- Available trunk gas

- What is more expensive: propane-butane or pellets?

- Ease of connection

- Plinth entry

- Heating with coal or wood

- General Features

- Manufacturer

- The cost of heating equipment

- The choice of energy carrier, taking into account ease of use

- Service

- Warehousing

- Ease of use

- How to choose a gas tank

- Where is the efficiency higher and what is more expensive - a kilowatt of propane butane or pellets

- Features of the operation of a gas-pellet boiler

- Which is better - a combined boiler or two separate ones?

- Features of the operation of a gas-pellet boiler

- Which is better - a combined boiler or two separate ones?

- Consumption of liquefied gas and pellets for heating

- CONCLUSIONS - BENEFITS!

Available trunk gas

If a house is being built on a plot to which communications have already been connected (in particular, main gas), homeowners usually do not puzzle over the problem of choosing fuel. Modern gas equipment is convenient in terms of operation: fuel is supplied automatically, which means that the homeowner does not have to constantly monitor the combustion process.

Mains gas is currently the cheapest way to heat a house. According to calculations, the cost of 1 kWh of gas heating is 0.87 rubles. A well-insulated house with an area of 200 m² will “spend” about 34,680 rubles per season.

Calculation

The specific heat of combustion of domestic gas is 9.6 kWh/kg. Gas tariffs in the Moscow region, effective from July 1, 2017: price for 1 m³ - 5.34 rubles, density 0.75 kg / m³, therefore, the cost of 1 kg is 5.34 / 0.75 \u003d 7.12 rub. So, 1 kWh costs 7.12 / 9.6 = 0.74 rubles, with a boiler efficiency of 85%, the actual cost of 1 kWh will be 0.74 / 0.85 = 0.87 rubles.

The main difficulties in this type of heating:

1. Long-term approvals that require a large package of documents. Waiting for a connection can take several years. During this time, it is necessary to obtain all the necessary permits, develop and agree on the project.

2. High connection cost. If the distance to the main is more than 200 m, it is cheaper to use the second most efficient heating method - a heat pump. In our experience, there were objects where gas even passed along the border of the site, but the gas service billed such a bill for supplying gas to the house that it was more profitable to install a heat pump along with a geothermal circuit.

3. The annual increase in gas prices, which is faster than the increase in electricity prices.

In addition to connecting gas, it is necessary to purchase a gas boiler, install a chimney and equip a boiler room that is commensurate with the capacity of the boiler according to the standards with supply and exhaust ventilation. You will also need to purchase a gas meter, which the gas supplier must check. In addition, once a year it is necessary to have the system checked by the gas supply organization.

In addition, our country still has a huge number of settlements where there is simply no mains gas.To date, among the most affordable alternative heating options for the average homeowner, one can indicate: liquefied gas (pumped into a gas tank), pellets, diesel fuel and electric energy.

In addition, the heat pump segment has been actively developing lately - judging by the statistics, every year more and more people choose a heat pump as a source of heat in the house because of its advantages. For example, in Scandinavia, heating private households with a heat pump has already become traditional.

What is more expensive: propane-butane or pellets?

