- Causes of blowing out the boiler and ways to eliminate them

- The head of the heating device was covered with a large ice build-up

- Low pressure of gas entering the boiler

- Chimney problems

- Weak supply ventilation

- Pipe burnout

- Automation out of order

- Lack of electricity

- Causes of attenuation of turbocharged gas boilers with a closed combustion chamber

- Chimney cap or chimney icing

- Fan or turbine failure

- The gas boiler blows with the wind what to do

- Reasons for the extinction of the burner flame

- Reasons for blowing out a gas boiler

- Design errors

- Other factors

- How do device malfunctions manifest themselves?

- Thermostat not in the right place

- Insufficient supply ventilation or absence of a ventilation duct

- Solving problems with the attenuation of the boiler

- Traction recovery

- If there is no electricity

- If the gas pressure drops

Causes of blowing out the boiler and ways to eliminate them

There are several reasons why the boiler may go out.

The head of the heating device was covered with a large ice build-up

You can't beat him quickly. Otherwise, the components of the heating system may be damaged. When ice freezes on the head and inside it, the access of oxygen stops, and the gas boiler dies out.The defrosting of the head must be carried out gradually.

It is first removed, then brought into the room, and it is defrosted. While the tip is thawing, the boiler can function without it. The gas supply to the burner is shut off before the start, and after the igniter is lit, the valve is gradually opened.

After the main burner lights up, it is necessary to warm up the boiler. That is, it is necessary that he work on a small pressure of gas. After warming up, the gas pressure can be increased.

During the operation of the unit, it is necessary to control the state of the contacts of the piezo ignition element. They should be red-hot. If the contacts cool down, the gas pressure must be reduced to keep the thermocouple cool. Otherwise, a signal will be sent that will trigger the automation.

Low pressure of gas entering the boiler

This reason may arise due to malfunctions of the gas transmission network as a whole, but most often it appears:

- In the event of a malfunction of the gas meter. The meter breaks down, and it does not pass the required fuel flow. To check this, you need to look at the state of the counting mechanism. In the event of a breakdown, the meter makes uncharacteristic sounds for it.

- In case of breakage of leakage or temperature sensors. The gas service, guided by the approved rules, requires the installation of gas analyzers. When they are triggered, the gas boiler goes out.

- In case of violation of the tightness of the connections. In this case, gas leaks occur, which lead to a pressure drop, and a signal is given. As a result, the automation system is activated, and subsequently the unit is turned off.

