- Tank Features

- Advantages and disadvantages

- Why is the safety valve on the water heater so important?

- How a safety valve works

- How does the valve work

- How to save electricity

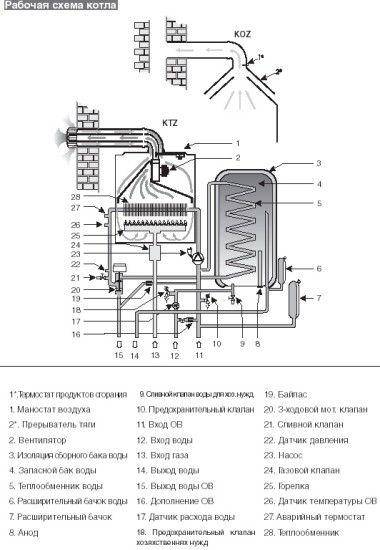

- Boiler (accumulative) of indirect heating

- Hot water supply is good

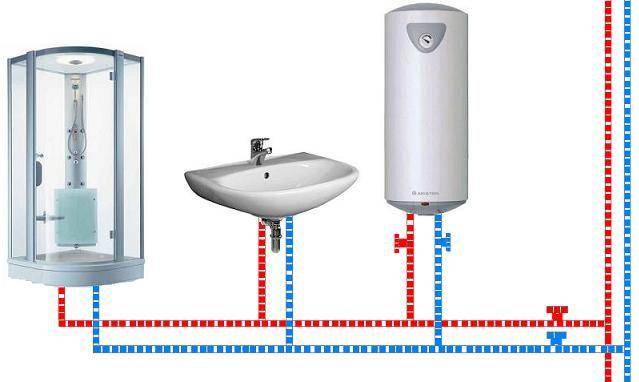

- Wiring diagram for an electric water heater

- Storage water heaters

- Boiler design

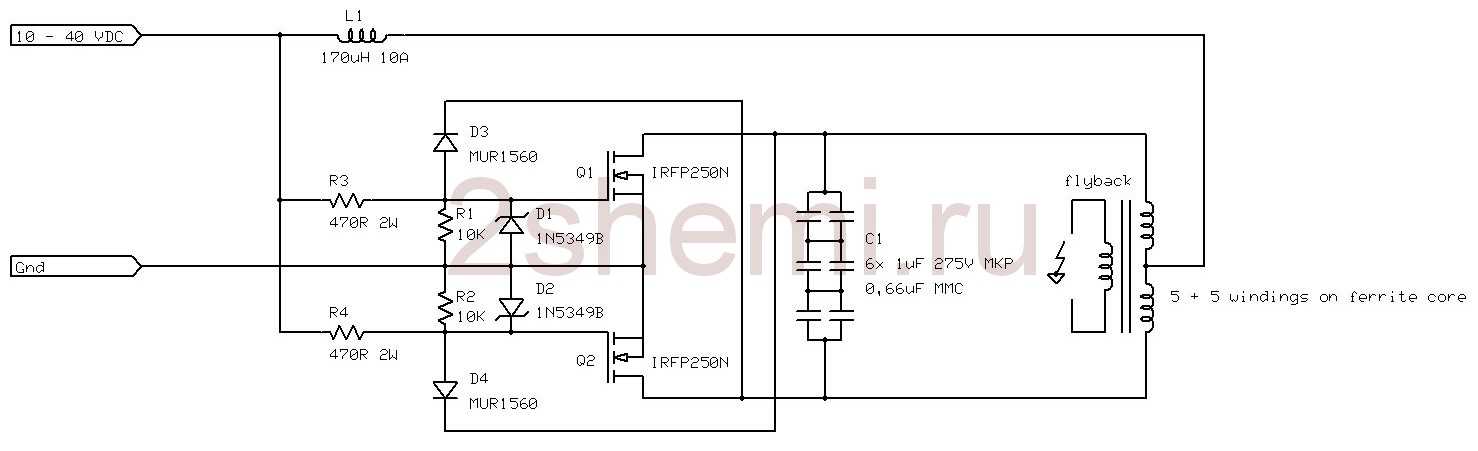

- electric boiler

- Instantaneous electric water heaters

- gas boiler

- How does a gas flow boiler work

- How to choose a gas flow boiler

- How to install a gas flow boiler

- Choice of electric water heaters Thermex

- Overview of water heaters for electric heating

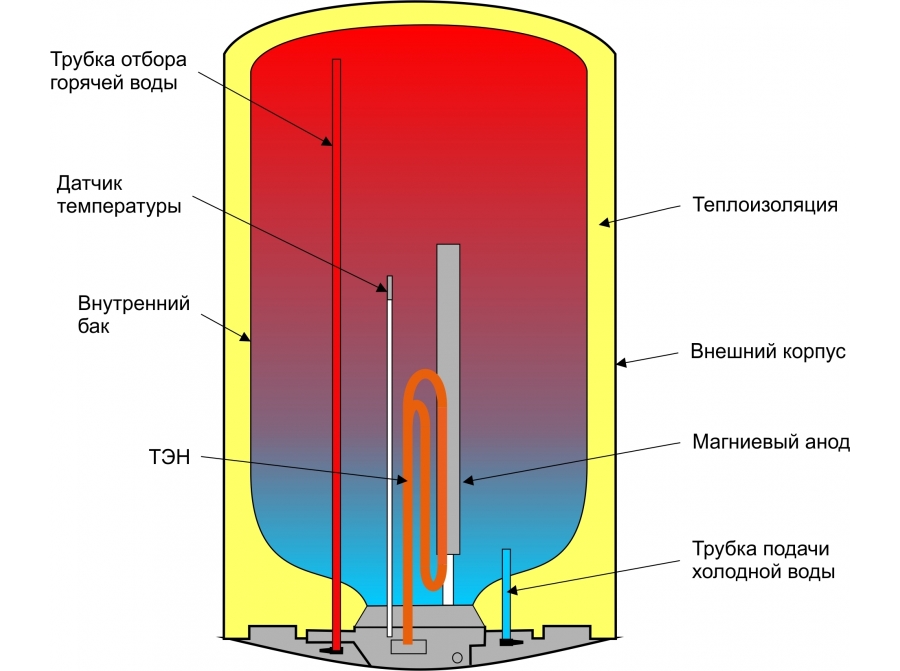

Tank Features

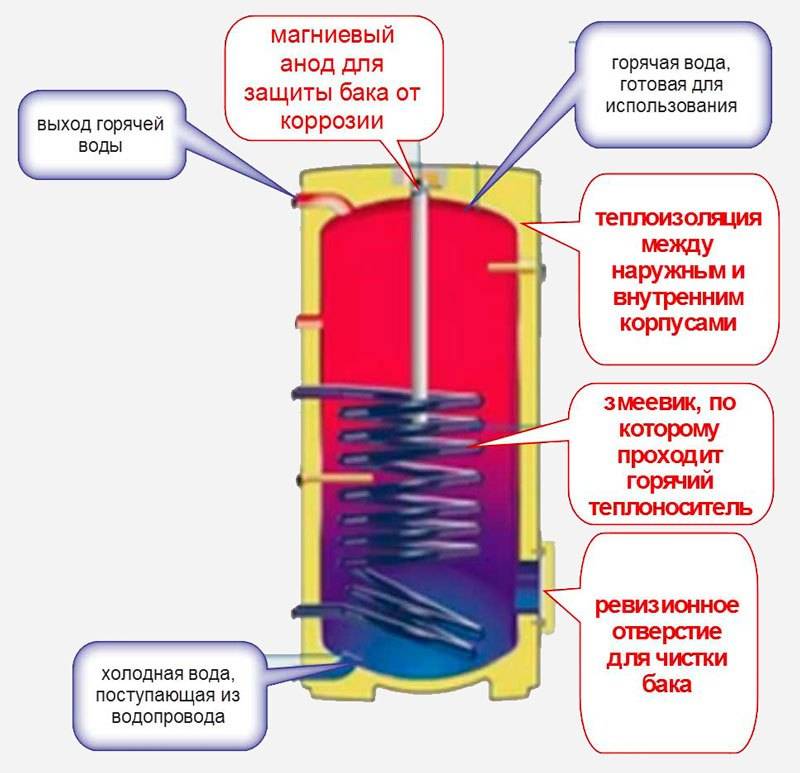

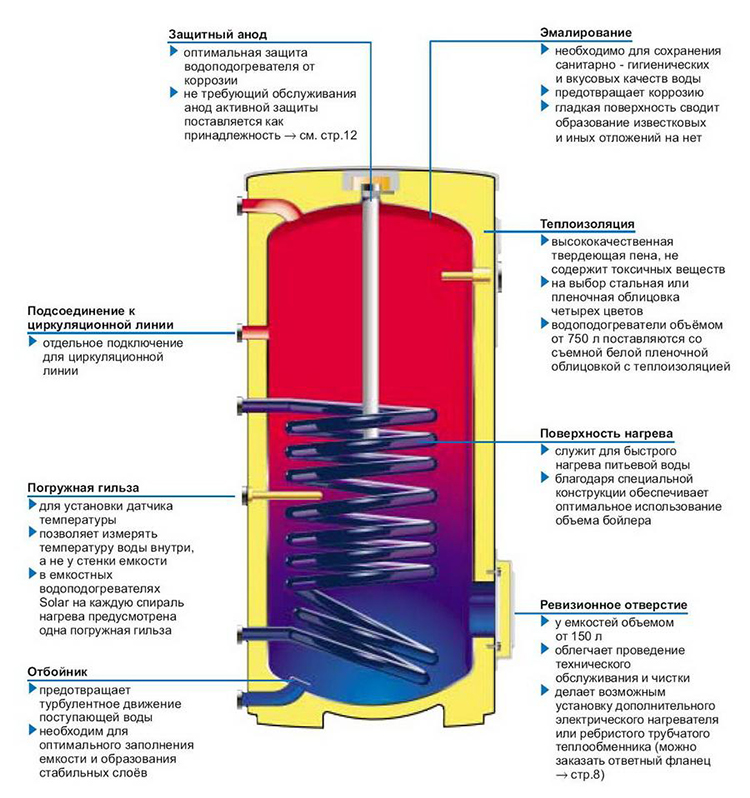

The most modern storage water heaters have a tank made on the basis of stabilized and high-strength steel alloys, which are characterized by resistance to corrosive changes.

The inner surface is covered with a layer of glass porcelain, which is subjected to high-temperature firing. The glass-porcelain coating is chemically neutral and corrosion-resistant.

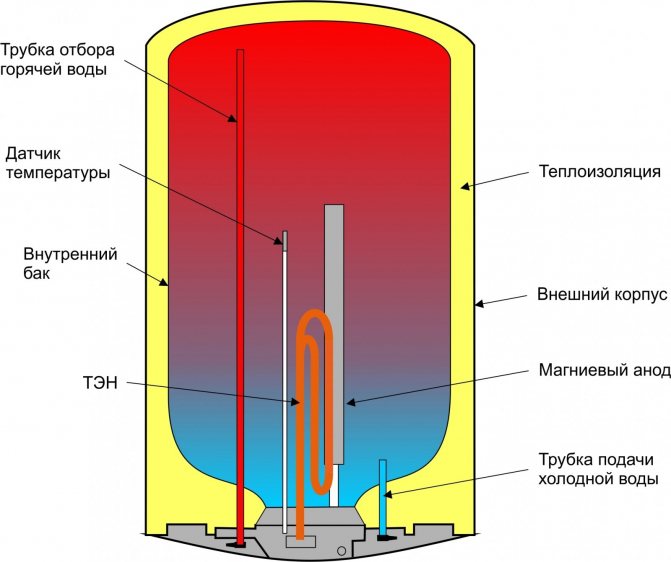

Storage water heater device for vertical installation

The special crystal structure of the glass-porcelain tank is able to withstand even very high deforming loads.The internal tank is protected by a magnesium anode, which effectively prevents electrochemical type corrosion processes.

Periodic replacement of such an element has a positive effect on the service life of the water heater.

Advantages and disadvantages

