- If the pump sucks air from the well. Why is air in the water from the well and what to do

- Key components of the pumping unit

- The order of operation of the unit

- Breakdowns most commonly encountered

- The pump spins but does not pump water

- Causes of air in the well for water

- Separate room in the house

- Main tasks of the device

- cavitation as the reason

- Types, principle of operation

- Correction of errors in work

- Violation of the rules of operation

- Engine malfunctions

- Problems with water pressure in the system

- Video review - The principle of operation of the accumulator

- Elimination of cavitation

- Revision of the storage tank

- The role of the accumulator in the operation of the system

- Air pressure control

If the pump sucks air from the well. Why is air in the water from the well and what to do

Residents of private houses, dachas, country houses often urgently need to install a pumping structure for pumping water from a well or well. For some, this is the only way to have water indoors. Therefore, when, one day, the pump stops buzzing, it is urgently necessary to understand the origin of the breakdown.

If the pumping station stops pumping water, it is urgent to find the cause of the breakdown

Often the stumbling block is the air that enters the pump along with the liquid.Everything can be prevented, only initially you need to find out what elements the pumping structure is assembled from.

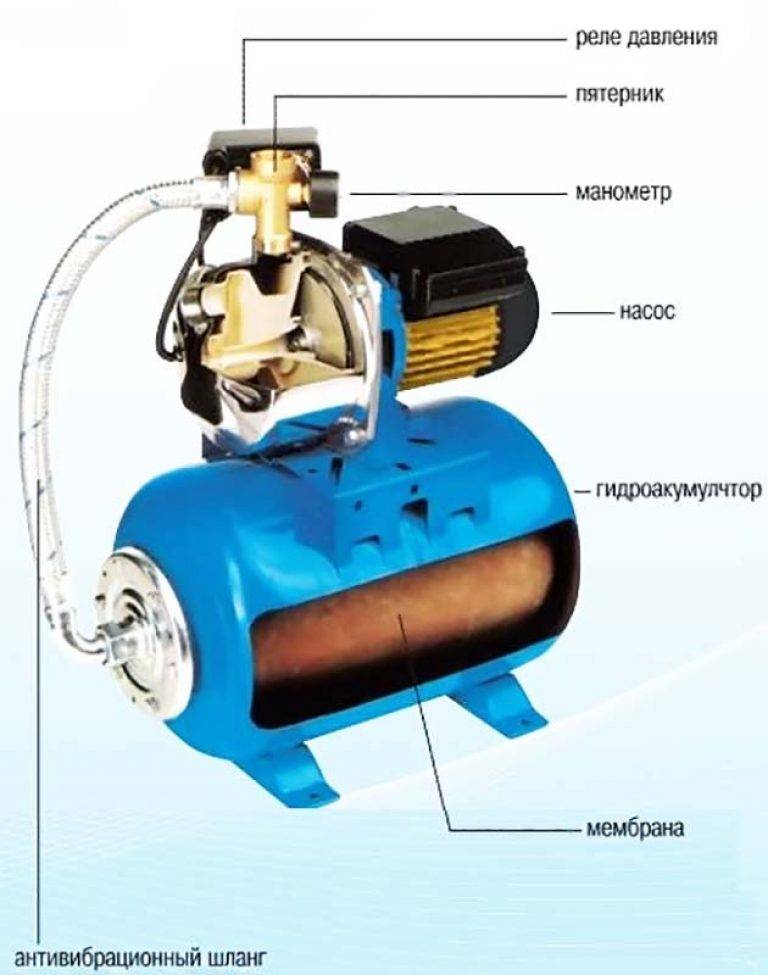

Key components of the pumping unit

There are many varieties of stations, but the main components are common to all.

- Self-priming pump. Principle of operation: the pump independently draws liquid from the recess with the help of a tube, one end of which is in the well, the other is connected to the equipment.

