- Troubleshooting

- How to clean a chimney

- Chimney insulation

- How to protect the smoke channel from precipitation

- Types of chimneys

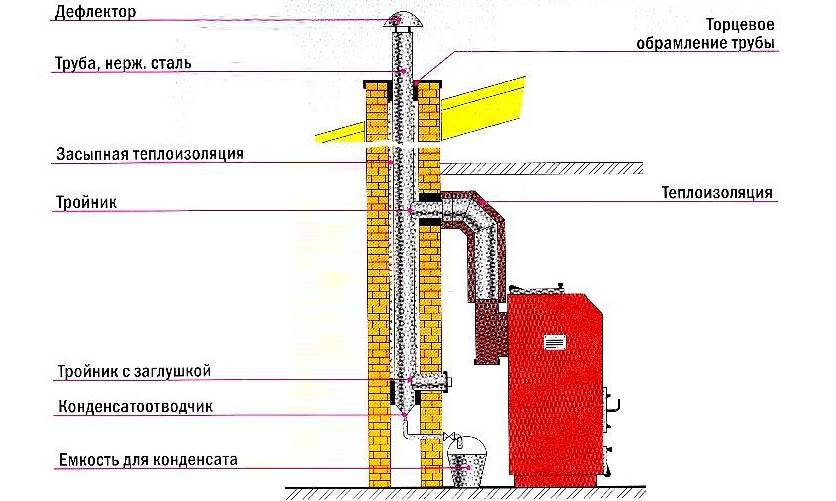

- Brick

- galvanized pipe

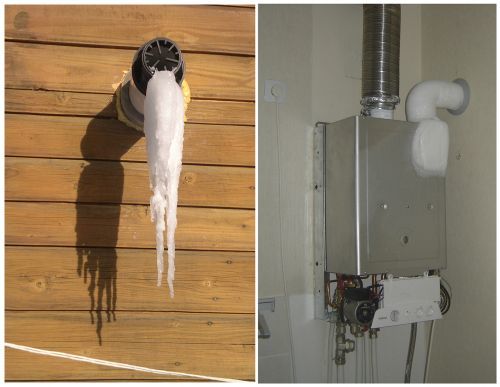

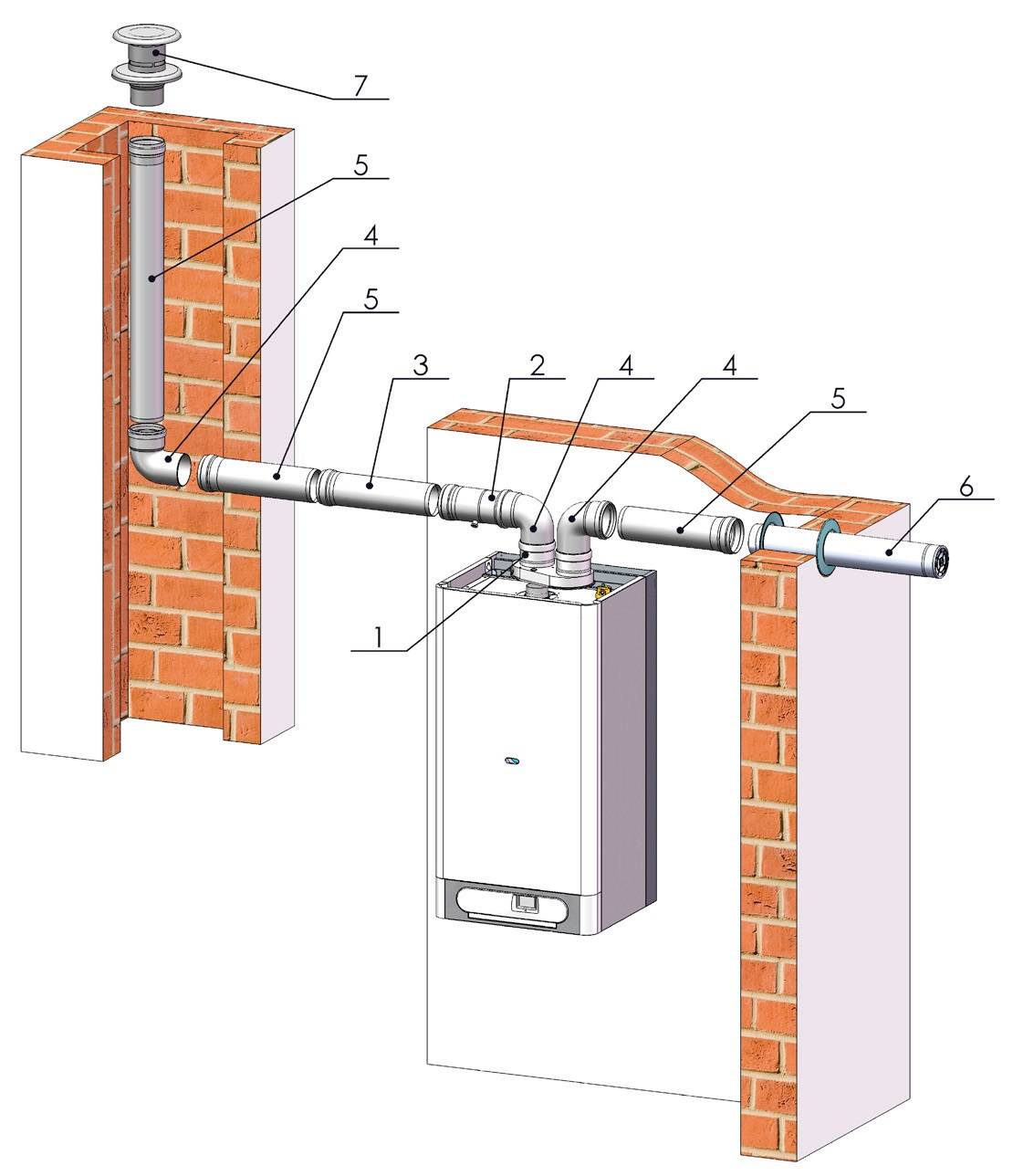

- coaxial chimney

- Ceramic

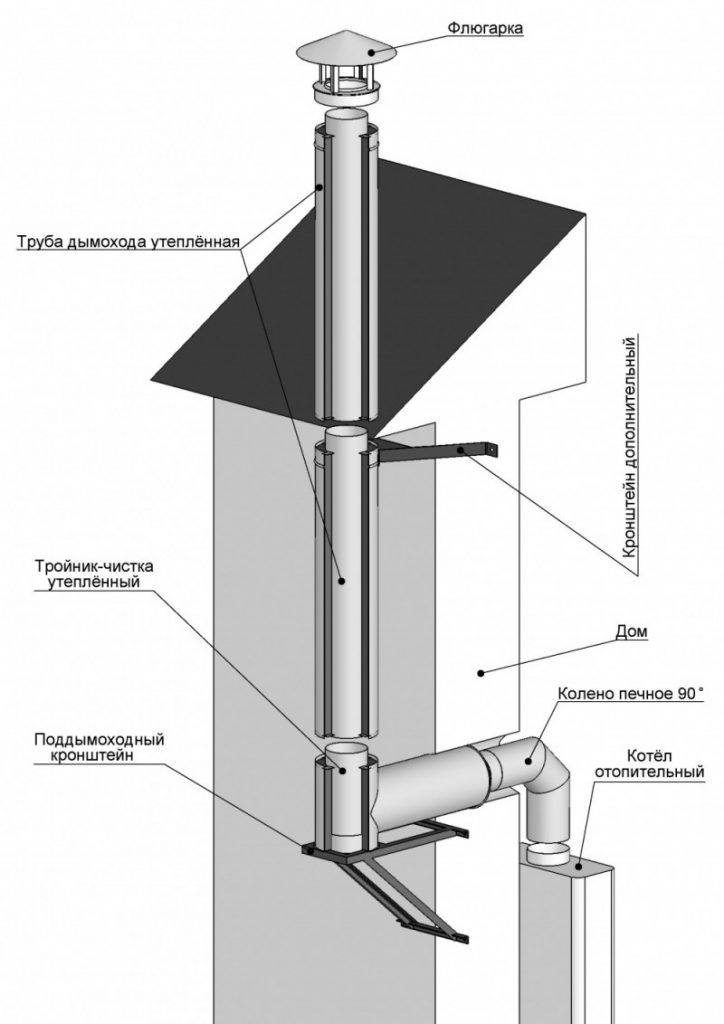

- Stainless steel

- What is condensate?

- Determination of the probability of condensation formation

- Options for gas ducts for a country house

- Selection Guide

- Chimney of solid fuel boiler

- A lot depends on the boiler itself.

- Factors affecting the formation of condensate

- Methods for insulating a metal chimney

- How to wrap stove or fireplace metal chimney pipes?

- How to isolate the metal pipes of the chimney of a gas boiler?

- Installation rules

- Signs of a clogged chimney

- What to do if the chimney is clogged

- Reconstruction of the chimney is one of the solutions to the problem

- Solutions

- Do-it-yourself insulation installation

- Making a deflector

- Required tools and materials

- Calculation of dimensions and scheme

- Table: dimensions of the deflector parts relative to its diameter

- Instructions for making a deflector with your own hands

- Video: self-manufacturing of the TsAGI deflector

Troubleshooting

Depending on the cause of the condensate, a method is selected to eliminate it, which include:

- chimney cleaning;

- chimney insulation;

- rain protection.

How to clean a chimney

If condensate accumulates in the chimney due to a blockage, then an immediate chimney is required. To clean the chimney, you can use:

- special chemicals that, when burned, decompose soot deposits. For example, the log "Chimney sweep";

- mechanical cleaning.

To clean pipes manually you will need:

The cleaning device smoothly lowers into the smoke channel from the roof of the house.

- folk remedies that were used in the villages. You can clean the smoke channel:

- ordinary salt, sprinkling it during the heating of the furnace;

- potato peelings, which are also loaded into the oven during the furnace.

With any cleaning method, elementary safety rules must be observed.

Chimney insulation

If condensate accumulates on the boiler pipe due to the use of heating equipment in the cold season, that is, the cause of moisture is the temperature difference, it is recommended to insulate the chimney.

As heaters you can use:

- mineral wool;

- any fibrous insulation;

- expanded polystyrene boards;

- plaster.

Mineral wool and fiber insulations are suitable for metal and asbestos-cement chimneys. The brick chimney is insulated by plastering the surface.

