- Which geysers work with low pressure?

- Typical problems for individual models

- Thermocouple problems at Junkers Bosch

- Speaker contact oxidation Vector

- Problems with the stem in the Neva models

- Other problems when using a geyser

- The most common causes of breakdowns

- Removing a clogged burner

- Why is the faucet humming

- How to fix a bathroom faucet problem

- Elimination of violation of traction

- User opinions

- Gas column repair Neva

- How to repair the union nut of the heat exchanger

- Repair of the microswitch in the start-up system of the geyser

- Sources of the accident

- Clogged heat exchanger

Which geysers work with low pressure?

If the reason for the low pressure of hot water is not in gas equipment, but in water pipes, you can solve the problem either by normalizing the pressure in the pipes or by purchasing a gas water heater that will function properly even with poor water pressure.

Modern geysers, which are equipped with a water pressure control device, will cope with this task. They work according to the following principle: the stronger the water pressure, the higher its temperature, and vice versa. Thus, if you set the minimum water temperature, the column will turn on even with low pressure.However, if problems with the pressure of hot water are observed constantly, it would be more appropriate to supply the system with a pump.

To flush the heat exchanger from scale yourself, you can watch the following Youtube user video, in which everything is described and described in detail.

Typical problems for individual models

Even speakers from well-known companies can break down over time for a variety of reasons. During operation, device owners noticed breakdowns that most often occur in specific models.

Thermocouple problems at Junkers Bosch

For example, the weak point of the Bosch Junkers WR 13-P device is a thermocouple.

Two or three years after the start of operation, it ceases to respond normally to heating from the pilot burner. As a result, the igniter flame is constantly fading, over time it will simply stop igniting normally.

Sometimes careful cleaning of the thermocouple with fine sandpaper helps, but when this method ceases to bring the desired effect, the element will have to be replaced.

In some models of geysers, a thermocouple fails over time, which is easy to replace with a new element

In some models of geysers, a thermocouple fails over time, which is easy to replace with a new element

Displacement of the igniter tube, which is not too rigid in these models, can also lead to similar problems. The tube can be moved accidentally, even just hitting it with a match during ignition. Between the nozzle of the gas tube and the burner there is a gap through which air enters.

With displacement, this gap decreases, the air necessary for normal ignition becomes insufficient. The flame tongue does not reach the thermocouple, it does not heat up, gas does not enter the main burner. If you restore the normal position of the tube, the column will work properly again.

Practical recommendations for cleaning and troubleshooting the JUNKERS dispenser:

Speaker contact oxidation Vector

For speakers "Vector" a typical problem is the oxidation of the contacts in the power supply. If this is the case, then replacing dead batteries with new cells will not give the desired result, a spark will not appear until the contacts are cleaned. Sometimes in such columns there is a souring of the microswitch stem on the water valve.

If the column hisses or whistles a little during operation, the fastenings of the coil tubes may have loosened, you need to check and solder them

After cleaning, normal operation of the device is usually restored. If a characteristic whistle appears shortly after turning on the column, you need to check the condition of the connections in the exhaust pipe, they may need to be resealed.

Problems with the stem in the Neva models

In columns of the Neva brand, jamming of the stem in the gas valve is sometimes observed. As a result, this element stops normal operation.

To eliminate such a malfunction, you need to remove and disassemble the water-gas unit, and then move the stem with a conventional screwdriver. If the part is not mechanically affected, the element should be completely replaced.

This video demonstrates the troubleshooting for the NEVA column:

Other problems when using a geyser

When using a geyser, other problems may arise when the equipment works poorly or with obvious violations. Possible options for such malfunctions and solutions to the problem:

The geyser turns on, but pops are heard. Microexplosions (and this is pops) occur for several reasons:

- lack of draft for equipment operation in the ventilation duct;

- battery discharge, that is, the ignition simply does not work;

- jets and other structural elements are heavily contaminated;

- too much gas flow.