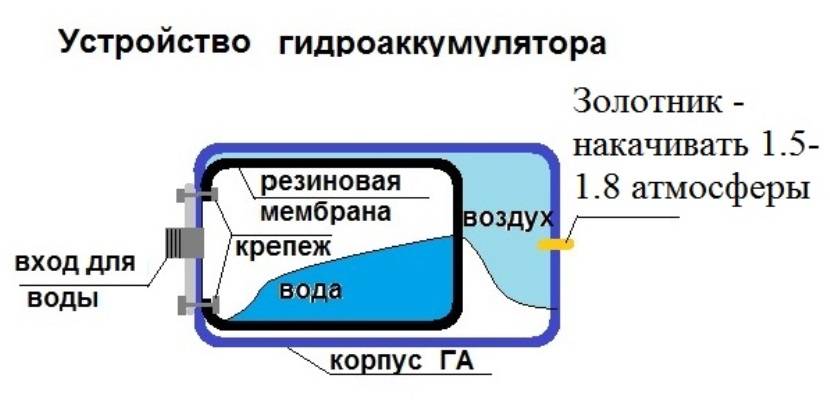

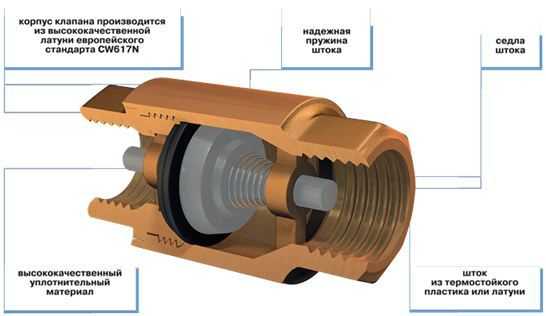

The pump is located a short distance from the water tank. The depth of the tube is also adjustable. - All units are equipped with a hydraulic accumulator. The vessel, using the energy of compressed gas or a spring, transfers liquid under pressure to the hydraulic system. It accumulates hydraulic fluid and releases it at the right time, thereby avoiding water surges in the system. Outside, it is metal, inside there is a rubber membrane, above it there is a gas cavity filled with nitrogen, and a hydraulic cavity. Water is filled until the pressure in both cavities is equal.

- Electrical engine. Through the coupling, it is connected to the pump, and with the relay - using the electrical circuit. Due to the fact that the pump does not turn on for short liquid intakes, the motor does not wear out.

- Air outlet.

- collector element.

- Pressure gauge. It allows you to monitor the level of pressure.

- Relay. By changing the pressure, by opening / closing the contacts, it supports the independent operation of the equipment.

The main purpose of pumping stations is to maintain continuous pressure in the water supply structure.

In order for all components to function like a clock, it is important to correctly select the required volume of the hydraulic accumulator and control the connection between the regulator and the pump itself

