- Device, design features

- No. 6 - Weissman Vitopend 100W

- What are its advantages of energy-dependent species

- Tips and recommendations from experts

- Possibility to connect a boiler

- Heater power

- Features of layer-by-layer heating of a liquid

- Exploitation

- Advantages and disadvantages

- Rating TOP-5 wall-mounted single-circuit boilers

- Buderus Logamax U072-18

- BAXI LUNA-3 1.310Fi

- BAXI LUNA Platinum+ 1.32

- MORA-TOP Meteor Plus PK24SK

- Protherm Panther 25 KTO (2015)

- Which boiler to choose

- Dimensions

- Life time

- Saving

- Convenience

- Price

- Heating area

- Additional functions

- Conclusion - which boiler is better

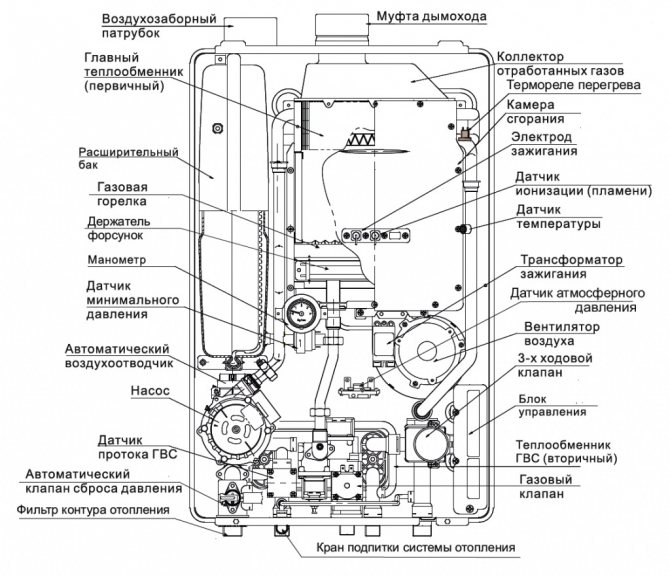

Device, design features

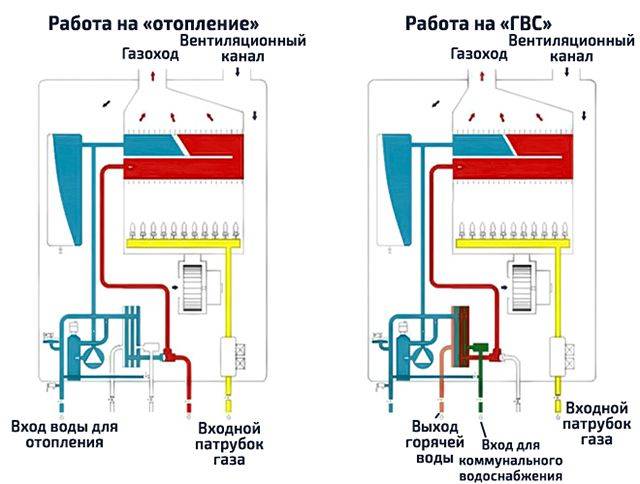

The design of a single-circuit boiler is a flow heater, the main element of which is a gas burner and a heat exchanger. They are combined into one unit, which allows you to create conditions for maximum fuel combustion efficiency.

There are two burner designs:

- open (or atmospheric). It was originally used on non-volatile models, but today it is also found on modern designs. Combustion air is taken directly from the room, which simplifies the operation of the burner, but makes it dependent on drafts, pressure drops and other external conditions;

- closed (turbocharged).A turbofan is installed to supply air. The air flow is stabilized, not affected by external factors. Smoke is also removed with the participation of a fan, which eliminates back draft and other undesirable effects.

Boilers with a closed burner are much more convenient and safer. But they depend on the state of the fan and need power.

What is the design of the burner in your gas heating boiler?

OpenClosed

There are models with different methods of heat transfer:

- convection. These are boilers equipped with conventional open or closed type burners;

- condensation. These are designs in which the heating of the coolant occurs in stages. First, primary heating is carried out due to the thermal energy obtained by condensing water vapor from flue gases. For this, the boiler is equipped with a special condensation chamber. The second stage is conventional convection heating in a heat exchanger.

Expert opinion

Torsunov Pavel Maksimovich

Convection models are much more widespread than condensation models. They are able to work in any conditions and do not require any additional devices. Condensation models have appeared relatively recently. They can only work under certain conditions.

