- What are the parameters for choosing a pump for a well

- Types of pumps for lifting water to the surface

- How to choose a pump based on needs?

- Calculation of the pressure of a borehole pump

- Well characteristics accounting

- Measurement of static and dynamic levels

- Static level

- dynamic level

- Debit definition

- Formula for calculating the debit

- Specifics of submersible pumping equipment

- Vibration pump + well: yes or no?

- Guidelines for choosing a centrifugal pump

- A few words about popular models

- Characteristics

- Performance

- pressure

- Tips to know

- An example of the selection of equipment for a well

- What pumping equipment should be?

- Warranty, quality, performance

- How is the required pressure determined?

- Unit for a well 20 meters

- Pump type

- Submersible

- Surface

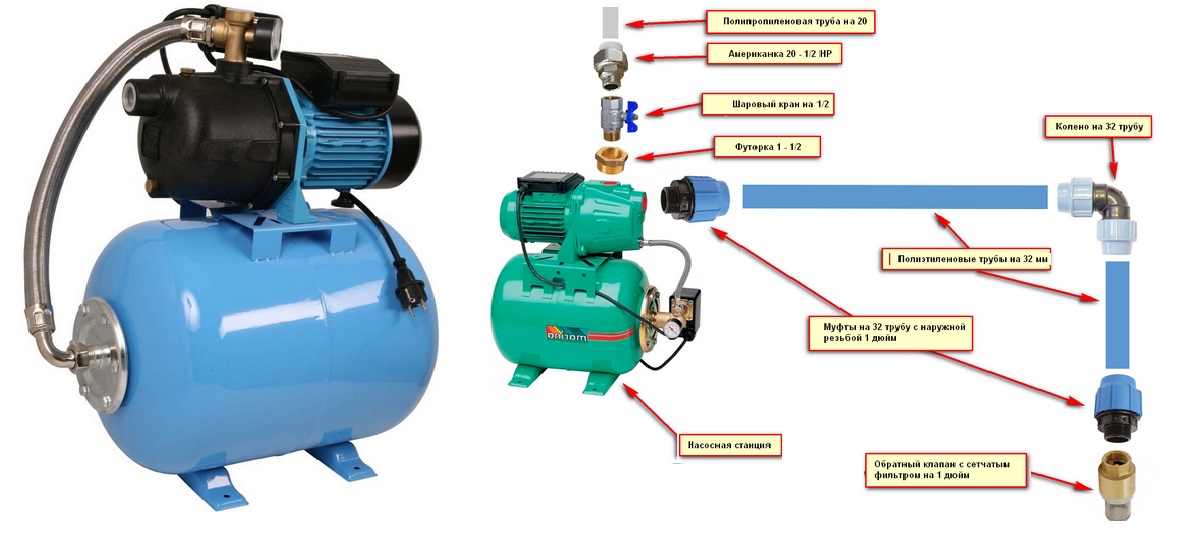

- Pumping stations

What are the parameters for choosing a pump for a well

As a rule, the owner must know to what depth the well was drilled and its diameter, the selection of the pump largely depends on this. If the owner decided to drill a well on his own, then it is recommended to determine these criteria in advance, but when the work was carried out by a specialized organization, these data are indicated in the well's passport.

Installation deep well pump.

Most pumps are designed for wells with a diameter of 3 or 4 inches (1 inch equals 2.54 cm), with the choice of the latter being much larger.

Based on the parameters of your source, we determine the following criteria:

- Water level.

What pumps are best for a well? The characteristics of the pumps must indicate the immersion depth of the unit, there are devices that operate only at a depth of up to 9 meters, and there are those that raise water from 50 meters.

If you do not know the height of the water column of your well, then you can determine it yourself using a rope with a load at the end, lowering the device into the hole to the bottom. Then it remains only to measure the dry and wet parts of the rope: the first number will show the distance from the surface to the water table, and the second - the height of the water column.

If the depth of the well is known, then it will be enough for the load to submerge a little in the water. Then it is enough to subtract the footage of the dry part of the rope from the total depth to get the height of the post.

- Well flow rate.

Each well produces a characteristic amount of water only for a certain period. This mass is called debit. The desired parameter is determined as follows: the time is recorded for which the water will be completely pumped out of the well, and then the recovery time of the water column. Dividing the second number obtained by the first, we obtain the desired characteristic.

I must say that the data calculated in this way are quite approximate, but they will be enough to select a pump.

- Performance.

Performance is an important factor when choosing a pump.

If you have not yet decided which pump choose for well, then pay attention to the performance of the unit. This factor directly depends on the owner's water consumption.

It is necessary to determine what functions the device will perform - serve only for home use or also for watering the site

This factor directly depends on the water consumption of the owner. It is necessary to determine what functions the device will perform - serve only for home use or also for watering the site.