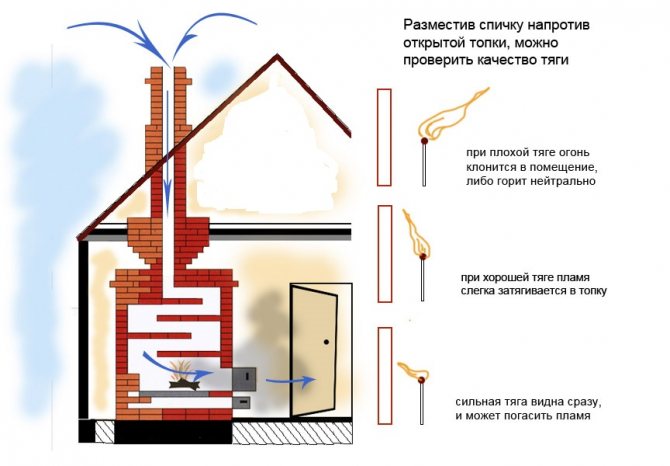

Chimney problems

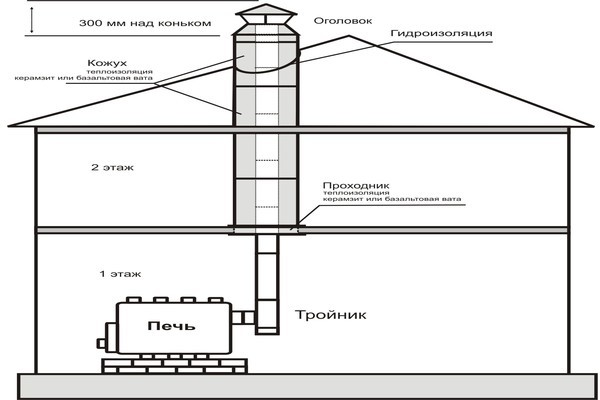

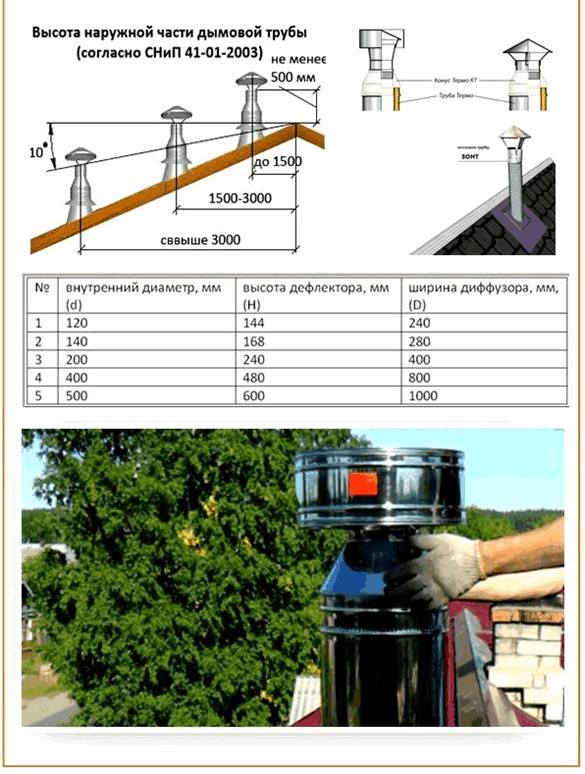

Chimneys on the roof

This is a frequently occurring reason why the boiler turns off. Chimney failure can occur:

- Due to the formation of ice. It occurs because the steam that enters the chimney with the products of combustion when raised, cools and settles in the form of condensate on the walls. The condensate freezes and forms a thick layer of ice. As a result, the draft decreases, the automation turns on, and the boiler goes out. To solve this problem, the chimney must be cleaned and insulated, which will allow the condensate to drain down, and not freeze.

