- Plate and fasteners

- fittings

- Factors affecting the profitability of the two options

- Gas and electricity costs

- Operating and maintenance costs

- Starting investments

- Factors affecting the profitability of the two options

- Gas and electricity costs

- Operating and maintenance costs

- Starting investments

- Wall thickness

- Operating costs

- gas pipeline

- Advantages and disadvantages

- Electric heating

- gas holder

- Gas consumption for independent gasification

- What affects the gas consumption of a gas tank?

- How long does independent gasification refueling last?

- Gas consumption by a gas tank depending on the area of \u200b\u200bthe house

- Starting investments

- Advantages and disadvantages

- Electric heating

- gas holder

- Case steel

- Final Comparison Table

Plate and fasteners

The base plate is needed in order to prevent the ascent of the gas tank. For reliable anchoring, the width is decisive: the slab must protrude at least 20 cm from the side of the tank on each side.

Another factor is the material from which the plate is made. Alkali-acid-resistant concrete does not collapse in any soil and securely holds the tank. But standard hollow slabs are not suitable for anchoring, as they are designed for dry use. The service life of hollow core slabs can be less than five years.After the destruction of the plate, the tank may float.

Finally, it is important that the reservoir is properly secured. Firstly, the fastener must be made of stainless steel, otherwise it will quickly collapse.

Secondly, the tank must be attached to the plate by its legs. The absence of paws increases the likelihood of damage to the coating and, accordingly, reduces the service life of the gas tank.

All these requirements are met only by gas holders AvtonomGaz.

| AvtonomGas | Eurostandard gas holders | Sold under the FAS brand | RP, RPG and other Russian gas tanks | |

|---|---|---|---|---|

| base plate | Massive, acid-alkali-resistant concrete, 1.8 m wide, ready. | Hollow, ordinary concrete, shir. 1.2 m | Hollow, ordinary concrete, shir. 1.2 m, finished | Hollow, ordinary concrete, shir. 1.2 m |

| Support legs for stress relief on the bottom cover and secure fastening | Available | Only available on some models | Not | Available |

| Fixing the tank to the base plate | Behind tank feet with stainless steel anchors | A galvanized cable or packing tapes with galvanized fasteners are attached to the ears of the plate or to the paws with a galvanized anchor | A stainless steel cable with a galvanized turnbuckle (tensioner) is attached to the ears of the plate | Behind tank feet with carbon steel anchors |

| Corrosion protection of fasteners | Fasteners are made of non-corrosive material | Fasteners and ears of the plate are subject to corrosion | Fasteners and ears of the plate are subject to corrosion | Fasteners subject to corrosion |

| Fastener service life | At least 50 years old | Less than 10 years old | Less than 10 years old | Less than 10 years old |

fittings

Valves are equipment for controlling the flow of gas.The most important advantages of fittings for AvtonomGaz gas tanks are the presence of safety valves that shut off the gas supply in case of damage to the gas tank, as well as means that do not allow filling the tank by more than 90%. Both measures make AvtonomGaz gas holders much safer than competitors' products.

| AvtonomGas | Eurostandard gas holders | Sold under the FAS brand | RP, RPG and other Russian gas tanks | |

|---|---|---|---|---|

| Valve manufacturer | Rego (USA) | Rego (USA) | Rego (USA) | Rego (USA), Russia |

| pressure gauge | Sealed, alcohol-filled | Sealed, alcohol-filled | Leaky | Leaky |

| Safety high-speed valves for protection against vandalism | Available on all valves | Only on the vapor phase valve | Not | Not |

| Fill Cutoff 90% | Available | Not | Not | Not |

| Periodic tightening of valves and flanges during maintenance | Not required | Rarely required | Required | Required often |

| Rebar material | Plastic | Galvanized sheet 1 mm or plastic | Galvanized sheet 0.5 mm | Black steel 2 mm bituminous |

Factors affecting the profitability of the two options

When choosing a heating system, you need to take into account the initial investment, maintenance of equipment and the cost of fuel / energy

When choosing a heating system, you need to take into account the initial investment, maintenance of equipment and the cost of fuel / energy

The main selection parameter is cost. But all components should be evaluated: the price of the energy source, the cost of equipment, the timing and price of installation and maintenance. Also take into account the cost of repairs and maintenance.