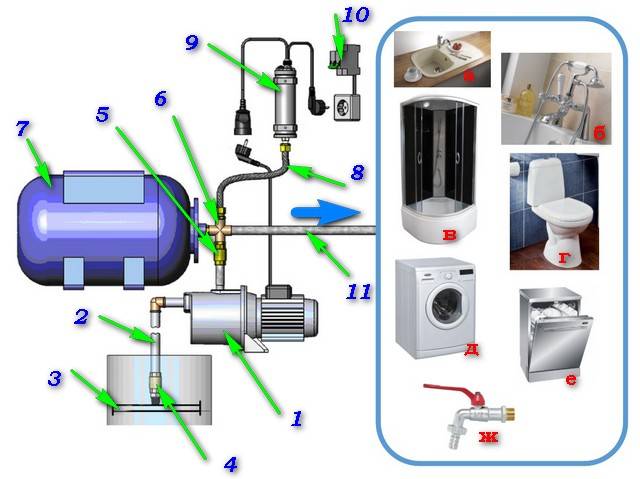

The order of operation of the unit

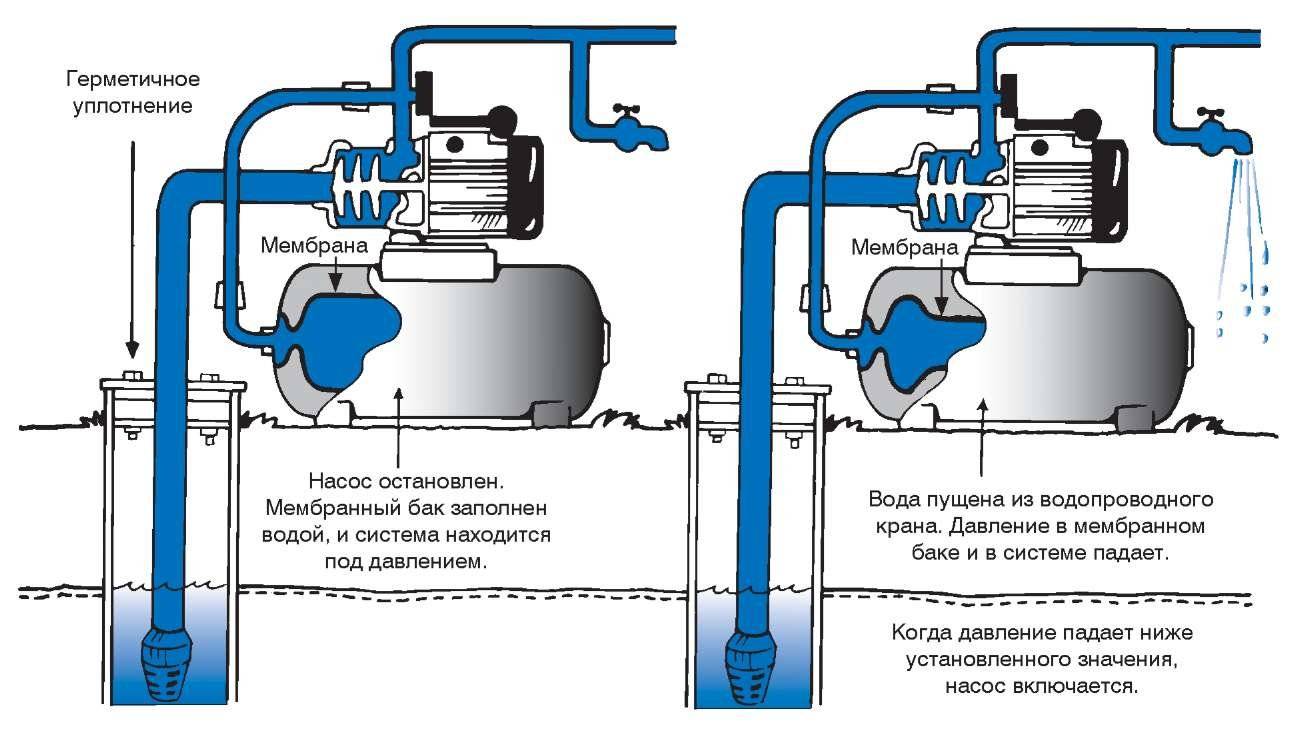

When turned on, the electric motor is the first to come into play, it starts the pump, and it pumps the gradually incoming liquid into the accumulator. When the accumulator is full to the limit, excess pressure will be created and the pump will turn off. When the faucet is turned off in the house, the pressure decreases and the pump starts working again.

The house has a battery connected to the water supply. The pipes fill with water when the pump starts. When the pressure in the station reaches the required peak, the pump is switched off.

The pump unit will solve the difficulty of supplying water to houses, baths, summer kitchens, outbuildings and other premises on the territory of your site. Having familiarized yourself with the details of the operation of the station, it is necessary to study the possible causes of the failure of the device and ways to eliminate them.

Breakdowns most commonly encountered

In the process of using any equipment, there comes a moment when it either wears out or breaks.

So in the second case, it would be important for the owner to understand the causes of damage. Here is a short list of grounds that disrupt the operation of the pumping station:

- no electricity - trite, but also not excluded, since the operation of the unit directly depends on the electric current;

- the pipeline is not filled with liquid;

- pump malfunction;

- hydraulic accumulator broken;

- damaged automation;

- cracks in the hull.

The pump spins but does not pump water

What to do when the station does not pump water? A frequent cause of failure is the lack of fluid in the pipes or in the pump itself. It happens that the unit is functioning, but the water is not pumping. Then you should inspect the tightness of the entire water supply, if there are any places where the pipes are poorly connected.

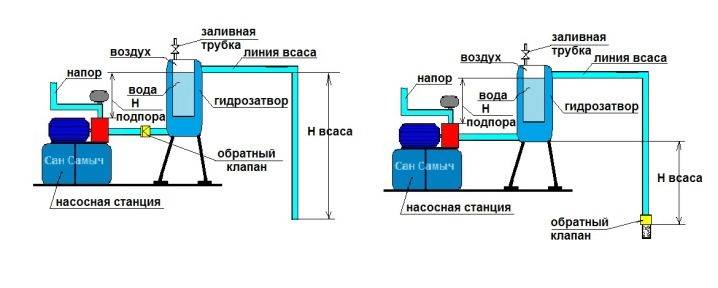

Check that the pump is not empty. The check valve is not working properly. The throughput must be one-way. This is one of the most important parts of the station, because, after the pump is turned off, it prevents water from flowing back into the well.

Diagram of a pumping station valve that can become clogged with debris

It happens that the valve is clogged and does not physically close, debris, salt, grains of sand can get into it. Accordingly, the liquid does not reach the pump. We solve the problem.

Before spinning the unit, we advise you to check the voltage of the electric current. It happens that it is below normal, and the pump is simply unable to turn on. Etc

Causes of air in the well for water

As a rule, households using small volumes of water from a source or seasonal use of pumping equipment face the problem of air entering the water. The causes of this phenomenon may be the following problems in the system:

The suction of the air mass at the place of water suction has failed. The problem will not be solved until the pipeline is completely replaced with all the necessary parts. It is easy to make sure that it works properly - just pump water in the pipeline, for example, in the bathroom.