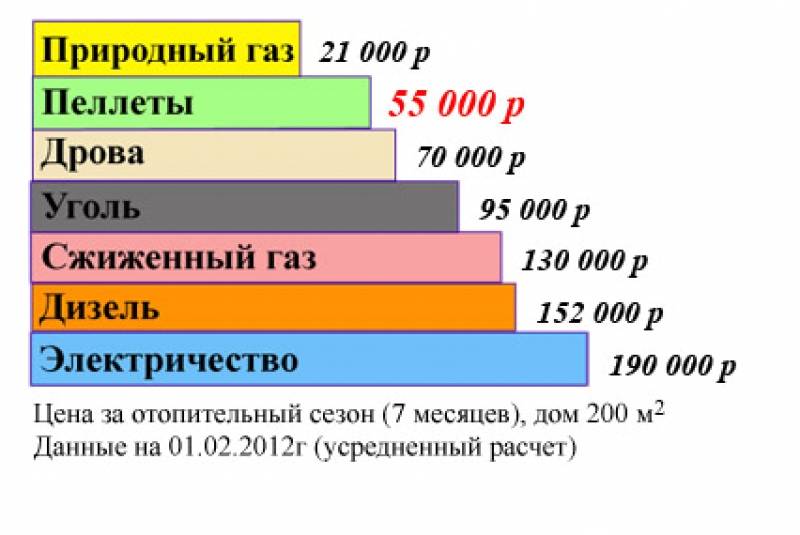

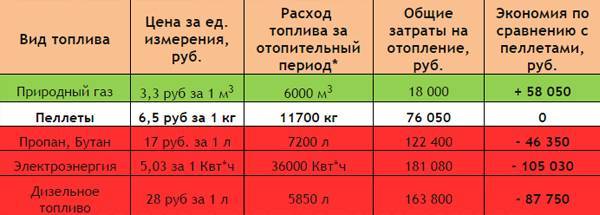

When burning 1 kg of solid fuel, 5 kW of thermal energy is released, and 12.8 kW is obtained from 1 kg of liquefied gas. Moreover, the efficiency of propane-butane is higher than that of pellets. However, fuel pellets are distinguished by a lower price - about 7 rubles /kg compared to 27 rubles./kg. That is, 1 kW of pellets costs approximately 1.4 rubles, while the cost of 1 kW of propane-butane is 2.1 rubles.

So, we found out that LPG is 1.5 times higher than that of fuel pellets. However, when choosing a heating option, one should take into account not only the upcoming costs, but also the performance of the systems. The gas tank is usually located underground, due to which it does not require free space on the plot of land. To store pellets, you need a special room in which the humidity of the air is maintained at a minimum level. In addition, fuel pellets must be periodically loaded into boilers. The gas tank, in turn, is refueled no more than twice a year.

Thus, pellets are best used in small businesses, especially in the woodworking industry.Fuel pellets can be made from wood residues, obtaining waste-free production. In addition, in such conditions it is easy to organize a suitable place for storing fuel. But for country houses, autonomous gasification is more suitable. Despite the fact that 1 kW of propane-butane is more expensive than pellets, the convenience during operation of such a system covers this minus.

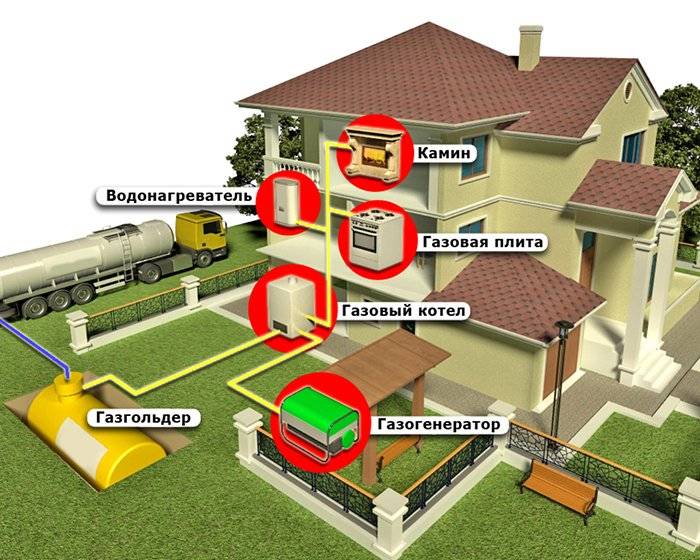

A universal or multi-fuel boiler for pellets and gas is a heating equipment with the ability to quickly switch from one type of fuel to another. The refurbishment takes place by replacing the burners. In most models, a built-in electric heating element is also provided.

Ease of connection

Connecting electricity is nowhere easier. With one caveat: the local power grid must "pull" your heating system. If it doesn’t “pull”, then it’s bad, it’s just as difficult to install another network as it is for main gas. Then it's better to immediately look at the gas.