To install a gas boiler and a gas tank, a permit from the gas service is required. Electric boilers or heaters do not require a permit.

Gas and electricity costs

Heating is designed to compensate for the heat loss that a house or apartment carries in winter. Based on this value, the volume of consumption of electricity or gas is calculated. Determine the duration of the heating period - E, in hours. In the calculations, errors are allowed, therefore, consider:

- Electric boiler efficiency - 98%;

- Gas efficiency - 92%;

- the calorific value of liquefied gas varies from 12.6 to 24.4 kWh/kg.

If there is a two-tariff meter, electricity costs may be less than liquefied gas

All values are substituted into the formulas and get:

- V= Q × E / (1260 × 0.92), where V is the volume of liquefied gas and Q is the heat of the building. The calorific value of a propane-butane mixture is best calculated based on the minimum values.

- V= Q × E / 0.98, where V is the conventional amount of electricity.

- multiply by the amount of gas received and find out how much heating costs.

To understand what is more expensive - gas from a gas tank or electricity, the cost is calculated.

- On average, with a one-tariff connection, 1 kW of electricity costs 3.2 rubles. The price is multiplied by the conditional amount of energy and the cost of heating for the entire period is obtained. With a two-tariff connection, the amount will be less.

- The cost of a liquefied gas mixture is on average 18 rubles. per kg.

Operating and maintenance costs

Maintenance of the gas tank is more expensive - it needs to be refueled periodically, the integrity of the installation must be checked

Maintenance of the gas tank is more expensive - it needs to be refueled periodically, the integrity of the installation must be checked

From this point of view, electricity is much more profitable than a gas tank, and in any case: an electric boiler with water heating or electric stationary heaters.

Maintenance of an autonomous heating or gas supply system is more expensive:

- The installation and inspection of the gas pipeline of the stove and boiler, and even the gas meter, can only be carried out by an employee of the gas service. Electric heaters or an electric boiler do not need to be checked periodically.

- If any of the devices fails, you must call the gas service. The cost of repair or replacement depends on the type of equipment.

- The procedure for replacing the gas supply is more complicated and takes more time than replacing an electrical appliance.

- The fuel supply in the gas tank must be replenished. The consumer pays for transportation and injection of gas.

When changing the heating method, for example, connecting to a gas main, in both cases, you will have to completely change the equipment.

Starting investments

At the stage of installing a gas tank, the costs are several times higher than when buying and installing an electric boiler

At the stage of installing a gas tank, the costs are several times higher than when buying and installing an electric boiler

The total cost of the energy supply system is determined by capital investments. If the house is equipped with an electrical system, the initial investment looks like this:

- the purchase and installation of an electric boiler is made at any time and does not require permission;

- an electric stove, boiler, oven are bought in a store, installed in any convenient place and plugged into an outlet.

The only limitation is wiring. If the house is equipped with an electric heating system, it is worth installing a three-phase electrical network.

Investments in the organization of autonomous gas supply are much higher:

- development and approval of the gasification project;

- you need to dig a pit under the tank, lay the gas pipeline underground and fill in the trenches;

- purchase, installation and connection of a gas boiler - is carried out only with permission and only by employees of the gas service;

- laying a gas pipeline in the house.

Factors affecting the profitability of the two options

The main selection parameter is cost. But all components should be evaluated: the price of the energy source, the cost of equipment, the timing and price of installation and maintenance. Also take into account the cost of repairs and maintenance.

To install a gas boiler and a gas tank, a permit from the gas service is required. Electric boilers or heaters do not require a permit.

