- Types of installation of fan coil units

- Main chiller classes

- Absorption unit device

- The design of vapor compression plants

- Vapor Compression Chiller Specifics

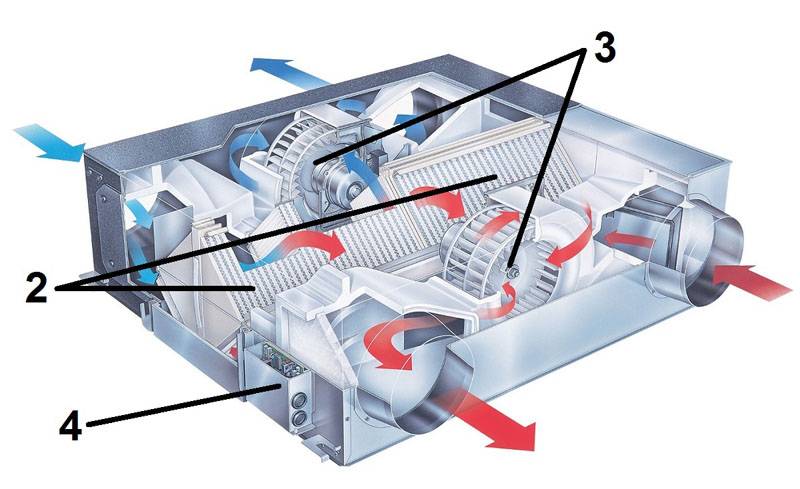

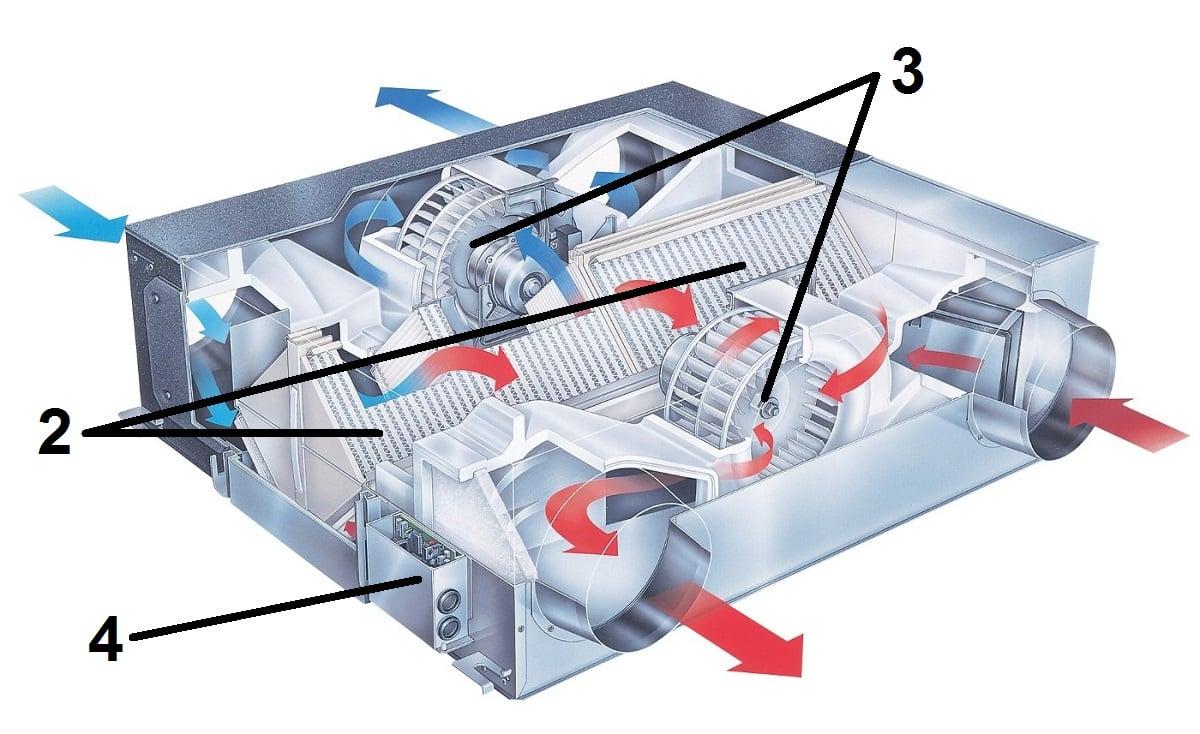

- Installation of a cassette fan coil

- The role of the fan coil in the air conditioning system

- Advantages of the chiller-fan coil system

- Varieties of fan coil units

- System types

- Operating principle

- What is a fancoil

- How to choose?