Carrying out autonomous gas is a little more difficult. The installation team at a distance of 10 meters from the house will dig a foundation pit and install a concrete base. On it, with the help of a manipulator, a gas tank will be placed and the tank will be fixed with anchors. After backfilling with soil, only the cover of the carpet will remain on the surface.

98% of installations are carried out in 8 hours. Separately, specialists will connect gas to the heating system in the house. Further, as in the case of electricity, liquefied gas is supplied to the heating element without human intervention.

Plinth entry

During seasonal swelling of soils and settlement of the building at the basement input (the place where the gas pipeline enters the house) and the connection of the gearbox with the gas pipeline, stresses can occur that can destroy the structure.Stainless steel bellows expansion joints are used for stress relief.

The AvtonomGaz company uses all-welded structures and bellows compensators for soil movement. Gas tanks from other manufacturers are used in combination with less reliable screwed socle entries, non-ferrous metal valves and are not equipped with a bellows compensator.

| AvtonomGas | Eurostandard gas holders | Sold under the FAS brand | RP, RPG and other Russian gas tanks | |

|---|---|---|---|---|

| Plinth entry | All-welded | On threaded connections | On threaded connections | On threaded connections |

| Plinth faucet | Steel Broen -40°C/+ 40°C | Non-ferrous metal 0°C/+40°C | Non-ferrous metal 0°C/+40°C | Non-ferrous metal 0°C/+40°C |

| Bellows expansion joint | Yes | Not | Not | Not |

| The period of trouble-free service of the socle input | Lifetime Warranty | Less than 5 years | Less than 5 years | Less than 5 years |

Heating with coal or wood

Firewood and charcoal have the same disadvantages. They need to be loaded very frequently (so often that a large house might need a stoker), they require regular ash cleaning, and they take up a fair amount of yard space to store. In addition, they also emit a strong odor.

Frequent download. Firewood needs to be loaded into the heating system three to four times a day. During the season, this will take at least hours. More than three working weeks of continuous physical labor worked out from start to finish. Not surprisingly, many people prefer to find a stoker. However, this in turn affects the price.Taking into account the payment of the stoker, the annual heating of a house of 100 square meters with the help of firewood will cost. This is more than the same amount for diesel fuel () or electricity ().

Coal is not particularly better in this sense. It must be loaded into the heating system two to three times a day, that is, a little less than firewood. As a result, the time spent (and, accordingly, money, if you have to pay the stoker) turns out to be slightly less than when using firewood, but the difference is insignificant: for heating a house with an area of 100 square meters, taking into account the payment of the stoker.

In fairness, it should be noted that this problem has a partial solution. There are special boilers with a bunker, in which coal is refueled not several times a day, but only once every three to four days. This is a significant improvement compared to refueling every few hours, but against the background of propane-butane or even diesel fuel, it looks rather pale.

Warehouse place. A feature of firewood is the need for a large room for storage and drying. So that up to 40% of energy is not spent on evaporation of moisture, they must be dried for three years. A large room will occupy part of the site, which could otherwise be found to a more useful use. Coal storage also requires a significant area.

Danger of poisoning. An unpleasant smell is a constant companion of any type of solid fuel, but in this case we can talk about a threat not only to smell, but also to life. If the boiler room is located directly in the house, when using solid fuels, the risk of carbon monoxide poisoning cannot be completely excluded.

General Features

Equipment systems work according to the general principle - fuel enters the burner, the coolant (most often water) is heated. The liquid is distributed to all elements of the heating system.

The operation of the gas tank and pellet boiler is almost completely automated. The owner sets the desired temperature that the device must maintain.

The gas tank runs on natural liquefied gas. The material is completely environmentally friendly, no harmful hazardous waste is produced during the application. The pellet boiler runs on clean natural fuel, so the operation of the equipment does not pollute the environment.