The gradation of water delivery from modern pumps is wide: from 20 to 200 liters per minute. It is estimated that one person consumes about 200 liters per day, then for an average family of 4 people a pump with a capacity of 30–50 l / min will be enough.

If it is planned to water the site (and this is approximately plus another 2000 liters per day), then the unit should, accordingly, produce more water. So you need to choose a pump with a capacity of 70-100 l / min, of course, the price of such a device will be an order of magnitude higher.

Table for determining the flow

- Head.

Not only should a properly selected pump uninterruptedly deliver the right amount of water, but also the pressure should be such that the liquid does not flow in a thin stream, but in a normal stream, which will water the garden and serve household appliances.

The calculation of this parameter is easy to do with your own hands: the depth of the well is taken in meters, 30 meters are added to this number, it turns out the height of the water column, which the unit must master. For safety net, another 10% of the amount received is usually added.

For example, the depth of the well is 20 m, add 30 m and get 50 m, adding another 5 m (10%), we find the estimated height of the column - 55 m. So, to the question "Which one to choose a well pump with these parameters?", We answer: optimal an option would be to purchase a unit with a head of at least 60 m.

These are the main technical characteristics necessary for choosing a pump for a well

In addition to these, there are several other factors that you should also pay attention to.

Types of pumps for lifting water to the surface

Now there are several types of pumps that are used to pump liquids from deep. The main ones among them are:

- superficially installed;

- submersible vibration;

- submersible centrifugal (rotary).

The first type of equipment is characterized by the fact that the mechanism is on the surface, while an attached pipe (hose) is placed in the water, through which water is sucked in. Surface-mounted pumps have a limited liquid lifting depth (up to 9 meters), so they cannot be considered as full-fledged downhole equipment. With the help of such devices, it is possible to raise liquid only from surface aquifers (perch water), where the quality of water is suitable only for irrigation.

Submersible vibration pumps, which work due to the movement of the membrane and the valve system, are structurally simple, inexpensive and can pump water from a depth of up to 30-40 meters (depending on the power of the model). However, it is categorically not recommended to install such equipment in aquifer deep wells for several reasons:

- strong vibration destroys the well structure;

- the strong turbulence that occurs during operation raises silt and sand from the bottom of the water mine, which pollute the water;

- the shape of vibrating pumps is not adapted to use in narrow casing pipes, so the device often gets stuck in them, after which it is necessary to carry out expensive repair and restoration work.

In water-bearing wells of medium and large depth, only rotary type equipment is used. Centrifugal submersible pumps are specifically designed to work in narrow borehole conditions and, if properly maintained, last from 10 to 20 years. What is this type of device, we will consider further.

How to choose a pump based on needs?

Scheme of a submersible type drainage pump.

When planning to arrange a well and install a submersible pump for it, it is necessary to take into account what needs will have to be met

Such equipment can supply water from a depth of 350 m, but is it always necessary for private households? Attention should also be paid to the diameter of the well itself, to the performance of the equipment.

Among the most important parameters on the basis of which the choice of device is made, it is necessary to note the pressure and flow, i.e., the need for water for the site itself and those living in a country house. The indicators are calculated based on the number of water intake points, the level of water consumption for them. Typically, for a private house, the following parameters are used:

- for the kitchen - up to 500 liters per hour;

- for a washbasin - up to 60 liters per hour;

- for the bathroom as a whole - up to 300 liters per hour;

- for a toilet cistern - up to 80 liters per hour (for economical drain systems, this value is much lower);

- for a shower - up to 500 liters per hour;

- for a bath or sauna - up to 1000 liters per hour;

- if it is necessary to water flower beds, vegetable gardens and other things - from 3-6 cubes for 1 m².

Calculation of the pressure of a borehole pump

The pressure is calculated according to the following formula:

Head = (distance from the point of installation of the pump in the well to the surface of the earth + horizontal distance from the well to the nearest draw-off point * + height of the highest draw-off point in the house) × water resistance coefficient **

If the borehole pump will be operated together with a storage tank, then the pressure value in the storage tank must be added to the above formula for calculating the head:

Head = (distance from the point of installation of the pump in the well to the surface of the earth + horizontal distance from the well to the nearest draw-off point + height of the highest draw-off point in the house + pressure in the storage tank ***) × water resistance coefficient

Note

* - when calculating, keep in mind that 1 vertical meter equals 10 horizontal; ** - coefficient of water resistance is always equal to 1.15; *** - each atmosphere is equal to 10 vertical meters.

everyday mathematics

For clarity, we will simulate a situation in which family of four a person needs to pick up a pump for a well 80 meters deep. The dynamic level of the source does not fall below 62 meters, that is, the pump will be installed at a depth of 60 meters. The distance from the well to the house is 80 meters. The height of the highest draw point is 7 meters. The water supply system has a storage tank with a capacity of 300 liters, that is, for the entire system to function inside the accumulator, it is necessary to create a pressure of 3.5 atmospheres. We believe:

Pressure \u003d (60 + 80 / 10 + 3.5 × 10) × 1.15 \u003d 126.5 meters.