For example, the difference between the indoor and outdoor temperatures must not exceed 20°, otherwise the condensation process will not be possible. For Russia, where during the cold season the temperature difference is about 25 ° -35 ° and more, the use of such structures is useless. Given that they cost almost twice as much as conventional condensing models, the lack of demand is understandable.

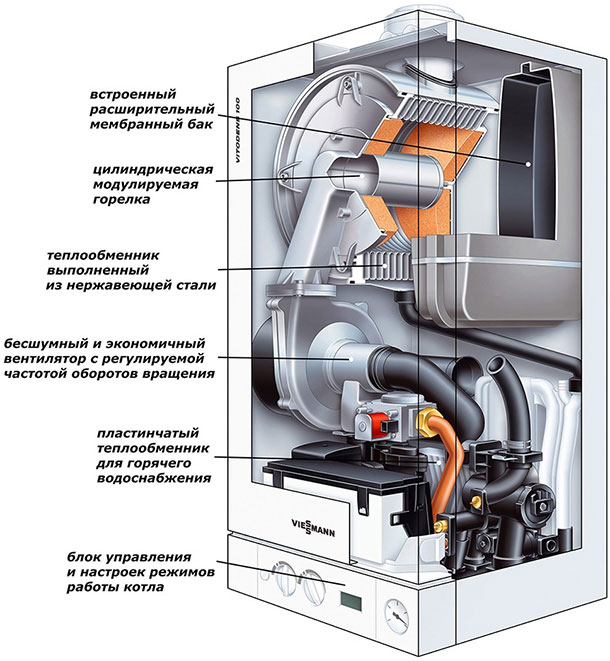

No. 6 - Weissman Vitopend 100W

The Viessmann Vitopend 100 model A1JB010 Kombi can be placed in 6th place. The boiler has 2 circuits, a closed furnace, electronic control

An important difference is that the control system is equipped with self-diagnostics. Power is adjustable from 14 to 24 kW, which allows you to heat a room with an area of 220-240 sq.m.

Dimensions - 73x40x34 cm. In the heating system, water passes through a copper heat exchanger with a temperature of up to 84-86 degrees. For hot water, an independent stainless steel circuit is provided. The water temperature is up to 58 degrees. Productivity - 12 l / min.

Pros:

- turbocharged chimney with fan;

- high-quality display;

- reduced noise level;

- small dimensions;

- use of modern technologies.

Minuses:

- expensive spare parts;

- Composite hydraulic tubing durability claims.

A high place in the ranking provides high-quality assembly, absolute safety and sufficient power.

What are its advantages of energy-dependent species

Non-volatile installations operate only on a mechanical principle, without needing to be connected to the power supply system.

This makes them indispensable in remote villages, in areas with dilapidated or overloaded electrical networks. Frequent shutdowns cause the heating to stop working, which is unacceptable in the conditions of the Russian winter.

Non-volatile models provide continuous heating of the house, regardless of external conditions. However, such possibilities limit the possibilities of non-volatile boilers. They work only on natural physical processes - the circulation of the coolant requires the installation of the heating circuit at a slight angle and is based on the rise of warm liquid layers upwards.

Smoke removal occurs under the action of conventional draft in the chimney. It should be borne in mind that natural processes proceed with minimal intensity and are unstable, therefore, external additional devices are usually installed - a turbo nozzle and a circulation pump.

They make the unit more productive, and operation in a non-volatile mode occurs only during a power outage.

If there is no power supply to the house at all, only the basic capabilities of the unit are used.

Tips and recommendations from experts

Experts recommend paying attention, for example, to the type of ignition of the boiler. Electric is considered simpler and more economical

But in non-volatile models, a less convenient piezo ignition is standardly implemented.

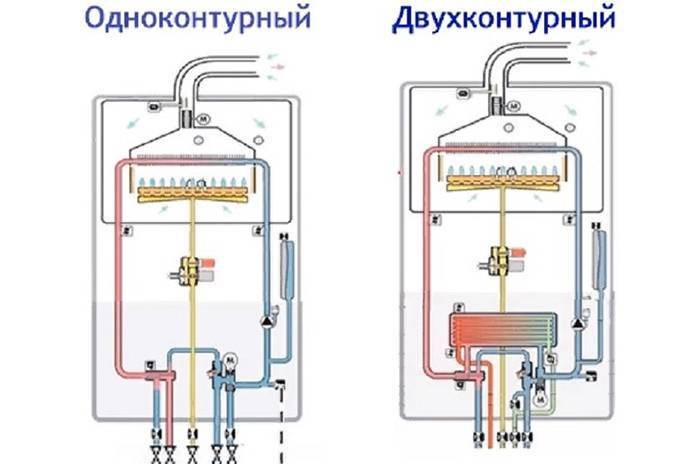

An important criterion is functionality. It is believed that double-circuit boilers are the best in this regard.

