Its cause is the clogging of the space between the ball and the seats in the cartridge. Even a microscopic mote can break the tightness of the valve and subsequently deform the seat.

The pressure is not difficult to regulate by changing the position of the rod connecting the lever and the ball to each other. By changing the position of the stem, it is possible to set the position of the pipes in such a way as to provide the necessary pressure in the tap.

There may also be problems due to clogged shutter. This problem is easily solved by taking the aerator out, cleaning it and returning it to its original position. In order to avoid blockages in the future, it is necessary to install water filters that can trap solid elements that clog the faucet.

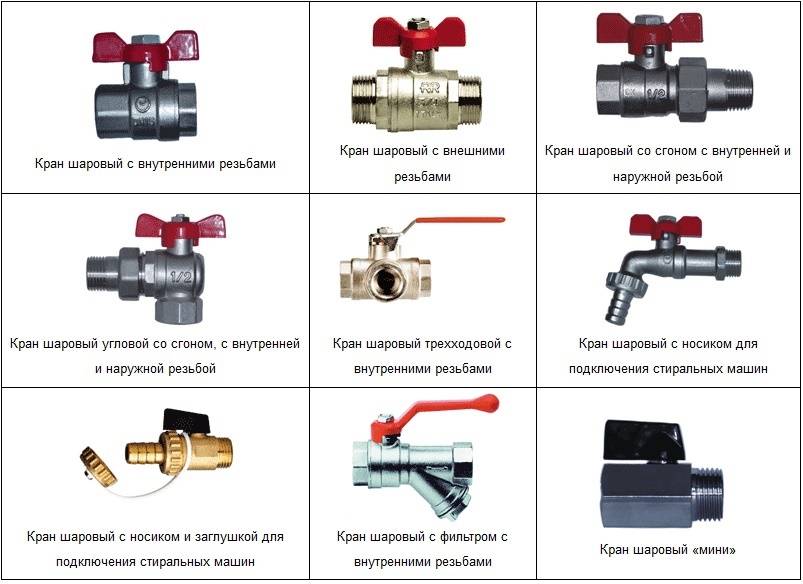

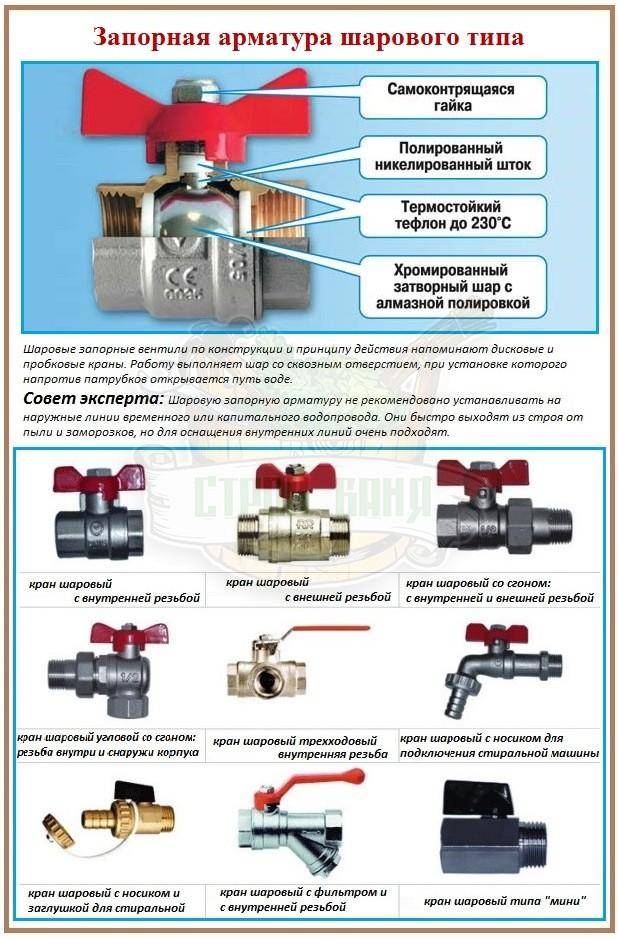

Types of ball valves

Shut-off ball valves for water supply are used in many utility systems, so they have many varieties according to different classifications. There are over 4,000 different models of these valves, grouped into several groups.