This problem can be fixed using the following methods:

- cleaning the chimney with a lack of traction (it is best to call a specialist, and not try to do this work yourself);

- replacement of batteries when the ignition is not working;

- for repairs in other cases, you must immediately contact the gas service, the geyser must be turned off, and the gas supply must be shut off.

- When the equipment is turned on, a strong smell of gas is emitted. This is a clear sign that the column is faulty, since the equipment should in no case smell of gas. If such a situation has arisen, then you must immediately close the supply valve, open windows to ventilate the room, call the gas service to determine the malfunction. Do not attempt to repair the device yourself, as this may cause an explosion.

- When turned on, there is no gas supply. At the time when the geyser is turned on, a characteristic sound of incoming gas should be heard, that is, a slight hiss. If the column does not light up in any way, then listen. If there is no sound, then the gas mixture simply does not flow. Such a malfunction involves the following procedure:

the column must be turned off, the gas supply from the pipe must be stopped (it does not matter that you do not hear the sound, the tap must be turned off);

after that, you should call the appropriate gas service to find out if any work is being done on your site that involves turning off the gas;

if there is no repair, that is, the gas in the line is supplied properly, it is necessary to call the master who will inspect the condition of the column, perform the necessary repairs if the gas column is subject to repair.

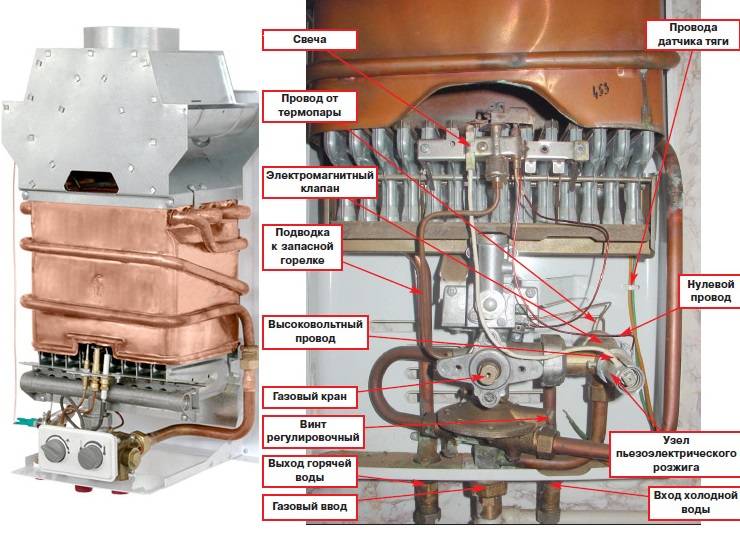

The most common causes of breakdowns

Let's start the review of breakdowns using the example of such simple gas water heaters as Oasis or Neva. These are fairly simple devices, so almost any man who knows how to work with tools and has relatively straight hands can handle their repair. Here is a short list of possible faults and causes:

- Lack of traction;

- Insufficient water pressure;

- Insufficient gas pressure;

- Inoperative ignition system;

- Clogged pipes and water supply filter;

- Burner blockage;

- Membrane or gas block malfunction;

- Inaccurate mixing of cold water in the mixer;

- Malfunction of electronics or sensors.

Now we will see how to eliminate breakdowns and the reasons for the lack of ignition.

Removing a clogged burner

Unfortunately, the burners in the gas water heaters Neva and Oasis (as in many others) are prone to blockages. Most often, this picture is observed in models with piezoelectric ignition. The cause of clogging is the accumulation of soot. It must be removed, for which the column is disassembled and the burner itself is removed from it. For cleaning, any improvised tools are used. After cleaning, the burner should be installed in place and checked. If necessary, you can immediately clean the heat exchanger - its clogging leads to a loss of traction and a deterioration in heating.

If your geyser does not light up, and you decide to clean it, do it on the balcony or in the open air.Otherwise, soot flying into the air will surely stain the entire room in which the column is installed.