Manufacturer

The Polish plant Chemet, which manufactures gas tanks AvtonomGaz, has more advanced equipment for the production and quality control of gas tanks than its competitors.

The fact is that Chemet is the only company in the European Union that is allowed to manufacture vessels for especially hazardous substances under ultra-high pressure (up to 150 bar). The accident of such a vessel can lead to an ecological catastrophe. To prevent possible environmental problems, the European Union is helping Chemet finance the equipment of laboratories and control lines, research and development work. Other companies are deprived of such state support.

Unlike other manufacturers, Chemet carefully controls the distribution and installation of its products. In Russia, it is carried out only by the AvtonomGaz company and dealers who have been trained at the plant itself. This removes doubts about the qualifications of specialists who are engaged in installation. Gas tanks from other manufacturers can be installed by anyone, so their qualifications are unpredictable.

| AvtonomGas | Eurostandard gas holders | Sold under the FAS brand | RP, RPG and other Russian gas tanks | |

|---|---|---|---|---|

| Manufacturer | Manufactured at the Polish Chemet plant specifically for AvtonomGaz | Made in the EU at factories in the Czech Republic, Bulgaria, Italy | Made in Russia | Made in Russia |

| Factory Qualification | Chemet is the only company in the European Union authorized to manufacture vessels for highly hazardous substances under ultra-high pressure (up to 150 bar) | The factories produce vessels for liquefied petroleum gas under pressure up to 16 bar, accidents in which do not pose an environmental hazard. | The plant manufactures vessels for liquefied petroleum gas under pressure up to 16 bar, accidents in which do not pose an environmental hazard. | The factories produce vessels for liquefied hydrocarbon gas under pressure up to 16 bar, accidents in which do not pose an environmental hazard. |

| Manufacturer experience | Over 65 years | About 10 years | About 5 years | Less than 40 years old |

| Geography of application of the manufacturer's products | EU, Norway, Middle East, Russia | Europe, Russia ("gray" dealers) | Russia | Russia |

| Distribution and installation control | Gas tanks manufactured by Chemet are installed only by AvtonomGaz and dealers who have been trained at the factory (service centers) | The manufacturer does not control the installation and distribution of products and does not train specialists; there are no authorized service centers in Russia | The manufacturer does not control the installation and distribution of products and does not train specialists. | The manufacturer does not control the installation and distribution of products and does not train specialists. |

| Suitability of the gas tank for operation in Russia | Gas holders AvtonomGaz, manufactured at the Chemet plant, are designed specifically for central and northern Russia. | Suitable for operation in the southern regions of Russia (Crimea, Krasnodar Territory, etc.), use in central Russia and the northern regions is uncomfortable. | Fashimmash gas holders are suitable for operation in central and southern Russia. | Russian gas tanks are suitable for operation in central, southern and northern Russia. |

| Warranty for equipment and installation | Lifetime Warranty | 1 year | 1 year | 1 year |

| Annual maintenance cost | Is free | 12-20 thousand rubles | 12 thousand rubles | more than 20 thousand rubles |

The cost of heating equipment

An approximate estimate for a house with an area of 100 meters 2:

| Electric boiler and water heater | |

| Aluminum radiator (64 sections for 340 rubles) | 21 760 |

| Accessories for radiators | 5 600 |

| Materials for heating installation | 11 000 |

| Electric boiler 9 kW | 9 110 |

| Circulation pump | 3 000 |

| Water heater 80 l | 7 500 |

| Total by materials: | 57 970 |

| Heating system installation | 28 000 |

| Double-circuit gas boiler | |

| Aluminum radiator (64 sections for 340 rubles) | 21 760 |

| Accessories for radiators | 5 600 |

| Materials for installation of heating, boiler room | 10 000 |

| Gas double-circuit boiler 11 kW + chimney | 28 100 |

| Total by materials: | 65 460 |

| Installation of heating system, boiler room | 30 000 |

The average cost of equipment for an electric boiler and for a double-circuit gas boiler does not differ significantly and is approximately 58-65 thousand rubles. The cost of installation work will be about 28-30 thousand rubles.