To insulate the chimney with fibrous materials or mineral wool, you need:

- cut the material into pieces required for wrapping the pipe;

- attach the material with metal wire or clamps over the entire surface of the chimney;

- close the insulation with a metal box or foil.

How to insulate a brick pipe with expanded polystyrene plates can be seen in the video.

Plastering a brick chimney for the purpose of its insulation is carried out in several stages:

- a plaster mesh is attached to the wall of the chimney for better adhesion of materials. Fastening is required to be carried out with special bolts with an enlarged head;

- the first layer of plaster is applied, consisting of a mixture of cement, lime, water and fine slag. The thickness of the first layer should not exceed 4 cm;

- after some time required to dry the solution, the remaining layers are applied, which should be from 3 to 5;

- to give the chimney an aesthetic appearance after the plaster has dried, it can be painted.

To insulate the pipe, the total layer of plaster must be at least 7 cm.

How to protect the smoke channel from precipitation

To protect the chimney from atmospheric precipitation, special ones are used that are installed on the top of the chimney.

Some heads are equipped with built-in deflectors. Such devices not only protect the pipe from precipitation, but also contribute to increased draft in the chimney.

Types of chimneys

Pipes are made from different materials, which we will consider in more detail.

Brick

Classic brick chimneys for a gas boiler are still in demand, regardless of their many disadvantages and poor thermal performance. At the same time, they comply with sanitary standards and rules, which state:

- The pipe is made of fireclay bricks.

- For the construction of walls, a solution of clay or special glue is used.

- To improve draft, the chimney rises above the level of the roof ridge.

Standards regulate the height of the pipe in relation to the roof ridge, depending on the distance between them

- The masonry provides tightness.

- At the inner hole, the deviation is no more than 3 mm per 1 m.

- To protect against precipitation, a deflector is installed on the head of the pipe.

And also the chimney can have a mono design, which, due to low thermal characteristics, is repaired every 5-7 years.

galvanized pipe

A sandwich device is today the most effective chimney design option. The undoubted advantage of these chimneys is their resistance to aggressive environments and various mechanical influences.

The product consists of two pipes of different sizes, with one inserted into the other. Basalt wool is usually used as a filler between them.

coaxial chimney

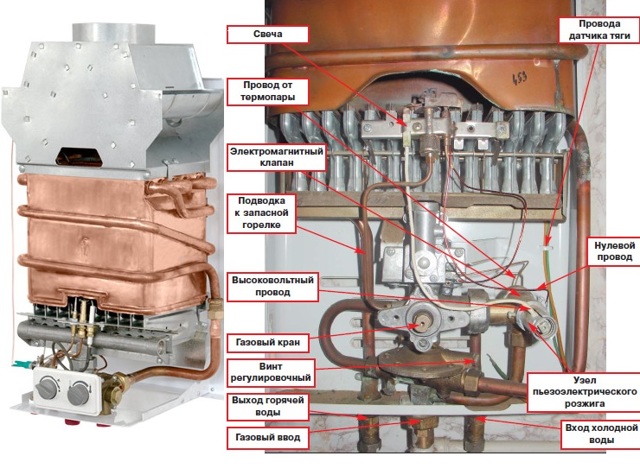

Currently, gas boilers use closed-type combustion chambers. Here, air intake and smoke removal are produced by a coaxial pipe. This is an original device, relatively recently introduced, but already very popular among users.

The non-standard solution lies in the intake of air through a pipe that removes combustion products. It turns out that one pipe performs two functions due to the design features.

A coaxial chimney is a pipe in a pipe

And its characteristic difference from ordinary pipes is as follows ... A smaller pipe (60-110mm) is located in a pipe of a larger diameter (100-160mm) in such a way that they do not touch each other.

At the same time, the structure is a single whole due to the jumpers along the entire length and is a rigid element. The inner pipe serves as a chimney, and the outer pipe serves as fresh air.

Air exchange at different temperatures creates traction and sets the air mass in a directed motion.The air in the room is not used during the operation of the boiler, thus maintaining the microclimate in the room.

Ceramic

Such a chimney is a composite structure, including:

- Smoke duct made of ceramic material.

- Insulation layer or air space.

- Claydite concrete outer surface.

This complex design is due to several reasons. First, the chimney pipe is too fragile to be left unprotected.

A ceramic pipe is always located inside a solid block.

Secondly, ceramics has a high thermal conductivity, and therefore it needs reliable insulation. The inner tube of a circular cross section has a smooth surface, while on the outer tube, roughnesses are allowed that do not affect the integrity of the product.

Typically, such chimneys are available in lengths from 0.35 to 1 m, depending on the manufacturer. The connection of the inner and outer pipes occurs by means of a lock, which is a thinning in external size from one end and an expansion of the inner pipe from the other side.

The expanded clay concrete outer surface is made of a square shape with a round hole inside. In addition, this product provides a place for a heater, which is held by metal jumpers. At the same time, they are fixed on the outer surface and make a reliable fastening for this pipe.

Stainless steel

A gas chimney made of steel seems to be more reliable than a brick one. They are resistant to corrosion, immune to temperature fluctuations, they are not affected by increased air humidity and aggressive environments.

Stainless steel chimney

In addition, such stainless steel pipes have a number of advantages:

- Long period of operation.

- Multifunctionality.

- Relatively low cost.

- Great strength.

- Probable realization of a product of any complexity.