Breakdown of the pumping equipment itself due to irregular or poor-quality maintenance. Air bubbles are formed as a result of a fragile stuffing box seal. The solution to the problem is to disassemble the working unit of the station and fix the breakdown.

Insufficient filling level of the well with a large pumping out. Drilling a new well, purchasing a less powerful pump, reducing the amount of water used can solve the problem

However, when drilling a new well, it is important not to reach the same aquifer where the chance of re-airing the system is very high.

Separate room in the house

The optimal solution for a pumping station would be

use of a separate room where noise will not be heard. Sure to do

such a design will not be difficult, but it will have to be heated, which

entails certain costs. Considering today's price for

energy source, it is worth understanding that this

option is absolutely not suitable, since it takes more money to heat the room.

@Nasosnaya_stanciya

@Nasosnaya_stanciya

Of course, if possible, you can install the station in the utility room. This option is possible when a well or well is located in close proximity to the house. A good solution for a station would be a basement that is below ground level.

@Nasosnaya_stanciya

@Nasosnaya_stanciya

Firstly, the noise will be absorbed by the ground, without transmitting it to the house, and secondly, a certain temperature always remains at a certain depth and the water will not be able to freeze. If you allocate a pantry for the pumping station, then in this case the room will have to be carefully soundproofed.

Main tasks of the device

To know how to choose a hydraulic accumulator, it is important to clearly understand what tasks it can solve. So, the accumulator solves the following series of tasks:

- the accumulator is designed to maintain a given level of water pressure inside the system;

- the accumulator-receiver should reduce the number of pump starts;

- the hydraulic accumulator is designed to reduce the likelihood that there will be hydraulic shocks in the system;

- the hydraulic accumulator retains a certain supply of water if electricity is not available for some reason.

At the same time, it is very important that if there are any malfunctions of the accumulator, they must be immediately eliminated. It will help avoid serious consequences and accidents

So, if you carefully look at the tasks that hydraulic accumulators solve for water supply, you can come to the conclusion that they are able to extend the life of the pump for a long time. In addition, hydroaccumulators for water supply are often needed for backup water replenishment. It is very convenient and practical

It does not matter what kind of horizontal or vertical accumulator you have. Its performance will depend on the setup and application.

If we take into account that the accumulator (or rather its tank) has a usable volume of around forty percent, then we can find out how much “reserve” water will turn out. The most optimal tank volume, which is better to buy, is one hundred liters. There is no need to try to buy a large tank if it will not be used at full capacity.

Important! If only two people live in the house, then it is quite enough for them to purchase a 24-liter hydraulic accumulator

The calculation is quite simple. It has been proven in practice. If three people live, you can purchase a tank of 50 liters

Well, for four people, you need to pay attention to tanks from 80 liters and above. There is probably no need to purchase a large tank for a family of two.

This can be more expensive both at purchase and during operation.

cavitation as the reason

The presence of a transparent section of the pipeline will help detect the presence of air in the line