Today, many users, having tried storage water heaters, are inclined to purchase a flow-through option - this saves a lot of room space, since they are all quite compact in size, and reduces the heating time many times over.

Let's take a look at the benefits point by point.

- Simple operation - turned on, washed or washed dishes and turned off.

- They provide an unlimited amount of hot water for any need - it will take no more than 2 minutes to wait for heating.

- Does not require periodic maintenance by specialists.

- The compact size allows installation of the product even under the sink in the bathroom, so as not to disturb the established interior.

- When a large volume of hot water is not required, such devices become quite economical (compared to the storage option).

- Their initial price is lower than that of storage water heaters.

- When heated, water does not lose its qualities, because it is consumed immediately. There is no possibility of reproduction of harmful bacteria - if desired, you can even drink it.

Minuses:

- this type of product heats water no higher than 40C;

- with a high power of the product, the power consumption increases;

- when a large amount of water is required, the device works for a long time and the electric meter will wind up a decent flow;

- this type of product imposes special requirements on the home electrical network - the voltage must always be a constant value;

- instantaneous water heaters provide only one point of water intake.

The conclusion from everything is simple: water heaters of the type described above are convenient for a family of two when the need for hot water is minimal, otherwise it is best to put a storage-type boiler with a large volume that satisfies all household needs.

