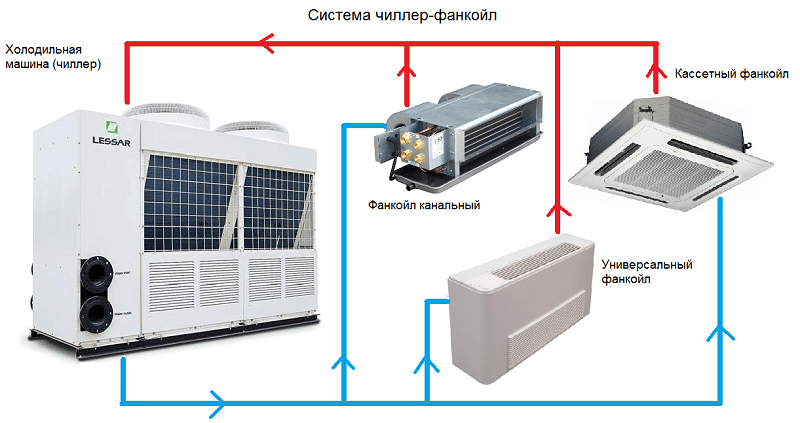

- The role of the fan coil in the air conditioning system

- Components of the chiller-fan coil circuit

- Question answer

- Types of chillers and their description

- How much do fan coil units cost - price overview

- Service Features

- Water cooling in the aquarium

- Features of choice

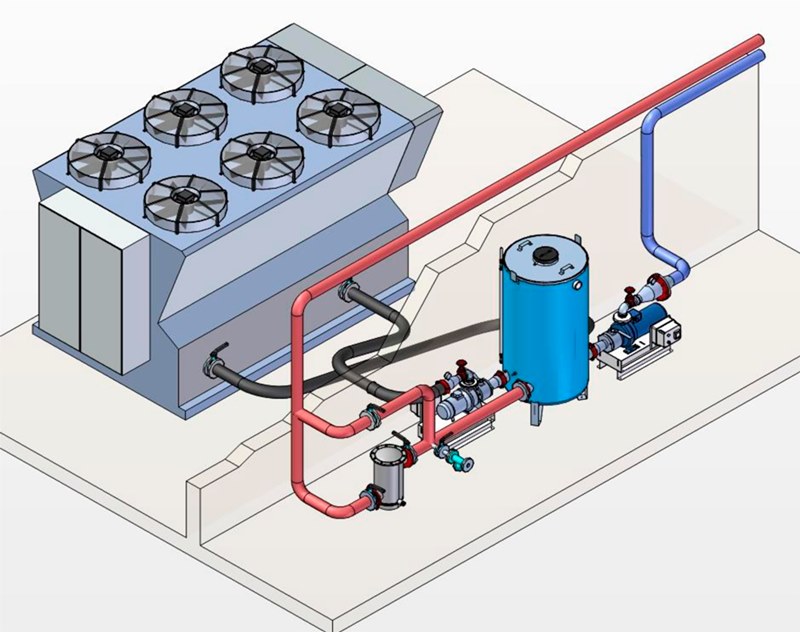

- Hydromodule

- Glycol

- heat exchanger

- Compressor

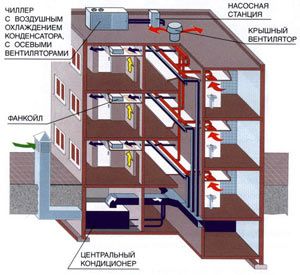

- The device and principle of operation of the chiller-fan coil system

- Design features of chillers

- Main chiller classes

- Absorption unit device

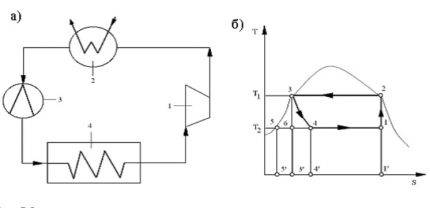

- The design of vapor compression plants

- Vapor Compression Chiller Specifics

- How to choose the right chiller?

The role of the fan coil in the air conditioning system

Fancoil is an important element of a centralized air conditioning system. The second name is a fan coil. If the term fan-coil is literally translated from English, then it sounds like a fan-heat exchanger, which most accurately conveys the principle of its operation.

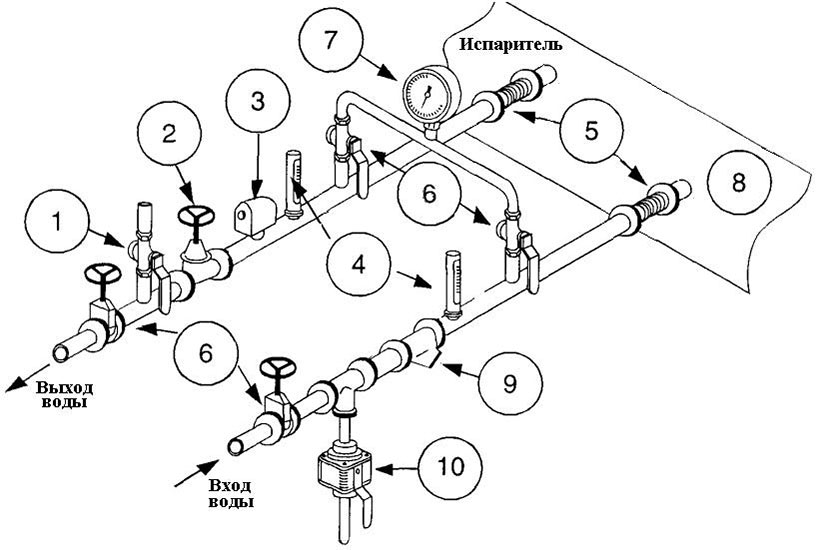

The design of the fan coil unit includes an electrical connection panel (1)‚ casing (2) - ceiling version‚ fan (3)‚ copper or aluminum heat exchanger (4)‚ condensate pan (5)‚ air valve (6)‚ pump connection for condensate and tubes (7) (+)