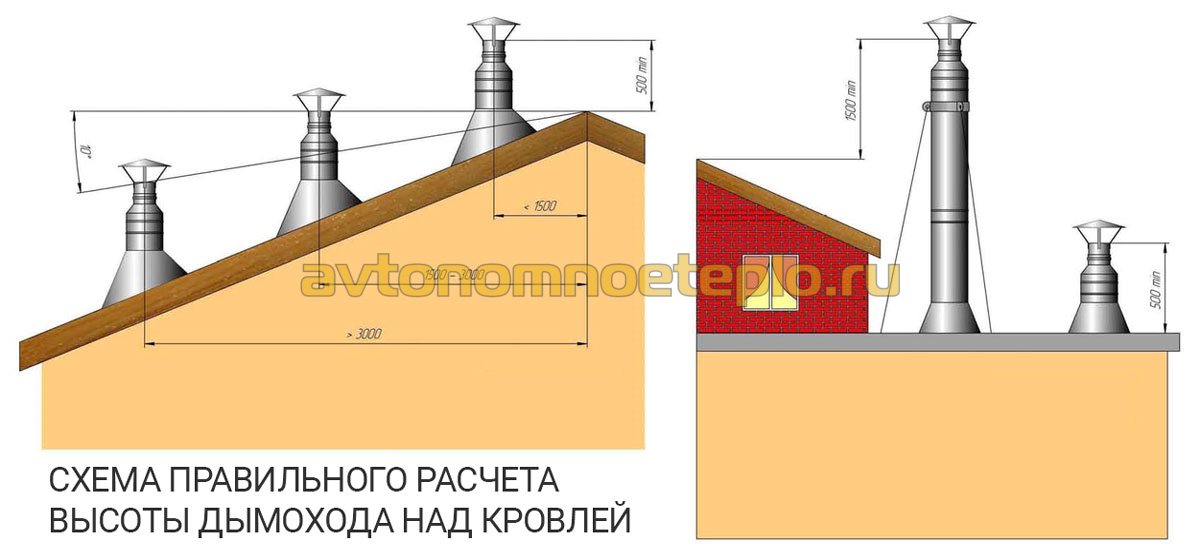

- Due to reverse thrust. It occurs if the wind intensifies or changes its direction outside. In this case, air enters the chimney and blows out the flame in the boiler. Sometimes this happens due to the insufficient height of the chimney pipe. This is a dangerous phenomenon if a boiler with poor automation is operated. After all, combustion products are not thrown out into the street, but are pushed out by the wind into the house. If there is a problem due to the size of the pipe, it must be increased. It should be 50 cm higher than the roof ridge.

Weak supply ventilation

Sometimes it is enough to open a door or a window, and the burner lights up, and the boiler starts to work. In boiler rooms, to improve air circulation, the hole at the bottom of the door is closed with a fine mesh.

Pipe burnout

This also leads to the attenuation of the unit, as the wind blows into the burnt hole and impairs the operation of the chimney. If such a problem occurs, the chimney pipe must be replaced.

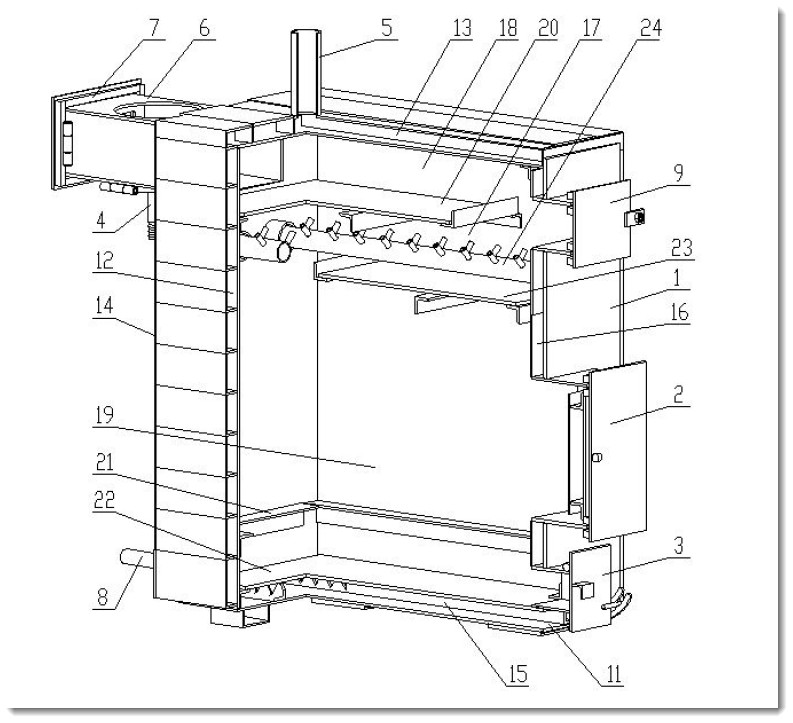

Automation out of order

Burner with windshield

Turbocharged boilers have a built-in fan that provides traction. When it breaks, it starts to hum strongly or does not make sounds at all. If it fails, it must be replaced.

Atmospheric gas boilers work with a draft sensor.It begins to function when the temperature in the smoke trap rises, when steam penetrates into it that has not entered the pipe. If this sensor breaks down, a signal is sent and the burner goes out.