Why is the faucet humming

Possible reasons why the faucet may make unpleasant sounds:

- The most common is gasket damage - wear, hardening - or improper installation. The problem is fixed by replacing the defective part.

- Cartridge failure is a part in modern single-lever faucets responsible for distributing cold and hot water flows. The way out is to buy a new cartridge.

- Increased pressure in the risers of cold or hot water. Liquid is squeezed out from one riser to another through a damaged mixer in one of the apartments with a corresponding sound. The problem is eliminated by finding and repairing a damaged mixer and normalizing the pressure in the system. The latter is in the competence of the service organization.

- Unreliable fixation of the hoses supplying water to the mixer. The rigid fixing of these nodes will partially solve the problem of why water pipes and taps are noisy.

- Leakage at the junction of the faucet with the hose carrying the shower head, or rupture of the inner tube of the hose. Eliminated by replacing the gasket and hose.

How to fix a bathroom faucet problem

If preventive work to eliminate extraneous sounds has been effectively completed, however, when you turn on the mixer or tap in the bathroom, the water pipes are buzzing again, you need to check the serviceability of these water taps

First priority is the condition of the gaskets

To determine which of the taps - cold or hot water - generates noise, turn them on one by one. Having identified the culprit, the crane box should be unscrewed from the body and inspect the gasket.If it is made of rubber and is able to serve for some time, its edge is cut at an angle of 45 °. The worn gasket is replaced with a new one. Any defect in the ceramic part will require replacement. The updated crane box is being returned to its place.

At the end of the work, be sure to check the reliability of the measures taken and the absence of leaks.

It may turn out that after the tested measures, when the tap valve is opened, the water pipe is buzzing again. There is another reason - a silicone sealant for ceramic parts of a crane box. When it sags, leaks are possible. It is not difficult to solve the problem - it is necessary to cover the seal with plastic.

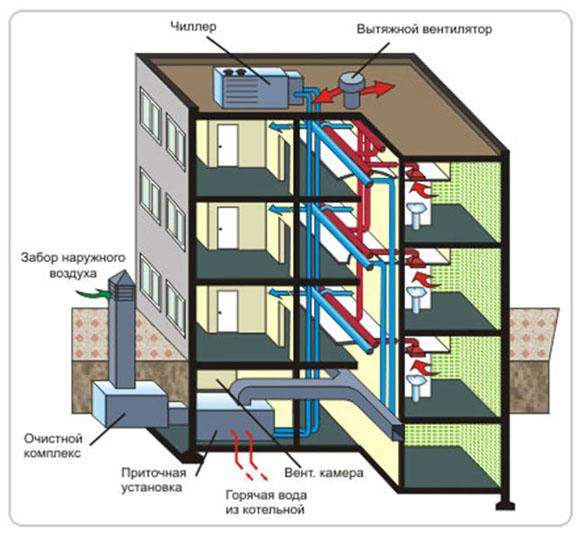

Elimination of violation of traction

To test the thrust, try using an ordinary match. Bring it to the chimney and determine if there is a draft, then the flame will deviate towards the chimney.

If there is no draft, then the geyser will not ignite, and users will not receive hot water. In many columns, draft sensors are installed, and if they show insufficient draft, ignition will not be possible. There are situations when the flame ignites and immediately goes out - this is due to the fact that the combustion products simply have nowhere to go, they remain in the combustion chamber, and the flame goes out due to lack of oxygen. Lack of draft will require an inspection of the flue gas collector and the chimney itself. If there are blockages, they can interfere with the normal passage of combustion products. The column perceives this as a lack of traction and does not allow the gas to ignite (or the gas goes out immediately after switching on). Unfortunately, only a part of the chimney, which is visible before entering the wall, can be independently checked - further work should be carried out by specialists.If the house is private, you can try to deal with the chimney yourself.

User opinions

Definitely, the advantages of this water heater are the price, a wide range of capacities, design, compact dimensions. Given the feedback on Geysers Oasis the cons include an unmodulated burner, capricious sensors, inconsistent overall reliability.