Gas and electricity costs

Heating is designed to compensate for the heat loss that a house or apartment carries in winter. Based on this value, the volume of consumption of electricity or gas is calculated. Determine the duration of the heating period - E, in hours. In the calculations, errors are allowed, therefore, consider:

- Electric boiler efficiency - 98%;

- Gas efficiency - 92%;

- the calorific value of liquefied gas varies from 12.6 to 24.4 kWh/kg.

All values are substituted into the formulas and get:

- V= Q × E / (1260 × 0.92), where V is the volume of liquefied gas and Q is the heat of the building. The calorific value of a propane-butane mixture is best calculated based on the minimum values.

- V= Q × E / 0.98, where V is the conventional amount of electricity.

- multiply by the amount of gas received and find out how much heating costs.

To understand what is more expensive - gas from a gas tank or electricity, the cost is calculated.

- On average, with a one-tariff connection, 1 kW of electricity costs 3.2 rubles. The price is multiplied by the conditional amount of energy and the cost of heating for the entire period is obtained. With a two-tariff connection, the amount will be less.

- The cost of a liquefied gas mixture is on average 18 rubles. per kg.

Operating and maintenance costs

From this point of view, electricity is much more profitable than a gas tank, and in any case: an electric boiler with water heating or electric stationary heaters.

Maintenance of an autonomous heating or gas supply system is more expensive:

- The installation and inspection of the gas pipeline of the stove and boiler, and even the gas meter, can only be carried out by an employee of the gas service. Electric heaters or an electric boiler do not need to be checked periodically.

- If any of the devices fails, you must call the gas service. The cost of repair or replacement depends on the type of equipment.

- The procedure for replacing the gas supply is more complicated and takes more time than replacing an electrical appliance.

- The fuel supply in the gas tank must be replenished. The consumer pays for transportation and injection of gas.

When changing the heating method, for example, connecting to a gas main, in both cases, you will have to completely change the equipment.

Starting investments

The total cost of the energy supply system is determined by capital investments. If the house is equipped with an electrical system, the initial investment looks like this:

- the purchase and installation of an electric boiler is made at any time and does not require permission;

- an electric stove, boiler, oven are bought in a store, installed in any convenient place and plugged into an outlet.

The only limitation is wiring. If the house is equipped with an electric heating system, it is worth installing a three-phase electrical network.

Investments in the organization of autonomous gas supply are much higher:

- development and approval of the gasification project;

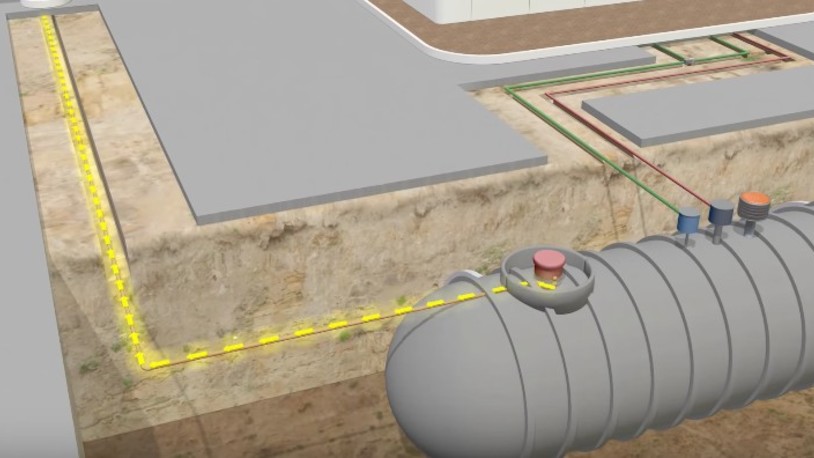

- you need to dig a pit under the tank, lay the gas pipeline underground and fill in the trenches;

- purchase, installation and connection of a gas boiler - is carried out only with permission and only by employees of the gas service;

- laying a gas pipeline in the house.