What pump is needed for the well in this case? - An excellent option would be to purchase Grundfos SQ 3-105, the maximum pressure of which is 147 meters, with a capacity of 4.4 m³ / h.

In this material, we have analyzed in detail how to calculate a pump for a well. We hope that after reading this article, you will be able to calculate and select a borehole pump without outside help, which, thanks to a competent approach, will last more than one year.

To organize the water supply of a private house, before installing pumping equipment, it is first necessary to calculate its parameters. In this case, it is necessary to take into account the technical characteristics of the source, the distance to the consumer and the volume of water intake. A homeowner who independently mounts a water supply line to the house does not need to calculate the pump for a well according to complex formulas - for This is the purpose of the online calculators posted on the web.

Rice. 1 Online calculator for determining the volume of delivery - appearance

Their significant drawback is the approximateness of the results obtained - many important parameters that affect the final result are not included in the input data. Almost all online calculators calculate only one of the parameters: lift height, performance, or required line pressure, the rest of the data has to be determined in other ways. Another problem is choosing an accurate and reliable calculator from the many options available online.Therefore, the most correct solution to the question of how to calculate a pump for a well is to calculate its parameters using formulas using loss tables and use calculators as an aid to verify the correctness of the calculations.

Rice. 2 Online - calculator for calculating the pump for water supply

Well characteristics accounting

If it was drilled on an official request by employees of a specialized organization, the owner should be given a passport indicating all performance characteristics. However, wells are often drilled by brigades of "shabashniks", or the work is carried out on their own. In addition, after a long period of inactivity or non-use of the well, its characteristics may change. This requires re-determining the parameters in order to select the right equipment and avoid possible errors.

The main characteristics of wells are:

- static and dynamic liquid levels

- productivity (debit)

These indicators will allow you to navigate when choosing a pump, reasonably select a certain type of device. Otherwise, the selection will be made at random, which will create all the possibilities for a quick failure or impossible conditions for work. Let's take a closer look at well performance.

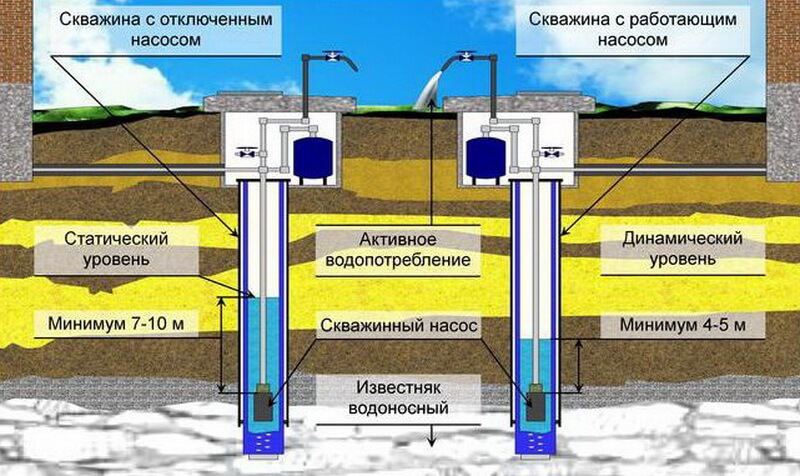

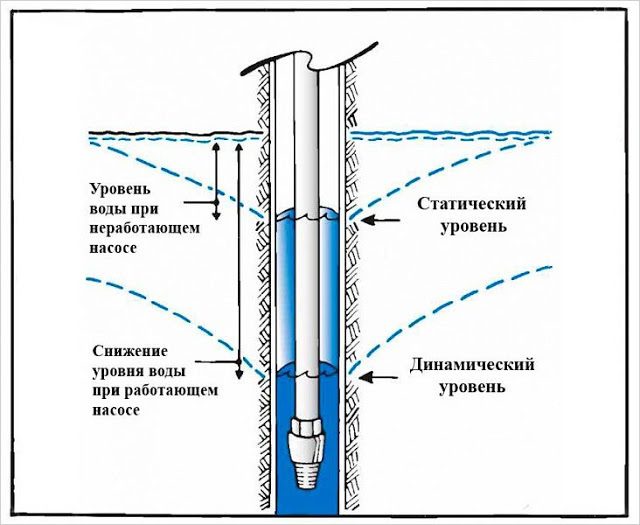

Measurement of static and dynamic levels

Static and dynamic levels are indicators that are compared with each other. Individually, they do not provide complete information, especially since in many wells they do not differ from each other. This indicates high performance when the water arrives immediately and does not change its level.

Static level

You can measure the static level yourself, using twine or twine with some kind of load at the end.Its shape should be a kind of dome (tube or cone). This is necessary so that when it comes into contact with the surface, a characteristic sound is heard, by which the point of contact is determined.