- Fancoil connection diagram

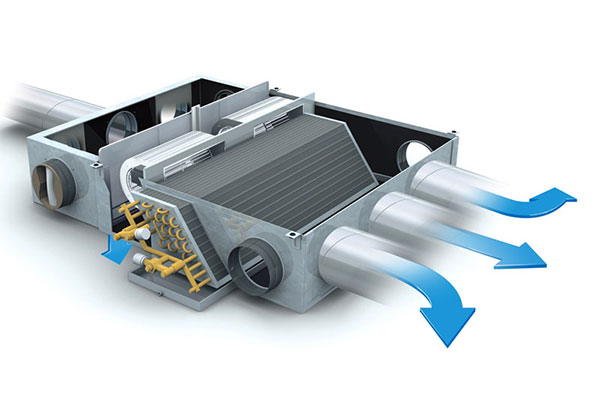

- Cassette and duct fan coil units

- Classification

- System types

- How the system works

- Mounting Features

- Differences in installation of different types of indoor units

- Shut-off valves

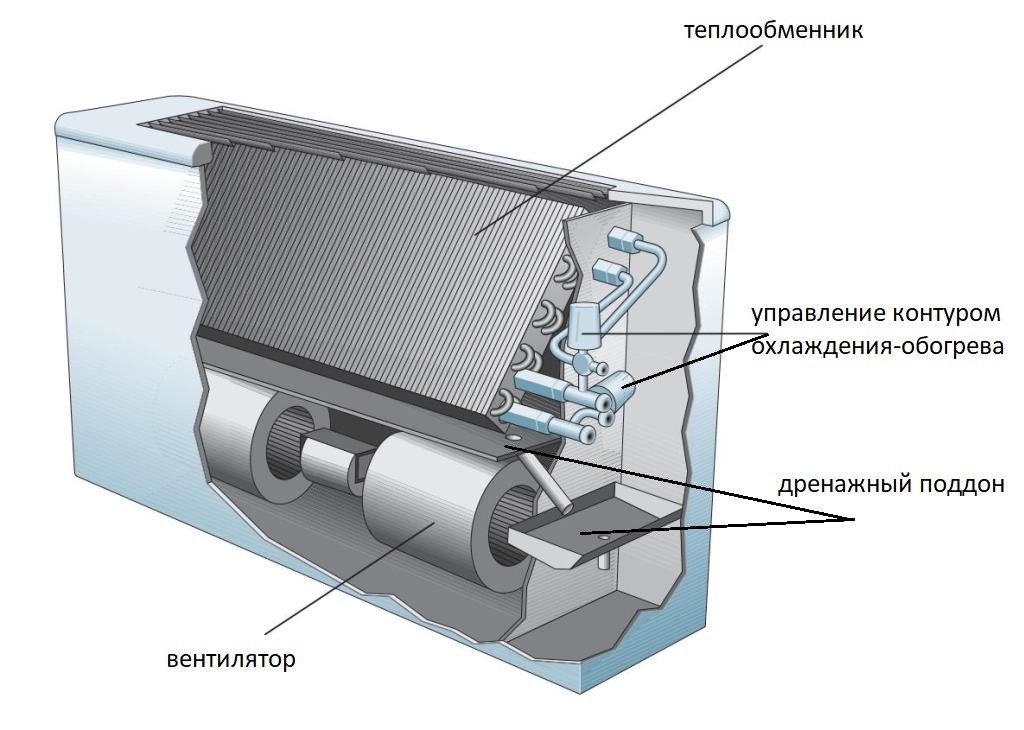

- Fan coil design

Types of installation of fan coil units

The schematic diagram of the fan coil provides:

- the presence of a pipeline that transports hot or cold water, depending on the tasks in a certain period of time - winter, summer;

- the presence of a chiller that prepares the desired water temperature and creates a flow of fresh air taken from the street;

- internal devices (fan coils) through which the temperature in the room is controlled.

Internal climate devices:

- Cassette. Installed behind suspended ceilings. Suitable for large areas in shopping centers, industrial premises.

- Channel. They are located in ventilation shafts.

- Wall.A good choice for small spaces - apartments, offices.

- Floor and ceiling. Suitable for placement under the ceiling or against the wall.

Installation of chillers and fan coil units of various types has its own characteristics, as well as advantages and disadvantages:

- The duct is capable of performing three functions (cooling, heating, ventilation), but requires accurate calculations of the air volume consumed, expert advice in terms of installing a water heating system for the winter period.

- The installation of cassette-type fan coil units saves space, air-conditions large rooms, but requires space under the ceiling, which is allocated for the installation of the unit.

- The installation of floor-mounted fan coil units makes it possible to discreetly cool rooms of complex design without affecting people's health, but it requires more power and space on the floor or under the ceiling.

- Connecting a wall-mounted fan coil is the least economical way, but easier.

Systems are two-pipe and four-pipe. The price of a four-pipe wiring is higher, since it simultaneously provides both heating and cooling. A two-pipe system is cheaper, but for the heating function, pipes will need to be taken away from the refrigeration unit and connected to the boiler during the heating season.

The duct fan coils are mounted using the concealed connection method. The section in the ceiling must be movable to access the device.

Cassette, floor and wall units are mounted in an open way. Operation and maintenance of open-type devices is easier to carry out.

Main chiller classes

The conditional division of chillers into classes occurs depending on the type of refrigeration cycle.On this basis, all chillers can be conditionally classified into two classes - absorption and vapor compressor.

Absorption unit device

An absorption chiller or ABCM uses a binary solution with water and lithium bromide present in it - an absorber. The principle of operation is the absorption of heat by the refrigerant in the phase of converting vapor into a liquid state.