“I have had such a speaker for more than two years, the batteries were changed once.”

Bogdan, Krasnodar.

“Disappointed. After one year of work, the cap burned out, the radiator melted, a leak appeared.

Eugene, Moscow.

“Two years of work - no problems. At this price, the column is normal. Batteries last for 1 year.

Mikhail Samuelevich, Stavropol.

“I bought an Oasis instantaneous water heater. After installation, there was a problem - it lights up and goes out. I turned off the draft sensor - I worked for half a year, there was not enough pressure. Adjusted - enough for 1 month. Dismantled, cleaned, reassembled - once lit up and that's it. While working, the temperature constantly jumped: one washes, and the second monitors the temperature controller.

Alexander, Moscow.

“I decided to replace the old domestic column. I chose the unit from the manufacturer Oasis. Installed a fully automatic model. It turns on and off when the tap is opened and closed. If the pressure is low or the water is turned off abruptly, the water heater turns off by itself. Batteries lasted six months. I really like that the display shows the temperature. When she gave birth to a child, it became easy to control the degrees of water in which to bathe the baby. We have been using the column for three years, we didn’t even need a guarantee. ”

Alina, Tula.

“I recently bought an instant gas water heater from Oasis. When I started using it, there were problems. It heats up for 10 minutes, and then the burner goes out, sometimes it turns off every 2 minutes. We're not happy."

Andrey, St. Petersburg.

Possible breakdowns and repairs

The main malfunctions that may occur while using the Oasis instantaneous water heater depend on the manufacturer's defect, on improper installation or operation of the equipment:

- No spark. There is a spark, but in the wrong place.

- The flame goes out when the ignition button is released.

- The burners, main and pilot, go out a couple of minutes after being turned on.

- Unable to adjust maximum gas pressure.

- The burner did not turn off after the hot water tap was closed.

- The water temperature is less than the set one.

The duration of operation of the Oasis column depends on proper operation and timely service. These heaters come with a 2 year warranty. Individual parts will be replaced free of charge. In the future, you will have to pay for repairs. In such cases, it is better to use original spare parts. Depending on the complexity of the breakdown, for work, not counting spare parts, gas services charge from 400 to 2,200 rubles.

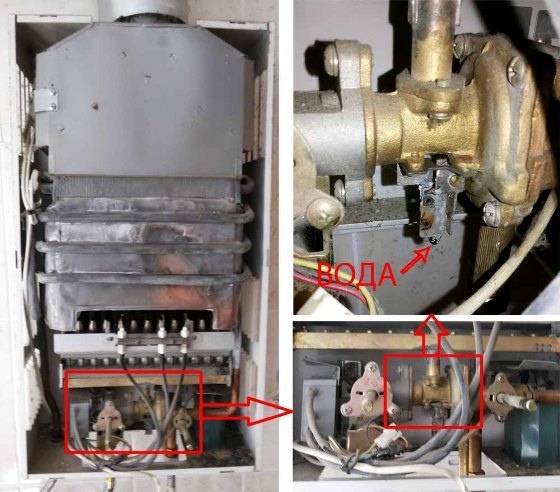

Gas column repair Neva

Most models of Neva gas water heaters have shown themselves to be simple and affordable water heaters for repair. They are far from the reliability of European models, but their repair is much cheaper, and almost always you can do it yourself.

The failure and subsequent repair of the spark plug is considered by the rules to be an atypical case of breakdown, therefore, having completed the repair work, it will be correct to look for the cause of the defect.Most often, plastic burnout occurs due to condensate flowing through the ventilation system onto the gas burner body.