After that, measure the length of the string

It is important that water is not taken from the well for at least 1 hour before the measurement (the longer the holding time, the more correctly the static level will be determined)

dynamic level

In order to determine the dynamic level, the same actions are performed, only instead of an hour (minimum) exposure, it is necessary to actively pump out water, waiting for the moment when its amount stops decreasing. This is the dynamic level, which must be measured immediately, without waiting for the replenishment of the liquid volume.

Debit definition

This is the main indicator that determines the well's ability to meet the water needs of its users. It may change due to natural factors:

- seasonal fluctuations in groundwater levels

- soil composition

- thickness (thickness) of the aquifer

In addition, the well flow rate is greatly influenced by technological factors:

- condition of pumping equipment

- clogged filters

- depressurization of suction (or supply) pipelines

Well flow rate is one of the main criteria for choosing a pump. If its performance is higher than the amount of water, there will be constant interruptions in the supply of liquid - for some time the pump pumps water properly, and then stops.

Formula for calculating the debit

The formula for calculating the flow rate is as follows: D=H*V/(Hd-Hst), where:

- D - debit;

- H is the height of the water column;

- V - pump performance;

- Hd is the dynamic level of the well;

- Hst is the static level of the well.

It is recommended to calculate the amount of water at the stage of exploration and search for an aquifer. Otherwise, you will have to sort out the pumps, achieving an optimal match between the parameters of the well and the equipment.

It is noteworthy that the well flow rate can be increased. To do this, different methods are used, from increasing its depth (before entering the lower aquifer) to various influences (chemical or technical) on the layer used. If the issue cannot be resolved, the well is transferred to another location.

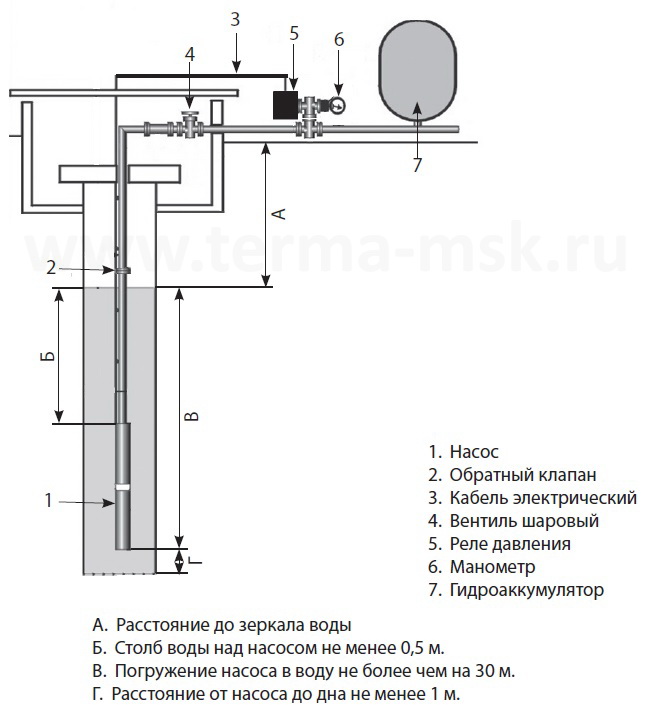

Specifics of submersible pumping equipment

According to the type of device, centrifugal and vibration pumps are distinguished. In the first, a rotating disk with blades is used to supply water, and in the second, a special membrane that transfers water with the help of numerous vibrations. These design features are important because they affect well integrity in different ways.

Vibration pump + well: yes or no?

Is it possible to install a vibration pump in the well? These models are relatively inexpensive, easy to operate, and have performance that is suitable for a significant number of wells.

Many experts categorically object to the use of any vibration technique in the well shaft. However, owner reviews report that pumps of this type are used quite successfully without any damage to the structure. So which pump - vibration or centrifugal - for a well better?

The objections of experts are well founded. Prolonged vibration exposure almost always negatively affects the state of surrounding objects. The well is no exception.

Vibrations from the pump located next to the filter affect the condition of the casing and the surrounding soil, which are gradually destroyed. Vibration can cause a significant acceleration of the processes of silting and sanding.

But it doesn't happen right away. Typically, wells successfully resist vibration for some time. Therefore, with the help of such a pump, it is possible to pump the well, and clean it, and successfully operate it without visible damage.

But destruction from vibration still occurs, although not too quickly. The constant use of a vibration pump can significantly reduce the life of the structure.

If necessary, the use of vibration models is quite acceptable, but only as a temporary option. But at the first opportunity, such a pump should be replaced with a safer centrifugal device.

Guidelines for choosing a centrifugal pump

To do this, you need to carefully study the technical passport of the centrifugal device and find out several important points:

- what is the performance of the pump;

- whether its dimensions are suitable for the well;

- from what depth can he raise water;

- what are the features of its installation and operation;

- how and under what conditions warranty service is carried out, etc.