Lack of electricity

When the voltage drops in the mains, the boiler goes out, including the Russian-made Keber unit, as the automation immediately picks it up. When electricity appears, the automation works, and the heating system starts to work. Such shutdowns adversely affect the electronics of the unit, and it may fail. If the gas does not ignite when electricity appears, then the automation has failed. To avoid such problems, you need to buy a voltage stabilizer.

If, after eliminating all of the above reasons, the boiler does not work for you, then the reason for the attenuation is in the unit itself.

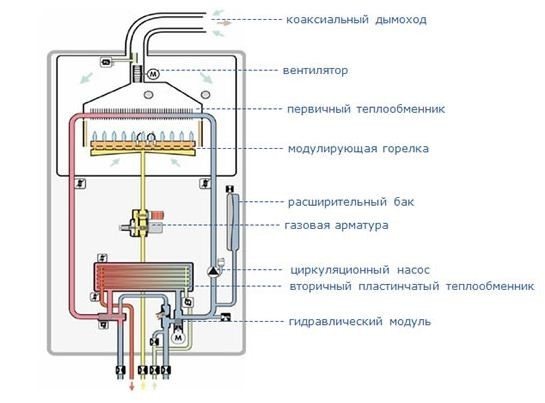

Causes of attenuation of turbocharged gas boilers with a closed combustion chamber

Turbocharged models of gas boilers have additional equipment, so in addition to the above problems, there may be other difficulties with them:

- ice formation inside and outside the chimney;

- malfunction of the built-in air blower.

Chimney cap or chimney icing

If the gas boiler goes out mainly in cold weather, then it is possible that the target of its chimney is blocked by an ice mass. This happens for two reasons:

- accumulation of condensate on the walls of the duct;

- snow sticking to the outside of the chimney.

The first situation is typical for convection boilers, usually with a coaxial chimney. In them, hot exhaust gases, when cooled already on the street, form condensate, which settles in the pipes. Therefore, when the thermostat turns off the heating after reaching the set temperature, all this moisture freezes.Over time, plugs form that block access to air.

As a rule, the problem can be identified visually: the surface of the pipe begins to get wet, and the wall at the level of ice is covered with frost on the outside.

It’s not always easy to knock down ice, so you should buy a disposable construction burner with a can in advance so that you can use it to defrost the air duct. When it warms up, the boiler will be ready for operation again, but so that this does not happen again, it is recommended to insulate the pipes.

The second situation arises when installing a coaxial pipe or cornice-type caps: the desire to protect the chimney from precipitation is understandable, but using them for gas equipment, as mentioned earlier, is highly undesirable. Instead, it is recommended to put open tapering nozzles on the headband.

Fan or turbine failure

When the igniter suddenly goes out in a unit with a built-in supercharger, you should listen to its work: the turbocharging system or the fan should emit a measured hum, so if extraneous noises appear (creaking, crackling, whistling) or the sound comes out intermittently, you should think about their malfunction.

If they stop making any sounds, the breakdown is obvious: at the same time, the automation does not allow the protective valve to be opened and the igniter does not light up at all.

You can try to fix the failed equipment, but, as practice shows, it is difficult to repair. In any case, only specialists should do the work, because without the necessary skills, all manipulations with the supercharger are associated with a high risk of carbon monoxide entering the room.

The gas boiler blows with the wind what to do

Often the reason for stopping the operation of a gas heating boiler is wind blowing. Its shutdown in winter is a very unpleasant surprise for the owners. This can lead not only to a sharp decrease in the temperature inside the house, but also damage to the entire heating system. Let's deal with the problem.

If your gas boiler unexpectedly turns off, do not panic and, for starters, exclude such a possible reason as a sharp decrease in gas pressure in the pipeline. To do this, you can simply turn on the gas stove and look at the flame, its size, check how quickly the water boils. You will immediately notice low gas pressure on the hob. In this case, your boiler is definitely not to blame, call the gas workers and find out the causes of the problem. Most likely, it is not only with you, but also with all the neighbors.