The purpose of the device is to receive media with a low temperature.The list of its functions also includes both recirculation and cooling of the air in the room where it is installed, without the intake of air from outside. The main elements of the fan-coil are located in its body. These include:

- centrifugal or diametral fan;

- heat exchanger in the form of a coil consisting of a copper tube and aluminum fins mounted on it;

- dust filter;

- Control block.

In addition to the main components and parts, the design of the fan coil unit includes a condensate trap, a pump for pumping out the latter, an electric motor, through which the air dampers are rotated.

The photo shows a frameless fan coil model Trane. The performance of double-row heat exchangers is 1.5 - 4.9 kW. The unit is equipped with a low-noise fan and a compact housing. It fits perfectly behind bezels or suspended ceiling structures.

Depending on the installation method, there are ceiling, channel, mounted in channels, through which air is supplied, unframed, where all elements are mounted on a frame, wall-mounted or console.

Ceiling devices are the most popular and have 2 versions: cassette and channel. The first are mounted in large rooms with false ceilings. Behind the suspended structure, a body is placed. The bottom panel remains visible. They can disperse air flow on two or all four sides.

Here is a schematic representation of the principle of operation of a fan coil unit. If the system is planned to be used exclusively for cooling, then the best place for it is the ceiling. When the structure is intended for heating, the device is placed on the wall in its lower part

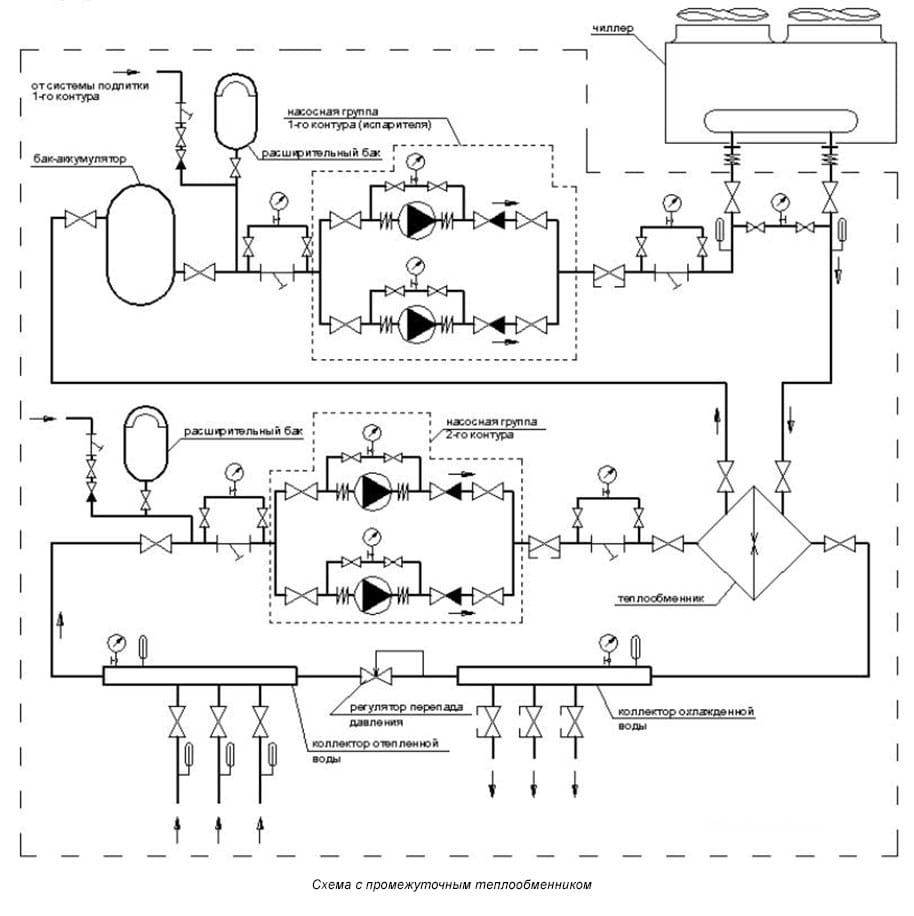

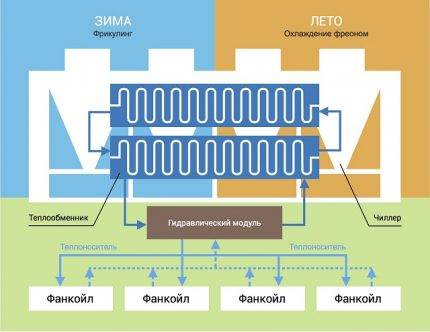

The need for cooling does not always exist, therefore, as can be seen in the diagram that transmits the principle of operation of the chiller-fincoil system, a container is built into the hydraulic module that acts as an accumulator for the refrigerant. The thermal expansion of the water is compensated by an expansion tank connected to the supply pipe.