The choice of energy carrier, taking into account ease of use

The comfort of operation of boiler equipment that supplies heat to water heating is an important factor, since any extra trouble and inconvenience is your time and money. That is, the total costs increase indirectly in proportion to how much effort is put into keeping the system running. In some cases, economical heating systems after the first season no longer seem so economical, and sometimes you want to pay extra money, just not to get involved in such problems.

Unlike financial indicators, ease of use is the same value for each type of fuel, so it can be found out immediately, which will help you make a choice. Convenience will be evaluated according to the following criteria:

- complexity of repair or maintenance of the boiler plant;

- necessity and convenience of warehousing;

- comfort in daily operation (the need to load fuel, and so on).

To find out which of the energy carriers will provide comfortable and economical heating of a private house, we will compile a second table, where for each of the criteria we will put down all types of fuel on a five-point system, after which we will summarize.

Service

Electric boilers do not require any maintenance other than occasionally opening the lid and dusting or cleaning the contacts, for which they receive the highest praise. Some actions are required if you heat a country house with liquefied gas. Once every 2 years, it is recommended to check and, if necessary, clean the igniter and burner, which is why propane is a solid four. Pellet boilers get 3 points for requiring several times a year to clean the combustion chamber and once a chimney.

Accordingly, wood and coal units need to be cleaned frequently, as they become dirty. The worst situation in this regard is diesel fuel, as often its quality leaves much to be desired, which is why the frequency of service is unpredictable.

Warehousing

It is clear that electricity does not require storage space, while liquefied gas and diesel fuel may require some space. But when economical heating of a private house with firewood is organized, then a lot of space for a warehouse will be required. The same goes for pellets, as they need a dry room or a special silo. As for coal, there is a lot of waste, dust and dirt from it, therefore - the lowest rating.

Ease of use

And here, economical electric heating turned out to be at its best, since it does not require any intervention during operation. Pellets and liquefied gas must be replenished periodically, 1-2 times a week, or even less often

A little more attention should be paid to diesel fuel, more for supervising work than for the purpose of adding fuel

Well, and most of all, autonomous heating in a private house on coal and wood traditionally delivers the most trouble, here loading into the combustion chamber is needed from 1 to 3 times a day.

In the last column, by summing up, the results are summed up, according to which the most comfortable and convenient is heating a country house in winter with the help of electricity. If this result is considered in combination with financial costs, then electricity may not be the worst option.

How to choose a gas tank

Understanding the design features of the gas tank, we note what to look for when choosing:

- Volume. For food preparation, a small cylinder of 100-500 liters is enough.If home heating is required, then a tank of 1000-20000 liters is used. Large containers containing 20,000-50,000 liters of fuel are used only for cottage settlements or in industry.

- Land area. If the land next to the object is small, then it is advisable to purchase a vertical gas tank. But then you should think about additional heating, accelerating evaporation. When the installation area is not limited by anything, then a horizontal vessel is optimal.

- Temperature in the region. In warm regions, it is enough to fill in the foundation and place the gas tank above the ground. It's cheap and efficient. Residents of cold regions are better off immediately spending money on underground installation, which will provide year-round gas supply and eliminate the need to heat the contents of the tank.

Where is the efficiency higher and what is more expensive - a kilowatt of propane butane or pellets

When burning 1 kg of solid fuel, 5 kW of thermal energy is released, and when burning 1 kg of liquefied gas - 12.8 kW. The efficiency of propane-butane is higher than that of fuel pellets. At the same time, pellets have a lower cost - 7 rubles / kg versus 27 rubles / kg. Simple calculations show that 1 kW of solid fuel costs 1.4 rubles, while the price of a kilowatt of liquefied gas is 2.1 rubles.

As can be seen, the cost of thermal energy obtained from a propane-butane mixture is 1.5 times higher

However, when choosing the most suitable heating option, not only the price of fuel is taken into account, but also some operational aspects.