In addition, check and eliminate the possibility of gas leakage - using a soapy solution, which is applied with a sponge or spray gun to the joints of pipes and parts. No smell and no bubbles - so it's not a leak.

However, often the reason for turning off the gas boiler is obvious - there is a hurricane wind outside, which simply whistles in the pipes. Strong gusts of wind, falling into the chimney, cause reverse draft, the valve is activated, and the flame in the boiler automatically goes out.

Thinking about preventing the risk of blowing out the boiler should be at the stage of installing the chimney. It is highly desirable to take into account the wind rose in your area. An incorrectly located chimney relative to the wind backwater zone significantly increases the risk of blowing out the boiler burner. Incorrect chimney configuration can also cause this problem.

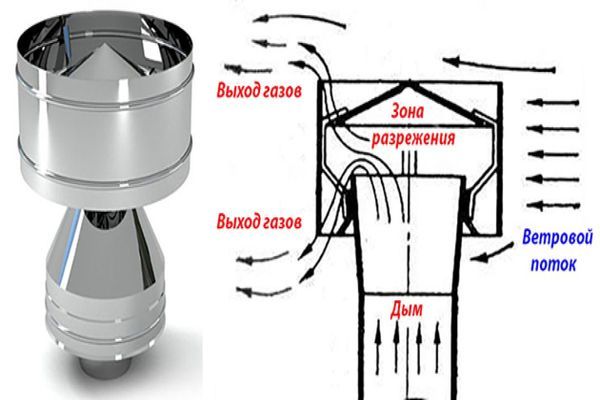

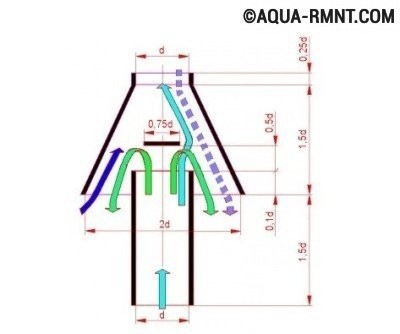

The deflector installed on the head of the chimney copes well with the problem of blowing out the boiler. This is a fairly simple design that enhances the draft in the chimney, protects it from precipitation and blowing. Be sure to think about installing a deflector or immediately purchase a design with such a device.

Important! Actions with gas equipment require coordination with the relevant service. Therefore, before installing a deflector or wind vane, consult with the gas workers. The cause of blowing out a gas boiler can also be a burnout of a metal chimney pipe.

As a result of burning, a hole is formed where the air flow enters - there are problems with the chimney. Only replacing the pipe will help to cope with the situation. In the case of coaxial chimneys, there is no risk of burnout, because the hot gas from the boiler goes through the inner pipe, being cooled by the oncoming cold air flow

The cause of blowing out a gas boiler can also be a burnout of a metal chimney pipe. As a result of burning, a hole is formed where the air flow enters - there are problems with the chimney. Only replacing the pipe will help to cope with the situation. In the case of coaxial chimneys, there is no risk of burnout, because the hot gas from the boiler goes through the inner pipe, being cooled by the oncoming cold air flow.

Two more possible reasons for blowing out a gas boiler:

Formation of frost on the chimney. This often happens with coaxial structures in frost -10..-15 °C. Hot steam leaves the chimney, gradually cools, turns into water droplets, condensate, which freezes, forming icicles and a thick layer of ice.This leads to a violation of traction, the boiler automatics work, it stops work. If such a problem arises, do not rush to knock down the ice build-up - you can damage the chimney itself. It is best to remove the head, the upper part of the pipe and bring it into a warm room so that the ice melts naturally. Before removing and cleaning the pipe, the gas supply must be shut off! Helps to avoid the appearance of frost additional insulation of the chimney;

Poor ventilation in the boiler room can lead to problems with the operation of the atmospheric boiler. The arrangement of forced ventilation in the room or a fine mesh hole at the bottom of the boiler room door will help.