Fancoils are controlled both in manual and automatic modes. If the fan coil is working for heating, then the cold water supply is cut off in manual mode. When it is working for cooling, hot water is blocked and the path is opened for the flow of the cooling working fluid.

Remote control for both 2-pipe and 4-pipe fan coil units. The module is connected directly to the device and placed near it. The control panel and wires for its power are connected from it.

To work in automatic mode, the temperature required for a particular room is set on the panel. The specified parameter is supported by thermostats that correct the circulation of coolants - cold and hot.

The advantage of a fan coil unit is expressed not only in the use of a safe and cheap coolant, but also in the rapid elimination of problems in the form of water leaks. This makes their service cheaper. The use of these devices is the most energy-efficient way to create a favorable microclimate in a building.

Since any large building has zones with different temperature requirements, each of them must be served by a separate fan coil unit or a group of them with identical settings. The number of units is determined at the design stage of the system by calculation.The cost of individual components of the chiller-fan coil system is quite high, therefore, both the calculation and the design of the system must be carried out as accurately as possible.

Components of the chiller-fan coil circuit

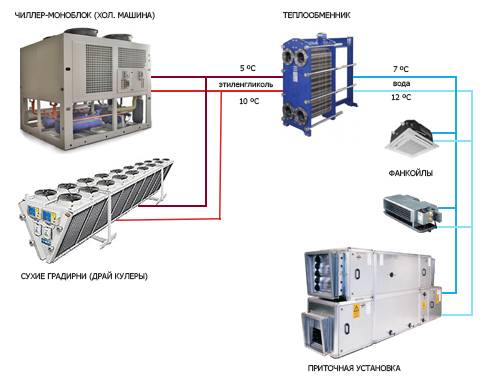

The role of the cooling device is assigned to the chiller - an external unit that produces and supplies cold through pipelines with water or ethylene glycol circulating through them. This is what distinguishes this system from other split systems, where freon is pumped in as a coolant, for the transfer of which expensive copper pipes are needed. Here, water pipes with thermal insulation perfectly cope with this task.

Its operation is not affected by the outdoor temperature, while split systems with freon lose their efficiency already at -10⁰. The internal heat exchange unit is a fan coil unit. It receives low temperature liquid, then transfers the cold to the room air‚ and the heated liquid returns back to the chiller.

Fancoils are installed in all rooms. Each of them works according to an individual program.

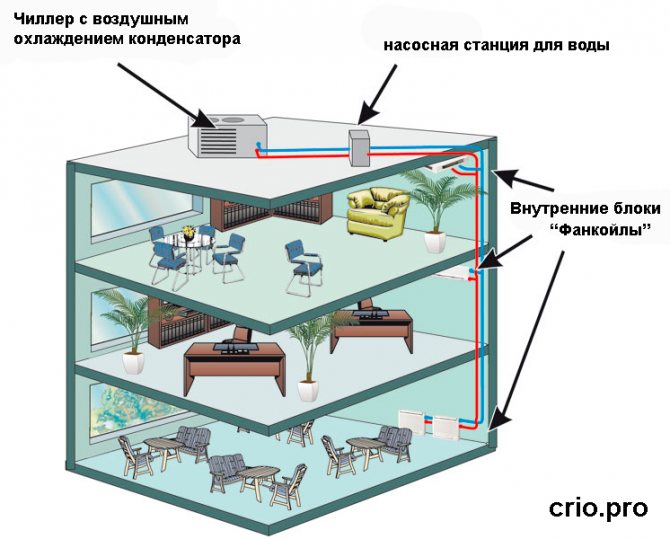

The photo shows the main elements of the system - pumping station, chiller, fan coil unit. The fancoil can be installed at a great distance from the chiller. It all depends on how powerful the pump is. The number of fan coil units is proportional to the chiller capacity

Typically, such systems are used in hypermarkets‚ shopping malls‚ buildings‚ built underground‚ hotels. Sometimes they are used as heating. Then, through the second circuit, heated water is supplied to the fan coils or the system is switched to a heating boiler.

Question answer

Question:

What do chillers run on?

Answer:

The main working substance of the chiller is the refrigerant. Freon is the most common refrigerant.It circulates around the circuit of the device and evaporates in the heat exchanger due to the heat received from the cooled liquid. Cold transfer is carried out with the help of a coolant (water, ethylene glycol).

The circulation of the refrigerant is provided by the compressor, the smooth operation of which depends on many factors. Thus, the operation of the chiller is impossible without a refrigerant and coolant.

Question:

What is better freecooler (cooling tower) or chiller?

Answer:

The freecooler provides cooling of water or other coolant in the radiator to the level of heat in the surrounding air. Fans are used for this. Freecooling technology does not provide for the presence of a compressor module. Due to this feature, they consume much less electricity than chillers.