Usually consultants give quite professional recommendations when choosing such equipment. It should be remembered that many manufacturers indicate limiting rather than average characteristics for pumps, so you need to take into account some margin of operational life.

Directly in the marking of a domestic pump or in the technical passport of a foreign one, two numbers that are important for choosing are indicated. The first (in example 55) is the flow in l/min, the second (75) is the maximum head in meters

A few words about popular models

If the decision is made to use a vibration pump, most likely, “Kid” or “Brook” will be bought. These models are distinguished by good performance, resistance to breakdowns and quite affordable price.

They are easy to clean or repair with your own hands. But for permanent use, vibration technology is not suitable, it must be replaced as soon as possible.

Vibration pump "Kid" is a popular, but not very suitable choice for a well, since the vibrations of the device can cause its destruction

Among the popular brands of submersible centrifugal pumps, it is worth noting "Aquarius" and "Vodomet". They are very similar, but according to user reviews, Aquarius noticeably wins in quality and durability, although it costs more.

However, the Water Cannon also has its adherents. If you are lucky enough to get a well-assembled model, it will show quite decent results.

Submersible centrifugal pumps of the Aquarius brand have proven to be reliable and durable. well equipmentable to handle high loads

Special well pumps will cost a substantial amount, but such costs will fully justify themselves over time. As an example of such a technique, it is worth noting the 3STM2 and 4STM2 models manufactured by TAIFU.

Characteristics

The main parameters by which the pump is selected are pressure and performance.

Performance

The performance or flow rate of a pump indicates how much water it can pump per unit of time. It is expressed in liters per minute or cubic meters per hour.

The amount of water you need is determined in different ways:

- It has been experimentally revealed that one person needs from 200 to 400 liters of water per day for a comfortable existence. These figures simply need to be multiplied by the number of people permanently residing in the house and the result converted to the required unit of measurement.

- To find a suitable water supply pump, selection should be carried out according to the maximum flow rate, when water is consumed simultaneously by several or all available points of analysis. To do this, add up the consumption of all these points, including washing machines and dishwashers.

Table of water consumption by different consumers

For irrigation, it is more convenient to use a separate pump, since its use is limited by the duration of the warm season.

In this case, the maximum flow rate must be correlated with the flow rate of the well: there should be enough water in it for the normal operation of the pump. If it pumps out water faster than it enters the source, then the equipment will run idle with the risk of overheating. In the absence of protection against dry running, this is fraught with breakdowns.

The dynamic water level in the well depends on the performance of the pump

pressure

The pressure indicates how high the pump can lift the water. Measured in meters.

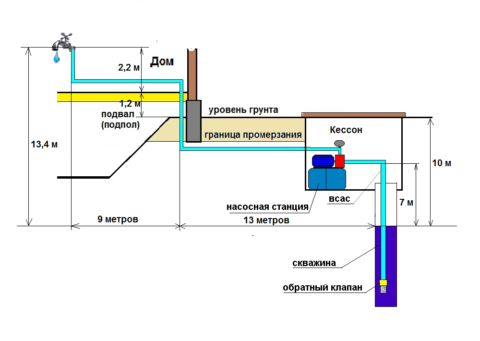

To calculate the optimal pressure, the instruction requires that several factors be taken into account:

Outflow pressure. This is the pressure of water flowing from a faucet. Its optimal value is 2 bar or about 20 meters of water column;

Spout pressure for comfortable use of plumbing fixtures should be at least 1.5-2 bar

Height difference from the water surface in the source to the highest point of water intake;

In this example, the height difference is 13.4 meters

Pressure losses in pipelines. They depend on many factors, including the length of the pipes, their diameter, material of manufacture, the number of turns, filters, valves, etc.

Metal-plastic water pipes

To correctly determine each of these parameters, you need to know the dynamic level of the well and have a detailed scheme for distributing water from the source with marked distances.

Plumbing scheme (interior)

The most difficult thing is to calculate the pressure loss. A simplified method suggests simply multiplying the length of the pipeline by a factor of 0.1.

But it is better to contact the consultants of the store selling pumping equipment. They usually have special programs with which, based on all available data, the main characteristics of the pump are calculated.

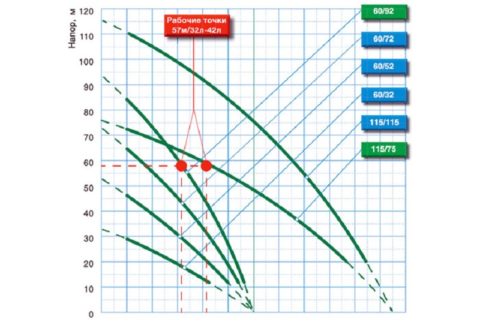

It is also worth noting that with an increase in flow, the pressure in the system decreases, and vice versa. This dependency is shown in the performance chart supplied with each pump model. The model is suitable for you, on the graph of which the parameters you calculated intersect at one point.