For chimneys made of this material, an assembly of modules is characteristic, which allows the replacement of a damaged segment if necessary. The installation of chimneys is made with the help of special bends, which allow them to harmoniously fit into certain elements of the roof.

What is condensate?

Whatever type of fuel you use, you are burning hydrocarbons. Coal, coke, firewood, fuel oil, gas, pellets - everything consists of hydrogen and carbon with small impurities of sulfur and some other chemical elements. Any fuel also contains a small amount of water - it is impossible to completely remove it. During combustion, they are oxidized by atmospheric oxygen and the output is water, carbon dioxide, and other oxides.

Sulfur oxides react with water at high temperatures and form very aggressive acids (sulphuric, sulphurous, etc.), which also enter the condensate. A few other acids are also formed: hydrochloric, nitric.

Determination of the probability of condensation formation

Calculations can be carried out if condensate is formed as a result of a large release of steam and overheating of the chimney walls, and the power of the operating equipment is known. The average rate of heat release is 1 kW per 10 square meters. m.

The formula is relevant for rooms with ceilings below 3 m:

MK = S*UMK/10

MK - boiler power (kW);

S is the area of the building where the equipment is installed;

WMC is an indicator that depends on the climatic zone.

Indicator for different climatic zones:

- south - 0.9;

- north - 2;

- middle latitudes - 1.2.

When operating a double-circuit boiler, the resulting MK indicator should be multiplied by an additional coefficient (0.25).

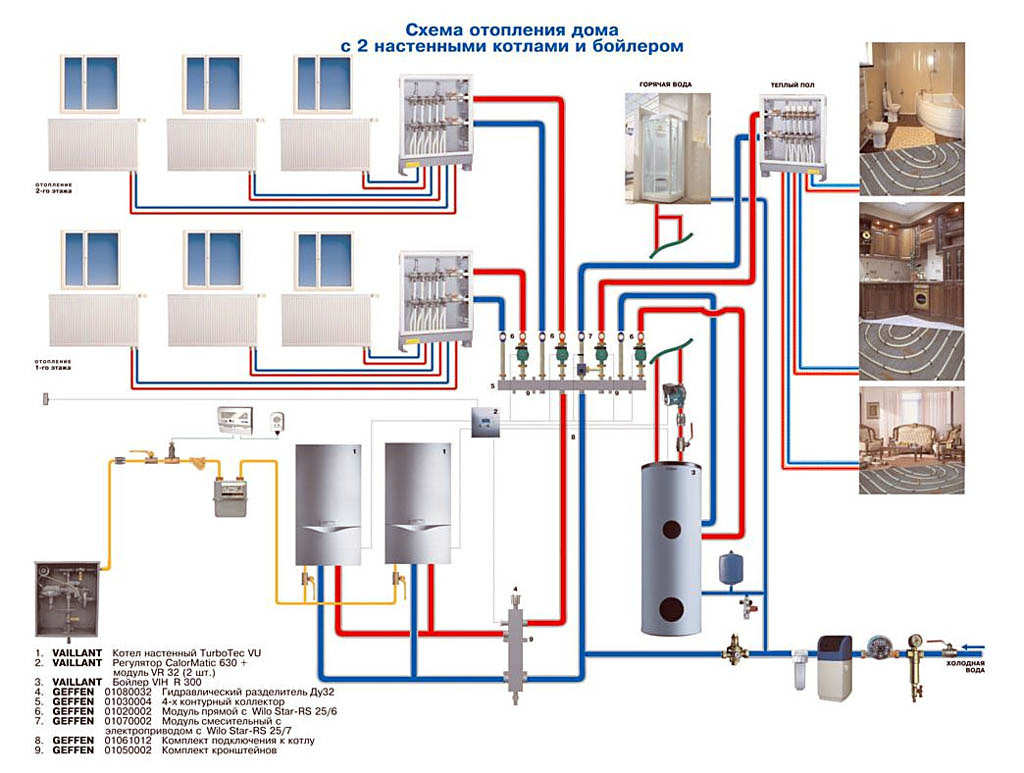

Options for gas ducts for a country house

To discharge combustion products with a relatively low temperature (up to 120 ° C) emitted by gas boilers, the following types of chimneys are suitable:

- three-layer modular stainless steel sandwich with non-combustible insulation - basalt wool;

- a channel made of iron or asbestos-cement pipes, protected by thermal insulation;

- ceramic insulated systems such as Schiedel;

- brick block with a stainless steel pipe insert, covered from the outside with heat-insulating material;

- the same, with an internal polymer sleeve of the FuranFlex type.

Three-layer sandwich device for smoke removal

Let us explain why it is impossible to build a traditional brick chimney or put an ordinary steel pipe connected to a gas boiler. The exhaust gases contain water vapor, which is a product of the combustion of hydrocarbons. From contact with cold walls, moisture condenses out, then events develop as follows:

- Thanks to numerous pores, water penetrates into the building material. In metal chimneys, condensate flows down the walls.

- Since gas and other high-efficiency boilers (on diesel fuel and liquefied propane) operate periodically, frost has time to grab moisture, turning it into ice.

- Ice granules, increasing in size, peel the brick from the inside and out, gradually destroying the chimney.

- For the same reason, the walls of an uninsulated steel flue closer to the head are covered with ice. The passage diameter of the channel decreases.