Such units use the heat released during the operation of industrial equipment. In this case, the absorbent absorber with a boiling point significantly higher than the corresponding parameter of the refrigerant dissolves the latter well.

The operation scheme of a chiller of this class is as follows:

- Heat from an external source is fed to a generator where it heats up a mixture of lithium bromide and water. When the working mixture boils, the refrigerant (water) evaporates completely.

- The vapor is transferred to the condenser and becomes a liquid.

- The liquid refrigerant enters the throttle. Here it cools down and the pressure drops.

- The liquid enters the evaporator, where water evaporates and its vapors are absorbed by a solution of lithium bromide - an absorber. The air in the room is cooled.

- The diluted absorbent is reheated in the generator and the cycle is restarted.

Such an air conditioning system has not yet become widespread, but it is fully in tune with modern trends regarding energy saving, and therefore has good prospects.

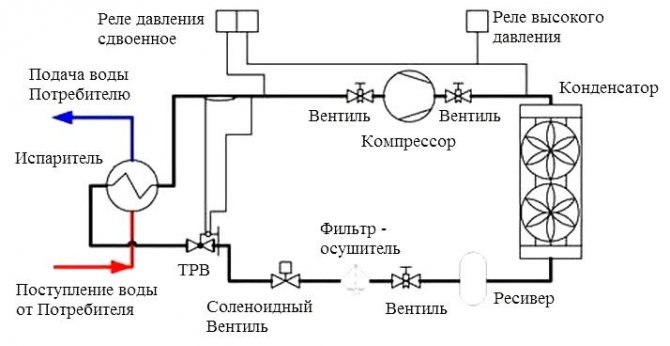

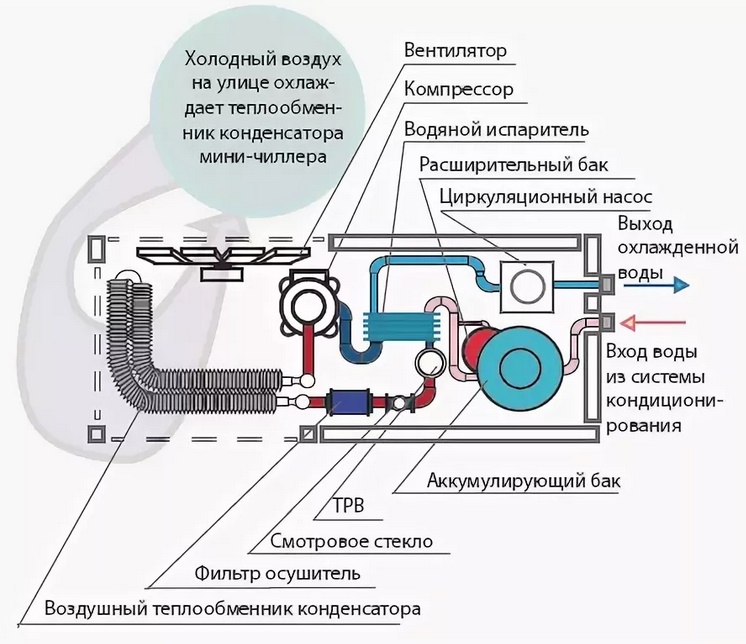

The design of vapor compression plants

Most refrigeration systems operate on the basis of compression cooling. Cooling occurs due to the continuous circulation, boiling at low temperatures, pressure and condensation of the coolant in a closed-type system.

The design of a chiller of this class includes:

- compressor;

- evaporator;

- capacitor;

- pipelines;

- flow regulator.

The refrigerant circulates in a closed system. This process is controlled by a compressor, in which a gaseous substance with a low temperature (-5⁰) and a pressure of 7 atm is compressed when the temperature is raised to 80⁰.

Dry saturated steam in a compressed state goes to the condenser, where it is cooled to 45⁰ at a constant pressure and turns into a liquid.

The next point on the path of movement is the throttle (reducing valve). At this stage, the pressure is reduced from the value of the corresponding condensation to the limit at which evaporation occurs. At the same time, the temperature also drops to approximately 0⁰. The liquid partially evaporates and wet steam is formed.

The diagram shows a closed cycle, according to which the vapor compression plant operates. The compressor (1) compresses wet saturated steam until it reaches pressure p1. In the compressor (2), the steam gives off heat and transforms into a liquid. In the throttle (3), both the pressure (p3 - p4)‚ and the temperature (T1-T2) decrease. In the heat exchanger (4), pressure (p2) and temperature (T2) remain unchanged

Having entered the heat exchanger - evaporator, the working substance, a mixture of vapor and liquid, gives off cold to the coolant and takes heat from the refrigerant, drying at the same time. The process takes place at constant pressure and temperature. The pumps supply low temperature fluid to the fan coil units. Having traveled this path, the refrigerant returns to the compressor to repeat the entire vapor compression cycle again.

Vapor Compression Chiller Specifics

In cold weather, the chiller can operate in natural cooling mode - this is called free-cooling. At the same time, the coolant cools the outside air. Theoretically, free cooling can be used at an external temperature of less than 7⁰С. In practice, the optimum temperature for this is 0⁰.