Of the six pumps shown in the graph, only two are suitable for operating parameters.

Tips to know

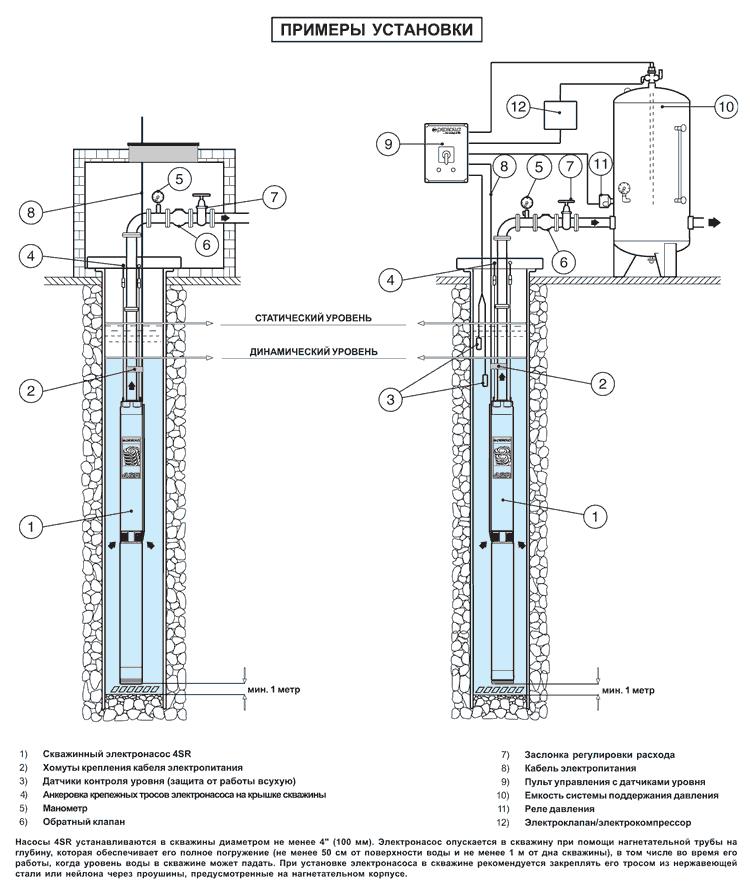

It is important to know the distance from the base of the earth to the filter, since the pumping structure must be installed at least 1 m away from the well filter. Even if the manufacturer of the pumping equipment recommends reducing the distance to 0.4-0.5 m, you should ignore these instructions and install the pump at a distance of 1 m

The thing is that after a while a natural filter is formed around the installed filter, which consists of large cells of sand. The operation of a submersible structure close to the filter can lead to the fact that a large amount of fine sand will intensively enter the well through it. Sanding is a common situation in Russia. A large number of wells that were not made quite correctly, as well as the misuse of submersible pumping structures, have contributed to the fact that today a large number of wells do not allow the installation of submersible structures that are not protected from sand.

In such cases, it is recommended to use well pumps that will not become clogged with sand and do not need to be constantly lifted to the ground for cleaning. If the well is new and made correctly, then you can purchase a borehole structure.

Such devices are less prone to clogging, since the functioning centrifugal wheels will be able to pass large mechanical particles.

It should be taken into account the fact that the parameters of the pump design after some time fall due to the mechanical wear of the functioning wheels.

Some manufacturers indicate in the documentation the maximum parameters for performance and pressure. In this case, the pump may be selected incorrectly. The actual operating point of the pump design is reflected in the nominal parameters. The point is located approximately in the center of the working curve of the structure.

Devices for wells are special mechanisms that involve a rather complex immersion process and the subsequent dismantling process. They will work in pipes that are completely filled with liquid.That is why the issue of the quality of the pump design must be approached with all seriousness. High-quality fixtures from well-known manufacturers are able to work for decades without any problems.

An example of the selection of equipment for a well

In order for the choice of a pump for a well to be made correctly, you can use the following example.

Scheme for determining the height of the pump.

Initial data for the well:

- the total depth is 100 m;

- dynamic water level - 70 m;

- the water static level is 75 m;

- water well diameter is 133 mm;

- flow rate is 3 m³/h;

- filter installation depth - 95 m;

- the equipment control unit is located at a distance of 25 m from the well;

- from the well to the entrance to the house, the distance is 20 m;

- a head is used to design the wellhead;

- the highest point for water intake is 8 m from the ground surface (3rd floor of the house);

- power is supplied from a 220 V network, the system is used single-phase, there is a possibility of drawdowns up to 190 V.

The selection of a pump for a well is carried out in this way:

- First, it is necessary to take into account the number of draw-off points with an allowable flow rate limit of 2.6 m³ / h. This amounts to 5-6 cranes open at the same time, the performance of which is average. Even for a large house, this amount is enough.