The ball valve according to the material of the body can be:

- Brass. The most suitable option for water and gas supply with a good price-quality ratio. Not used in hot water systems.

- Steel. Most affordable. There is a huge selection of sizes. Does not function well in the cold water supply line. Subject to corrosion.

- From stainless steel. Compared to steel products, they are more efficient and reliable. As the quality increases, so does the price.

- Cast iron. Inferior to models made of modern materials in all respects. Almost never used.

- Polypropylene. Installed in plastic pipelines. In terms of strength and durability, it is practically not inferior to brass products. Differs in the small weight and low price, it is not subject to corrosion.

By type of connection, the following types are distinguished:

- Coupling. Possess the big range of standard sizes, are equipped with carving connections. Often used in public utilities and private construction.

- Under welding. Lightweight and compact models. The welded connection with the pipeline guarantees high tightness, but significantly complicates the maintenance, repair and replacement of the product.

- Flanged. Large-sized devices that are used in systems with large pipe diameters, more than 40 mm. They are characterized by ease of maintenance and installation, require regular monitoring of the condition of the tightening bolts.

There are two types of hull:

- Collapsible. The device is easy to disassemble and, if necessary, replace parts that are out of order.

- All-welded. Cheaper than collapsible models. However, if one element fails, the entire structure must be replaced. At the same time, the service life is about 15-20 years.

According to the method of management are divided into the following types:

- Manual. The most used type of ball device in everyday life. The flow of water is blocked by turning the handle or "butterfly".

- With electric drive. Control occurs remotely, using electrical signals.

- With pneumatic drive. Another way to remote control. It is used in those products where the use of electricity is dangerous.

- With gearbox. The device is installed on taps with a diameter of more than 30 cm and on some smaller products, where you need to smoothly change the intensity of the fluid flow.

By type of passage are divided:

- Full bore. The size of the hole in the ball coincides with the cross section of the inlet and outlet of the valve. They are used where even small pressure losses cannot be tolerated.

- Standard bore (reduced). The size of the conditional passage is slightly larger than the diameter of the hole in the ball. As a result, the likelihood of water hammer is reduced. The cost is lower than full-bore analogues.

Thus, a ball valve can have many modifications that contribute to the effectiveness of its use in a particular situation.