And below is a video on the production of pellets:

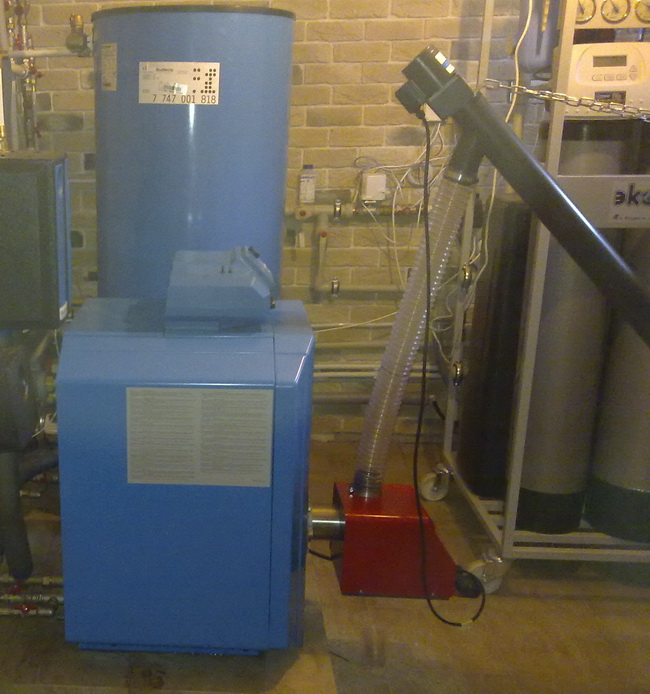

Features of the operation of a gas-pellet boiler

Despite this, a multi-fuel combined heating boiler operating on gas and pellets requires the following measures:

- Installation is carried out with strict observance of all existing norms of SNiP and PPB.

- Installation work is carried out on a previously prepared solid base. The walls and floor of the room used for the boiler room are lined with ceramic tiles or other non-combustible materials.

- The minimum requirements for a boiler room are: ceiling height of at least 2.4 m; area 12 m²; the box of entrance doors should not have a lower threshold; ventilation holes are provided in the canvas.

- Installation of a chimney for a pellet boiler that switches to gas is carried out in compliance with the PPB standards. Provide fire breaks when passing the roof, walls and floor slabs. To increase traction, install a deflector. To prevent fire, a spark arrester is placed on the head of the pipe.

Which is better - a combined boiler or two separate ones?

- Smaller footprint.

- The cost is less, about a third, than you have to pay for two separate boilers.

- The possibility of using an alternative source of thermal energy.

- The consumption of a pellet boiler, compared to a gas boiler operating on bottled fuel, is somewhat less. But when connecting the highway, it becomes more profitable to use natural gas. The design of the boiler allows you to quickly switch from one type of fuel to another.

- Installation costs are halved.

With stable supplies, it becomes possible to choose which fuel is more economically beneficial.In these aspects, universal boilers are more convenient than mono-fuel units.

If there is a central gas supply, the question of the method of heating disappears by itself, since natural gas is the cheapest and most efficient raw material for the heating system. However, in case of his absence, several questions arise immediately before the owners of private houses and country cottages: the easier it is to heat the room, which is more expensive – kilowatt propane butane or pellets, on which option to stop, etc.

Features of the operation of a gas-pellet boiler

Despite this, a multi-fuel combined heating boiler operating on gas and pellets requires the following measures:

- Installation is carried out with strict observance of all existing norms of SNiP and PPB.

- Installation work is carried out on a previously prepared solid base. The walls and floor of the room used for the boiler room are lined with ceramic tiles or other non-combustible materials.

- The minimum requirements for a boiler room are: ceiling height of at least 2.4 m; area 12 m²; the box of entrance doors should not have a lower threshold; ventilation holes are provided in the canvas.

- Installation of a chimney for a pellet boiler that switches to gas is carried out in compliance with the PPB standards. Provide fire breaks when passing the roof, walls and floor slabs. To increase traction, install a deflector. To prevent fire, a spark arrester is placed on the head of the pipe.