Ordinary iron pipe insulated with non-combustible kaolin wool

Selection Guide

Since we initially undertook to install an inexpensive version of the chimney in a private house, suitable for do-it-yourself installation, we recommend using a stainless steel pipe sandwich. Installation of other types of pipes is associated with the following difficulties:

- Asbestos and thick-walled steel pipes are heavy, which complicates the work. In addition, the outer part will have to be sheathed with insulation and sheet metal. The cost and duration of construction will definitely exceed the assembly of a sandwich.

- Ceramic chimneys for gas boilers are the best choice if the developer has the means. Systems such as Schiedel UNI are reliable and durable, but too expensive and out of reach for the average homeowner.

- Stainless and polymer inserts are used for the reconstruction - lining of existing brick channels, previously built according to old projects. Specially fencing such a structure is unprofitable and pointless.

Flue variant with ceramic insert

A turbocharged gas boiler can also be connected to a conventional vertical chimney by organizing the supply of outside air through a separate pipe. The technical solution should be implemented when a gas duct has already been made in a private house, brought to the roof. In other cases, a coaxial pipe is mounted (shown in the photo) - this is the most economical and correct option.

Noteworthy is the last, cheapest way to build a chimney: make a sandwich for a gas boiler with your own hands. A stainless pipe is taken, wrapped in basalt wool of the required thickness and sheathed with galvanized roofing. The practical implementation of this solution is shown in the video:

Chimney of solid fuel boiler

The mode of operation of wood and coal heating units involves the release of hotter gases. The temperature of the combustion products reaches 200 ° C or more, the smoke channel warms up completely and the condensate practically does not freeze. But it is replaced by another hidden enemy - soot deposited on the inner walls. Periodically, it ignites, causing the pipe to heat up to 400-600 degrees.

Solid fuel boilers are suitable for the following types of chimneys:

- three-layer stainless steel (sandwich);

- single-wall pipe made of stainless or thick-walled (3 mm) black steel;

- ceramics.

Brick gas duct of rectangular section 270 x 140 mm is lined with an oval stainless pipe

It is contraindicated to put asbestos pipes on TT-boilers, stoves and fireplaces - they crack from high temperatures. A simple brick channel will work, but due to roughness it will become clogged with soot, so it is better to sleeve it with a stainless insert. Polymer sleeve FuranFlex will not work - the maximum operating temperature is only 250 ° C.

A lot depends on the boiler itself.

One of the most important elements of such a design is considered to be the chimney itself. It is on how correctly it is designed and equipped that the quality of the hood and the efficiency of the boiler equipment itself depend.

Icing may occur due to incorrect installation

Icing may occur due to incorrect installation

The passage of the chimney through the brick wall of the house

The passage of the chimney through the brick wall of the house

Scheme of air inflow and flue gases

Scheme of air inflow and flue gases

Additional advantages of steel chimneys include:

- The inner walls are ideally smooth, which does not allow condensate and gases to accumulate;

- Steel pipes are not prone to absorbing various substances, moisture (unlike brick);

- If necessary, such a system can be additionally insulated with your own hands;

- After cooling, the structure can be easily and quickly cleaned, and moisture (condensate) evaporates on its own in 5-15 minutes;

- A large selection of additional fittings and fasteners allows you to create a fairly complex installation with various bends, slopes and branches.

One pipe performs two functions at once

One pipe performs two functions at once

All components and parts must be perfectly matched and compatible

All components and parts must be perfectly matched and compatible

Accommodation is possible even in a wooden house

Accommodation is possible even in a wooden house

Designation of connections and fittings required for assembly

Designation of connections and fittings required for assembly

Factors affecting the formation of condensate

The process of formation of condensate in the chimney channel depends on several factors:

- Humidity of the fuel used by the heating system. Even seemingly dry firewood contains moisture, which turns into steam when burned. Peat, coal and other combustible materials have a certain percentage of moisture content. Natural gas, burning in a gas boiler, also releases a large amount of water vapor. There is no absolutely dry fuel, but poorly dried or damp material increases the condensation process.

- Traction level. The better the draft, the faster steam is removed and less moisture settles on the pipe walls. It simply does not have time to mix with other combustion products.If the draft is bad, a vicious circle is obtained: condensate accumulates in the chimney, contributing to clogging and further worsening the circulation of gases.

- The temperature of the air in the pipe and the gases leaving the heater. The first time after kindling, smoke moves along an unheated channel, also having a low temperature. It is at the start that the greatest condensation occurs. Therefore, systems that operate constantly, without regular shutdowns, are least susceptible to condensation.

- Temperature and humidity of the environment. In the cold season, due to the temperature difference inside the chimney and outside, as well as increased air humidity, condensate forms more actively on the outer and end parts of the pipe.

- The material from which the chimney is made. Brick and asbestos cement prevent the dripping of moisture drops and absorb the resulting acids. Metal pipes can be prone to corrosion and rust. Chimneys made of ceramic blocks or stainless steel sections prevent chemically aggressive compounds from catching on a smooth surface. The smoother, smoother the inner surface and the lower the moisture absorption capacity of the pipe material, the less condensate is formed in it.

- Integrity of the chimney structure. In case of violation of the tightness of the pipe, the appearance of damage on its inner surface, traction worsens, the channel becomes clogged faster, moisture from the outside can get inside. All this leads to increased steam condensation and deterioration of the chimney.