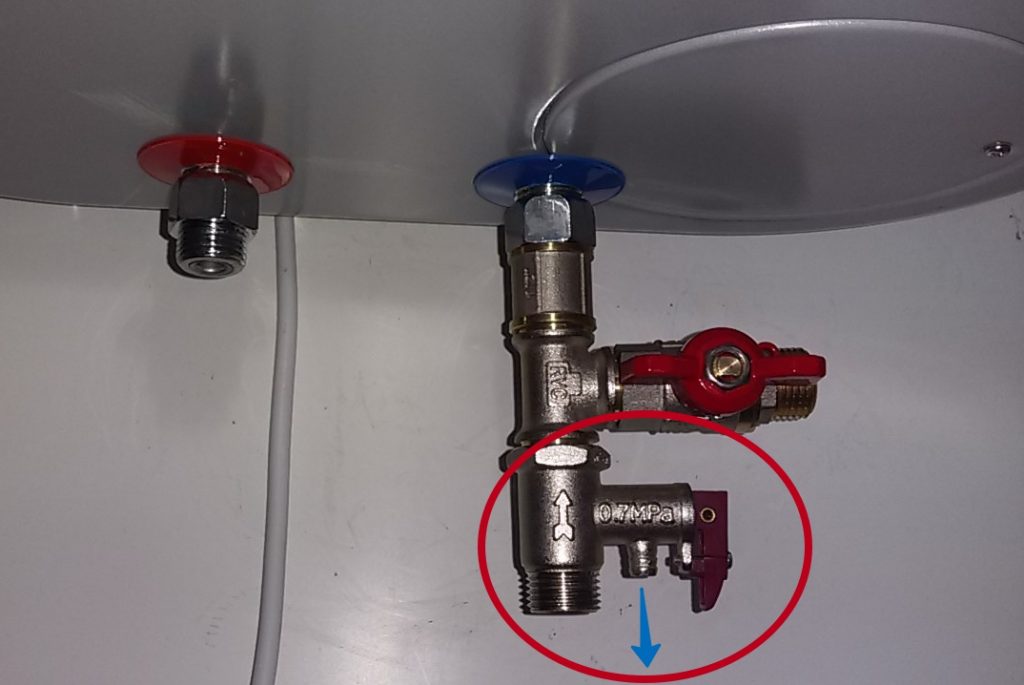

Why is the safety valve on the water heater so important?

To understand the importance of this safety device, you need to familiarize yourself with its design and principle of operation.

How a safety valve works

The device of the safety valve for the water heater is quite simple. Structurally, these are two cylinders with a common cavity, located perpendicular to each other.

- Inside the large cylinder there is a poppet valve, preloaded by a spring, which ensures the free flow of water in one direction. In fact, this is a familiar non-return valve. The cylinder ends at both ends with a threaded part for connecting the valve to the heater and pipe system.

- The second cylinder, placed perpendicularly, is smaller in diameter. It is muffled from the outside, and a drain (drainage) pipe is made on its body. A poppet valve is also placed inside it, but with the opposite direction of actuation.

Often this device is equipped with a handle (lever) that allows you to forcefully open the drainage hole.

How does the valve work

The principle of operation of the safety valve is simple.

The pressure of cold water in the water supply presses the “plate” of the check valve and ensures the filling of the heater tank.

Upon filling the tank, when the pressure inside it exceeds the external one, the valve will close, and as the water is consumed, it will again ensure its timely replenishment.

The spring of the second valve is more powerful, and is designed for increased pressure in the boiler tank, which necessarily increases as the water heats up.

If the pressure exceeds the maximum allowable value, the spring compresses, slightly opening the drainage hole, where excess water drains, thereby equalizing the pressure to normal.

Importance of proper valve operation

Perhaps the description of the device and the principle of operation of the valve did not bring complete clarity to the question of its extreme importance. Let's try to simulate situations where its absence can lead to

So, let's say there is no valve at the inlet to the heater that blocks the return flow of water supplied to the tank.

Even if the pressure in the plumbing system is stable, the device will not work correctly. Everything is explained simply - according to the laws of thermodynamics, when water is heated in a tank with a constant volume, pressure necessarily increases.

At a certain point, it will exceed the supply pressure, and the heated water will be discharged into the plumbing system.

Hot water can come from cold faucets or go into the toilet bowl.

The thermostat in this case continues to work properly, and the heating elements consume expensive energy for nothing.

The situation will become even more critical if, for one reason or another, the pressure in the water supply system suddenly drops, which is practiced quite often, for example, when the load at water stations is reduced at night.

Or if the pipes turn out to be empty as a result of an accident or repair work.The contents of the boiler tank are simply drained into the water supply, and the heating elements heat the air, which inevitably leads to their rapid burnout.

It may be objected that the automation should prevent idle operation of the heater. But, firstly, not all models provide such a function, and secondly, the automation may fail.

It would seem that in order to avoid such situations, you can limit yourself to installing a conventional check valve? Some “wise men” do this, not fully realizing that by doing so they are literally “planting a bomb” in their home.

It is scary to imagine what can happen if the thermostat fails.

Water reaches the boiling point in the tank, and since there is no exit from the closed volume, the pressure rises, and with increased pressure, the boiling point of water becomes much higher.

Well, if it ends with cracking of the enamel on the inside of the tank - this will be the least evil.

When the pressure drops (crack formation, open faucet, etc.), the boiling point of water drops again to the normal 100 degrees, but the temperature inside is much higher.

There is an instantaneous boiling of the entire volume of liquid with the formation of a huge amount of steam, and as a result - a powerful explosion.

All this will not happen if a serviceable valve is installed. So, let's summarize its direct purpose:

- Do not allow water to flow back from the heater tank into the plumbing system.

- Smooth out possible pressure surges in the water supply, including hydraulic shocks.

- Discard excess liquid when it is heated, thus keeping the pressure within safe limits.

- If the valve is equipped with a lever, it can be used to drain water from the water heater during maintenance.

How to save electricity

You can save a little electricity that the boiler consumes during operation. To do this, it is recommended to set the heating temperature not to the maximum (75-85 degrees), but to 55-60. When cold water enters the tank and combines with the liquid that is already there, it will take less energy to heat the mixed mass. In addition, the temperature regime of 55-60 degrees will help to significantly reduce the process of scale formation on the heater.

Scale on the heater

It is necessary to choose the correct location of the boiler so that the pipeline from it to the sink or shower is not too long. Due to this, heat from hot water will be dissipated less.

Periodically, it is necessary to carry out preventive cleaning of the heating element from scale. Due to this procedure, the efficiency of its work increases - the cost of electricity for heat generation will be less.