But not every model has additional features. For example, when choosing, they look to see if there is a blocking thermostat button. Some manufacturers call it a flame sensor. It improves the reliability of equipment operation.

Companies equip models with a large number of "smart" devices. Often such solutions only provide comfort without affecting safety. For example, remote control is not always necessary. And weather-dependent automation increases the efficiency of equipment use.

Experts advise choosing manufacturers who have managed to establish the work of a whole network of service centers. These companies give longer warranties.

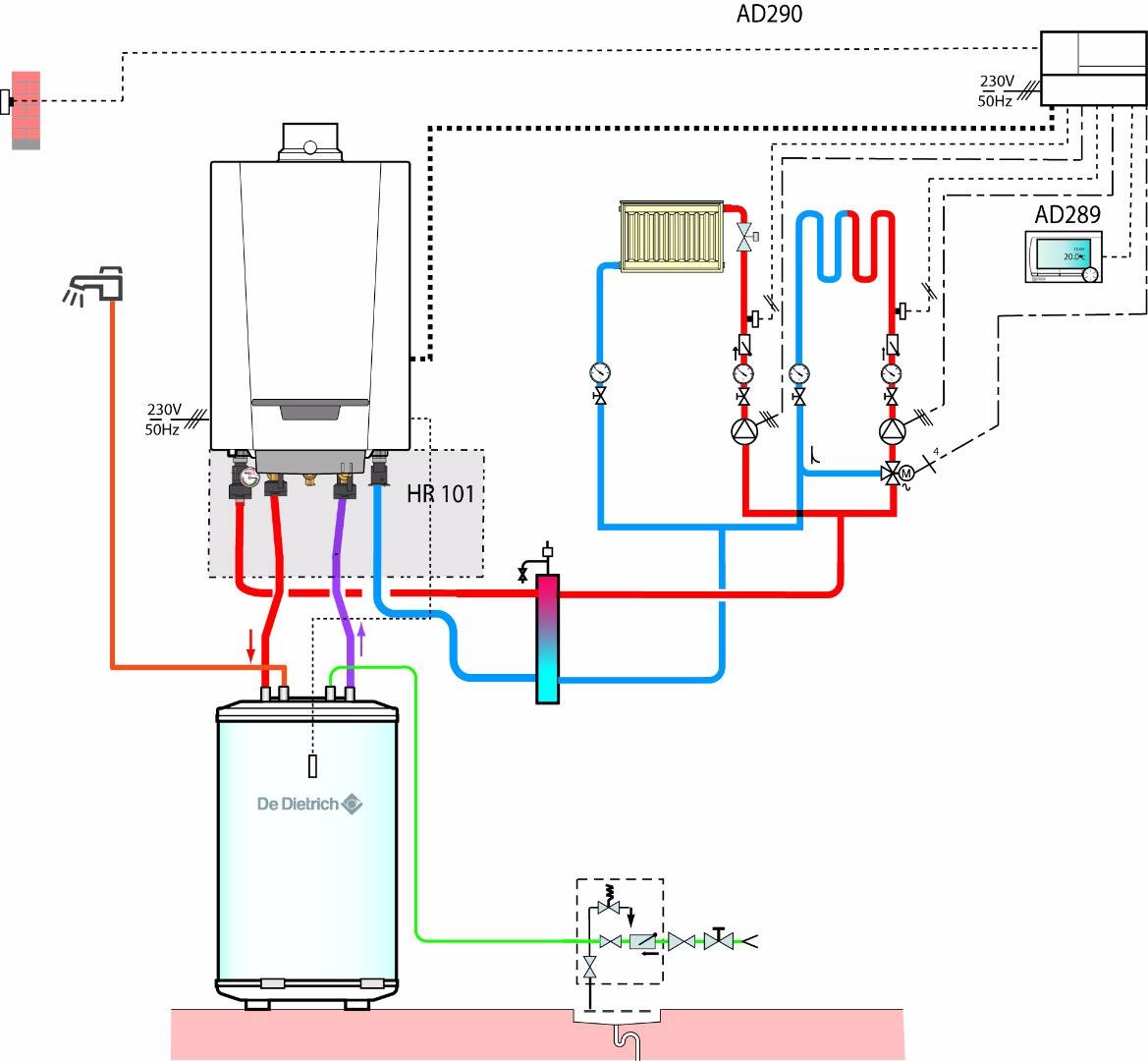

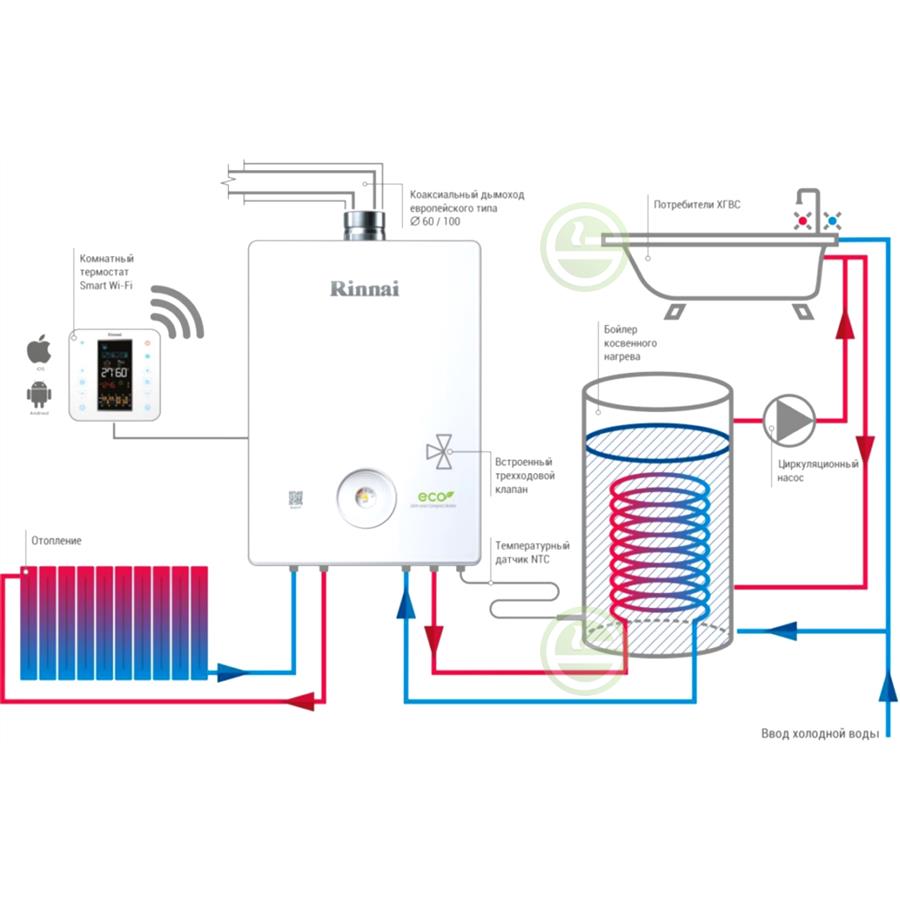

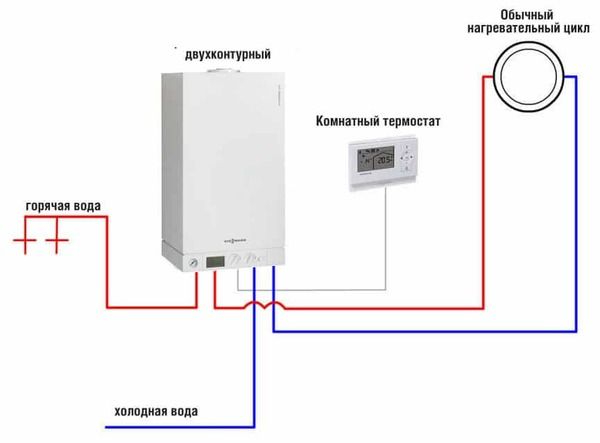

Possibility to connect a boiler

A boiler for a gas boiler is a storage tank, inside of which a heat exchanger is placed. This model, in fact, is a double-circuit, as it has a connection for both the heating system and the hot water supply.