Disadvantages of freecoolers: the impossibility of their full use in hot weather, since cooling occurs to the level of air temperature. Freecoolers are easily integrated into existing air conditioning units, so they are convenient to use in combination with chillers that operate independently of the outside temperature.

Question:

Which chillers are better water or air?

Answer:

According to the type of condenser cooling, chillers are water or air. Devices that use water for these purposes are suitable for operation throughout the year. They are more compact, can be installed inside a building, but are much more expensive than equipment where the temperature is lowered by a directed air flow.

Air units are offered at a low price, but their installation requires large areas to accommodate all units and modules. For example, the cooling system is often installed outdoors.This allows more rational use of space inside the building, but reduces the functionality of such equipment.

Question:

What is the difference between chillers with and without a heat pump?

Answer:

Devices in which a heat pump is installed can not only cool, but can also heat the surrounding space or provide hot water. This useful feature allows such installations to be used for heating large public or industrial premises. Equipping with a heat pump increases the cost of equipment, but significantly expands its functionality.

Question:

What is the principle of operation of absorption chillers?

Answer:

Absorbed devices use waste heat in factories as the main energy. In such systems, the main working substance includes several components. The solution consists of an absorbent and a refrigerant. The absorbent is lithium bromide, and the coolant is water. It enters the low-pressure evaporator, from where it exits cooled and is absorbed by lithium bromide. The liquid is concentrated in the condenser, and then the refrigerant is transferred through pipes to end users. Absorbed chillers do not have a compressor module, so they consume a minimum of electricity.

Question:

What is the cost of modern chillers?

Answer:

The cost of modern chillers depends on their design features and power. These are industrial air conditioning systems that are designed to service large industrial or public buildings, so the price of new units starts from 100 thousand rubles.rub. The cheapest are low-power mini chillers, while the most expensive ones have output power measured in thousands of kW, and their cost is several million rubles. Many vendors, upon request, provide a cost estimate after specifying the main required features and functions.

Types of chillers and their description

According to the type of coolant, chillers are divided into:

- propylene glycol;

- ethylene glycol;

- water.

The devices are equipped with a microprocessor-based specialized control system. For each model of chillers, there is always the opportunity to pick up additional. equipment, and this makes it possible to mount the equipment in any place.

The devices are equipped with a microprocessor-based specialized control system. For each model of chillers, there is always the opportunity to pick up additional. equipment, and this makes it possible to mount the equipment in any place.

The condensing units are designed according to the latest technical and engineering developments, as a result of which they are equipped with microprocessor control, low-noise fans and special scroll compressors.

The refrigerant used (HFC-407°C) is absolutely harmless and does not have the slightest negative effect on the ozone layer.

An additionally developed evaporator in the form of a plate heat exchanger makes it possible to rationalize the thermodynamic characteristics of the equipment as much as possible. The devices are endowed with a protective system of the heater against freezing during the time when this equipment is not connected to work.

Small-sized modules are mounted on a base frame, which includes all the components necessary to start and operate the equipment.

How much do fan coil units cost - price overview

The cost of a chiller-fan coil system depends on many factors, especially on its functionality and power.The most important parameters are: cooling capacity, minimum and maximum temperatures for cooling and heating water, the presence or absence of filters.

Let's consider several models.

Kentatsu KFZF30H0EN1 is a cassette fan coil unit with a capacity of 4 and 3 kW (heating-cooling), designed for installation in a false ceiling in rooms with an area of 20 - 30 m².

All models of the KFZF series are equipped with a wired remote control

All models of the KFZF series are equipped with a wired remote control

The device features easy installation and operation, high energy efficiency, special fan impeller design and low noise performance.

Kentatsu KFZF30H0EN1

Channel medium-pressure fan coil RoyalClima VC-S20P2. The RoyalClima brand has always focused on high performance and energy efficiency in the development of appliances, and the VC-S 20P2 is no exception.

Channel fan coil unit RoyalClima VC-S 20P2 is an example of advanced engineering

Channel fan coil unit RoyalClima VC-S 20P2 is an example of advanced engineeringRoyalClima VC-S 20P2

Quite compact, but at the same time powerful model. Allows you to maintain and adjust the microclimate parameters at objects for various purposes (from residential to industrial). Quite versatile and easy to use.

On average, the cost of models ranges from 10 to 20 thousand rubles.

And if you have your own experience of using fan coil units to control the microclimate at home, tell other readers of our online magazine about your experience.

Watch this video on YouTube

Watch this video on YouTube

Previous EngineeringDrainage on a flat roof: how to properly organize it so as not to sit in a puddle

Next Engineering Invisible heat: drywall infrared heating

Service Features

During the operation of the equipment, attention should be paid to planned inspection activities.All elements of filtration systems must be changed within the period specified by the manufacturer, radiators installed in the premises must be checked for corrosion and leaks

Inspection of the main nodes, depending on the scale of the system, is carried out weekly or monthly.

The control panel must be periodically monitored for the accuracy and speed of execution of the commands given. Electrical components are checked for amperage and other characteristics that may indicate a leak or abnormal condition. The voltage is measured on the line and in phases.

Requires maintenance and ventilation equipment. It is cleaned, lubricated, monitor the functionality of the work, the speed of rotation of the shaft. The drainage system is checked for the efficiency of moisture removal. Also, the radiator periodically requires sanitary antibacterial treatment, which makes it possible to exclude the spread and formation of pathogenic microflora.