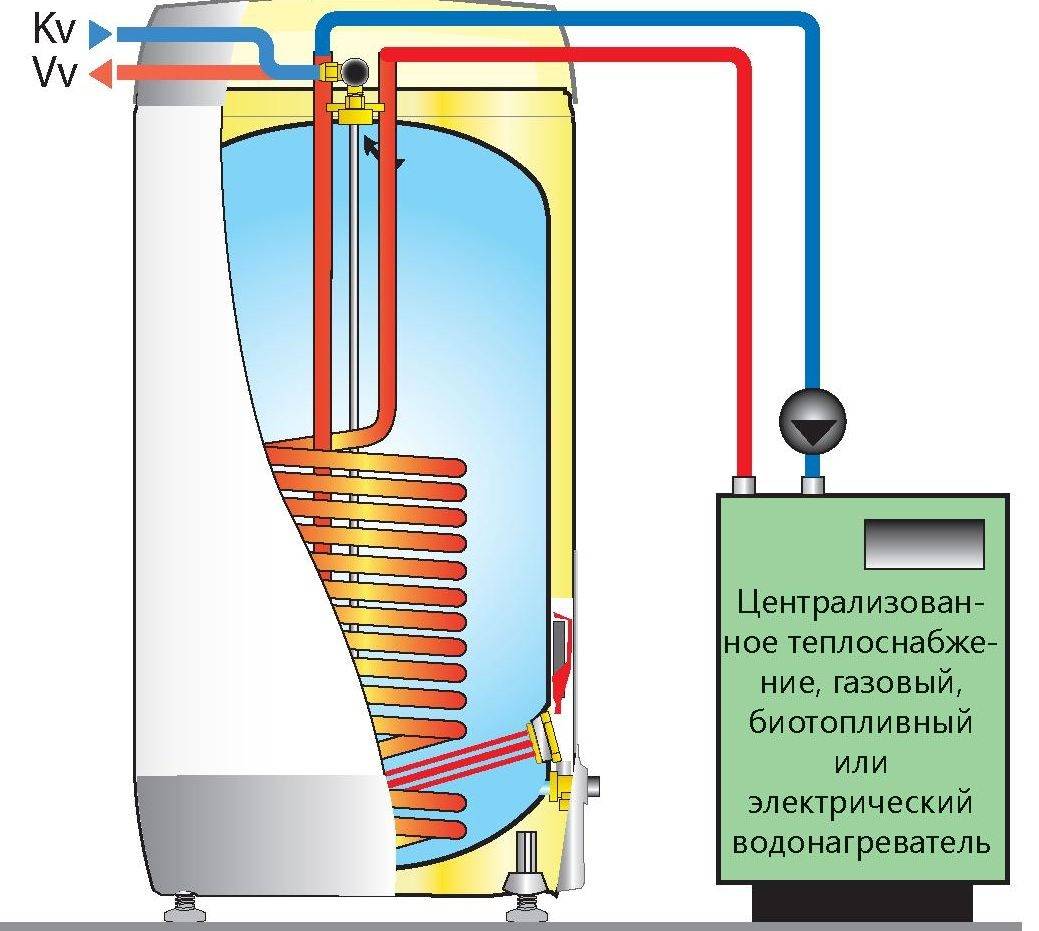

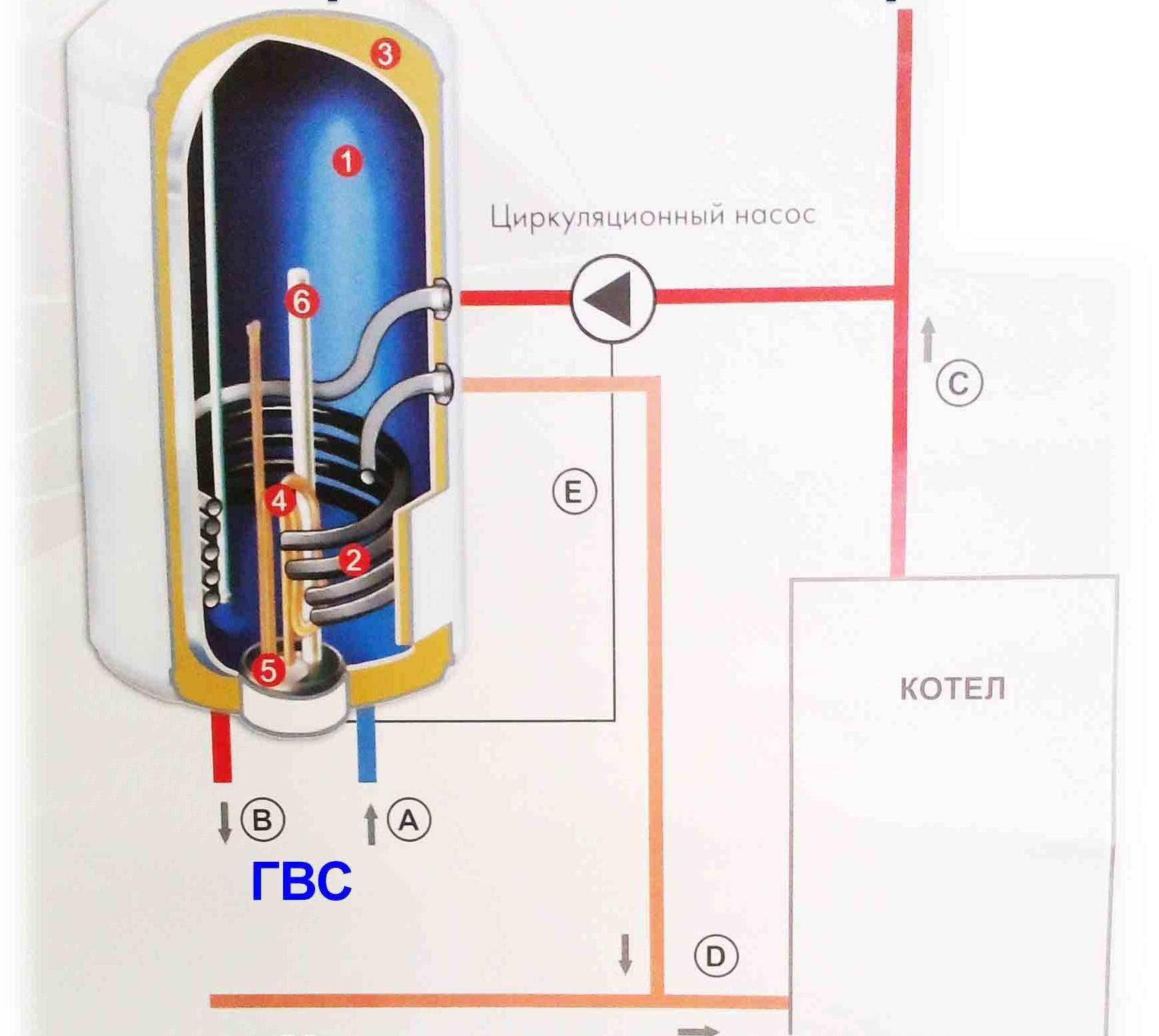

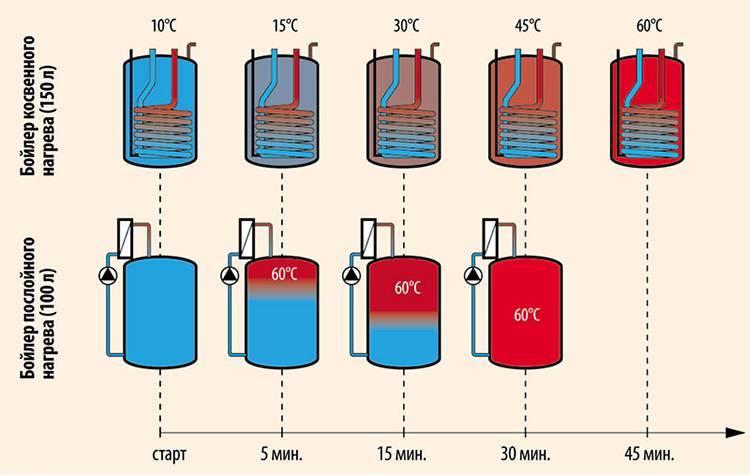

Boiler (accumulative) of indirect heating

In the event that you mount a double-circuit boiler, then this requires less space, and its cost is cheaper. Indirect heating heaters come in different types.

Consider how the boiler works, which is represented by a metal cylinder, its volume depends on the model. It is worth noting that some of them are designed for 100 or more liters. If the boiler room has a small area, then vertical boilers are used.

The water heater is fixed on the wall. The body consists of metal, plastic and painted steel. When choosing a boiler, it is better to purchase a model in which the steel sections are painted, as they can corrode.

Inside the tank there is a brass or steel coil, the shape of which is presented in the form of a spiral with additional turns, they are necessary for high-quality water heating. In order for the incoming cold water to be heated in time, the spiral is shifted to the bottom of the tank. In some models, it is evenly distributed throughout the contents of the container.

There are models on which two heat exchangers are mounted: one is connected to the heating, and the second to the heat pump. I would like to note that the operation of this type of boiler is quite simple. Cold water enters from below, which is heated by a spiral, and already warm liquid comes out from above. The magnesium anode extends the life of the heater and thermostat.

Such a boiler can be without a coil, but consist of two tanks of different sizes, which are inserted into each other. Hot water comes from a large tank and heats up a cold liquid placed in a smaller tank, and the heat exchanger in this design is the distance between their walls.

Hot water supply is good

The heat exchanger in them with hard water can be so filled with scale that the water will barely flow. This does not happen in a boiler. A large volume of water heats up relatively slowly. A hundred-liter water heater with a heating element of 1.5 kW will heat water to 60-70 degrees Celsius in about 3 hours. But it takes a long time to cool down. And this is the main advantage of storage water heaters - users have a supply of hot water with a constant good pressure.