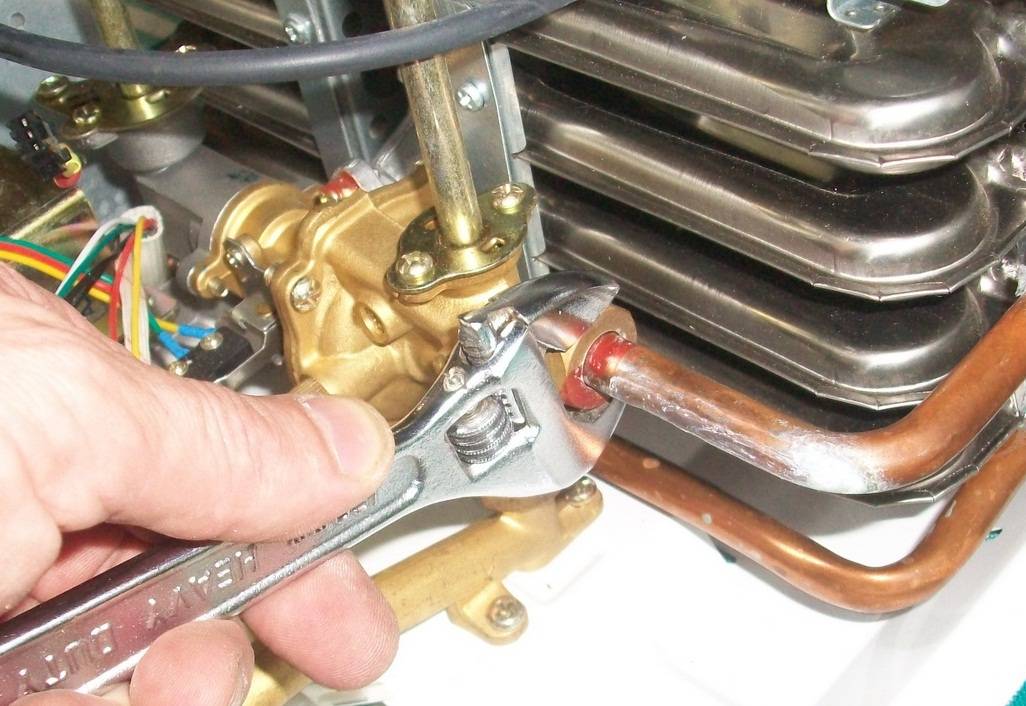

How to repair the union nut of the heat exchanger

One of the most common defects in Neva gas water heaters for almost all models is the low quality of the heat exchanger metal. According to the rules, the heat exchange circuit through which water moves must not come into contact with aluminum parts, for example, a gas burner or a control unit. Any such contact can cause electrochemical corrosion of copper walls, and then the repair will be simply useless.

In addition, the rules for tightening the union nuts with which the heat exchanger is attached to the regulator and the outlet pipe are not always followed. With each removal and repair of the heat exchanger, the nuts cut a thin, barely visible track in the copper wall. Ultimately, the flared end and part of the copper pipe simply break off for the tenth time of twisting.

In this case, it is necessary to cut and level the breakage point, install a new nut with an external thread and connect the heat exchanger to the control unit with a conventional flexible hose. Any other repair option, as practice shows, is short-lived.