See the following videos for all the technical features for the installation, maintenance and operation of chillers and fan coil units.

Water cooling in the aquarium

Chillers for cooling water are used not only for industrial purposes. They are also used to cool various liquids, including cooling water in an aquarium.

The use of additional lighting in the aquarium leads to an increase in the temperature of the water. To maintain a favorable temperature throughout the time, a chiller is perfect. The principle of its operation is the same as in industrial chiller systems.

Features of choice

Due to the high price, a water chiller is rarely used at home.But if you still decide to purchase a chiller for your home, you need to approach this process responsibly.

When choosing a chiller, consider:

- Equipment price;

- Energy consumption (in new models they try to balance low energy consumption and high performance. Do not take an overly powerful aquarium refrigerator. Choose strictly according to your parameters);

- Noise level (larger chillers emit more noise);

- Ease of maintenance and availability of spare parts on the market and in service centers;

- Compliance of the equipment with the size of the aquarium;

- Design, harmonious combination with the interior;

- A set of useful features.

Hydromodule

Experts call a hydromodule a pumping station, which is necessary for the circulation of water throughout the entire multi-meter chiller system.

In order for water to reach the end consumer from the chiller, a powerful circulation pump is needed, which will have to drive thousands of liters of water through pipes. In addition, the hydronic module also includes an accumulation tank, which serves as a reservoir for ice water. With it, the device works much more stable and less time. Since water changes its volume when the temperature changes, the system has an expansion tank built directly into the water circuit. It is necessary so that the system does not burst when the temperature of the circulating water rises - with an increase in the volume of water, it fills the expansion tank.

Glycol

The transfer of air heat from the cooled room to the refrigerant is carried out due to heat carriers (coolers), which can be:

- water;

- water solution;

- liquid with a low freezing point.

The most common coolants are solutions of polyhydric alcohols, including ethylene glycol, propylene glycol and glycerin.

Glycol is a colorless, sweetish and highly viscous liquid with a freezing point below -50 degrees. There are two main types of glycol: propylene glycol (non-toxic, used even in food production) and ethylene glycol (toxic, used where its leakage will not harm people, animals or food products, much cheaper than propylene glycol).

heat exchanger

The heat exchanger (evaporator) is a heat exchanger in which the refrigerant boils and thereby cools the coolant.

Most often, a brazed plate heat exchanger is used as an evaporator, as it is distinguished by efficiency in terms of heat transfer and compactness compared to other devices. Other designs can also be used: coaxial or shell-and-tube.

Compressor

The compressor is the main device of the chiller, designed to compress freon to the required high pressure and its subsequent supply to the pipeline.

There are three main types of compressors:

- piston;

- screw;

- spiral.

It should be noted that the cost of compressors plays a huge role in chiller pricing.

This is interesting: Four-sided woodworking machine: consider from all sides

The device and principle of operation of the chiller-fan coil system

This equipment is universal in application: it allows you to maintain a comfortable indoor climate in all seasons, regardless of the number of storeys of the building, its area, configuration and type.

If we consider the most primitive scheme of work: depending on the settings specified by the user, the radiator of the closer moves the liquid, which is endowed with exactly the temperature that corresponds to the specific goal set. The water heats or cools the air around the working element. The fan, in turn, forces this air into the room.

The principle of operation of the chiller-fan coil system

The principle of operation of the chiller-fan coil system

Advanced models are also capable of mixing indoor and outdoor air. The closer passes the media through the radiator, gives it the required temperature in a continuous cycle. To prevent the device from running “idle”, it has special bypass pipelines with valves and thermoelectric actuators.

Condensation, which inevitably occurs on the radiator, is removed using a receiving tray. The drain pump, which works in tandem with a float valve, removes accumulated moisture from the collector and sends it to the receiving pipe, and from there to the sewer drain.

Air conditioning systems can be air or water cooled. By the criterion of the features of the capacitor, you can find models of a remote or built-in type. Heating can be done with or without a heat pump. Next, the key design features of each work item included in a highly productive bundle will be considered.

A chiller is an air conditioner that passes antifreeze or water through the evaporator. The liquid is supplied through a piping system to fan coil units installed in separate rooms. The bundle works in the same way as split systems.Chiller and fan coil units can be separated by a considerable distance - this indicator depends only on the power of the pumping equipment introduced from the circuit. The chiller works with several fan coil units, depending on its performance, the maximum allowable number of connected segments of the air conditioning system is set.

Chillers are vapor compression and absorption. The latter are sold in the high price segment, they are large and may not be used in all types of buildings. Vapor compression models, in turn, are divided into:

- outdoor (work on the basis of axial fans, have air cooling);

- internal (they have water cooling, a centrifugal fan is installed in them, which ensures the movement of air masses);

- reversible (can work for cooling and heating).

Reversible chiller example

Reversible chiller example

A fancoil is equipment that accepts a cooled carrier; it is responsible for air circulation in the serviced room. The built-in fan helps to mix street and internal flows, send the resulting mixture in the right direction.

There are several types of fan coil units:

- floor;

- wall-ceiling;

- wall;

- ceiling.