Which is better - a combined boiler or two separate ones?

- Smaller footprint.

- The cost is less, about a third, than you have to pay for two separate boilers.

- The possibility of using an alternative source of thermal energy.

- The consumption of a pellet boiler, compared to a gas boiler operating on bottled fuel, is somewhat less. But when connecting the highway, it becomes more profitable to use natural gas. The design of the boiler allows you to quickly switch from one type of fuel to another.

- Installation costs are halved.

With stable supplies, it becomes possible to choose which fuel is more economically beneficial. In these aspects, universal boilers are more convenient than mono-fuel units.

If there is a central gas supply, the question of the method of heating disappears by itself, since natural gas is the cheapest and most efficient raw material for the heating system. However, in case of his absence, several questions arise immediately before the owners of private houses and country cottages: the easier it is to heat the room, which is more expensive

– kilowatt propane butane or pellets

, on which option to stop, etc.

Consumption of liquefied gas and pellets for heating

Consider first the consumption of liquefied gas when organizing an autonomous heating system. As you know, the heating period in our country lasts an average of about 250 days. However, the operation of the boiler at full capacity is only necessary for 50-60 days.

In addition, it is important to understand that the boiler does not always work a full day. In addition, winters are getting warmer every year.

As a result, it turns out that the gas boiler operates at full capacity for a hundred days a year. So, if we need to heat a 150m2 room with a 20 kW boiler and a 2.7-3 thousand liter tank, then the boiler will operate at full capacity for about 180 days a year. This is about 25 liters of liquefied gas per day.

In the cold season, 50 kg of pellets will be needed to heat a house of 150m2 every day. That is, about 1.5 tons will be consumed per month. I would like to note that this is rather unprofitable, since the cost of heating in this case will significantly affect the budget.

Consumption ecology. Homestead: As a comparison, let's consider connecting and heating a house with a gas and pellet boiler in order to understand which option is more efficient.

As a comparison, consider connecting and heating a house with a gas and pellet boiler in order to understand which option is more efficient.

CONCLUSIONS - BENEFITS!

Well, as you yourself understand, GAZ is really in the first place, while in terms of efficiency it does not even have close competitors.

The second is to burn wood, pellets, coal - but in our case this is not an option at all (troublesome, garbage, dirty and dangerous), unless you have a private house and the “ash” from burning is useful for seedlings.

The third is electricity itself, of course, many can now tell me - what did you count here, I have much less, I spend 4000 - 5000 rubles per 100 square meters. - a month, for electricity! Guys, this may be true, but think about how much you would have spent on gas then? Basically a penny! Many are heated by electricity only because there is no choice and will not be, because the area is remote and there is simply NO gas nearby!

Now the video version of the article

Here is such an article turned out, I think it was useful to you, read our construction site.

Today I will try to reveal a useful topic, the thing is that now many citizens of our country live in private homes, and when winter comes, they ask themselves - what is really more profitable to heat a house? The first thing that comes to mind is, of course, gas, electricity, firewood (coal can also be included here), there are, of course, more non-traditional sources for heating, such as diesel or gasoline, but it is difficult to use them, and sometimes even dangerous. In general, let's think about what is now more profitable and what is preferable ...

- Given conditions

- Gas heating

- Heating with electricity

- Firewood, coal and more

- CONCLUSIONS - BENEFITS + VIDEO

In this article I will try to give a full assessment of one or another heating system, that is, we will estimate by calculations and derive the optimal source of heating. Of course, now electric heating is starting to progress, but about 60-70% of households are still stably “hung” on gas, and many apartments now have the so-called autonomous gas heating option

! So why is it so beneficial? For example, I want to take an apartment or a house with an area of 100 square meters, which I consider “optimal” for a family of three to four people (you can read what area is comfortable here). In general, read my reasoning and calculations below. Let's start with the condition.