Double-circuit models have a built-in flow-type water heater, which single-circuit models cannot boast of. The advantage of a gas boiler with a built-in storage tank is that there is no need to create an indirect heating boiler. In addition, water is heated much faster than in single-circuit versions and does not reduce the efficiency of the heat carrier for heating.

A separate boiler can also be connected to double-circuit boilers to provide more hot water. Such equipment belongs to the technique of layer-by-layer heating. You can also buy a double-circuit gas boiler with a built-in indirect heating boiler. Such devices are combined with the boiler, although separate devices can be purchased. Depending on what is best for you: ease of transport and installation or compact placement, you can choose a separate or adjacent model.

If a single-circuit boiler is already installed, you can purchase a special one for it layer heating boiler, which is equipped with a flowing liquid heater. If you need to save space in the apartment, you can opt for a single-circuit boiler with a built-in indirect heating boiler.

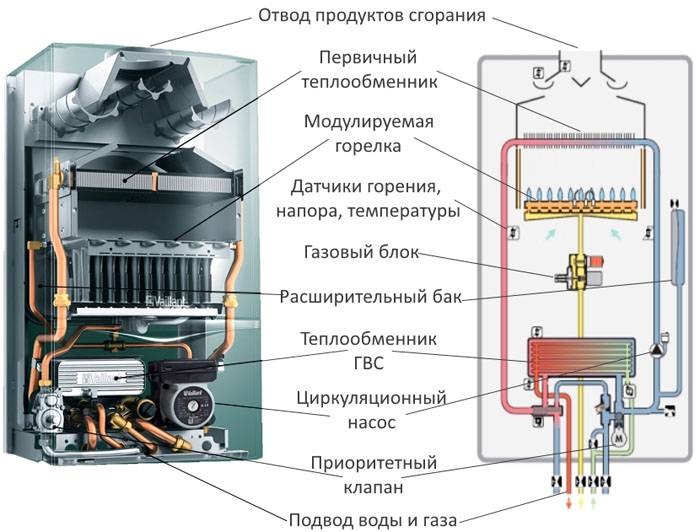

Heater power

Depending on the power of the gas burner, the flow rate of the liquid in the instantaneous water heater varies. Also, the rate of water heating depends on the design features of the heat exchanger.A feature of heating the liquid is its short contact with the heat exchanger, therefore, in order to warm the coolant to the desired temperature, a lot of heat is needed. To increase the performance of the heating element, it is necessary to increase the burner power and increase the gas flow.

In order for the water temperature in the shower to be 40 degrees, you will have to adjust the burner to a generated power of 20 kW, but if the burner is not designed for such power, then it is impossible to take a warm shower. The bath also requires a powerful burner, as the water must be heated quickly in large volumes for a normal set.

Most boilers have a capacity of about 20–30 kW, and 10 kW is enough to heat a house. Thus, all the difference can be used to provide domestic hot water. For hot water boilers, modulating burners have been developed that cover a range from 30 to 100 percent of the maximum output.

However, even the weakest boilers have excess power, which leads to frequent switching on and off of the burner. This process leads to rapid wear of equipment and increases fuel consumption. These problems make buying a more powerful boiler model to provide more hot liquid an unprofitable and unjustified solution.

That is why in dual-circuit models a boiler is provided that contains hot water, which allows it to be given in large volume while taking a shower or bath. Thus, layer-by-layer heating of water is optimal: it ensures the normal operation of the equipment and does not lead to burner wear.

Features of layer-by-layer heating of a liquid

Features of layer-by-layer heating of a liquid

In double-circuit models with stratified heating, water is heated using a plate radiator or a tubular water heater. The presence of an additional heat exchanger is beneficial in condensing models, as it provides additional heat from the combustion products. The liquid enters the boiler with layer-by-layer heating already heated, which allows you to quickly prepare the hot liquid in the required volume.

Floor double-circuit gas heating boilers with a boiler have a number of advantages.

- The flow of hot water into the upper layers of the boiler allows you to take a shower 5 minutes after turning on the heat exchanger. In contrast, boilers with an indirect heating boiler provide longer heating of the liquid, since time is spent on the convection of warm water from below the heat source.

- The absence of a heat exchanger inside the storage tank allows you to collect more warm water for domestic needs. The performance of such boilers is 1.5 times higher than in models with indirect heating.

Exploitation

All the rules and requirements for the operation of a gas single-circuit boiler are described in detail in the instructions, which must be carefully studied.

All the rules and requirements for the operation of a gas single-circuit boiler are described in detail in the instructions, which must be carefully studied.