They help to cope with the blowing of the boiler by manipulating the pipe - the diameter of its outlet can be reduced or increased in length. If the chimney opening is too large, it can be reduced by installing an additional inner pipe. Remember that the vertical chimney must be 50 cm higher than the roof ridge.

At the same time, too long a chimney can cause excessive, strong draft, which will literally tear off the flame from the boiler burner.

We strongly advise you to call specialists in case of problems in the operation of the gas boiler! Only they will be able to accurately determine the cause of the device shutdown and eliminate it.

Reasons for the extinction of the burner flame

Attenuation of the boiler from the wind is not such a rare problem. This concerns apartment owners less often - 95% of the equipment has a coaxial duct. But the owners of houses are often faced with the attenuation of the burner. Let's try to find the source of the problem and restore the device's performance.

So, the boiler may go out due to a mismatch between the technical parameters of the chimney and operating conditions. Another factor is inadequate ventilation. It is reasonable to entrust the elimination of such malfunctions to specialists.

In most cases, the burner goes out due to the design features of the entire heating system or under the direct influence of third-party interference.

In most cases, the burner goes out due to the design features of the entire heating system or under the direct influence of third-party interference.

Often a situation arises when the air mass acting from the outside creates pressure and the check valve is activated. A strong gust of wind returns it to the closed position, the gas supply to the furnace stops. In this case, the reconstruction of the chimney is needed.

The attenuation of the boiler may be due to:

- Failure of the flame control sensor. A worn out thermocouple or ionization electrode knocks out automation after the slightest breath of wind. The solution is to replace the defective part.

- Weak burning of the wick due to the fact that it is clogged or there is insufficient pressure at the inlet. If there is a regulator, you need to check its settings and increase the pressure. Plus clean the wick.

- Bad draft in the chimney.

- Accessibility of the system to the wind - no protection. Refers to single-story buildings and the upper floors of high-rise buildings. The problem is solved by installing a weather vane-deflector.

- Improper chimney design - when there are not enough turns. If it leaves the boiler immediately into the wall, the wind enters the boiler without hindrance. But on the outlet pipe, you can not make more than three turns.

- Incorrect ventilation system or lack of channels.

- Malfunction of safety sensors - draft sensor, limit thermostat. It is necessary to check the contacts of the protective equipment and clean them.

- The location of the chimney in the zone of wind backwater.

Why else can a gas boiler go out in the wind? Sometimes the equipment is located in the kitchen with a balcony on the second or third floor of the building. It is enough to open the balcony door for a strong draft to form sharply, the wick began to oscillate and died out.

The reason for the attenuation of the burner may also be the burning of the pipe, when air enters through the hole and interferes with the normal operation of the chimney. In this case, you need to change the chimney structure

The reason for the attenuation of the burner may also be the burning of the pipe, when air enters through the hole and interferes with the normal operation of the chimney. In this case, you need to change the chimney structure

It is useful to inspect the external elements of the heating system for the presence of ice build-up.

It's not worth hitting him. It is necessary to turn off the gas, bring the removable parts into the room for slow thawing. After returning them to their place, warm up the device, gradually increasing the gas pressure.

Reasons for blowing out a gas boiler

The owners of private houses are well aware of the situation when, with a strong wind, the gas boiler simply goes out. Residents of city apartments are not familiar with this problem if the gas boiler installed in the apartment has a coaxial air duct - this design does not allow a strong gust of wind to get inside, causing the burner to blow out.

In a private house, the design of the chimney and the ventilation device looks different, and blowing out the gas boiler is not uncommon.

There can be many reasons.

Other reasons, as a result of which the burner flame suddenly goes out, are associated with the design features of the gas heating equipment or the influence of third-party factors.