Ceiling fan coil example

Ceiling fan coil example

Cassette indoor units contribute to cooling, heating and uniform distribution of air masses in rooms where suspended ceiling equipment is installed. Thanks to such a device, the working elements of the air conditioning system are masked, and associated noise is minimized. In this case, air flows can be distributed in no more than 2-4 directions.

Channel fan coil units are mounted directly in the ventilation shaft.Separate air ducts are used for air intake, channels arranged behind suspended ceiling segments are used to remove waste masses. Such models of closers are characterized by high performance, they are actively adopted in the construction of warehouses, trading floors and other premises with a large area.

Design features of chillers

Among the main features are:

- All parameters set in each room will be maintained automatically.

- The cooling system is considered to be flexible and the distance between the chiller and fan coil units is only limited by the pump capacity. The length of the location can reach hundreds of meters.

- The device is environmental and safe.

- Due to the fact that shut-off valves are used, the likelihood of a flood is minimized.

- The device is convenient to use, thanks to the flexibility of the layout and the low consumption of usable space for installation.

- The chiller, like a refrigeration unit, makes practically no noise during operation, so it will not attract attention.

- The equipment can be used at any time of the year, regardless of weather conditions.

The selection of a suitable device should include an assessment of the characteristics, consideration of different types of devices, as well as familiarization with the rating of a particular model. To choose the appropriate option, you should consult with people who understand chillers.

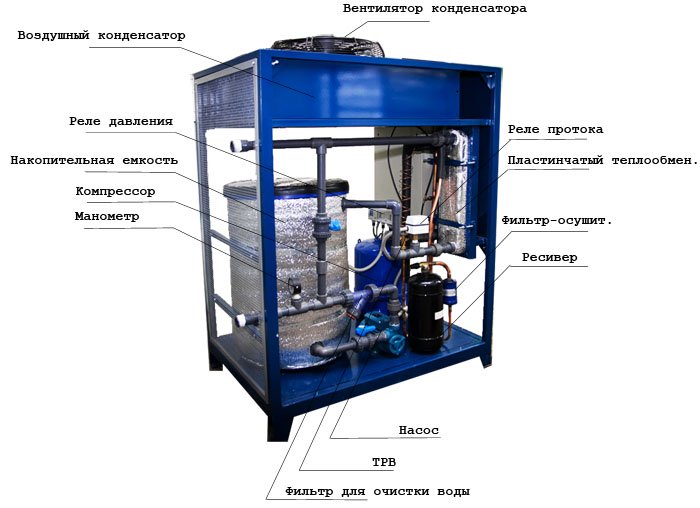

Chiller scheme

Chiller manufacturers produce several varieties of these devices. First of all, they differ from each other in the way of heat removal.