Each model differs from others in certain specific features, so it is important to learn in advance all the requirements set out by the manufacturer. In addition, it is necessary to create conditions for the trouble-free operation of the boiler. Experts recommend using a voltage stabilizer, as the electronic control unit is sensitive to the quality of the power supply

If surges occur or the voltage does not match the specified parameters, errors may occur, and sometimes the control unit burns out

Experts recommend using a voltage stabilizer, since the electronic control unit is sensitive to the quality of the power supply. If surges occur or the voltage does not match the specified parameters, errors may occur, and sometimes the control unit burns out

In addition, it is necessary to create conditions for the trouble-free operation of the boiler. Experts recommend using a voltage stabilizer, since the electronic control unit is sensitive to the quality of the power supply. If surges occur or the voltage does not match the specified parameters, errors may occur, and sometimes the control unit burns out.

When connecting to the power supply network, it is imperative to make high-quality grounding, otherwise the self-diagnosis system will start to give incorrect information and constantly show an error.

Water quality is also an important factor. If the water in the region is too hard, softeners and special filters should be used. Scale in the heat exchanger slows down the heat transfer, due to which it is necessary to increase the temperature. Excessive heating quickly disables boiler parts, and excessive gas consumption increases the amount of payment.

Wall-mounted single-circuit gas boilers are convenient and popular sources of thermal energy in private houses, apartments and other premises. They are reliable, durable, able to work in difficult conditions. At the same time, the user must ensure all the requirements of the manufacturer in order to keep the unit in order for the entire service life.

The main advantage of a single-circuit boiler is the ability to work in tandem with a storage boiler, which allows you to provide the room with hot water in sufficient quantities.Gas single-circuit wall-mounted boilers are highly valued by their owners and are in high demand.

- How to choose the right gas heating boiler for a private house: types, classification, overview of popular manufacturers, their pros and cons

- How to choose the best diesel heating boiler: types, device, selection criteria, an overview of 6 popular models, their pros and cons

- How to choose the best long-burning solid fuel boiler: types, purpose, features, selection criteria, an overview of 9 popular models, their pros and cons, as well as owner reviews

- Which boiler for heating a private house is better to choose: a comparison of gas, electric, solid fuel appliances, as well as liquid fuels, their pros and cons

Advantages and disadvantages

The advantages of single-circuit boilers include:

- simplicity, reliability of the design;

- the absence of unnecessary components and parts;

- less risk of breakage, more stable operation of the device;

- the absence of additional nodes reduces the weight of the boiler;

- when using an external boiler, it becomes possible to supply hot water, moreover, this method is considered more efficient;

- the price of single-circuit models is lower.

The disadvantages can be considered:

- there is no possibility of independent preparation of hot water;

- the cost of external boilers is quite high, and installation requires space;

- in the summer, you have to spend fuel to heat water in an external boiler (if any);

- the use of external storage increases the load on the heat exchanger and increases fuel consumption.

IMPORTANT!

The disadvantages of single-circuit boilers do not pose a significant problem. Experienced people prefer to purchase just such units in order to get a more reliable heating system and a stable supply of hot water using a boiler.

Rating TOP-5 wall-mounted single-circuit boilers

Among single-circuit wall-mounted boilers, the following models compare favorably:

Buderus Logamax U072-18

Buderus is a subsidiary of the world famous Bosh concern. Experts note the high quality of products, not inferior to the products of the parent company. The Buderus Logamax U072-18 boiler is a single-circuit unit with a capacity of 18 kW, which is suitable for heating a house of 160-180 sq. m.

The manufacturer warns that if the water hardness is more than 16 ° dGH, you will need to use softeners or special filters.

Boiler parameters:

- coolant temperature - 40-82 °;

- pressure in the heating circuit (max) - 3 bar;

- dimensions - 400/299/700 mm;

- weight - 32 kg.

The unit can be connected to an external indirect heating boiler, which will provide the home with hot water.

BAXI LUNA-3 1.310Fi

BAXI is considered Italian, although the enterprises are scattered throughout Europe, and the head office is located in the Netherlands. The LUNA-3 1.310 Fi boiler is a 31 kW convection unit.

This is a solid device that can heat a residential building or office up to 310 square meters. m. High efficiency (93.1%) provides fuel savings and allows you to get the maximum performance from the boiler.