When set to "heat pump" mode, the chiller works for heating. The cycle undergoes changes, in particular, the condenser and evaporator exchange their functions. In this case, the coolant must be subjected not to cooling, but to heating.

The simplest are monoblock chillers. They compactly combine all the elements into one whole. They go on sale 100% complete up to the refrigerant charge.

This mode is most often used in large offices‚ public buildings‚ warehouses. The chiller is a refrigeration unit that provides 3 times more cold than it consumes. Its efficiency as a heater is even higher - it consumes 4 times less electricity than it produces heat.

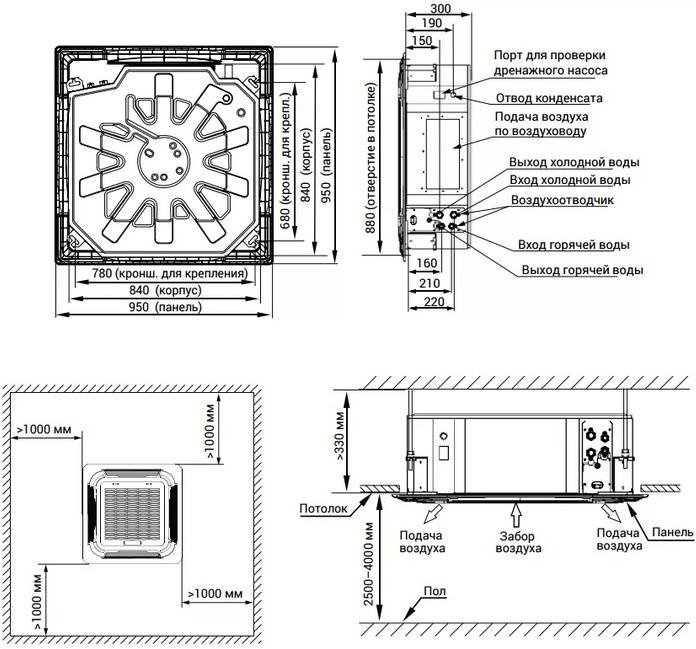

Installation of a cassette fan coil

A variety of ceiling devices, located inside the ceiling space between the Armstrong plates. Standard sizes: 600x600 mm, 900x600 mm, 1200x600 mm. Only the front side of the intake grille is visible.

Installation methods:

- hidden installation inside a suspended structure. Standard option, often used for office space, business centers;

- open placement on the ceiling with anchor bolts. It is applied: big hypermarkets, shopping centers.

Layout scheme:

- choose the installation location;

- mark the mounts under the ceiling;

- fasten with anchor bolts;

- connect to a chiller, central heating system (if heating is planned, 4-pipe piping);

- laying the route of the pipeline, thermal insulation to protect against condensate;

- pump drainage system equipment;

- collection of mixing unit, 2 or 3 way valve;

- tightness test;

- commissioning works.

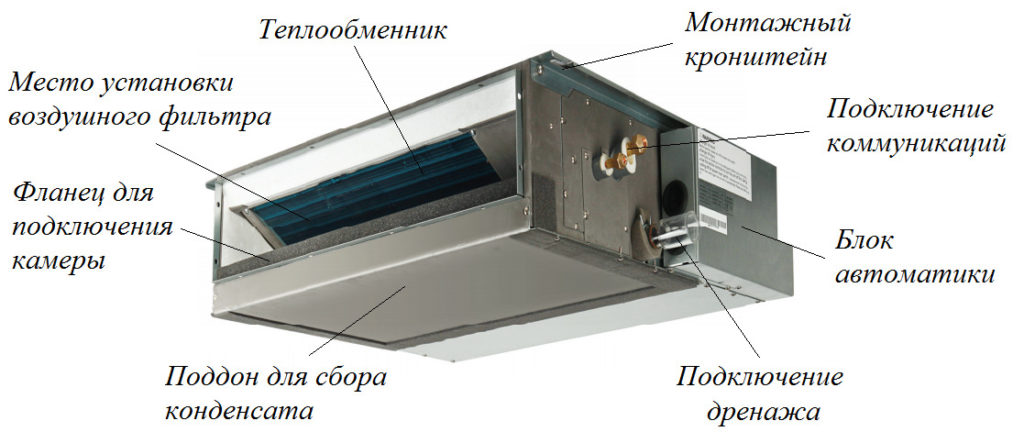

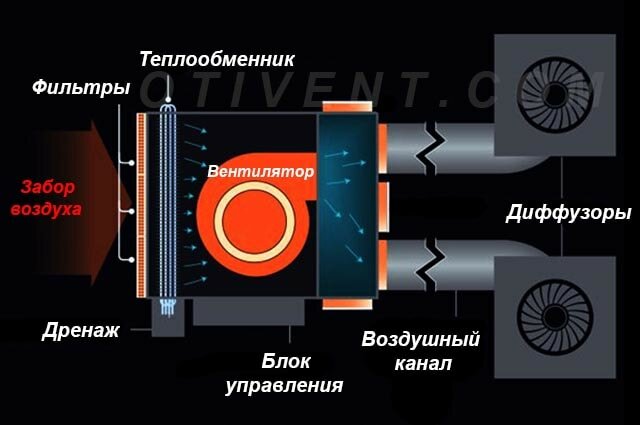

The role of the fan coil in the air conditioning system

Fancoil is an important element of a centralized air conditioning system. The second name is a fan coil. If the term fan-coil is literally translated from English, then it sounds like a fan-heat exchanger, which most accurately conveys the principle of its operation.