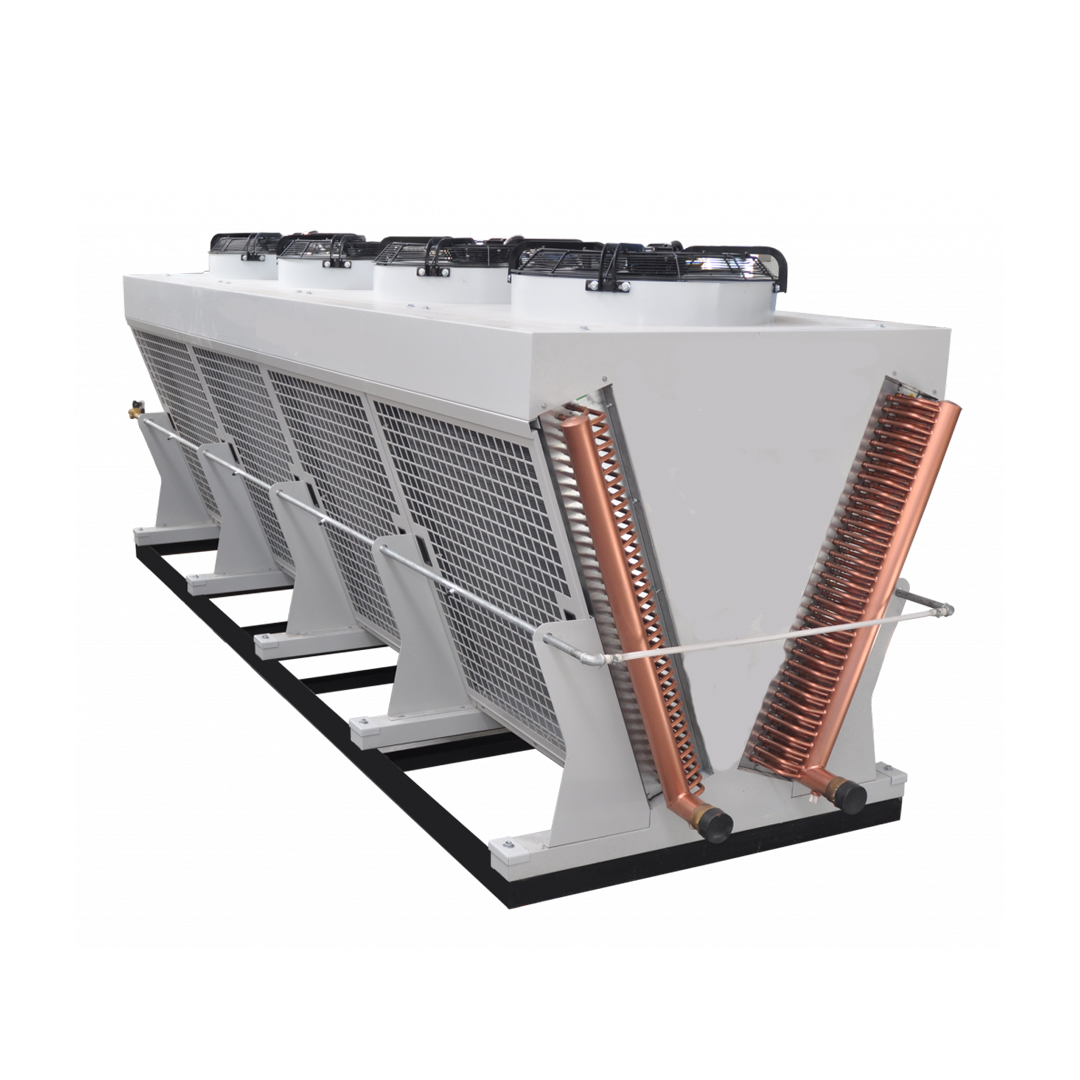

The most commonly used chillers are air-cooled outdoor installations.Externally, they are a single unit that includes the chiller and fan directly. The latter is used to force air onto the condenser and remove heat. The chiller is installed on the roof of the building. The main disadvantage of this design is that with the advent of cold weather, water has to be drained from the outer part of the circuit. But this is offset by the low cost of the chiller and the fact that it does not occupy the internal volume of the building.

If such a chiller is installed inside the building, then it will not be affected by the environment (no need to drain the water in cold weather). The air supply to the chiller is carried out through air ducts, for which centrifugal fans are used. But such a design feature increases the cost of the device, requires the allocation of space inside the building and the installation of additional air ducts.

An alternative option is a chiller with a remote condenser. It is a large split air conditioner used to cool water. A chiller with a remote condenser combines the advantages of the above options: moderate cost, independence from the change of seasons, but it also has one drawback. The capacitor must be located at a certain distance relative to the main unit.

A water-cooled chiller is a design that does not have the above disadvantages. This version of the chiller device can be called two-loop. Of course, their cost is higher and they are more difficult to operate.

Main chiller classes

The conditional division of chillers into classes occurs depending on the type of refrigeration cycle.On this basis, all chillers can be conditionally classified into two classes - absorption and vapor compressor.

Absorption unit device

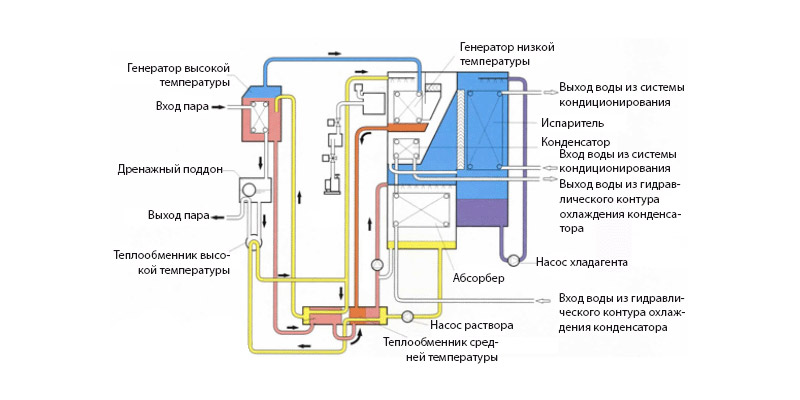

An absorption chiller or ABCM uses a binary solution with water and lithium bromide present in it - an absorber. The principle of operation is the absorption of heat by the refrigerant in the phase of converting vapor into a liquid state.

Such units use the heat released during the operation of industrial equipment. In this case, the absorbent absorber with a boiling point significantly higher than the corresponding parameter of the refrigerant dissolves the latter well.

The operation scheme of a chiller of this class is as follows:

- Heat from an external source is fed to a generator where it heats up a mixture of lithium bromide and water. When the working mixture boils, the refrigerant (water) evaporates completely.

- The vapor is transferred to the condenser and becomes a liquid.

- The liquid refrigerant enters the throttle. Here it cools down and the pressure drops.

- The liquid enters the evaporator, where water evaporates and its vapors are absorbed by a solution of lithium bromide - an absorber. The air in the room is cooled.

- The diluted absorbent is reheated in the generator and the cycle is restarted.

Such an air conditioning system has not yet become widespread, but it is fully in tune with modern trends regarding energy saving, and therefore has good prospects.

The design of vapor compression plants

Most refrigeration systems operate on the basis of compression cooling. Cooling occurs due to the continuous circulation, boiling at low temperatures, pressure and condensation of the coolant in a closed-type system.