Methods for insulating a metal chimney

Chimneys of different types and designs require different methods of insulation.There are types of insulation depending on the purpose of the chimney.

How to wrap stove or fireplace metal chimney pipes?

Steel chimneys can be used for decorative stoves and fireplaces that do not function as a permanent source of heating. It is enough to isolate such a chimney with a layer of plaster mortar. This method is mainly used for masonry chimney insulation, but a variation calculated for metal pipes is also possible.

The mixture is prepared from a special mixture and water. It would be technologically correct to first pour water into the mixing container, and then add the dry mixture there. After beating with a construction mixer, a homogeneous dense mass should be obtained.

To insulate a fireplace pipe or a decorative stove, you can use special plaster

The solution is applied to the surface to be insulated with spots using a spatula. Lumps of mortar must be distributed evenly over the entire area of the pipe. These sections are needed to fix the reinforcing frame of the fiberglass mesh on them. Without a frame, a thick layer of plaster may soon crack and become unusable.

First, a rough layer of plaster is applied to the reinforcing frame, adjacent to the duct. After applying the main thickness of the plaster, a final finishing layer can be formed.

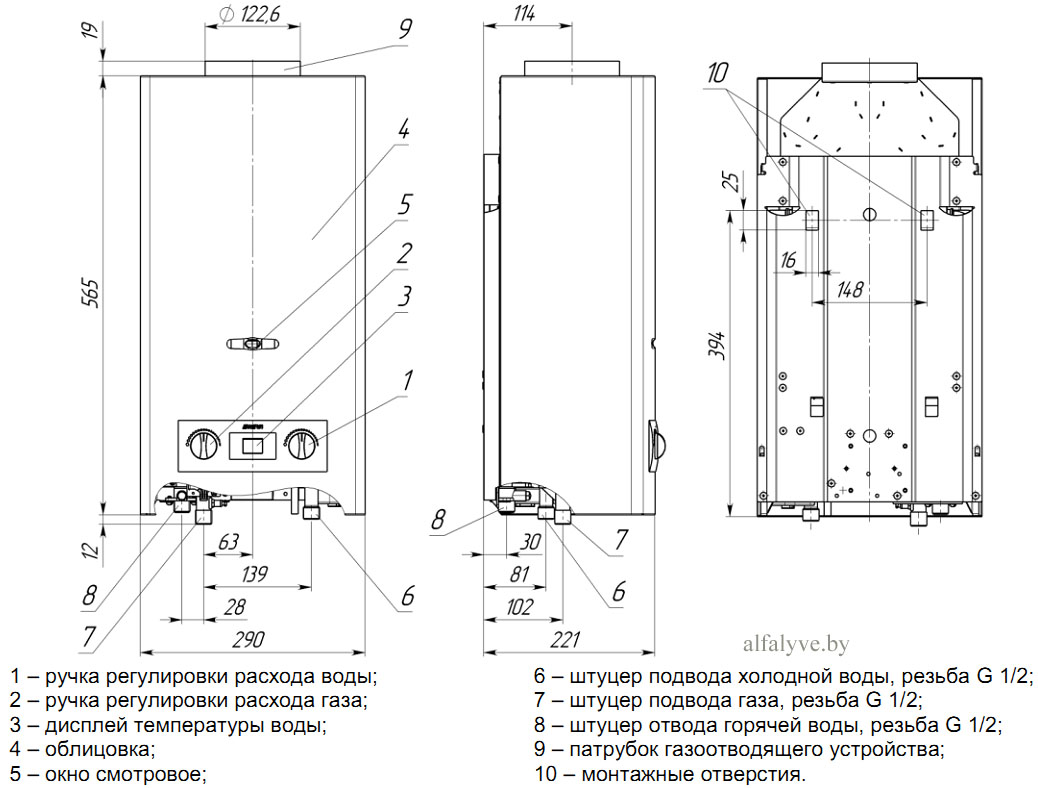

How to isolate the metal pipes of the chimney of a gas boiler?

Insulation of functional chimneys with your own hands can be done using a "sandwich" type design. This method is the most popular and effective in terms of protecting the structure from condensation and saving energy. The design of the sandwich chimney consists of two metal pipes and a layer of mineral wool between them.Moreover, a pipe with a large diameter in this case is a protective sleeve, while a smaller pipe will be a chimney.

A chimney pipe insulated in this way is not fire hazardous, since the winding layer is protected by stainless steel or galvanized iron.

Mineral wool can be used to insulate both the inside and outside of the chimney

The formation of the sandwich chimney structure occurs in several stages:

- holes are made in the roofing and the roof itself, the diameter of which will be 25 cm larger than the chimney pipe;

- a metal chimney should be insulated with a layer of basalt wool (a more practical variety of mineral wool) at least 5 cm thick. The winding is overlapped;

- the insulation is fixed with steel wire, which must be wrapped several times around the pipe;

- a casing is put on from a larger pipe. If the casing was made from a sheet of thin iron, it is fixed with adhesive tape and tie-down straps.

After making sure that the insulation was carried out correctly and there were no unfixed joints, you can put insulated pipes on the furnace nozzle through a hole in the roof. After completing the installation work on connecting the chimney to the heating source, it is necessary to fill the sheet of metal surrounding the riser with non-combustible material. For this, expanded clay, asbestos or clay is used.