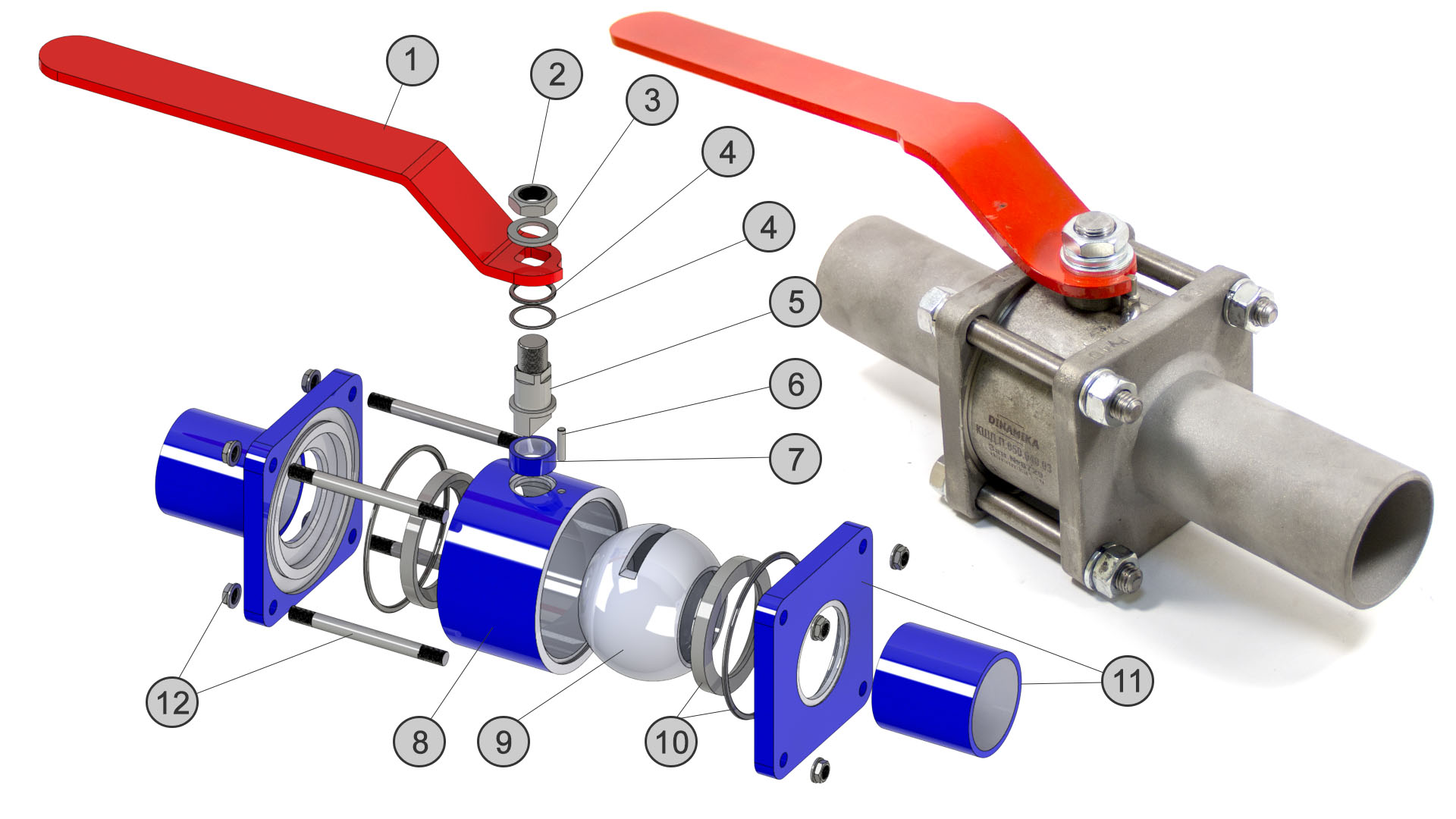

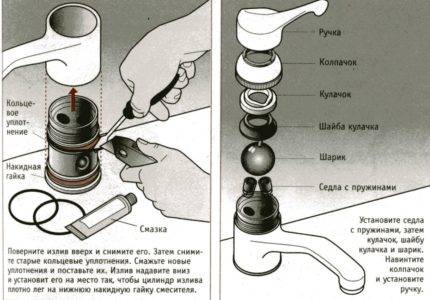

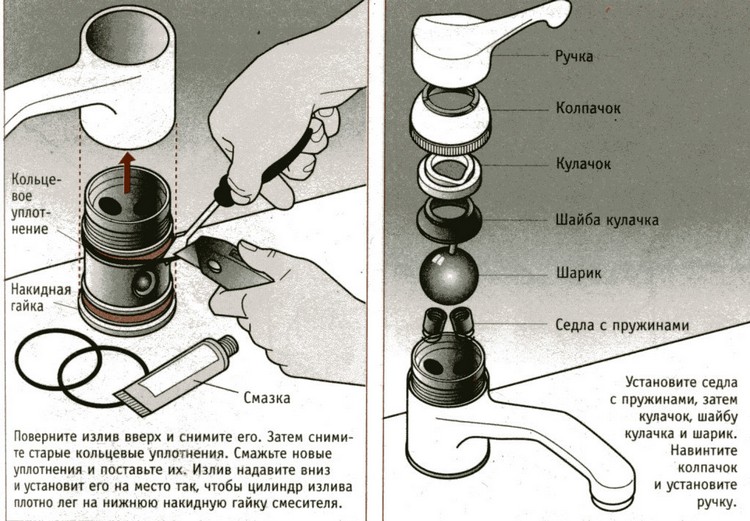

Repair of a single-lever mixer with a ball block

Problems with a single-lever ball faucet are usually caused by a broken valve mechanism. The lever, fixed with a screw, is removed in the same way as in the case of a cartridge faucet.The domed metal cap, which is located below, fixes the entire valve mechanism in the body. Under the cap is a plastic cam that limits the movement of the control lever. At the bottom of the cam is a dome-shaped washer for a snug fit to the mixer ball. The device of the ball and the principle of mixing, we have already described above.