Wall thickness

Corrosion is the main factor limiting the service life of a gas tank. It slowly but surely thins the walls of the tank until it finally becomes unusable. In the case of gas tanks AvtonomGaz, this process can take more than a century and a half. Gas tanks from other manufacturers are not able to hold out for so long. They only last a few decades.

| AvtonomGas | Eurostandard gas holders | Sold under the FAS brand | RP, RPG and other Russian gas tanks | |

|---|---|---|---|---|

| Wall thickness | 6-6,2 | 5-5,1 | 6,2-8 | 9-11 |

| Permissible minimum wall thickness, taking into account the strength of the metal and seams | 4 | 5 | 6 | 6.5 |

| Technological manufacturing error. The higher the level of production, the more accurate the alignment of the parts to be welded. | 0,1 | 0,4 | 1,6 | 2 |

| Actual minimum wall thickness.

The strength of the tank depends on the characteristics of steel, wall thickness and technological errors when combining parts. | 5.9 | 5.6 | 6.4 | 7 |

| Margin for corrosion | 1.9 | 0.6 | 0.4 | 0.5 |

| Steel corrosion rate | 0.012 | 0.014 | 0.02 | 0.025 |

| Theoretical reservoir life.

The wear period depends on the quality of electrochemical protection, the aggressiveness of the soil, the quality of liquefied gas. | 158 | 43 | 20 | 20 |

Operating costs

The operating costs of the installed gas equipment in both cases are almost the same. The cost of preventive maintenance is relatively small, since the boilers almost do not form soot and soot. The only disadvantage of a small capacity gas tank is the additional cost of electricity, which is necessary to convert liquid fuel into gas.

With a significant fuel consumption in a particular area, it is advisable to connect to the central gas supply system. For the gasification of a small country house, the installation of a gas tank would be an ideal option due to the low cost of installation work.

gas pipeline

The durability of the gas pipeline is related to the brand of polyethylene from which it is made. The fact is that liquefied gas (propane-butane) is much more aggressive to plastics than ordinary natural gas. Polyethylene grade PE 80, from which pipelines with natural gas are made, is poorly suited for the transfer of propane-butane.

By order of AvtonomGaz, the Polyplastic group produces gas pipelines from PE 100 grade polyethylene. Such polyethylene has a high nitrile content and better withstands the effects of liquefied gas. The service life of a gas pipeline made of PE 100 is at least 50 years.

Other companies, unlike AvtonomGaz, do not have the opportunity to order the production of a gas pipeline from a material that is designed specifically for propane-butane. They are forced to violate the requirements of SNiP and install conventional natural gas pipelines made of PE 80 polyethylene. When used with propane-butane, such gas pipelines will become unusable after just a few years.

| AvtonomGas | Eurostandard gas holders | Sold under the FAS brand | RP, RPG and other Russian gas tanks | |

|---|---|---|---|---|

| Gas pipeline material | PE 100 The gas pipeline made of PE 100 polyethylene is produced specifically for AvtonomGaz | PE 80

This grade of polyethylene is not suitable for use with propane-butane | PE 80

This grade of polyethylene is not suitable for use with propane-butane | PE 80

This grade of polyethylene is not suitable for use with propane-butane |

| Insulation of the gas pipeline on descents and ascents | Yes | Not | Not | Not |

| Service life of the gas pipeline | Over 50 years | Less than 10 years old | Less than 10 years old | Less than 10 years old |

Advantages and disadvantages

Electric heating

Advantages of the solution:

- safety - the risk of a short circuit is reduced to a minimum;

- installation of an electrical appliance is reduced to mounting on the wall and plugging it into a power outlet;

- no permission required for installation;

- repairs are carried out quickly, technical inspection is rarely carried out.