- The depth for installing the pump in the well is 72 m.

- For the consumer, a comfortable pressure at the highest point should be 2.5 bar. Given a pressure loss of 1 bar on the rise, a value of 1.5 for the high point is quite acceptable.

- For the riser pipe, the total length in this case will be 92 m, and for the supply cable to the control equipment panel, the length is 97 m.

- The diameter of the cable is 5 mm, its length is - 72 m + 2 m + 4 * 2 m (for cable loops) = 82 m.

- For a plastic water pipe, the diameter is best taken to be 40 mm, while the total loss will be approximately 4 m if the flow velocity is 0.8 m/s.

- Losses during the operation of the filters will be approximately 10 m, that is, about 1 bar.

- The required total head is H=1.5*10.2+70+(10+4) = 99 m.

What pumping equipment should be?

Taking into account all the above data, the well can be equipped with the following pumping equipment:

- Pump for 1.1 kW, power cable for 4 * 6 m³, while the voltage loss will be 2%.

- Pump for 1.5 kW, power cable for 4 * 6 m³, voltage loss will be 3.1%.

- 1.5 kW pump, 3 * 6 m³ power cable, voltage loss will be 2.9% along the entire length.

- Pump for 1.4 kW, power cable for 3 * 6 m³, loss in length will be 2.7%.

For the presented system, it is best to take a 150-liter accumulator for the first 3 options. At home, it is recommended to install a voltage regulator of 5 kW.

The choice of a pump for a well for water is a responsible process. Not only the characteristics of the pumping equipment itself are taken into account, but also numerous parameters. This is the length of the cable, the presence of a hydraulic accumulator and other elements of the system

During the selection, attention should be paid to the flow of water for the house and the site. Only in this case can the pump be considered fully suitable for a particular well.

In country houses, it is almost impossible to connect to the central water supply. What to do? Conduct your own water supply system, make a well or well. The second option is more convenient, but requires solving a lot of different issues.

Warranty, quality, performance

The success and popularity in the market of centrifugal submersible pumps for wells is due not only to their technical parameters, the popularity is primarily due to the reliability and unpretentiousness of the equipment. This approach to the development of the pump made it possible to saturate the market with both expensive models of well-known companies and offer the consumer relatively inexpensive models in an affordable price range.

Structurally, almost all pumps have lower engine position, and a multistage pump in its upper part.

Expensive models are characterized not only by better execution of the outer elements of the case, but also by the installation of a wheel with blades made of stainless steel or a high-quality alloy that is not susceptible to corrosion.

When choosing a particular model, a lot can be said about how the pump housing is made:

- how well the connections are made;

- the parts are connected by a simple metal connection or high-quality tin soldering of the joint takes place;

- the mesh filter is made of perforated metal or wire mesh;

- mesh filter opening size;

- the quality of rubber insulating elements, their fit to the electric cable;

- thread in the outlet, clarity of cuts, number of turns, surface treatment.

The manufacturer's warranty is also important.For well-known companies, this is not just a 1-year full warranty, it is also a service book with a mandatory list of pump maintenance operations, an operating and installation manual.

How is the required pressure determined?

This is the most important indicator of pumping downhole equipment. If you choose a device with insufficient pressure, the water simply will not reach the point of intake. Too powerful a pump will run half empty, which will lead to premature wear.

So it is important to calculate the required pressure, close to the ideal indicator.

How are the calculations made? To do this, the following data is summarized:

- installation depth of the pump relative to the mouth (head);

- height of the extreme point of water intake;

- the distance from the house to the well, divided by 10;

- overpressure (needed to create pressure at the points of water intake), which is equivalent to approximately 20 m of head.

The resulting amount will be an indicator that you should focus on when choosing a device that is optimal in terms of power.

Unit for a well 20 meters

The first and most important step when choosing a pump is to familiarize yourself with the passport for the well and recommendations for choosing a device.

If they are missing, the first step is to pay attention to the diameter of the pump and casing. Each deep device has its own marking

Many consumers prefer vibration models, but they are not very reliable. The best option is to install a submersible pump. For the right choice, you need to do the calculation water column height.

Things to consider:

- well depth;

- Distance from the pump to the bottom;

- Pressure;

- Pipeline length.

One of the most reliable and at the same time budget options is Unipump from a Russian-Chinese manufacturer. The average price category distinguishes the Belamos model from the Belarusian manufacturer. Aquario devices belong to a higher price category.

Pump type

There are two main types of pumps: submersible and surface. To make a choice, you need to know the depth of the source from which the water will rise.

Sources of autonomous water supply and their depth

Submersible

Submersible pumps lift water from a depth of more than 8 meters. They are used in artesian wells and deep wells.

When choosing equipment, you need to consider the following points:

Execution quality. Since water often contains mechanical impurities in the form of sand and silt, the equipment immersed in it is subjected to their abrasive effects. To resist it, the main working parts must be made of modern composite materials and high-quality corrosion-resistant stainless alloys.