Conventional boiler

Normal TEN. The best heat transfer, if it burns out, it is completely replaced.

A boiler is a tank of several tens of liters or more. Moreover, it is very durable, because it is connected to the water supply.And in it, as you know, a pressure of several atmospheres and hydraulic shocks are a plus. If such a container leaks, and even in the absence of residents, the consequences will be very unpleasant. For this reason, guaranteeing the integrity of the casing is the most important task for the boiler manufacturer. Although its body is similar to a thermos, the outer part performs decorative tasks and constructive functions in relation to thermal insulation.

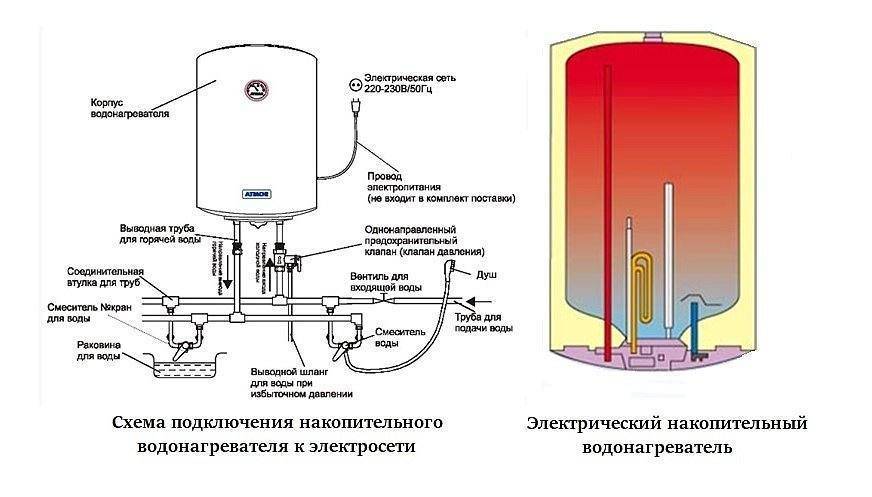

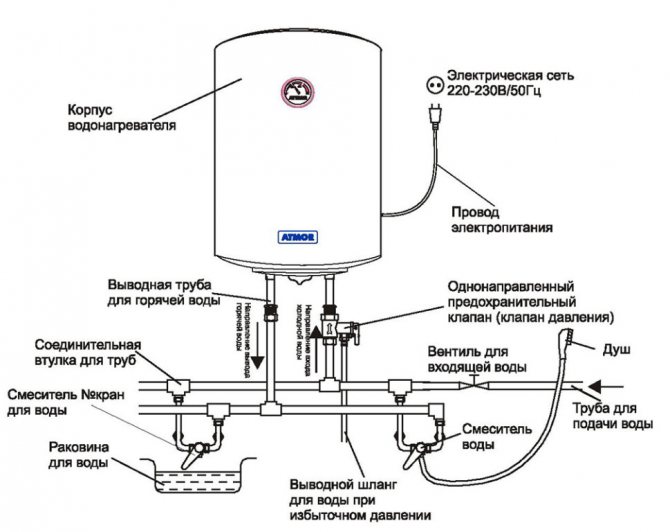

Wiring diagram for an electric water heater

One of the important factors affecting the life of the water heater is the fluctuation of water pressure in the storage tank of the device. For the correct operation of the device, it is necessary to correctly and accurately tie it.

The correct strapping scheme with a detailed indication of the work items

And if there should be no problems with the strapping scheme, then not all users know the meaning of the elements located on it.

Description of the main elements of the strapping:

Check valve. Mounted on water heaters up to 80 liters. The main job of a non-return valve is to allow water to flow in only one direction. When the pressure in the system decreases, the check valve closes and does not let the water flow through it.

check valve

- Safety valve. The principle of operation is slightly different from the check valve. It consists in the fact that when the set pressure is exceeded, the valve opens and discharges the coolant. To do this, a separate pipe must be provided in the water heater system.

- Pressure regulator. The pressure regulator is one of the main elements of the water heater system, which not only prolongs its life, but also reduces water consumption.The principle of operation of the pressure regulator is to control the flow of water at the inlet to the device.