Today, there are many options for how to insulate a chimney pipe. These works can be carried out independently, choosing a heater for chimney pipes is also quite simple. The main thing is that the design of the chimney system meets all the necessary requirements. Otherwise, thermal insulation can become an absolutely senseless waste of money.

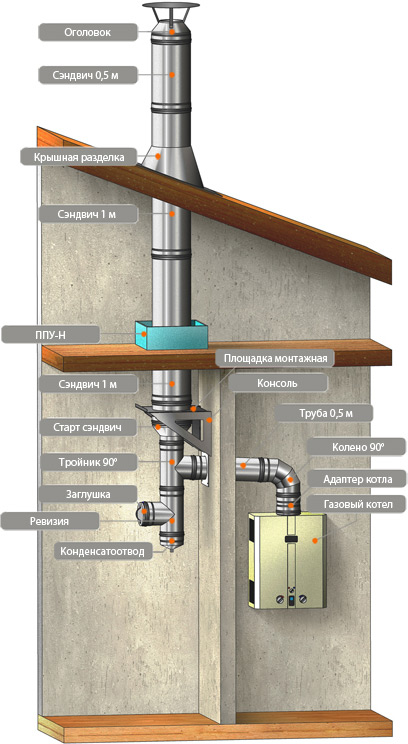

Installation rules

To prevent condensation from accumulating, the chimney system must be:

- waterproof;

- tight;

- protected from corrosion;

- insulated.

These conditions can only be ensured by the correct installation of the chimney, the choice of its materials, insulation and sealing during the assembly process. A description of the nuances of these processes can be found in the video below, with a brief overview of the types of chimneys and the requirements for their installation.

Basic provisions:

- the lower pipe is located with a bell to the outlet;

- all joints are treated with sealant;

- vertical deviations within 30% are allowed;

- horizontal distance does not exceed 1 meter;

- the cross section of the pipes throughout the channel is the same.

T-shaped condensate trap

Forbidden:

- the use of a brick chimney;

- the use of fungi and umbrellas at the headband.

To prevent condensate from collecting, it is necessary to have a condensate collector and a drain, ensuring good traction

It is important not to forget about the planned cleaning of the gas boiler and the prevention of the condition of the internal walls of the chimney

Signs of a clogged chimney

When the flue gas duct becomes clogged, it will be immediately visible. The main signs of a clogged channel will be the following phenomena:

- Deterioration of draft in the stove or fireplace. It is necessary to check the gate, and if it is in the open position, then the pipe cleaning is overdue.

- Gradual attenuation of the flame in the furnace of the thermal unit.

- Difficult combustion of fuel. If you are using dry wood and it does not burn, then the chimney is most likely to blame.

- Changing the color of the flame in the furnace. You should be especially wary if it has acquired an orange color.

- Sharp unpleasant odor. If acrid smoke appears in the room during the combustion process, it means that carbon monoxide (carbon monoxide) gets into it.In this case, the room must be well ventilated, the furnace must be interrupted and measures taken to clean the chimney.

The appearance of smoke when the gate is open indicates a lack of traction

What to do if the chimney is clogged

Before the start of the heating season, it is imperative to inspect the chimney from the inside for blockages. In the warm season, birds with a nest can settle in it or debris blown into the chimney by the wind can appear. To avoid this, the chimney must be equipped with a mesh cap at the installation stage to prevent such situations.

In such a case, the house should always have a backup heating unit in the form of a heater or an electric heater built into the heating system.

Having provided yourself with warmth with its help in the cold season, you can thoroughly consider the situation and think about options for getting out of it.

The presence of draft in the furnace must be checked every time the furnace is ignited - the flame must deviate towards the chimney

Reconstruction of the chimney is one of the solutions to the problem

The first sign of a permanently fading flame is an improperly designed chimney. It makes no sense to look for other reasons why the gas floor boiler blows out in the wind with such equipment. Gas supply is carried out under constant pressure, there are almost no significant drops. Any equipment malfunctions are unlikely, as modern boilers are reliable and simple in design. For example, the Conord boiler is known for its reliability and performance.

As for the chimney, here the answer to the question of why the boiler blows out in a private house can be called such moments:

The ventilation channel of the heater is covered with an ice crust. As a result, the air circulation inside the chimney is disturbed and the gas boiler does not receive enough oxygen. In addition, water vapor enters the chimney channel, which is cooled from the ice layer and forms condensate. In turn, water drops freeze on the walls of the chimney and the ice crust grows. To solve the problem of what to do so that the gas boiler does not blow out, the insulation of the chimney channel helps. In this case, the resulting condensate will flow down the walls. The occurrence of back draft due to insufficient height of the chimney. The increasing or changing direction of the wind creates a strong air flow that enters the chimney channel and reaches the combustion chamber. As a result, the flame in the burner is extinguished.

This situation is considered more dangerous, so it is important to know what to do when the boiler blows out in strong winds. The reverse movement of warm air captures the combustion products along the way, therefore, they enter the boiler and pollute the combustion chamber. It is not excluded the ingress of harmful gases into the living room

It is not excluded the ingress of harmful gases into the living quarters.

Solutions

You can find out how to solve this problem or how to melt the ice in the chimney in this section:

- To partially cope with this problem and reduce the amount of ice, you can remove the plug, which is located on the top of the device;

- Change the angle of inclination of the coaxial system (if it is vertical or horizontal and located at a right angle). This will allow the resulting condensate to drain and not freeze inside the pipes.