Disassembly order

- Remove the plastic red and blue pads and unscrew the lever as described above. The difference will be that the pin from which you want to twist the lever is not polymer and rectangular, but metal, with a thread for the screw fixing the lever.

- Unscrew the domed cap. It can be equipped with slots for a comfortable grip. But if there is no slot, use a screwdriver: rest it in the groove and gently knock it up and clockwise, tearing the part from its place. You can also use round nose pliers by inserting them into the grooves from inside the cap.

- After removing the cap, remove the cam with a figured washer. Clean them off with a rag.

- Take out the mixer ball and examine its valve part.

- Remove valve seats. They are easily removed with a thin screwdriver. With tweezers or a screwdriver, you can get the clamping springs under the saddles.

Typical Ball Mixer Valve Gear Problems

Leaks or excessive noise can be caused by the following problems:

- The inside of the dome washer or the seat in the body where the bottom of the ball rests is worn or heavily soiled. These spherical cavities must be thoroughly cleaned.

- Ball wear. It may show cracks, grooves. All this is caused by dirty and hard water with impurities of solid particles. The only way to fix it is to replace the ball.

- Valve seat wear.If they start to fit poorly on the ball, then they let water through. They also need to be replaced.

- Poor seat fit can be caused not only by worn seats, but also by loose springs. The problem is solved by replacing the springs with new ones.

Assembling a single-lever mixer with a ball mechanism

It is done in reverse order, with old parts cleaned and lubricated and new parts replaced:

Clean the faucet cavity.

Insert new springs into the saddles, place the assembly in the sockets intended for it.

The cleaned ball is lubricated with silicone grease. The ball is inserted into the mixer body.

A washer with a cam is installed. For proper assembly, there is a groove in the body that must be aligned with the lug on the cam.

Pure metal top cap bait and screw

It is important to avoid distortions.

Put on a metal rod and screw the lever to adjust the water.

Problems with the swivel spout

If water from a single-lever faucet flows above and below the swivel spout, this is due to worn seals. Rubber rings are used as seals, less often - cuffs. To replace the rings, you need to disassemble the mixer as follows:

- After removing the cartridge, you need to remove the swivel side of the spout from the body. How to do this will become clear when disassembling. In some models, this node is removed upwards. On the body, it is stopped by a special clutch. But more often, the spout block is removed downwards, where a corrugated flexible hose is attached. To remove the block, you need to disassemble it up to dismantling the mixer from the sink or sink.

- On the lower side of the dismantled mixer, you need to unscrew the ring-shaped nut and remove the fluoroplastic ring located under it.

- Now you can remove the spout block from the body by pulling it down. Worn rubber seals will be found at the joints with the body. You should purchase to put the same new ones, and at the same time replace the fluoroplastic rings on top and bottom before installing the mixer.

Crack in the hull

This malfunction is immediately noticeable, and requires the replacement of the entire mixer. Some home crafters resort to silicone sealant to "repair" the case. But this is a temporary measure. Soon you will have to go to shop for new mixer.

Clogged aerator

If, with fully open taps, you observe insufficient pressure, then there may be several reasons. This is a blockage in pipes and inlet hoses, and simply poor pressure in the water supply network. But it can also be a clogged aerator on the spout pipe. To repair, unscrew the aerator. If hand effort is not enough, then use an adjustable wrench. The aerator has slots for twisting. On the mesh inside, you will find a lot of solid particles and layers that prevent the flow of water and reduce pressure. The mesh can be cleaned under running water.

Helpful Hints

There are several aspects, the observance of which will help facilitate the installation procedure, as well as guarantee the successful operation of the ball valve. The first one concerns product selection. Before purchasing, you need to consider the following points:

diameter of the pipe on which you plan to install. It is necessary to select a ball valve with an appropriate indicator, thread type. Again, it all depends on where you will be installing.