Boiler pressure regulator

Expansion tank. It is installed on systems whose volume exceeds 80 liters, when the check valve no longer copes. It consists of two chambers (air and water), as well as a permeable membrane.

Example of an expansion tank for a boiler

Thermostatic mixer. Provides faster mixing of hot and cold streams. After installing such an element, not only the performance of the water heater increases, but also the consumption of electricity is reduced.

thermostatic mixer

It is also very important to install a fine filter in the system and replace it in time, which allows you to extend the life of the water heater.

Storage water heaters

By the principle of operation and structure, they resemble electric types of water heaters. The outer metal case, the inner tank also has a protective coating, only a gas burner acts as an energy source. Such equipment provides for operation on liquefied or main gas, including low flow, does not require connection to the electrical network.

It is worth noting that this type is less popular than its electric competitor. This is due to the high price, large dimensions and the possibility of installation not in all houses. But, according to experts, the high price of such equipment will pay off during its operation, since gas, as a source of energy, is much more economical than electricity.

Depending on the features of the structure, such equipment is divided into two types:

- with a closed combustion chamber;

- with an open combustion chamber.

As well as electric boilers, they can be:

- wall-mounted - from 10 to 100 liters (for example, Ariston SGA series models);

- floor-standing - from 120 liters or more (like Ariston models of the NHRE series).

The gas design also provides a control system with a choice of temperature, equipped with a thermostat to maintain the required temperature, shows how much hot water is left in the tank. Such equipment must be equipped with a security system.

But this is where bandwidth limitations come into play. Already for a water heater with a power of 8 kW, the cross section of the copper wire should be 4 mm, and for aluminum, with the same cross section, the maximum load is 6 kW.

At the same time, in big cities the mains voltage is almost always 220V. In villages, small towns or summer cottages, it often falls much lower. That's where the water heater comes in.