Design errors

High-quality ventilation of the heating system and the removal of combustion products depend on the chimney, so it is important to avoid mistakes during its design.The problem can lie both in an incorrectly calculated pipe section that does not correspond to the power of the heater, or in a low-set pipe

The exhaust gases from modern low-temperature boilers do not have enough energy to evaporate on their own, therefore, when using such facilities, it is better to buy electric smoke exhausters. These fans are installed on the roof, prevent blowing out, and also ensure the free exit of all products of combustion of the fuel.

Also, an error may be made in the thermal insulation of the pipe. Because of this, the descendants of the wind, together with the low outside temperature, prevent the normal removal of smoke and the operation of the heater, respectively. Often, partial insulation of the pipe in the upper part helps to cope with the problem. But it is advisable to initially ask the engineers to take care of the high-quality thermal insulation of the chimney in the boiler room, so that in the future you will not have such problems. After all, some options for insulation can be applied only at the stage of creation.

Another source of problems can be a strong vertical deviation of the ventilation ducts. According to GOST for wood and gas heaters, the maximum deviation is 30 degrees and in the area no more than 1 meter. If the boiler is equipped with a direct firebox, then you should take care of a direct-flow chimney; in this case, no other solutions are presented. Otherwise, there may be a danger of fire, from which good traction will save. There are no such clear rules with a gas boiler, however, it is better not to exceed the restrictions described above. Consider all these common design mistakes if you are thinking about an independent heat source.After all, learning from the mistakes of others is much better than learning from your own.

Other factors

The most common situation faced by the inhabitants of a private house is the operation of a check valve as a result of excessive pressure of the air mass coming from outside. With a strong gust of wind, the valve becomes in the closed position - the automation is sensitive to its position and shuts off the gas supply to the furnace. If this situation is repeated frequently, it is necessary to reconstruct the chimney

Pay attention to its height. For normal operation of ventilation, the upper edge of the chimney must be at least 0.5 m higher than the extreme point of the roof of the building, and the diameter of the air duct must correspond to the parameters of the boiler equipment and is determined by calculation

To improve draft, it is necessary to regularly clean the ventilation ducts, since the boiler constantly needs an influx of oxygen with air. The lack of oxygen in the combustion chamber causes a low intensity of fuel combustion. With poor draft, the flame can go out altogether.

How do device malfunctions manifest themselves?

Faults appear as follows:

Finding a reason

- The main burner burns weakly or does not turn on at all. Perhaps the cause is clogged injectors. Clean them with a small diameter wire. If air has entered the gas system, an error code is displayed on the boiler display. The boiler must be turned off and restarted. How to carry out these manipulations is described in the instruction manual.

- The burner does not ignite with automatic or manual ignition.If such a malfunction occurs, the gap in the ignition electrode may be broken, there is no contact with the electrical wire, or the filter supplying air to the burner is dirty. The gap can be adjusted by yourself, but it is quite difficult, so it is better to contact the master. You can clean the filter and check how the wire is connected, and you can do it yourself.

- The thermocouple has failed. In this case, it is necessary to remove the part that has broken in the Keber boiler or any other manufacturer. Select a thermocouple of the same brand as was previously installed and replace it.

- After a while, the burner goes out. This can happen if the ionization electrode is clogged, the gap is not adjusted in it, or the connecting wire is soldered. It is necessary to clean the electrode and set the gap or solder the wire.

- Breakaway flame. The nozzle makes a loud noise or whistle. The defect is corrected by adjusting the gas pressure on the igniter. A separation can occur if there is a strong draft or a large supply ventilation, and at the same time the air blows out the flame in the burner. This may be due to a too high chimney pipe.

- The unit makes noise and turns itself off. This is possible when the pump or fan in turbocharged boilers, the thermostat fails, as well as the flame breaking off or slipping in Keber boilers and others.

Usually, problems are displayed on the display in the form of an error code that will help the user understand what is the cause of the breakdown.