Flaws:

- in the event of an accident or a planned shutdown, the dwelling is left without heating;

- electricity is the most expensive source of energy;

- with a large area of \u200b\u200bthe dwelling, you will have to install three-phase wiring.

gas holder

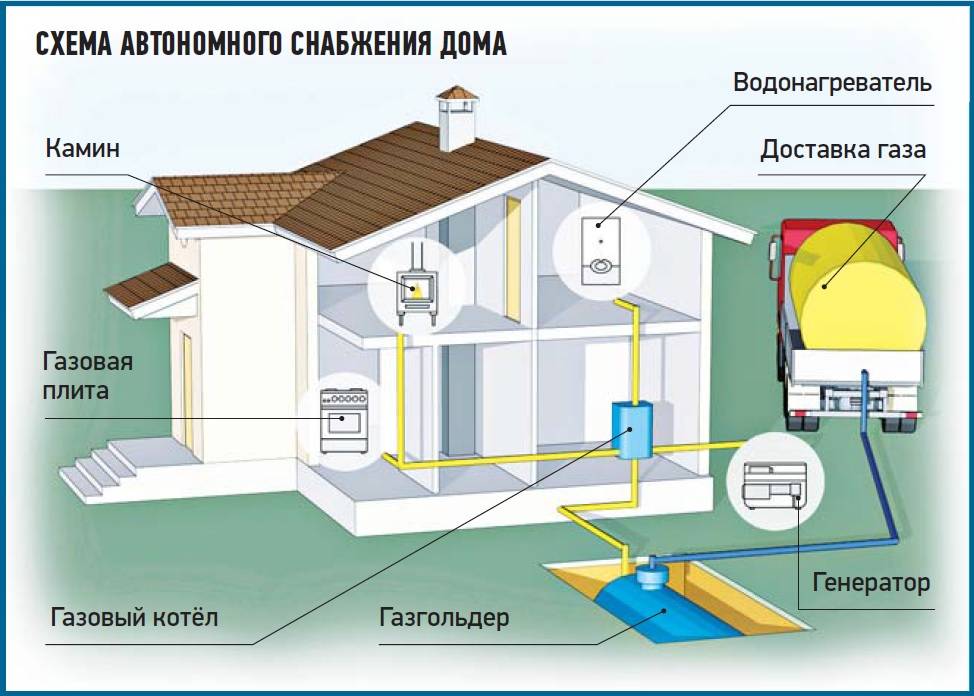

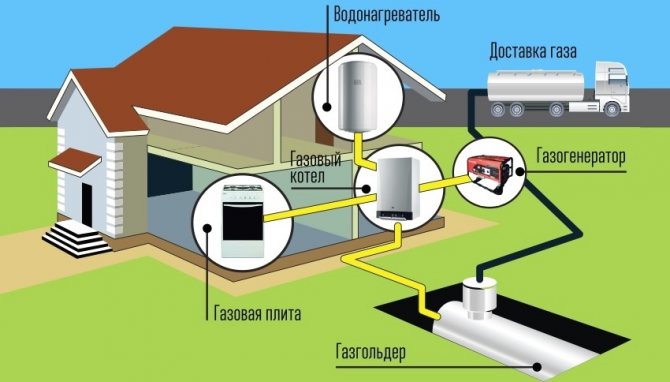

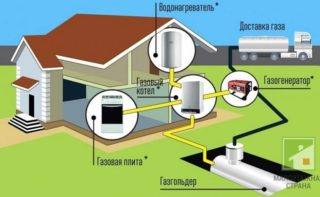

Advantages of autonomous gas supply:

- independence from the operation of the gas pipeline;

- constant supply of gas at the same pressure;

- safety - even with a leak, the gas goes into the soil, which eliminates fire or explosion;

- You can install an autonomous gas supply in any area and under any weather conditions.

Flaws:

- the cost of liquefied gas is less than electricity, but its calorific value is lower, heating costs are comparable to the use of electricity;

- the installation of a gas tank and a gas pipeline requires extensive excavation; for gas appliances in the house, you need to prepare a place;

- permission is required to install the system;

- inspection, repair and replacement of any parts of the gas supply are carried out only by gas workers.

Autonomous gas supply provides a higher degree of independence.