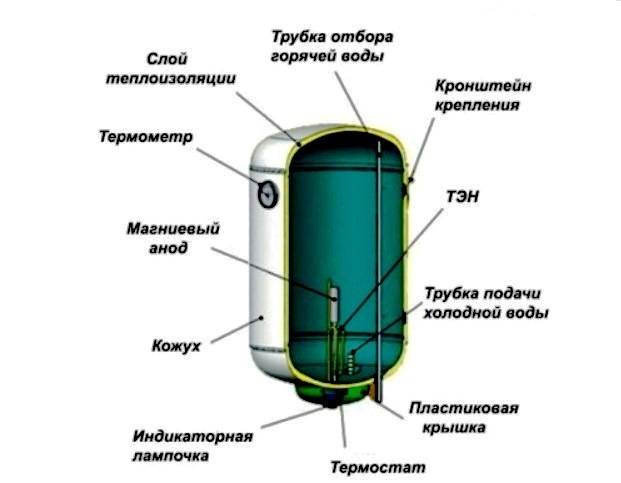

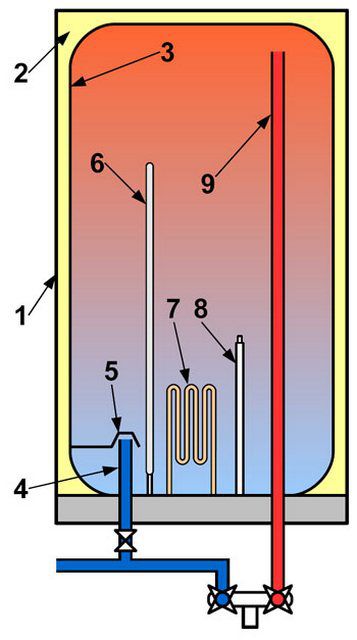

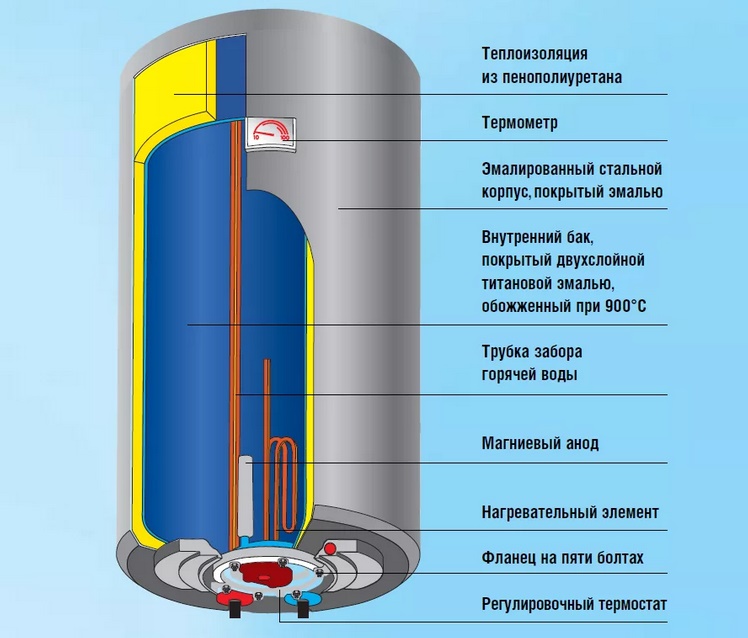

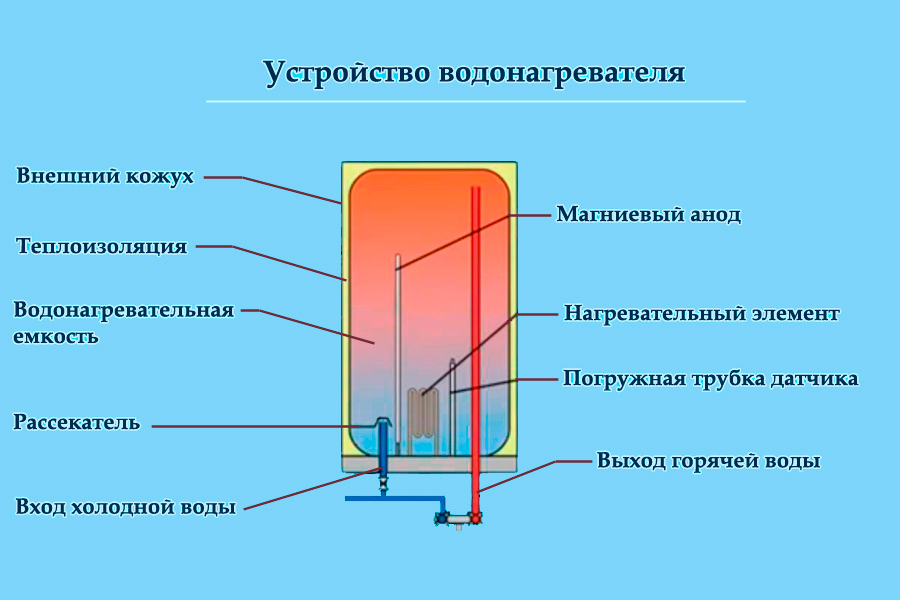

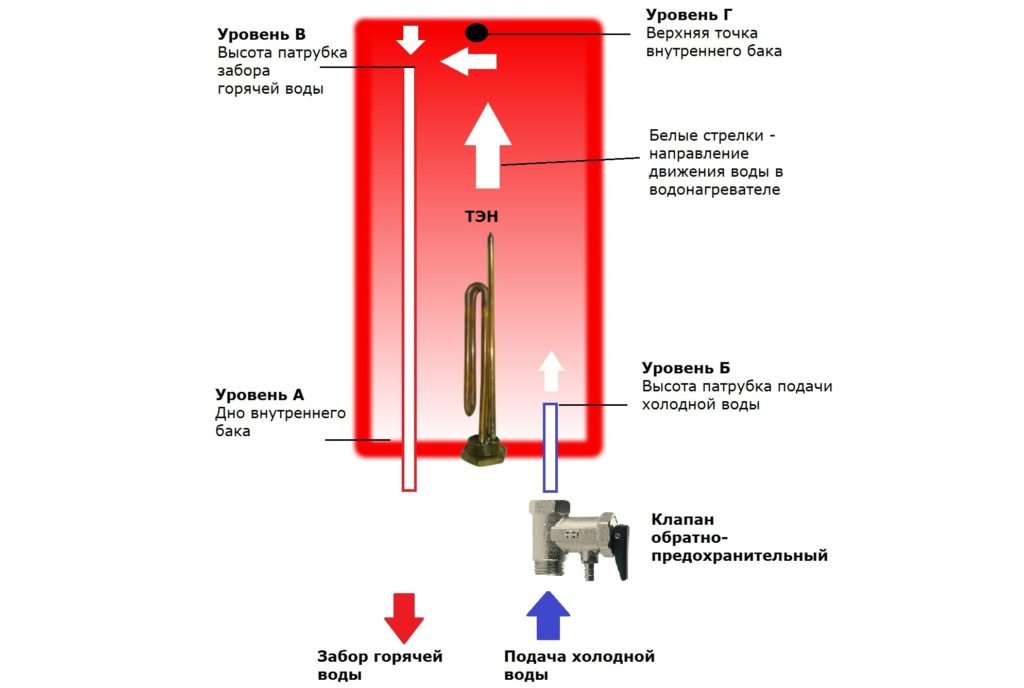

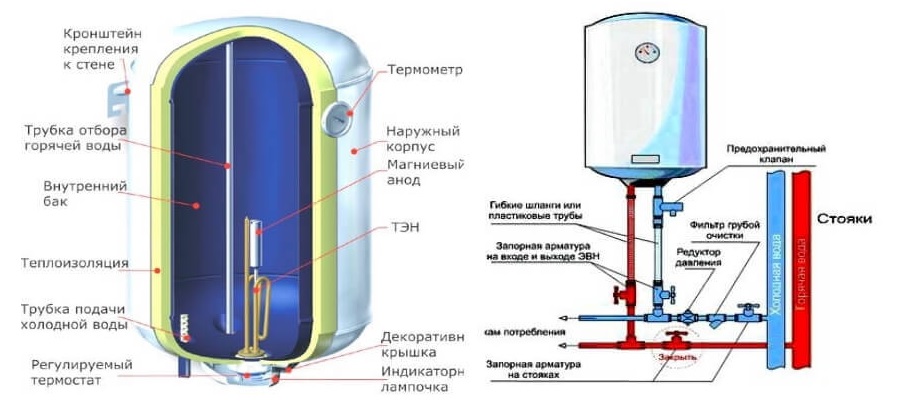

Boiler design

In simple terms, the boiler can be compared to a huge thermos, the water in which is heated and remains hot for a long time. It consists of the following main elements:

- oval or round inner tank;

- decorative case made of plastic, stainless or enameled steel (the internal structure of the boiler is covered with it from above);

- a protective layer of heat-insulating material (located between the inner tank and the outer casing, most often made of dense polyurethane);

- fasteners with which the boiler will be mounted on the floor or wall (located on the outer casing);

- a tubular electric heater (TEN), with the help of which the water is heated to the desired temperature (located at the bottom of the tank);

- a thermostat that limits the temperature to a maximum value of 75 degrees (located at the bottom near the heating element);

- pipes for supplying cold and draining hot water (mounted in the inner tank);

- protective magnesium anode;

- safety valve;

- control scheme.

Electric storage boiler device

The outer body can have a different shape: rectangular, oval or cylindrical. Models are produced in various colors and designs. On the body, in addition to fasteners, there are also controls, regulators and a thermometer, with which you can control the operation of the boiler.

Particular attention should be focused on the heating element. Heating elements use different power (this value also determines the power of the boiler). According to the principle of heating, they are:

According to the principle of heating, they are:

- Wet type. Such a heating element is in direct contact with water, as a result of which scale forms on it, which must be removed.

- Dry type. This heating element is much more advantageous, since it is structurally located in a metal tube through which contact with water is made. Thus, the dry-type heating element is protected from scale, as is the tube itself, covered with a glass-porcelain layer.

Boiler with dry heater

Another structural element is the safety valve. Why is it needed? When the water heater is operating normally, the valve does not play any role.But in an emergency, if, for example, the thermostat breaks down, the water in the boiler will heat up to a boil, which will lead to an increase in pressure to unacceptable values and a possible rupture of the internal tank. In this case, the safety valve is activated, which is located on the cold water supply pipe. When the pressure limit is reached, it opens and the water is discharged.

An important element in the device of the water heater is the magnesium rod. The purpose of this electrode (anode) is to reduce the ion exchange between the metal components inside the boiler. In return, it gives up its particles, as a result of which the effect of washing out electrons from the structural elements of the water heater is minimized, and they are less susceptible to corrosion. The anode itself breaks down quite quickly and needs to be changed periodically (if its length decreases to 200 mm and its thickness to 10 mm).

Replacing the spent magnesium rod (anode)

electric boiler

Storage electric boilers are very popular in modern homes. They are installed both in private mansions and in apartment buildings. The volume of their tank varies from 30 to 100 liters. Such devices are included in the water supply system immediately after the main pipeline and can supply several taps with hot water. Additional options in such devices are special thermostats for continuous heating or for frost protection.

electric storage boiler

The installation of such a device is relatively simple - as a rule, a heater is installed in the water distribution system immediately after the connection of the water supply network of your house or apartment.It can be built in parallel with the existing hot water supply system and allows you to use hot water even when the main system is turned off.