To prevent icing

To prevent icing, you can use special means "Anti-ice"

Insulated systems are less prone to icing

Insulated systems are less prone to icing

Although the instructions make it possible to partially solve the problem by removing the plug, ultimately, after the situation improves, it will be necessary to fix it in its original position, since its constant absence can lead to other malfunctions.

Do-it-yourself insulation installation

Chimney insulation using mineral, basalt or glass wool can be done in two ways: insulation under the casing or insulation of the chimney without a casing.

In order to isolate the chimney with mineral wool mats, you need to cut out several pieces of the slab from them, which will correspond to the sides of the pipe from the outside.

Then, with the help of wire firmware, fix them on the chimney.

After fixing the insulation on the chimney, it is recommended to make a casing to protect the insulation from atmospheric phenomena or to carry out the process of lining the chimney with bricks, asbestos-cement slabs.

To insulate a metal pipe, you need to wrap it with basalt wool and secure it with wire around the entire perimeter. After that, put a second pipe of a larger diameter on the chimney to make a kind of sandwich.

This method of thermal insulation of chimneys is the most effective and simple, but it allows to reduce heat loss by more than two times, as well as significantly reduce the fire hazard and the formation of condensate in smoke exhaust systems and protect them from destruction.

Thus, thermal insulation contributes to an increase in thermal efficiency and safe use of furnaces. At the same time, it gives the building and the structure itself a more aesthetic appearance.

During the operation of the heating system, the appearance of moisture in the chimney harms not only the chimney itself, but also the heater. Reacting with combustion products, moisture turns into chemically aggressive substances that disrupt the operation of the heating system.

It is impossible to get rid of condensate completely, but you can minimize its amount and prevent undesirable consequences.

Making a deflector

The simplest version of the Volpert-Grigorovich type deflector is quite easy to make with your own hands.

Required tools and materials

- Marker or marker.

- Ruler.

- Iron scissors.

- Mallet.

- Wooden beam for the stand.

- Riveting device.

- Drill, drill bits for metal (or - drill-tipped self-tapping screws).

- A sheet of galvanized iron with a thickness of 0.3-0.5 mm (aluminum sheet or thin stainless steel is suitable).

- Metal parts that are available: corner, studs, thick wire and the like.

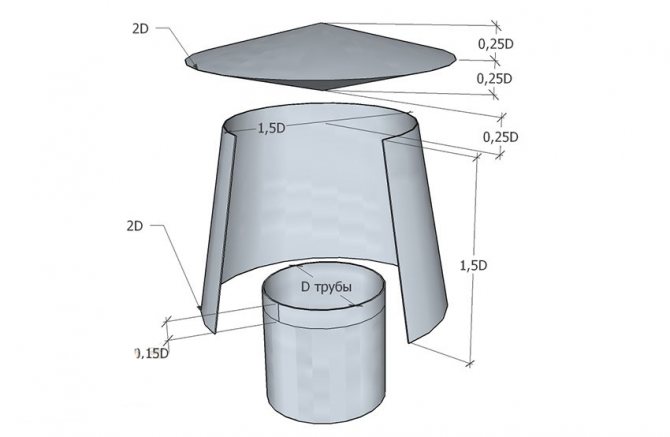

Calculation of dimensions and scheme

Since the quality of the deflector depends on the accuracy of manufacturing, drawing up the correct drawing is the most important step in the entire process. The dimensions were verified by scientists in a wind tunnel, and they must be followed.The parameter to be based on is the diameter of the chimney channel D.

The dimensions of all parts of the deflector are set in proportion to its diameter

Table: dimensions of the deflector parts relative to its diameter

| Index | Diameter ratio |

| Lower diffuser diameter | 2 |

| Upper diffuser diameter | 1,5 |

| diffuser height | 1,5 |

| Deepening the pipe into the diffuser | 0,15 |

| cone height | 0,25 |

| umbrella height | 0,25 |

| reverse cone height | 0,25 |

| Gap between umbrella and diffuser | 0,25 |

Instructions for making a deflector with your own hands

- We transfer the drawn details to cardboard and make a cardboard layout. We check the correspondence of the parts to each other.

- Opening the layout back. This cardboard pattern, laid on a galvanized sheet, is circled with a marker.

- Cut out all the details with iron scissors.

- We turn the casing and drill holes in its edges.

- We fasten the casing with rivets (or do not drill and do not fasten, but use drill-end screws).

- In the same way, we fasten the lower and upper cone plates in turn.

- The top cymbal is larger, so we cut out 6 tabs in its edge to attach to the bottom cymbal.

- We attach studs to the bottom plate for connection with the casing.

- We fasten them to the casing of the umbrella.

- To fix the finished deflector on the chimney, it is better to separate the upper part of the pipe and connect it to the deflector on the ground. The strength of this connection is extremely important. The wind load at altitude will be great and can get in the way.

The deflector may not turn out to be very beautiful, but you will immediately feel its usefulness: the draft will increase by a quarter, the roof will be protected from sparks. The pipe with it can be lower by one and a half to two meters.

Video: self-manufacturing of the TsAGI deflector

When installing any traction booster, you will immediately feel the benefits.But a self-made deflector will also create a weighty reason to make you proud of yourself.