Gas consumption for independent gasification

There are many formulas on the Internet that can be used to calculate gas consumption from the very beginning, but experts are of the opinion that the result will be an average indicator that has inaccuracies in some particular direction.

What affects the gas consumption of a gas tank?

Depending on the climate conditions of a certain area, the time of year, gas consumption during independent gasification can vary in a fairly significant range. First, this is set by the evaporation mirror that appears in the gas tank. Due to this, it is best to entrust the choice of this equipment to professionals, because. in other cases, it is acceptable to use a tank with a vertical design as opposed to a horizontal one, and vice versa. Also, this parameter can be adjusted, giving preference to the underground installation of the gas tank capacity, which protects it from the influence of ambient temperature conditions. But in most cases, a surface installation is recommended to equip a more productive off-grid gasification system.

Also significant factors that affect gas consumption are:

- the quality of insulation of the outer walls, foundation and roof of the house, which determines the amount of heat loss of the building;

- wind rose in a certain area;

- set temperature regime;

- building area, number of doors and windows;

- number of people living in the house;

- technical characteristics of the boiler;

- permanent or periodic mode of residence;

- the use of additional and additional equipment.

How long does independent gasification refueling last?

Our firm performed its calculations based on functional observations, according to which 1 m? area with systematic residence, on average, 20–30 liters of gas is spent daily per year.

In other words, one refueling of a gas tank with a tank volume of 4800 liters is enough for 160-240 days. Basically, the owners order the next gas station at the beginning of the heating period, because. in the summer, consumption is significantly reduced.

Gas consumption by a gas tank depending on the area of \u200b\u200bthe house

Again, we carried out observations in residential buildings, where our professionals completed the work to create an independent gas supply

Therefore, it is necessary to take into account not only the key set of equipment, but also auxiliary modules, such as underfloor heating, number of radiator points, etc.

Heating ‘target=”_blank”>’)

Starting investments

When installing a gas heating system, many users choose between connecting the house to a gas tank or a central line. In the first case, you need to choose a tank, the capacity of which will allow you to provide fuel throughout the year. According to the latest data, gas tank for a private house turnkey with a volume of 6.5 m3 will cost the customer 400-500 thousand rubles.

When connecting a residential building to a central gas main, the initial investment will be several times higher even if the gas pipeline is in close proximity. The fact is that the throughput of gas pipelines is limited. To connect to a pipe, a special permit and a pre-drafted project are required. The cost of investments may vary depending on the specific situation, throughput and distance to the pipe.

Advantages and disadvantages

Both gas tank, and electricity, and main gas have their pros and cons. It concerns not only the price for use and maintenance.

Both gas tank, and electricity, and main gas have their pros and cons. It concerns not only the price for use and maintenance.

Electric heating

Advantages of the solution:

- safety - the risk of a short circuit is reduced to a minimum;

- installation of an electrical appliance is reduced to mounting on the wall and plugging it into a power outlet;

- no permission required for installation;

- repairs are carried out quickly, technical inspection is rarely carried out.

Flaws:

- in the event of an accident or a planned shutdown, the dwelling is left without heating;

- electricity is the most expensive source of energy;

- with a large area of \u200b\u200bthe dwelling, you will have to install three-phase wiring.

gas holder

The main advantage of the gas tank is independence from the gas pipeline

The main advantage of the gas tank is independence from the gas pipeline

Advantages of autonomous gas supply:

- independence from the operation of the gas pipeline;

- constant supply of gas at the same pressure;

- safety - even with a leak, the gas goes into the soil, which eliminates fire or explosion;

- You can install an autonomous gas supply in any area and under any weather conditions.

Flaws:

- the cost of liquefied gas is less than electricity, but its calorific value is lower, heating costs are comparable to the use of electricity;

- the installation of a gas tank and a gas pipeline requires extensive excavation; for gas appliances in the house, you need to prepare a place;

- permission is required to install the system;

- inspection, repair and replacement of any parts of the gas supply are carried out only by gas workers.