The accumulative electric heater has a relatively small power of the thermal element, comparable to an electric kettle. It can be plugged into a regular outlet. But, nevertheless, in houses of old construction, before installing a storage electric water heater, it is recommended to revise the power supply system and, if necessary, lay a new wire to the outlet from the switchboard and a separate circuit breaker.

The price of a household storage heater can depend on many factors, for example, brand awareness, its volume, and the power of the heating element.

The main factor determining the price of such a device is the volume and material of the storage tank.

The minimum required volume of the storage heater for a family of three is 50 liters. But in this case, in the morning you will only be able to wash your face. There can be no question of any showering by several households. The most optimal volume will be a heater of 80 liters. In principle, this volume allows you to even comfortably take a bath.

Instantaneous electric water heaters

Such devices are usually used to connect one point of water intake. This is due to the fact that heating flowing water in a large volume requires a solid power of the heating element. This inevitably increases power consumption and often requires a separate power line. The most powerful flowers generally operate on three-phase electricity, which is simply not available in some homes.Also, such devices are very demanding on the quality of flowing water - they can very quickly become clogged with scale.

Basically, such a device is a pipe around which heating elements are located, controlled by automation. The undoubted advantage of such a device is its compactness - it can be installed literally in any free space.

gas boiler

The undoubted advantage of gas boilers is that hot water begins to flow into the tap after it is turned on almost immediately after it is turned on. You won't have to wait.

gas boiler

How does a gas flow boiler work

All main elements of the gas flow boiler are mounted inside a durable metal case. The water coming from the water supply line passes into the heat exchanger, under which the gas burner is located. The device is quite simple at first glance, but in order for the gas heater to work without accidents, the entire system must be equipped with rather complex automatic devices.

Immediately after you open a hot water tap, a valve opens in the boiler automation, which opens the gas supply. In good models, the incoming gas is ignited automatically, while in more modest ones you will have to press a special button for this.

From the combustion of natural gas, combustion products are formed, which are removed through the chimney. There are options for gas boilers with closed combustion chambers, in which combustion products are removed through a metal coaxial sleeve.

gas boiler connection

As a rule, gas heaters are mounted in houses connected to main gas supply systems. They certainly lead in terms of price-quality ratio under such conditions. Gas flow boilers are quite modest in size. The low cost of gas consumed for heating water makes them a good economical option. Thus, the cost of heating water in such a device is about three times lower than in its electrical counterpart. Apparently, as a result of this, and also because of the need to supply such devices with reliable automation, the cost of the gas column itself is higher than that of an electric boiler.

A gas flow boiler recommended for installation in an apartment can supply up to 17 liters of hot water per minute to the tap.

How to choose a gas flow boiler

The first characteristic that you need to evaluate when choosing such a device is its power. As a rule, manufacturers divide gas heaters by the number of liters of water that the device can heat per minute.

Therefore, it is necessary to soberly assess the possible consumption of hot water in your apartment, especially if it has several bathrooms. With low productivity, simultaneous morning washing will turn out to be somewhat uncomfortable. Usually, the temperature of the water supplied to the tap is regulated in a modern gas boiler using a thermostat.

At the same time, the system can automatically increase power when the number of consumption points increases. So, if you bask in the shower, then when you turn on the hot tap in the kitchen, the system will automatically increase the burner fire and the volume of heated water.

It is important to choose the type of ignition of the fire in your gas boiler.If earlier it was necessary to use considerable sleight of hand to ignite the burner, operating with a crane and matches, now boilers equipped with a piezo ignition system allow you to ignite the fire under the burner with a simple push of a button

There are also systems with automatic ignition, which is switched on by the flow of water. But with a long absence, it is better to turn off such a system in order to avoid trouble. Although very high-quality devices are equipped with a multi-stage protection system that will turn off the gas in any emergency, such as excessive heating or fire extinction, a sharp decrease in gas pressure or a stop in the water flow.

A system with "smart" electronic ignition can also work from built-in batteries, and such a column can significantly save gas consumption, reducing it by 15 percent. The HydroPower ignition system does not have any electrical power at all - the piezo ignition in it is powered by a small water turbine, which begins to generate current from the flow of water to it.

How to install a gas flow boiler

Due to the fact that geysers are classified as objects of increased danger, special requirements are imposed on them during installation. At the same time, they include not only the requirements for the equipment, but also the requirements for the room in which the device is installed. The installation of a gas boiler itself is usually entrusted to a specialized company. During installation, a gas pipe, cold and hot water supply pipes and, in some cases, an electric power cable are connected to the device.

Choice of electric water heaters Thermex

The table shows popular models from Termex with the main characteristics:

| Name | Water volume, l | Control | Number of magnesium anodes | Mounting type | Price, r |

| Flat Plus Pro IF 80V (pro) | 80 | electronic | 2 pcs. | vertical | From 13000 |

| Flat Plus Pro IF 30V (pro) | 30 | electronic | 2 pcs. | Vertical on the wall with bottom connection | From 10000 |

| Flat Plus Pro IF 50V (pro) | 50 | electronic | 2 pcs. | Vertical on the wall with bottom connection | From 12000 |

| Flat Diamond Touch ID 80H | 80 | electronic | – | Horizontal on the wall with bottom connection | From 16000 |

| Praktik 80V | 80 | mechanical | – | Vertical on the wall with bottom connection | From 9000 |

| ER 300V | 300 | mechanical | 1 PC. | Vertical to the floor with bottom connection | From 24000 |

| Surf Plus 4500 (flow-through) | – | mechanical | – | vertical | From 4000 |

Overview of water heaters for electric heating

Manufacturers of heating devices already produce conventional boilers adapted for installation in heat supply networks. Their thermal power is increased to 12 kW, in addition, they have increased diameters of inputs for connection in the house heating system.

Heating from a boiler is not difficult to implement. Since such equipment is widely represented on the market, both by domestic and foreign manufacturers. Their choice will depend on the required type of energy carrier and the type of heating: capacitive or indirect heating. The latter are more used in autonomous heat supply schemes, so the principle applies here - the more the better. They are well used during the heating season, and

in summer for hot water supply - it is more reasonable to use combined water heaters.

The most popular models of water heaters that are used in heating systems:

- Boiler for heating Thermex Champion Titaniumheat 150 V, made in Russia, heating element, volume 150 l, price - 12190 rubles.

- Water heater for heating Gorenje TGU150NGB6, made in Serbia, heating element, volume 150 l, price - 14320 rubles.

- Ariston ABS PRO R 150 V, made in Russia, heating element, volume 150 l, price - 14970 rubles.

- Bosch WSTB 200, made in Germany, indirect heating, volume 197 l, price - 40833 rubles.

- Baxi Premier plus 150 (30 kW), made in Italy, indirect heating, volume 150 l, stainless steel tank price - 68600 rubles.

- Buderus Logalux SU160/5 made in Germany, indirect heating “coil in a coil”, DUPLEX stainless steel, volume 160 l, price - 68869 rubles.