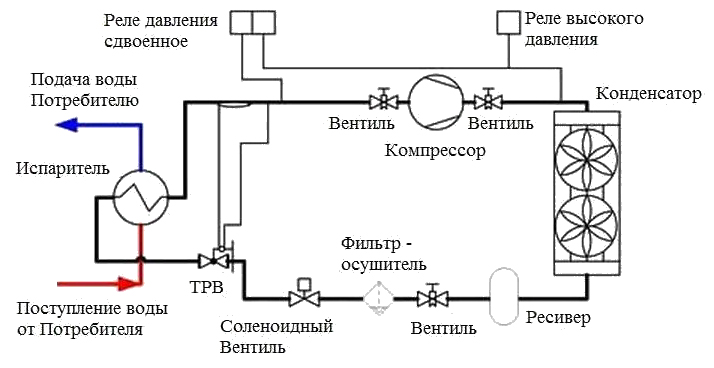

The design of a chiller of this class includes:

- compressor;

- evaporator;

- capacitor;

- pipelines;

- flow regulator.

The refrigerant circulates in a closed system. This process is controlled by a compressor, in which a gaseous substance with a low temperature (-5⁰) and a pressure of 7 atm is compressed when the temperature is raised to 80⁰.

Dry saturated steam in a compressed state goes to the condenser, where it is cooled to 45⁰ at a constant pressure and turns into a liquid.

The next point on the path of movement is the throttle (reducing valve). At this stage, the pressure is reduced from the value of the corresponding condensation to the limit at which evaporation occurs. At the same time, the temperature also drops to approximately 0⁰. The liquid partially evaporates and wet steam is formed.

The diagram shows a closed cycle, according to which the vapor compression plant operates. The compressor (1) compresses wet saturated steam until it reaches pressure p1. In the compressor (2), the steam gives off heat and transforms into a liquid. In the throttle (3), both the pressure (p3 - p4)‚ and the temperature (T1-T2) decrease. In the heat exchanger (4), pressure (p2) and temperature (T2) remain unchanged

The diagram shows a closed cycle, according to which the vapor compression plant operates. The compressor (1) compresses wet saturated steam until it reaches pressure p1. In the compressor (2), the steam gives off heat and transforms into a liquid. In the throttle (3), both the pressure (p3 - p4)‚ and the temperature (T1-T2) decrease. In the heat exchanger (4), pressure (p2) and temperature (T2) remain unchanged

Having entered the heat exchanger - evaporator, the working substance, a mixture of vapor and liquid, gives off cold to the coolant and takes heat from the refrigerant, drying at the same time. The process takes place at constant pressure and temperature. The pumps supply low temperature fluid to the fan coil units. Having traveled this path, the refrigerant returns to the compressor to repeat the entire vapor compression cycle again.

Vapor Compression Chiller Specifics

In cold weather, the chiller can operate in natural cooling mode - this is called free-cooling. At the same time, the coolant cools the outside air. Theoretically, free cooling can be used at an external temperature of less than 7⁰С. In practice, the optimum temperature for this is 0⁰.

When set to "heat pump" mode, the chiller works for heating. The cycle undergoes changes, in particular, the condenser and evaporator exchange their functions. In this case, the coolant must be subjected not to cooling, but to heating.

The simplest are monoblock chillers. They compactly combine all the elements into one whole. They go on sale 100% complete up to the refrigerant charge.

This mode is most often used in large offices‚ public buildings‚ warehouses. The chiller is a refrigeration unit that provides 3 times more cold than it consumes. Its efficiency as a heater is even higher - it consumes 4 times less electricity than it produces heat.

How to choose the right chiller?

For the needs of a large cottage, experts recommend using a water-cooled chiller. Such devices have a simpler design than air-cooled counterparts, respectively, and they are cheaper.

The design of the air-cooled chiller includes a fan (axial or centrifugal) to draw air from the room in which the unit is installed.

Some models of chillers can be used not only for air conditioning, but also for heating residential premises in the winter

To cool the condenser with water, you can use local water resources: rivers, lakes, atesian wells, etc.If for some reason access to such sources is not available, an alternative option is used: an ethylene or propylene glycol cooler.

Coolers of this type are ideal for use in the cold season, when ordinary water simply freezes.

The choice between a chiller in the form of a monoblock, when both the compressor, and the evaporator, and the condenser are enclosed in a common housing, and the option when the condenser is installed separately, is not so clear. The monoblock is easier to install, in addition, the performance of units of this type can be quite high.

When choosing a suitable chiller model, you should evaluate its performance and correlate it with the number of fan coil units that the device will serve

Remote systems are mounted in different places: the chiller itself is in the utility room inside the building (even in the basement), and the condenser is outside. To connect these two blocks, pipes are usually used through which freon circulates. This explains the increased complexity of the installation of the system, as well as additional material costs for installation.

But installing a chiller with a remote condenser uses less indoor space, and such savings may be necessary. When choosing a suitable device, you should also take into account the additional functions that the device is equipped with.

Among the popular and useful additions are:

- control and regulation of water balance in the system;

- purification of water from unwanted impurities;

- automated filling of containers;

- control and correction of internal pressure in the system, etc.

Finally, it is imperative to evaluate the cooling capacity of the chiller, i.e. its ability to extract thermal energy from the working fluid.Specific quantitative indicators are usually indicated in the product data sheet. The cooling capacity of each specific chiller-fan coil system is calculated separately.

This takes into account the maximum and minimum temperatures, chiller power, pump performance, pipe lengths, etc. These are only general guidelines for selecting chillers. In each case, you should consult with an experienced specialist who can take into account the various nuances and help you make the right choice.