Characteristics:

- coolant temperature - 30-85 °;

- gas consumption - 3.52 m3 / h;

- pressure in the heating circuit (max) - 3 bar;

- dimensions - 450x763x345 mm;

- weight - 40 kg.

According to the manufacturer, the service life of the boiler is at least 10 years with a 2-year warranty.

BAXI LUNA Platinum+ 1.32

Another representative of the Italian company is a single-circuit condensing boiler with a capacity of 34.8 kW.Its efficiency is 105.7%, which is nothing more than a clumsy marketing ploy.

A pre-heating stage has been added to the design of the unit, which allows to reduce the intensity of the burner and save fuel. However, the physical possibility of condensation with heat release is possible only under certain and rather narrow conditions, which are impossible in Russia.

Unit parameters:

- coolant temperature - 25-80 °;

- gas consumption - 3.49 m3 / h;

- pressure in the heating circuit (max) - 3 bar;

- dimensions - 450x760x345 mm;

- weight - 37.5 kg.

The price of a condensing boiler BAXI LUNA Platinum + 1.32 is an average of 76-80 thousand rubles.

Given the uselessness of an additional heating stage in most regions of Russia, the need for such a purchase should be carefully weighed.

MORA-TOP Meteor Plus PK24SK

Product of Czech manufacturers with a capacity of 23.7 kW. This is the optimal value for a room with an area of 220-240 square meters. m., which corresponds to the size of most cottages.

It is a single-circuit gas wall-mounted atmospheric boiler. Needs connection to a common stove-type chimney.

Its characteristics:

- coolant temperature - 30-80 °;

- gas consumption - 2.6 m3/hour;

- pressure in the heating circuit (max) - 3 bar;

- dimensions - 400x750x380 mm;

- weight - 27.5 kg.

Users note the high performance and reliability of the unit, the stability of work.

Protherm Panther 25 KTO (2015)

The Protherm brand is the brainchild of the Vaillant Group, and was created specifically for the production of low-cost, high-quality gas boilers. Initially, the products were focused on the market of Russia and the CIS countries.

The Protherm Panther 25 KTO (2015) boiler has a power of 25 kW, which is suitable for heating 250 sq.m.It features low fuel consumption and stable, trouble-free operation.

Main characteristics:

- coolant temperature - 30-85 °;

- gas consumption - 2.8 m3/hour;

- pressure in the heating circuit (max) - 3 bar;

- dimensions - 440x800x338 mm;

- weight - 41 kg.

When connecting an external boiler, it becomes possible to provide the room with hot water, which makes the unit a full-featured device.

Which boiler to choose

The choice of one or another type of gas boiler is determined by the working conditions and the needs of people.

When deciding which boiler is more suitable in a given situation, it is recommended to consider all the criteria:

Dimensions

The size of a gas boiler is not determined by its functionality. Most often, in one model line, all units are produced in the same frame size.

Wall-mounted boilers are more compact, but the main factors affecting the size are the power and performance of the units.

Life time

The duration of operation of gas boilers is determined by working conditions, loads and power levels.

In addition, an important indicator is the quality of water - the appearance of scale quickly disables the heat exchanger. This applies equally to single and double-circuit boilers.

Saving

Users note some advantage of single-circuit boilers in terms of gas consumption. This affects fuel bills. In this case, if an external boiler is connected, the gas flow increases.

Convenience

In terms of ease of use, double-circuit boilers definitely win. They do not require the installation of additional water heaters, which greatly simplifies the creation of communications.

Single-circuit models are convenient only where it is only necessary to heat the room, but such situations are rare.

Price

The cost of both boilers mainly depends on the power and other parameters of the boiler.

However, if we compare a single- and double-circuit model with the same characteristics, then a single-circuit boiler will be cheaper.

Heating area

The heating area of the boiler depends on its power. It is taken into account at the rate of 1 kW of power = 10 m2.

In this case, there is no dependence on the set of functions; the ratio is equally valid for both types of aggregates.

Additional functions

As a rule, dual-circuit models are equipped with additional functions. Here and remote control, and programming, and the ability to connect a room thermostat.

Single-circuit boilers are simpler and less equipped with additional devices due to lack of demand.

Conclusion - which boiler is better

It is impossible to say unequivocally which boiler is better. It is necessary to be guided by the needs and tasks of the premises, consider the number of people, lifestyle and other factors.

Both types of boilers may or may not be needed in different situations.

In order to name a suitable option, it is necessary to consider all the factors of influence, and only then make a decision.