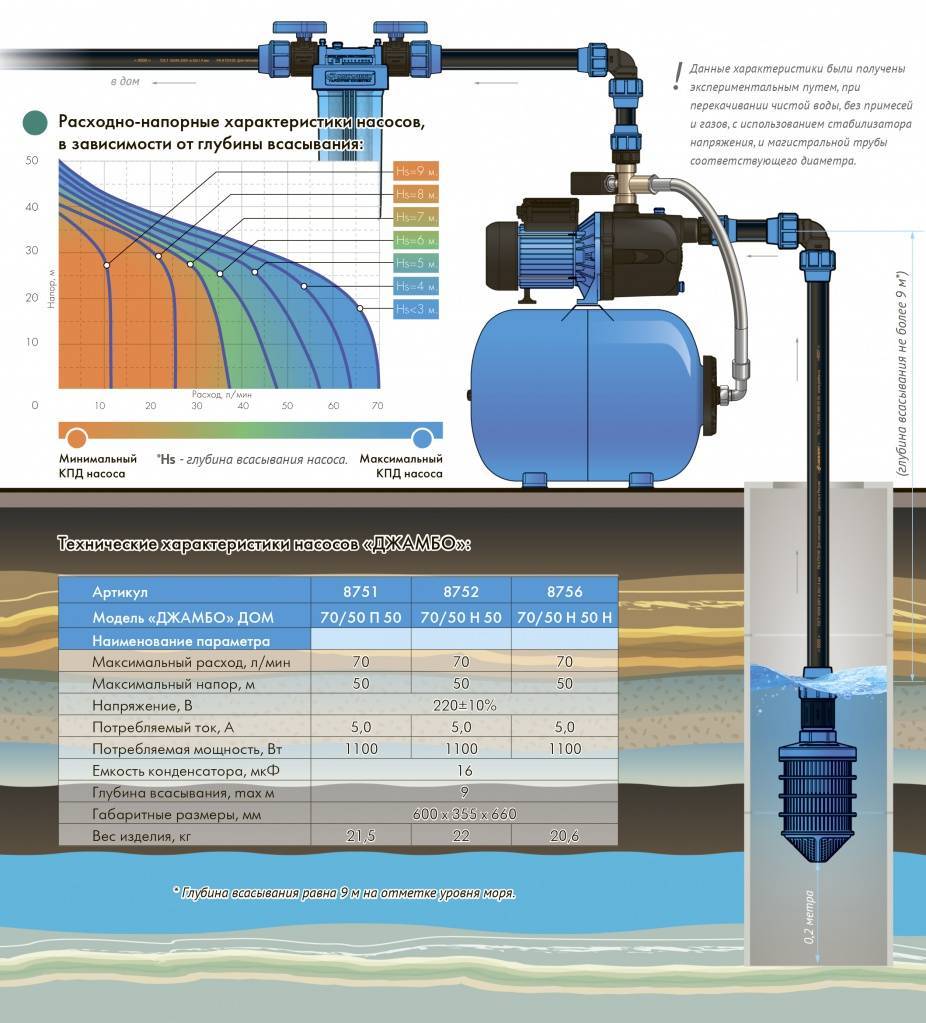

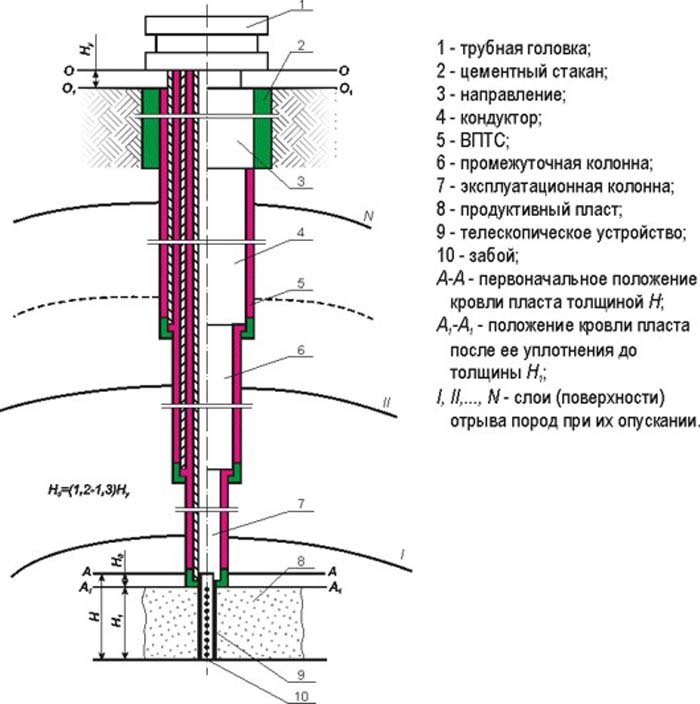

Before you start clarifying the issue, it is important to know: pumps are installed depending on the diameter of the well! For dimensions of 100 mm a submersible pump is suitable, smaller diameters require a circular or plunger pump. What is cavitation? This is a violation of the continuity of the liquid flow, otherwise - filling the water with bubbles

Cavitation occurs in those areas where the pressure drop reaches a critical rate. The process is accompanied by the formation of voids in the flow, the release of bubble formations of air that appear due to vapors and gases released from the liquid. Being in the area of reduced pressure, the bubbles can grow and collect into large hollow caverns, which are carried away by the fluid flow and, in the presence of high pressure, collapse without a trace, and in the conditions of an ordinary domestic well, they often remain and it turns out that the pump during operation pumps air bubbles from wells without producing the required amount of water

What is cavitation? This is a violation of the continuity of the liquid flow, otherwise - filling the water with bubbles. Cavitation occurs in those areas where the pressure drop reaches a critical rate. The process is accompanied by the formation of voids in the flow, the release of bubble formations of air that appear due to vapors and gases released from the liquid. Being in the area of reduced pressure, the bubbles can grow and collect into large hollow caverns, which are carried away by the fluid flow and, in the presence of high pressure, collapse without a trace, and in the conditions of an ordinary domestic well, they often remain and it turns out that the pump during operation pumps air bubbles from wells without producing the required amount of water.