Autonomous gas supply provides a higher degree of independence.

Case steel

The grade of steel from which the tank is made determines what loads it can withstand and how effectively it manages to resist corrosion.

Steel with large crystals is brittle and prone to intergranular corrosion. The more uniform the crystal structure, the weaker the intercrystalline stresses, and therefore the steel is more resistant to cyclic loads.

The steel of AvtonomGaz gas holders manufactured at the Chemet plant is subjected to normalization, a technological process that gives the steel product a uniform fine crystalline structure. In addition, it includes alloying additives that completely prevent corrosion.

Due to the selection of steel with the required characteristics, fine-grained structure and low carbon content, AvtonomGaz gas holders are more resistant to cracking in the body and are completely protected from corrosion. This extends the life of safe operation by three to four times compared to tanks from other companies.

The walls of AvtonomGaz gas tanks are 4%-10% thicker in the thinnest places (sheet junctions) than gas tanks from other manufacturers. At the same time, the steel of the tanks is 7%-25% stronger in rupture and more resistant to metal deformations under load and shock by 20%-32%.

| AvtonomGas | Eurostandard gas holders | Sold under the FAS brand | RP, RPG and other Russian gas tanks | |

|---|---|---|---|---|

| Steel | S355J2+N | S355J2 | 09G2S-12 | 09G2S |

| Crystalline structure of steel. The properties of steel are directly dependent on the crystal structure of the steel. | Normalized, fine-grained

Fine uniform crystalline grain prevents the formation of cracks and eliminates intercrystalline corrosion. | mixed | mixed | mixed |

| Steel selection | The best steel, selected for quality from all manufacturers of the European Union. | Steel is supplied by a single manufacturer from the European Union. | Steel is supplied by a single manufacturer from Russia. | Steel is supplied by a single manufacturer from Russia. |

| Factory quality control with ultrasound and X-ray | The metal of the product and welds are checked | Only welds are checked | Only welds are checked | Only welds are checked |

| Tensile strength | 560-590 | 500-560 | 460-538 | 380-460 |

| Tensile strength of welds.

The stronger the seam, the more force must be applied to break. | 590 | 540 | 460 | 380 |

| Yield strength of body steel.

With this pressure on the steel, deformation begins. The higher the pressure, the more resistant the steel to deformation. | 470 | 392 | 355 | 340 |

| impact strength

The higher this figure, the better the steel withstands impacts. | 67 | 60-64 | 60 | 55 |

Final Comparison Table

The above calculations are relevant for a house of 100 m2. Costs do not reflect all options, the real figures are affected by the climate of the region, the severity of winter, the level of thermal insulation of the house.

Options

Pellets

LPG (gas holder)

Efficiency

50-90%

97%

Fuel cost

48 thousand rubles in year

49-54 thousand rubles. in year

Cost of equipment

from 40 thousand rubles

from 155 thousand rubles plus gas boiler

Connection

Boiler installation

Installation of a gas tank on the site and a boiler in the house

Ease of operation

Need regular fuel loads daily or once a week

The quality of the pellets is important.

Full autonomy after refueling 1-2 times a year.

Reliability

high

High, problems can arise only with the wrong choice and installation

Safety

The danger of carbon monoxide

High, no risk

Dependence on electricity

Yes

Not

Fuel depot

Need

Not needed

Service

Loading, cleaning

Tank refilling, technical inspection twice a year

A combination of a gas tank and a gas boiler provides ease of use, a certain independence from external factors (electricity, the quality of pellet production). But it implies the presence of free space on a site away from residential premises and the implementation of such a project will cost more than a “competitor”.

Pellet equipment is cheaper, as is the fuel itself. But requires high quality pellet, ongoing maintenance or additional upgrade costs. At the same time, it gives low efficiency when compared with a gas tank. But the gas boiler also requires annual maintenance.

We also recommend that you familiarize yourself with the comparison between a gas tank and main gas.