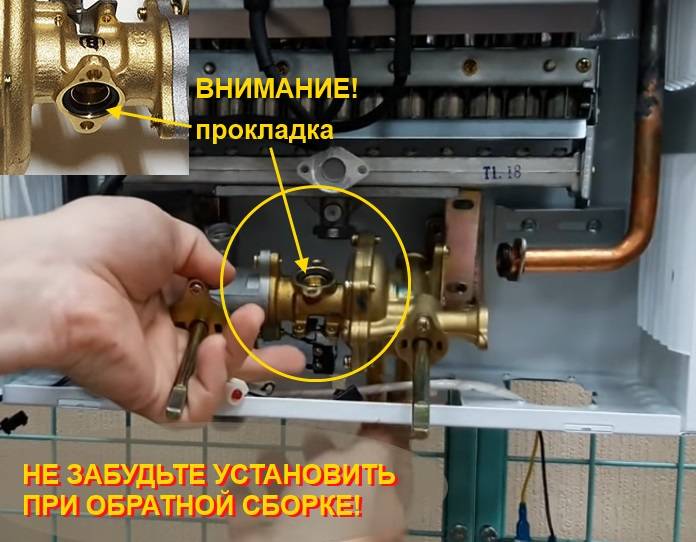

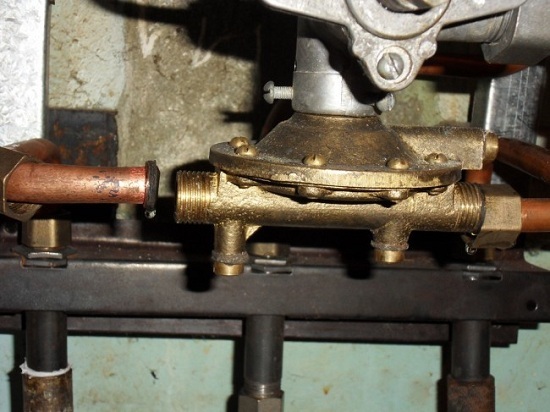

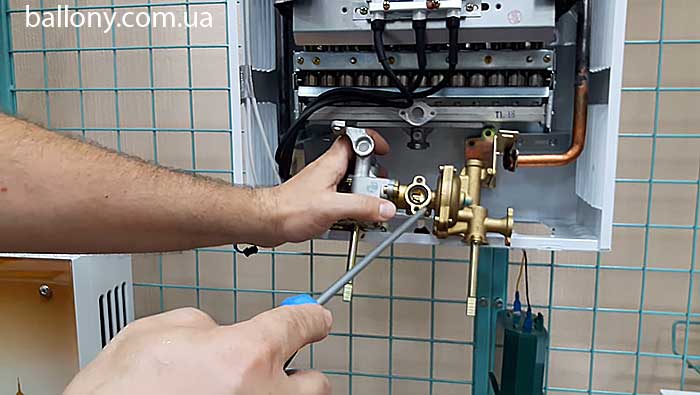

Repair of the microswitch in the start-up system of the geyser

A situation similar to the Oasis on dead batteries also happens with the Neva gas column. When you try to start the Neva, the indicator board lights up, but the gas burner does not ignite. Sometimes the column can be turned on 4-5 times.

In this situation, repair of the microswitch is required, due to premature wear of the part or improper adjustment of the assembly.

The switch is located next to the water pressure control unit.When the column is started, the membrane on the block squeezes out the stem, which unlocks the switch contact. Unlike the Oasis, all parts of the block, including the stem, are made of brass, so there is no corrosion, the microswitch itself is subject to repair and replacement.

To perform repair work, it is necessary to disconnect the connector, unscrew the two M3 screws and remove the switch housing from the bracket, as in the video

Replacing the mic is easy. You can buy an original part for 400-500 rubles. in a specialized salon or purchase an analogue for 50 rubles. at any radio parts store. There is no difference for repair, in both cases they will sell a part from Chinese consumer goods.

In order to carry out the repair, you will need to unsolder two strands of wire with a connector from the switch legs, put on a heat shrink tube and solder to the contacts of the new part.

At the final stage of the repair, the switch is screwed with old screws onto the mounting plate on the block. Next, you need to adjust the position of the microswitch body so that the stem completely releases the contact when moving. This is done using mounting screws. One of the screws bends with a radius, respectively, by rotating it, you can move the switch body in the right direction.

Sources of the accident

There are several reasons for the failure of the burner, the main ones are the following factors:

1. Lack of traction.

For any model, be it the Neva, Oasis or Vector, the flame goes out or does not light up due to the fact that the chimney is often clogged with dust, dirt and foreign objects.In modern equipment, in this case, a protective valve is activated, which automatically shuts off the fuel supply to the gas column. This is because the products of combustion are not discharged in full and in accordance with the technical requirements.