The design of the fan coil includes a network module that provides connection to the central control unit. The durable case hides structural elements and protects them from damage. Outside, a panel is installed that evenly distributes air flows in different directions

The purpose of the device is to receive media with a low temperature. The list of its functions also includes both recirculation and cooling of the air in the room where it is installed, without the intake of air from outside. The main elements of the fan-coil are located in its body.

These include:

- centrifugal or diametral fan;

- heat exchanger in the form of a coil consisting of a copper tube and aluminum fins mounted on it;

- dust filter;

- Control block.

In addition to the main components and parts, the design of the fan coil unit includes a condensate trap, a pump for pumping out the latter, an electric motor, through which the air dampers are rotated.

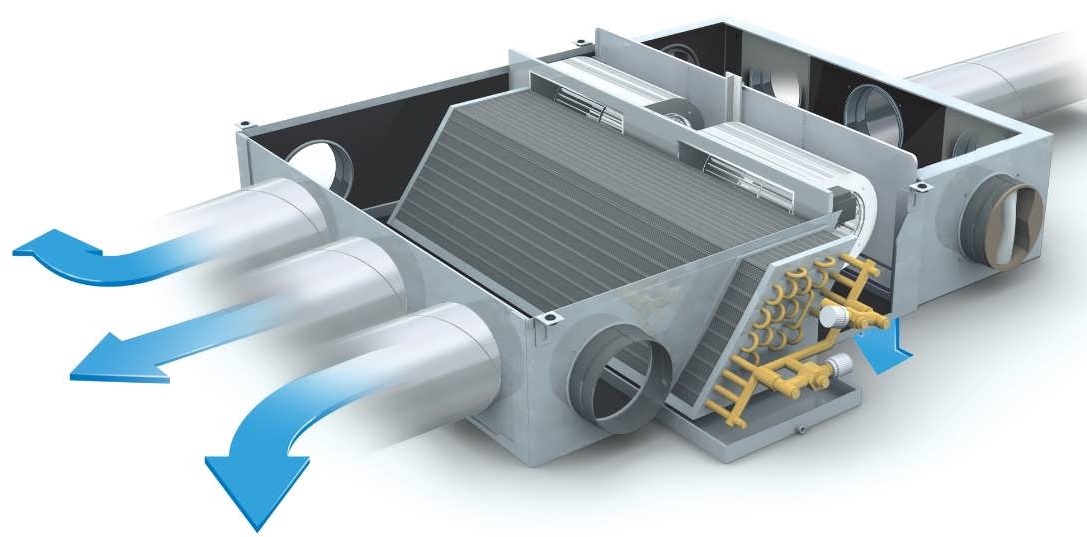

Pictured is a Trane ducted fan coil unit.The performance of double-row heat exchangers is 1.5 - 4.9 kW. The unit is equipped with a low-noise fan and a compact housing. It fits perfectly behind false panels or suspended ceiling structures.

Depending on the installation method, there are ceiling, channel, mounted in channels, through which air is supplied, unframed, where all elements are mounted on a frame, wall-mounted or console.

Ceiling devices are the most popular and have 2 versions: cassette and channel. The first are mounted in large rooms with false ceilings. Behind the suspended structure, a body is placed. The bottom panel remains visible. They can disperse air flow on two or all four sides.

If the system is planned to be used exclusively for cooling, then the best place for it is the ceiling. If the design is intended for heating, the device is placed on the wall in its lower part

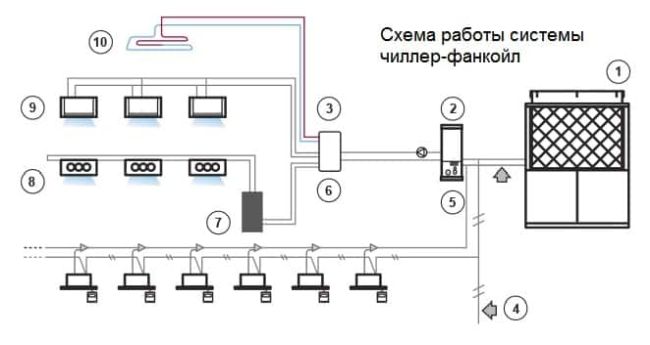

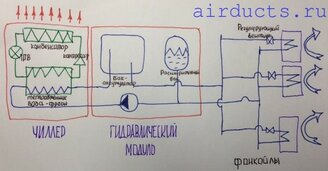

The need for cooling does not always exist, therefore, as can be seen in the diagram that transmits the principle of operation of the chiller-fincoil system, a container is built into the hydraulic module that acts as an accumulator for the refrigerant. The thermal expansion of the water is compensated by an expansion tank connected to the supply pipe.

Fancoils are controlled both in manual and automatic modes. If the fan coil is working for heating, then the cold water supply is cut off in manual mode. When it is working for cooling, hot water is blocked and the path is opened for the flow of the cooling working fluid.