Some models of boilers are phase-dependent, that is, they are sensitive to the location of the "phase" and "zero" on the wire. To fix this problem, you just need to turn the plug over to the other side.

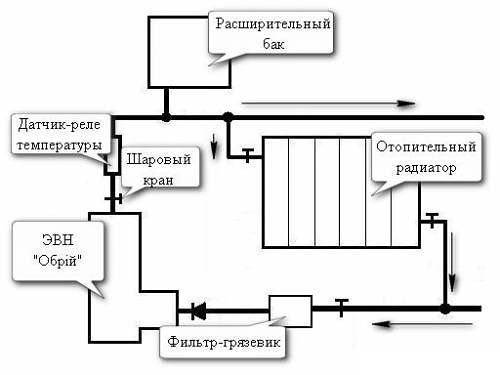

Thermostat not in the right place

For the correct operation of the boiler room, it is very important to adhere to the scheme for connecting the thermostat to the gas boiler. The use of a thermostat provides a short delay after reaching the set temperature, which can significantly reduce the number of switching on and off the boiler, save resources and reduce wear and tear on equipment

To connect the thermostat to the boiler with the Dry Contact circuit, two conductors are connected, while the cable length should not exceed 50 meters. In this case, the thermostat must not be installed next to the boiler. It is also unacceptable to install a thermostat in an unheated room.

Insufficient supply ventilation or absence of a ventilation duct

When burning one cubic meter of gas, ten cubic meters of air are burned. Accordingly, in most cases, in domestic domestic boilers, if it is not a turbine type of boilers with a coaxial tube, air from the room is used.

And, accordingly, if you have insufficient supply ventilation: the door is not cut, or holes are not made, and the room is permanently closed, there is not enough air supply for the boiler to burn.

Either the ventilation duct you may not have, or it may simply be clogged. Again, it is necessary either to clean the ventilation duct, or to ensure air flow from below. This is necessary in order to burn the required amount of air in the room and your gas boiler does not go out. If you do not have forced ventilation, or there is no draft in the ventilation duct, then the boiler will start to burn the air from the room. When all the room air is burned, it will begin to capture air from the street through the chimney. Thus, a reverse thrust is formed.A certain draft is formed and this draft can blow out your boiler.

Solving problems with the attenuation of the boiler

If the shutdown of the flame is not caused by malfunctions of the boiler itself, but by other external reasons, you can try to fix the problems yourself. Some models of simple boilers can even be cleaned from soot and soot on their own, but this is a topic for a separate article.

Traction recovery

You can deal with what is clogged - a boiler or a chimney - by disconnecting the corrugated pipe of the exhaust system from the boiler itself. If there is a draft in the pipe, then we solve the problem with the boiler by calling the master. Otherwise, you have to climb onto the roof and look into the pipe. If a blockage is found, it is necessary to remove those foreign fragments that interfere with the passage of smoke.

It is still possible to reconcile with the blowing of the channel due to strong wind if this happens once or twice during the entire heating season. But if winds are a frequent occurrence in your area, you should take measures:

- First, you can try to build a pipe. High altitude will prevent the wind from pushing the air back with force.

- Secondly, a competent head configuration can help out, which will close the hole from the side where the winds predominantly blow.

If there is no electricity

A non-volatile boiler in conjunction with a circulation pump consumes not so much. It can be adapted for DC power and switched to battery operation. But for powerful boilers this is not suitable. The only way out is to connect the boiler to an alternative source of electricity, such as a gasoline or diesel generator.

If the gas pressure drops

The first step is to check the gas pipeline in the place where it departs from the main line. The joints, where there are traces of welding, as well as valves and taps, are carefully checked. The specific smell that is given to natural gas at distribution stations will help detect a leak.

The only option is to write an appeal to the appropriate authorities. Contact your neighbors - they most likely have the same problem. Drafting a collective petition will help expedite the decision-making process within the natural gas supplier organization in your area.