The identification of the cavitation zone is sometimes impossible due to the lack of special instruments, but it is important to know that such a zone can be unstable. If the deficiency is not eliminated, then the consequences can be devastating: vibration, dynamic effects on the flow - all this leads to a breakdown of the pumps, because each device is characterized by a specified value of cavitation reserve

Otherwise, the pump has a minimum pressure, within which the water that has entered the device retains its density properties. With changes in pressure, caverns and air voids are inevitable. Therefore, the selection of the pump should be carried out depending on the volume of water needed to meet economic and domestic needs.

The destruction of air bubbles occurs only when they are carried by the flow to the area of high pressure, which is accompanied by small hydraulic shocks. The frequency of impacts leads to the appearance of a hissing sound, by which it is possible to determine the presence of air in the well.

Types, principle of operation

We do not need to consider how the accumulator is repaired. This should be the concern of professionals. By the way, at present there are many organizations specializing in repair, ready to work with any devices. It is enough for us to know, briefly, the device of the accumulator and how it works. Below we will consider its types and principle of operation.

The most basic purpose of all devices is to store hydraulic energy in order to then give it to the domestic water supply system. Currently, there are two main types of tanks - membrane and balloon. As for the balloon type, this is a tank that has a balloon made of rubber.When exposed to strong pressure, air saturates the space around the cylinder, and the cylinder itself is filled with water. Gradually, the pressure in the tank increases. If the need arises, the air that is at the cylinder begins to push out the water. It enters the domestic water supply.

If we consider membrane-type batteries, then they have a divided space using a membrane with elastic properties. One half contains air. The other half is water. The air pushes the water out to enter the system.

The first type of accumulator is considered more reliable and also practical. By the way, if you want to change the cylinder yourself, you can do it without calling the master.

A stainless steel accumulator is often offered. This is a good option, since a priori stainless steel acts as a strong and durable material. You can also immediately buy a pump with a hydraulic accumulator. If you are interested in the price, then you can choose the most acceptable option, depending on where the device will be used.

Many note that in order to understand the principle of operation of the receiver, it is enough to take a closer look and that's it. You don't even have to use the instructions. The scheme is very simple. For a person who has at least a little experience with mechanical devices, it will not be particularly difficult to deal with the operation of a hydraulic accumulator.

The hydraulic accumulator has a welded steel vessel, which is covered with a special paint. It helps protect against corrosion.There is also a rubber membrane, as well as an air valve. With the help of a steel flange, the device is connected to the domestic water supply system.

Important! When choosing a tank, it is necessary to take into account the type and brand of the pump. This directly depends its capacity

In order not to buy a tank that will later have to be changed, it is better to immediately seek help from a specialist. He will make a calculation and give recommendations not only on volume, but also on the brand of the tank and other elements.

Literally all homeowners should rely on certain recommendations before buying a hydraulic accumulator:

- the pump will be turned on much more often in a system in which the tank is with a smaller volume;

- a large tank can really be used as a water storage device if the power supply is interrupted;

- a hydraulic accumulator, which has a small volume, often contributes to pressure surges occurring inside the system.

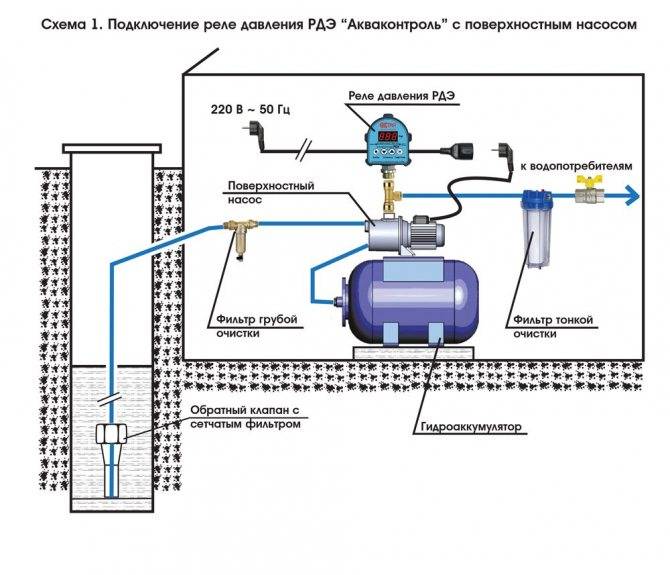

Correction of errors in work

Before embarking on a more serious intervention in the operation of the equipment, it is necessary to take the simplest measures - clean the filters, eliminate leaks. If they do not produce results, then proceed to further steps, trying to identify the root cause.

The next thing to do is to adjust the pressure in the accumulator tank and adjust the pressure switch.