Pay attention to what threads are on both sections of the pipe, and select the product so that it matches the existing parameters. The following types of ball valves are distinguished by the location of the thread on both sides: both external, both internal, one external, the other internal, one internal, the other "American"

If for some reason the ball valve does not match the pipe according to these indicators, then you can use an adapter, but this will significantly reduce the strength and reliability of the pipeline, since each additional connection increases the possibility of leakage, the presence of free space. The ball valve can be either with a short or with a long handle. The choice depends on how much free space there is where you will place this product. You should be able to turn the handle without bumping into obstacles. So, if the space around the connection is not spacious, it is better to purchase a model with a short handle.

The choice of location for the installation of the crane is also important. It is necessary, firstly, that there be free access to the connection points. That is, this section of the pipeline should be located in an open way. If, for the sake of aesthetics of the room, you mask the pipeline in the wall or in a special decorative box, then provide for the presence of a door in those places where you will need to look in order to check and maintain the joints.

During the installation process, knowledge of some of the nuances may also be useful:

when dismantling the old faucet, even if the riser is turned off, the remaining water will drain from the pipes.In order not to make a flood on the floor, prepare several large rags in advance, and place a basin or other suitable container under the place where the valve is installed. Thus, you will make the process of work more comfortable, do not forget about sealing the joints. To do this, you can use either FUM tape or linen tow in combination with a special paste. Both materials do an excellent job of their function, but they must be used correctly. Winding on the thread is carried out in the same direction in which the element will be wound

When installing a ball valve, pay attention to how freely it is screwed on: you must make efforts for this, but not excessive, because in this case you can seriously damage the element

If you are installing the pipeline on the street, then do it taking into account the climate. The use of ball valves is unacceptable at air temperatures below zero. Otherwise, the faucet will simply burst, freezing.

When using such a product in a central heating system or in the case of high pressure in the pipeline, it is necessary to choose especially high-quality equipment. Firstly, there must be an oil seal on such a crane. In the absence of it, when a leak occurs, you will not be able to fix the problem yourself, you will have to call the emergency service.

Secondly, pay attention to the popularity and reputation of the manufacturer. Ball valves are classified as equipment of increased responsibility

After all, it directly depends on them whether, in the event of, for example, a mixer failure, you can quickly turn off the water in the system, thereby minimizing trouble both for your home and for your neighbors' apartment.

Therefore, it is better not to skimp, but to give preference to products of well-known and well-established manufacturers, even if the cost of such products is several times higher than the price of the cheapest ones. But in return, you will receive a guarantee that, if necessary, the crane will work as it should.

As you can see, friends, the procedure for installing a ball valve does not raise any special questions or difficulties. If you follow all the installation rules, then the result will surely please you. To also get a visual picture of what you have to do, watch the video, the link to which is just above. I'm sure you'll do great. Good luck!

If necessary, close and remove the radiator

Work related to the removal of the radiator is best carried out after the end of the heating season. If work needs to be carried out during the heating season, a number of nuances must be taken into account. If you have a single pipe system heating and vertical wiring, the battery can only be removed if there is a bypass.

Such a system can be identified by pipes, one of which comes from the ceiling and connects to the radiator, while the other exits the radiator and disappears into the floor. The bypass is a jumper connecting the incoming and outgoing pipes. This is a pipe of approximately the same or slightly smaller diameter than the main pipes. The principle of operation of the bypass is as follows: if the radiator is turned off, the water begins to flow through the riser, passing through the bypass without passing through the battery. In this case, the riser works, the heating in neighboring apartments does not turn off.

If the system is two-pipe, if there are taps, it is enough to close them, after which you can remove the battery.

How to choose a ball valve

When starting the construction of a water supply or heating system, you should know exactly the sizes of pipes and fittings, which ball valve is better. You should start by creating a pipeline layout. According to it, you need to calculate the number of valves. Then buy valves or ball valves.

In places where the flow is blocked, at the beginning of the branches of the heating system, valves are used. They simply block the flow at the right time. At the end points of the pipes, at the outlet of the water, it is better to install ball valves.

The choice starts with the diameter. Fittings for the house fit threaded. Then you should choose the material of the case and the color of the handle:

- yellow, black - gas;

- blue, blue - cold water;

- red - hot water.

Faucets usually have shiny steel or decorative handles.

Large selection of ball valves

Large selection of ball valves