Remote control for both 2-pipe and 4-pipe fan coil units. The module is connected directly to the device and placed near it.The control panel and wires for its power are connected from it.

To work in automatic mode, the temperature required for a particular room is set on the panel. The specified parameter is supported by thermostats that correct the circulation of coolants - cold and hot.

The advantage of a fan coil unit is expressed not only in the use of a safe and cheap coolant, but also in the rapid elimination of problems in the form of water leaks. This makes their service cheaper. The use of these devices is the most energy-efficient way to create a favorable microclimate in a building.

Since any large building has zones with different temperature requirements, each of them must be served by a separate fan coil unit or a group of them with identical settings.

The number of units is determined at the design stage of the system by calculation. The cost of individual components of the chiller-fan coil system is quite high, therefore, both the calculation and the design of the system must be carried out as accurately as possible.

Advantages of the chiller-fan coil system

- All-the-year-round automatic maintenance by fan coil units of the necessary air parameters in each working area of the building at the same time.

- Economical effect. A fancoil (even a two-pipe one) can work both for cold and for heat. This saves a lot of money, since there is no need to install a separate heating system.

- Different variations in the location of the chiller and fan coil unit, the number of fan coil units, the length of pipelines, the possibility of increasing capacity.

- Flexible local control of heating and cooling capacity of fan coil units.

- Environmental friendliness. Harmless coolant.

- Maximum use of usable space.

- Low noise fan coil units.

Varieties of fan coil units

To date, there are four main types of such equipment:

- Console frameless.

- Console in the case.

- Horizontal.

- Fancoil cassette.

Depending on the installation, each type of this climatic equipment can be wall-mounted, floor-mounted, ceiling-mounted or built-in. Depending on the tasks, fan coil units can be equipped with two or four pipes. When using a two-pipe piping, the device can only work on cooling or heating the air in the room. The use of a four-pipe piping allows the use of both a cold and a hot chiller circuit, while operating the unit for both heating and cooling, making settings from the control panel. Due to the complexity of implementation, the cost of installing fan coil units with a four-pipe piping is much higher than with a two-pipe one.

System types

There are 2 types of systems: single-zone and multi-zone.

The single-zone system is designed for a year-round rhythm of operation of the device. The operation of this system consists of 2 stages of regulation. The first is represented by centralized maintenance of the water temperature in the network at a given level from the chiller to the fan coil, and then to the heat source. The second involves individual temperature control in each room using fan coil units.

So, with a single-zone system, the temperature in the rooms may be different, but the air in each of them heats up and cools down at the same time. The system uses single-circuit fan coil units connected according to a two-pipe scheme.

If there is a need for simultaneous heating of one room and cooling of another, a multi-zone system is installed.At the same time, cold and heated water are separated into different branches. By controlling groups of fan coil units, it is possible to simultaneously cool and heat different facades of a building. All actions of the system are carried out automatically.

Operating principle

The device works on the principle of the heater mentioned above: antifreeze or water temperature, the fan blows room air through the fins. Heat exchange occurs, the flow is heated or cooled. Hence the second name of the device is a fan coil.

Features of the fan coil:

- the unit is able to operate in heating or cooling mode, depending on the temperature of the incoming water;

- the main function is to transfer heat or cold produced by other installations to the air;

- the fluid flow is provided by an external pump, there is no own one;

- the sucked air stream is cleared by the filter of dust;

- usually the fan coil handles indoor room air (total recirculation);

- some models integrated into the forced ventilation system can heat / cool the supply air;

- regulation of heating/cooling power is carried out in two ways - by changing the performance of the fan and by limiting the water flow with a two-way solenoid valve.

So, a fan coil is an integral element of a centralized climate system that maintains the air temperature in a specific room or in a specific area of the production workshop. Additional functions:

- drainage;

- ventilation (ventilation mode);

- fresh air mixing is an option;

- remote control control;

- flow heating with an electric heating element (also an option).

The difference between a fan coil unit and a split system lies in the principle of operation - there is no vapor compression cycle in it, the working fluid is water, which does not change the state of aggregation. Moreover, thermal energy comes to the radiator from the outside along with the liquid, as provided in the heaters.

Sources of cold / heat can be:

- Traditional boilers using various energy carriers. It is clear that this equipment provides only heating of water or antifreeze.

- Heat pumps (HP) are of two types - geothermal and water. In winter, the unit heats up the coolant, in summer, on the contrary, it cools.

- Chillers are powerful refrigerating machines with air or water cooling of the condenser.

A valve is provided inside the unit to release air after installation and filling the pipeline network with coolant

A valve is provided inside the unit to release air after installation and filling the pipeline network with coolant

What is a fancoil

Fancoil is a modern device, the main task of which is to maintain an optimal microclimate in the room. In literal translation, the word "fan-coil" is translated as "fan-heat exchanger". The fancoil consists of several parts:

- centrifugal fan;

- filter;

- control unit;

- heat exchanger.

Each of the above elements is located in the common body of the device. The air conditioner-closer is also equipped with a tray designed to collect condensing liquid, an electric heater, taps and valves. There is a remote control for remote control of the device. Devices can have different dimensions and appearance.