The following are the most common malfunctions in the domestic pumping station, which the user can try to solve on his own. For more serious problems, contact the service center.

Violation of the rules of operation

If the station runs continuously without shutting down, the likely cause is incorrect relay adjustment - a high shutdown pressure is set.It also happens that the engine is running, but the station does not pump water.

The reason may lie in the following:

- When first started, the pump was not filled with water. It is necessary to correct the situation by pouring water through a special funnel.

- The integrity of the pipeline is broken or an air lock has formed in the pipe or in the suction valve. To find a specific cause, it is necessary to make sure that: the foot valve and all connections are tight, there are no bends, narrowings, hydraulic locks along the entire length of the suction pipe. All malfunctions are eliminated, if necessary, replace damaged areas.

- The equipment works without access to water (dry). It is necessary to check why it is not there or to identify and eliminate other causes.

- The pipeline is clogged - it is necessary to clear the system of contaminants.

It happens that the station very often works and turns off. Most likely this is due to a damaged membrane (then it is necessary to replace it), or the system does not have the pressure required for operation. In the latter case, it is necessary to measure the presence of air, check the tank for cracks and damage.

Before each start, it is necessary to pour water into the pumping station through a special funnel. She must not work without water. If there is a possibility of the pump running without water, you should purchase automatic pumps equipped with a flow controller

Less likely, but it can happen that the check valve is open and blocked due to debris or a foreign object. In such a situation, it will be necessary to disassemble the pipeline in the area of \u200b\u200bpossible blockage and eliminate the problem.

Engine malfunctions

The household station engine does not run and does not make noise, possibly for the following reasons:

- The equipment is disconnected from the power supply or there is no mains voltage. You need to check the wiring diagram.

- The fuse has blown. In this case, you need to replace the element.

- If you cannot turn the fan impeller, then it is jammed. You need to find out why.

- Relay damaged. You need to try to adjust it or, if it fails, replace it with a new one.

Engine malfunctions most often force the user to use the services of a service center.

Problems with water pressure in the system

Insufficient water pressure in the system can be explained by several reasons:

- The pressure of water or air in the system is set to an unacceptably low value. Then you need to configure the relay operation in accordance with the recommended parameters.

- Piping or pump impeller blocked. Cleaning the elements of the pumping station from contamination may help solve the problem.

- Air enters the pipeline. Checking the elements of the pipeline and their connections for tightness will be able to confirm or refute this version.

Poor water supply can also be caused by air being drawn in due to leaky water pipe connections or the water level has dropped so much that air is being pumped into the system when it is taken.

Poor water pressure can create significant discomfort when using the plumbing system

Video review - The principle of operation of the accumulator

A special relay block automatically turns off the pump when the pressure tank is full. And for some time the energy of the membrane does not give pressure to decrease. When the accumulator is empty, the pump starts again.Such an arrangement saves the water pumping unit from short-term and frequent starts / shutdowns. This reduces the wear rate of its parts. In order for everything to work correctly, the pressure tank must correspond in capacity to the volume of required water analysis. Normally, the tank must hold from a quarter to a half of the displacement that the pipes can pass per minute.

A properly selected volume of the device ensures the frequency of its operation from five to fifteen times per hour. In this mode of operation, it is extremely necessary to use a reliable and elastic membrane that can withstand heavy loads.

Since hydraulic accumulators work in domestic water systems, the material from which they are made must be non-toxic, approved for use in contact with clean drinking water.

The water that enters the accumulators for water supply mainly comes from underground wells or wells. Hence its saturation with oxygen, which is released during the operation of the system, accumulating in the membrane. To do this, most modern devices of this type have a safety valve on the upper part of the body that bleeds air if necessary. As a rule, accumulators are used on cold water supply lines, so the temperature regime in which they are used is more gentle.

It is advisable to install such a pressure element before the water supply circuit begins to branch. The best place is immediately after the water supply pipe enters the housing. Also, the installation of a check valve will not interfere .. Especially if one is not included in the pump.In addition, it is recommended to install a pressure gauge to control the pressure generated.