The materials from which the pump is made must be of high quality

The size. The bulk of domestic well pumps are available with a diameter of 3 or 4 inches. According to the diameter of the casing pipe of the well, from which the water supply is carried out, the selection of the pump is carried out. They must match.

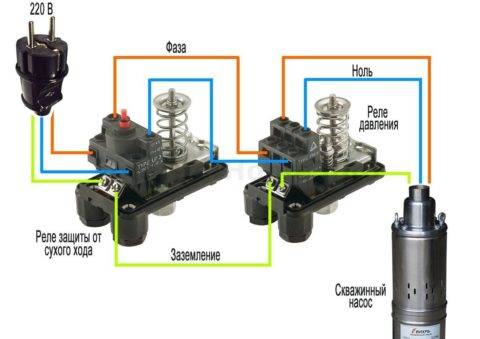

Scheme of connection of automatic protective systems

Surface

If water will be supplied from a well or a shallow sandy well, the selection of pumps for water supply is expanded by surface-mounted units. They can be located in a technical building next to the source, in the utility room of the house or in the caisson of the well.

They are connected to the source by a pipeline laid below the freezing level of the soil.But its length due to pressure loss should not exceed 200-250 meters.

There are also high demands on the resistance of such equipment to sand, since the content of suspended solids in shallow sources is higher than in artesian wells.

The advantages of surface pumps include a simple installation, which is easy to do with your own hands.

Wiring diagram

- And to the minuses - a high level of noise during operation. Therefore, they are placed in utility rooms remote from living rooms.

- In addition, they require protection from sub-zero temperatures and precipitation, so these rooms must be closed and heated or well insulated.

Grundfos MQ 3-35 pumping station with silent motor

Surface units can also be used as booster pumps for water supply if the pressure in the network is insufficient for the normal operation of all water-consuming devices.

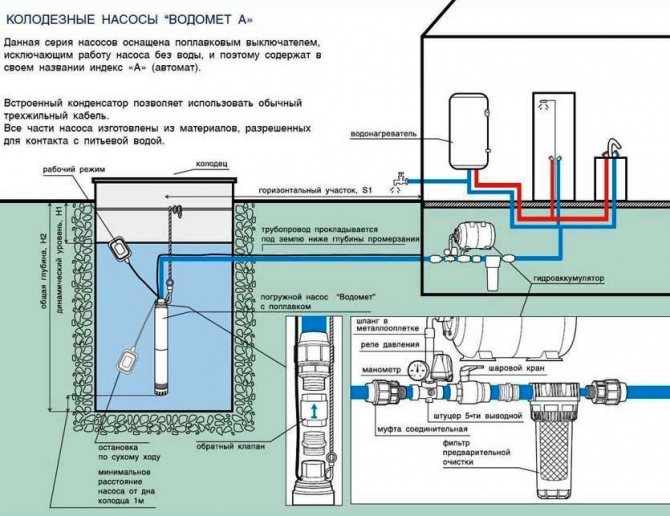

Pumping stations

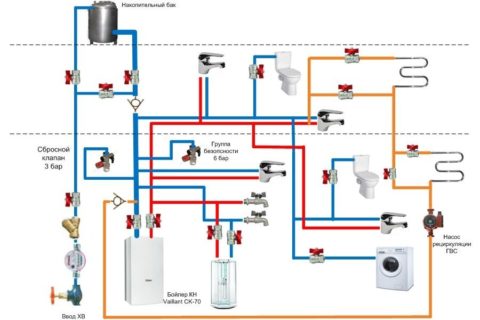

By itself, a pump for home water supply will not be able to provide a constant pressure in the system, maintain working pressure in it, and if the source's performance is low, then supply interruptions will occur.

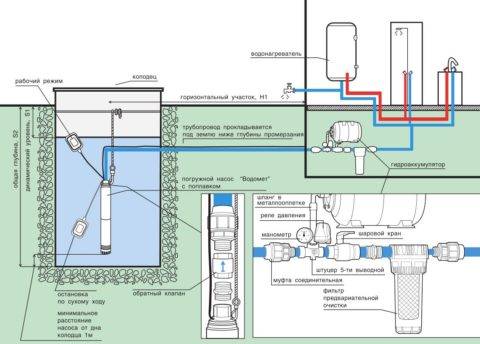

The installation of a pumping station will help to solve all these problems, which, in addition to the pump itself, includes a hydraulic accumulator, a storage tank and automation that regulates all indicators in the system and is responsible for turning the pump on and off in a timely manner.

On the photo - the simplest pumping station in basement of a private house

You will read more about how all this is mounted and works in other materials on the site.We only note that such a scheme allows the use of not only taps in the domestic water supply system, but also storage water heaters and household machines (washing machines, dishwashers, car washes, etc.).