How to choose?

If you choose equipment for apartments, you still cannot do without calculating the functional characteristics of the device in relation to a particular room.Fan coil units for industrial premises are purchased by specialists who produce even more accurate calculations.

When choosing, the following parameters will be important:

- the dimensions of the room itself and the purpose for which a household fan coil is purchased;

- the number of wall openings, as well as orientation relative to the cardinal points;

- climatic characteristics of the region in which the buyer lives, the humidity of the outside air, as well as the average temperature;

- floor material, building wall cladding;

- ventilation system installation;

- the number and capacity of indoor systems intended for heating;

- the average number of people inside the building.

It turns out that each of the listed parameters will affect the performance of technology, reducing productivity or increasing it.

Fan coil units are more often purchased at home, using the so-called estimated calculation method. It is better than others, as it does not require special knowledge. But it does not take into account all the parameters, therefore this method is not suitable for large rooms. If you still decide to use it, then you need to select a 1000 W fan coil unit for every 10 square meters of the room with a ceiling height of 2.7-3 m.

Fancoil connection diagram

Having learned what a fan coil unit is and how it works, you need to study the installation diagram. It depends on the chosen model and climate control system. The location of the module should provide efficient cooling (heating) of the air in the room. There are no obstacles in the way of air flows - furniture, interior items. There must be free access for maintenance and repair.

Installation is done according to the general scheme.

- Installation of the case in the chosen place.

- Pipe connection.

- Installation of piping - valves, taps, temperature sensors.

- Condensate removal. For this, a pump and a separate pipeline are used. Pump characteristics - performance and maximum lifting height.

- Electrical connection.

- Pressure testing and leak testing.

After that, the system is filled with working fluid. The instructions for a specific model describe how to connect the fan coil unit to the chiller. Dimensions, power requirements, temperature conditions are taken into account.

Cassette and duct fan coil units

Like an air conditioner, a fan coil does not take part in the air exchange of the room, only some types are able to mix part of the outside air with the air in the room. The main task of fan coil units is to heat or cool the air in the room, bringing it to the specified parameters. Therefore, fan coil units are sometimes called "closers".

The principle of operation of fan coil units:

- The fan blows air from the room into the fan coil housing.

- Under pressure, air passes through the heat exchanger, while changing its parameters.

- Then, cooled, it is fed into the working area.

When the air in the heat exchanger cools below the dew point temperature, condensation occurs on the surface, which accumulates in the fan coil pan. It is discharged outside the building by a drainage pipeline. The principle of operation of a fan coil unit is identical to that of air conditioners. The main difference and advantage of the first is the coolant - water. Thanks to which you can use pipes of various materials, and increase the length of the route from the outer to the indoor unit up to 100 m.

Classification

There are two main types of fan coil units - two-pipe and four-pipe.The former are connected to one source of working fluid, the latter can simultaneously use two - a chiller and a device for heating water.

In the latter case, it is possible to quickly switch the module from cooling to heating mode and vice versa. For two-pipe models, this is time-consuming work, physical switching of lines between sources of fluid treatment is necessary.

Design Classification:

According to the method of installation - floor, ceiling or wall.

- Cassette. Mounted in a suspended ceiling, they do not have an external casing.

- Channel. Installed in ventilation ducts. Models differ in the number of air flows - from 1 to 4.

- Air flow - low, medium or high pressure. The first create an air pressure up to 45 Pa, the second - up to 100 Pa. High-pressure can form an air flow with a force of 250 Pa.

For a smooth change in temperature, the liquids are equipped with a three-way valve. Types of used fans - centrifugal or diametrical. The heat exchanger is serpentine, consists of a copper pipe. To increase the area, aluminum fins are installed on it.

Advice. Some models have dust filters. They purify the air from impurities, protect the elements of the device from pollution.

This is important for rooms with special microclimate requirements.

System types

There are 2 types of systems: single-zone and multi-zone.

The single-zone system is designed for a year-round rhythm of operation of the device. The operation of this system consists of 2 stages of regulation. The first is represented by centralized maintenance of the water temperature in the network at a given level from the chiller to the fan coil, and then to the heat source.The second involves individual temperature control in each room using fan coil units.

So, with a single-zone system, the temperature in the rooms may be different, but the air in each of them heats up and cools down at the same time. The system uses single-circuit fan coil units connected according to a two-pipe scheme.

If there is a need for simultaneous heating of one room and cooling of another, a multi-zone system is installed. At the same time, cold and heated water are separated into different branches. By controlling groups of fan coil units, it is possible to simultaneously cool and heat different facades of a building. All actions of the system are carried out automatically.

How the system works

The simplest device works according to the following principle: depending on the need for heating or cooling the room, the closer radiator supplies heated or cold liquid to the heat exchanger. Here, the liquid carrier cools or heats the air, and the fan supplies the prepared air masses to the room.

In complex units, closers mix the air masses in the room with the air supplied by the air conditioner from the street. The closer maintains the required carrier temperature. It passes through the radiator, where the air masses are heated or cooled. To prevent the system from running continuously, bypass pipes with valves and a thermoelectric drive are installed in it.