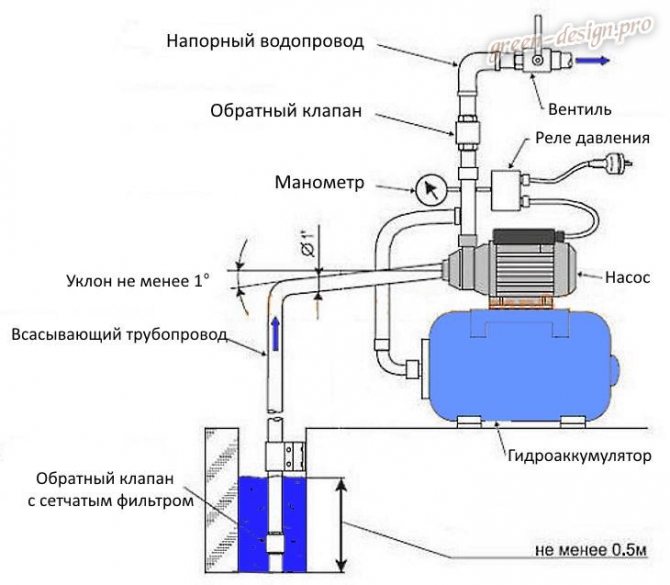

Elimination of cavitation

Most often, cavitation occurs in the trunk of telescopic wells.

What can be done to avoid the appearance of air in the well and the entry of water with bubbles:

- Replacing the suction pipe of small diameter with a larger one;

- Moving the pump closer to the storage tank.

Attention! When moving the pump, observe the established regulations: the distance from the pump to the tank must not be less than 5 diameters of the suction pipe!

- Reduce the pressure of the suction element by replacing it with a smooth pipe, and the valve can be replaced with a gate valve, and the check valve can be removed altogether;

- The presence of a large number of turns in the suction pipe is unacceptable, they must be reduced or the bends of a small radius of turns should be replaced with large ones. The easiest way is to align all the bends in the same plane, and sometimes it is easier to replace rigid pipes with flexible ones.

If all else fails, you will have to increase the pressure on the suction side of the pump by raising the level of the tank, lowering the axis of the pump installation or connecting a booster pump.

Note that all manipulations are shown based on a large amount of water consumption and the installation of powerful pumping devices.

And, it is important that cavitation can only occur at a depth below 8 meters. It is with such a length of all elements and the presence of high pressure in the pipes that the liquid passes into a gaseous state and water goes with air

Revision of the storage tank

Starting work on adjusting the equipment, disconnect the system from the network, close the pressure valve on the side of the water intake.The tap is unscrewed and the water is drained, and the remains are drained through the pressure hose, disconnecting it from the membrane tank. First, check the air pressure in the accumulator tank.

The role of the accumulator in the operation of the system

The membrane tank of the pumping station is, in fact, a metal container with a rubber pear located inside, which is designed to collect water.

Air is pumped into the free space between the rubber bulb and the walls of the tank. In some models of hydraulic accumulators, the tank is divided in half by a membrane that delimits the tank into two compartments - for water and air.

The accumulator tank maintains pressure in the system and creates a small supply of water. Once a month, the pressure in the hydropneumatic tank should be checked with the pump turned off and the water drained from the supply pipe.

The more water enters the device, the more it compresses the air, increasing its pressure, which tends to push the water out of the tank. This allows you to maintain a stable water pressure even when the pump is idle.

The accumulator requires regular maintenance, removal of air from the pear, which enters it along with water in the form of small bubbles and gradually accumulates there, reducing the usable volume.

For this, a special valve is provided on top of large tanks. With small containers, you have to contrive to remove air: de-energize the system and drain and fill the tank several times.

The selection of a hydraulic tank by volume is made taking into account the highest value of water consumption for a particular consumer.The allowable number of starts per hour specified by the manufacturer is taken into account, as well as the nominal values of the cut-in pressure, cut-out pressure and user-specified pressure in the hydraulic tank

Air pressure control

Although the manufacturer adjusts all elements of the pumping station at the production stage, it is necessary to double-check the pressure even in new equipment, since at the time of sale it may decrease slightly. The device that is in operation is inspected up to two times a year.

For measurements, the most accurate pressure gauge is used, because even a small error of 0.5 bar can affect the operation of the equipment. If it is possible to use a car pressure gauge, with a scale, with the smallest graduation, this will provide more reliable results.

The air pressure indicator in the membrane tank must correspond to 0.9 times the switching pressure of the pumping station (set using a relay). For tanks with different volumes, the indicator can be from one to two bar. Adjustment is carried out through the nipple, pumping or bleeding excess air.

For normal operation, the station is equipped with mandatory control and regulation devices:

The less air is pumped into the system, the more water it can store. The water pressure will be strong when the tank is full, and more and more weakened when water is taken.

If such drops are comfortable for the consumer, then the pressure can be left at the lowest acceptable level, but not less than 1 bar. A lower value can cause the bulb filled with water to rub against the tank walls and damage it.

To install a strong water pressure in the water supply system, it is necessary to fix the air pressure in the range of about 1.5 bar. Thus, the difference in pressure between a full and empty tank will be less noticeable, providing an even and strong flow of water.