To verify the malfunction, you need to check the traction. To do this, open a window and bring a lighted match or a sheet of paper to the pipe. If the chimney is clogged, the wind will not be felt, so the geyser does not light up. The cleaning of the combustion waste disposal system is carried out by specialists

It is important not to miss this moment, as the exhaust gas enters the room, which can lead to serious consequences.

An ingenious way to almost NOT PAY for electricity! A clever meter that saves electricity Pays for itself in 2 months!

Sometimes the automation works when the hood is turned on, located nearby, the flame goes out or does not appear. If the device has a large power, it interferes with the removal of waste, so you should never install two units in one place, especially in small rooms.

2. Malfunction of sensors.

If the igniter flame goes out, it is necessary to inspect the device that controls the exhaust of gases. To do this, disconnect the wires and check the resistance using a special device. The indicator must be indicated in the passport, if it does not reach the optimal value, the sensor will have to be replaced. The burner goes out when the thermocouple breaks. In this case, the gas column does not ignite due to low voltage, the optimal parameter of which is 10 mV.

3. Discharged batteries.

The main function of the batteries is to keep the valve open during operation.The service life of the elements is no more than a year, therefore, manufacturers of such gas units as the Neva recommend changing batteries on time. In addition, the reason that the burner does not ignite may be a malfunction of the piezoelectric element or the power cable. It is necessary to disconnect the wires and check them for internal and external breaks. If there is still no spark, the column does not turn on, then the source of the problem is different.

4. Blockage of the inside.

If dirt and soot get into the gas supply tunnel from the fittings to the burner, the flame goes out or does not ignite. The injectors need to be cleaned. If the fuel pressure is not adjusted, a characteristic whistle will be heard, flame separation appears, then it disappears. Also, a burner of the wrong diameter can create such a malfunction. In this case, you need to correct the gas supply or replace the elements. When airing, the gas column ignites, but immediately goes out. To eliminate the defect, you need to unscrew the nut on the fitting and bleed the air, then return the mount to its place, fix it and check if the burner goes out.

5. Deformation of elements.

If the water is too hard, scale appears in the pipes, which gradually clogs the filters, so the gas unit goes out or does not turn on. The grate is taken out, thoroughly cleaned. If it has been damaged by deposits, it is better to replace it.

The membrane of the water supply unit often breaks, so the column does not turn on. To determine its condition, remove the top cover of the case. The plate should not be in cracks and gaps, has the correct shape, smooth and even. In case of the slightest deformation, it will have to be replaced.It is better to choose a part made of a durable and elastic material that is resistant to temperature fluctuations and the influence of scale. Install the membrane carefully, crimping the fasteners around the perimeter.

6. Water pressure.

As in the draft situation, the automation blocks the gas supply; if the supply is poor, the burner immediately goes out. It is worth contacting the utilities to find out the reasons, turn off the unit until then. You can use the column only if the water pressure is normal. In private homes, the pressure is increased using a compact station and a regulator. If the column turns on and works normally, and the water is still cold, the device may not have enough power, the parameters are noted in the passport.

Here's the secret to saving water!Plumbers: You'll pay up to 50% LESS for water with this faucet attachment

Clogged heat exchanger

A clogged heat exchanger can also be the reason why your Bosch, Neva, or Indesit column produces boiling water at the outlet. There are many ways to eliminate this malfunction using purchased or self-prepared cleaning mixtures. The simplest - without removing the heat exchanger with hydrochloric acid 3-5% solution.

Unscrew the casing from the device, turn off all the taps, open the taps with hot water, remove its residues in the system. Disconnect the pipes from the heat exchanger, water may flow out, prepare a bucket. You will need two pipes that you will connect to the inlet and outlet of the radiator, attach one of them above the level of the column, seal the joints. Use a funnel to pour the reagent into the device.

Carry out the procedure until the moment until you get a good pressure. Rinse the heat exchanger thoroughly and reconnect everything.