During the operation of the radiator, condensate is formed, which flows into the receiving tray. Moisture is pumped out of it by a drainage pump, to which a float valve is connected.Then the water enters the receiving pipe, and from there to the sewer.

Mounting Features

Given the complexity fancoil-chiller systems its installation and configuration should be carried out by highly qualified specialists. Only they will be able to perform high-quality installation of fan coil units by performing competent:

- installation of the unit in the place where its operation will be most effective;

- assembly of piping units by installing the necessary taps, valves, temperature and pressure control devices;

- laying and thermal insulation of pipes;

- installation of a condensate drainage system;

- work on connecting devices to the mains;

- pressure testing of the system and checking its tightness;

- carrier (water) supply.

They will also make all the necessary calculations before starting work, taking into account what functional load this or that fan coil unit will perform, as well as the features of each room in the building.

Thus, you could be convinced not only that fan coil-chiller systems are very efficient, economical and reliable, but also that they require complex installation and commissioning of the system. And for this, it is necessary to involve employees of organizations specializing in the creation of such turnkey systems.

The multi-zone climate system chiller-fan coil is designed to create comfortable conditions inside a large building. It works constantly - it supplies cold in summer, and heat in winter, warming the air to a predetermined temperature. It’s worth getting to know her device, do you agree?

In our proposed article, the design and components of the climate system are described in detail. Methods for connecting equipment are given and analyzed in detail.We will tell you how this thermoregulation system is arranged and functions.

The role of the cooling device is assigned to the chiller - an external unit that produces and supplies cold through pipelines with water or ethylene glycol circulating through them. This is what distinguishes it from other split systems, where freon is pumped as a coolant.

For the movement and transfer of freon, refrigerant, expensive copper pipes are needed. Here, water pipes with thermal insulation perfectly cope with this task. Its operation is not affected by the outdoor temperature, while split systems with freon lose their efficiency already at -10⁰. The internal heat exchange unit is a fan coil unit.

It receives low temperature liquid, then transfers the cold to the room air‚ and the heated liquid returns back to the chiller. Fancoils are installed in all rooms. Each of them works according to an individual program.

The main elements of the system are a pumping station, a chiller, a fancoil. The fancoil can be installed at a great distance from the chiller. It all depends on how powerful the pump is. The number of fan coil units is proportional to the chiller capacity

Typically, such systems are used in hypermarkets‚ shopping malls‚ buildings‚ built underground‚ hotels. Sometimes they are used as heating. Then, through the second circuit, heated water is supplied to the fan coils or the system is switched to a heating boiler.

Differences in installation of different types of indoor units

Channel fan coil is installed in the ventilation shaft

The scheme of a four-pipe fan coil unit is fundamentally different from a two-pipe scheme. In the first case, 2 circuits are connected, operating from air conditioning and heating systems.When switching modes, no additional measures are required, the task comes from the remote control. For a two-pipe system, all liquid must be drained before switching, which is performed manually. This method requires additional seasonal maintenance and the introduction of prices in the estimate.

The installation method of indoor units differs if the devices are located:

- at different levels (floors), but have the same hydraulic resistance (HS);

- at the same level with the same HS;

- with different HS, but located on the same level;

- with different HS at different levels.

Installation work should be carried out at the stage of construction or rough repair of the building. After the repair is completed, the final activities are carried out - automatic adjustment of the equipment and installation of decorative grilles on the cassette blocks.

Indoor units are installed in case or unframed method:

- Case models are installed equidistantly around the entire perimeter of the room or building, regardless of the location of the rooms. This applies to a two-pipe system that works only for cooling.

- Frameless models are installed mostly hidden. For frameless units, anti-vibration mounts are provided.

Floor-standing units are considered easy to install, for which you need to install drainage with the required angle of inclination to avoid stagnation of the liquid, connect it to the mains. By following the instructions correctly or focusing on the videos, you can do the work yourself.

Wall models require the help of a specialist who must:

- make the binding correctly;

- set up control devices;

- check pressure;

- make thermal insulation;

- lay pipes;

- make a crimp;

- connect to the power supply.

For cassette models, it is necessary to provide sound insulation, vibration protection, correctly select and cut a hole in the false ceiling, then connect it to a cold water supply and heating circuit. All connections must be checked and tested before commissioning.

Shut-off valves

Three way shutoff valve

In cooling systems, three-way and two-way shut-off valves are installed. The two-way valve of the piping unit is simpler, but less reliable. In any case, it is recommended to install a three-way valve. The difference is as follows:

- When using a 2-way valve, chilled liquid continues to flow into the fan coil when it is turned off, but this happens less intensively. Cooling continues after switching off.

- The 3-way valve completely blocks the flow of refrigerant, therefore, when turned off, the system does not cool the room.

Fan coil design

Fancoil - an indoor unit, consisting of: a fan, a heat exchanger, an air filter and a control panel. Thanks to the fan coil heat exchanger, the air is cooled or heated, depending on the season. Hot or cold water is supplied to the fancoils by a piping system. A chiller is taken as a source of cold water with the required parameters (7-12°C). The source of warm water can be a boiler or an existing heating system. The circulation of the coolant is provided by a hydraulic module or a pumping station, consisting of circulation pumps, expansion tanks and safety groups.