- Other problems of gas boilers

- The principle of operation of the boiler

- Error 2E (the first three indicators flash)

- Dilemmas with cravings

- Problems of solid fuel boilers

- Reasons why the gas boiler does not turn on

- Pump not working well

- Low gas pressure

- Why the boiler does not heat water for the heating system

- What is a bimetallic plate

- Solving problems with the attenuation of the boiler

- Traction recovery

- If there is no electricity

- If the gas pressure drops

- Technical device and principle of operation of the Navien gas boiler

- How to connect and set up

- Brief operating instructions: operation and adjustment

- Common mistakes and causes of problems

- EMERGENCY STOP OF THE UNIT

- If the boiler does not start at all

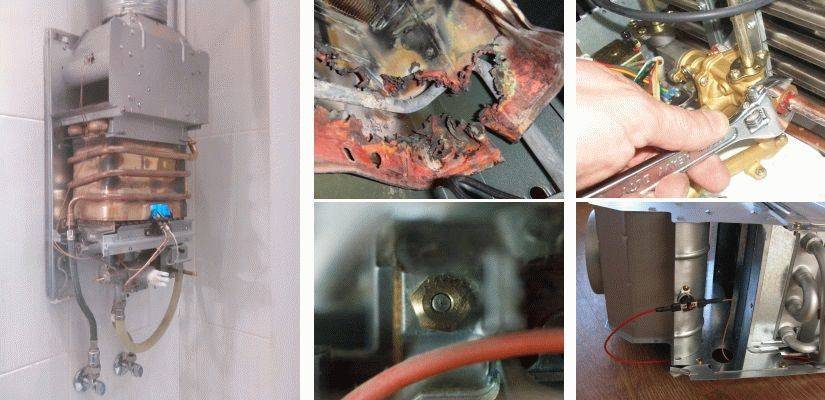

- Causes of breakdowns of gas boilers

- Gas boiler Conord specifications and features

- Chimney problems

- Ice formation

- Reverse thrust

Other problems of gas boilers

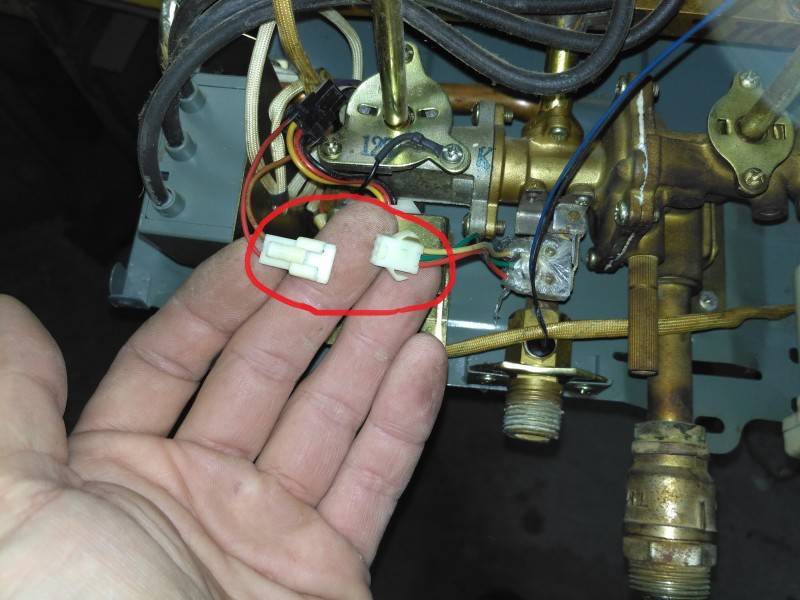

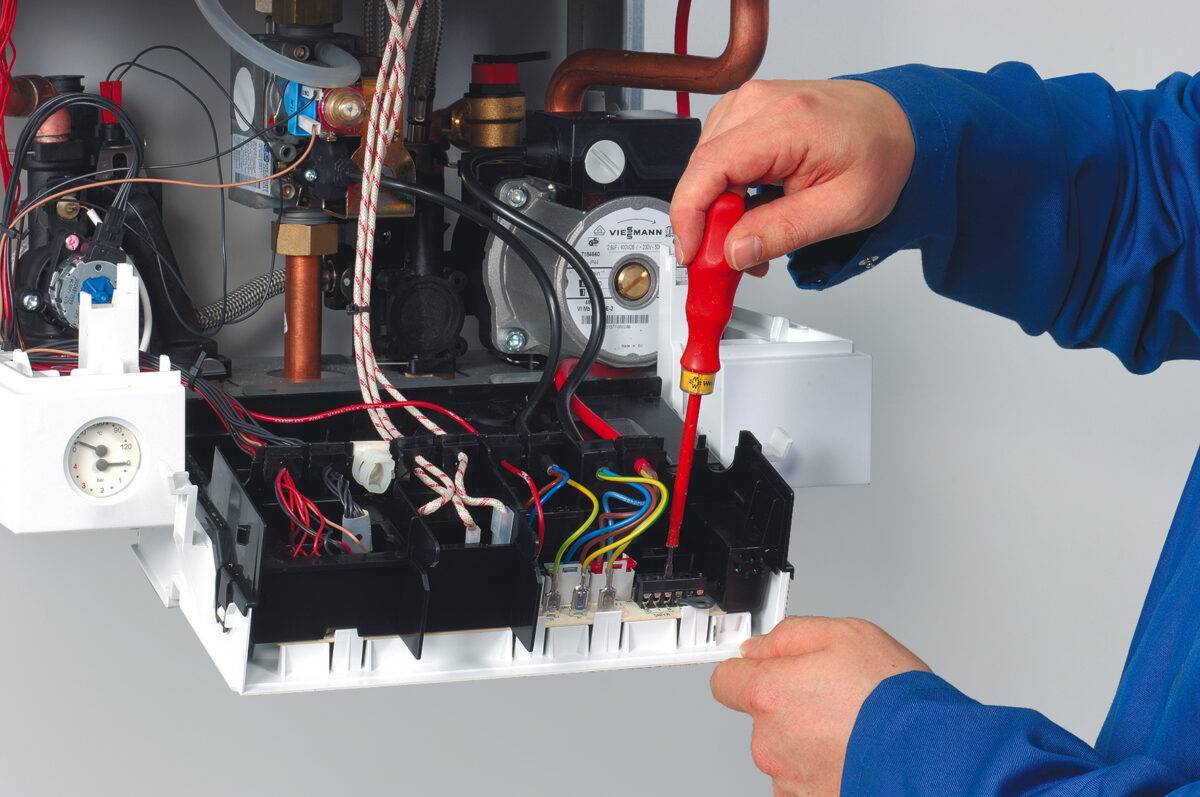

Almost all wall-mounted boilers are equipped with a panel with a screen or indicators, as well as a control board. If there is no indication, make sure that the boiler is connected to a power source. The connection is checked with a multimeter in the place where the board is connected to the device.When there is no voltage, you can try to connect the device again

Additionally, pay attention to the place where the fuses are located. In standard units, they are located on the board itself or in the connection area. If everything is in order with the fuses, the voltage in the control zones remains at around 220 volts, it is worth checking the control electronics and the gas generator

When the fuses blow, test the operation of the pump, priority valve, fan and instrument wiring for a short circuit. It is recommended to change the blown fuses and check the operation of the boiler again. There are situations when parts burn out again immediately after replacement, then it is worth turning off the high-voltage sections of the boiler in sequence to identify problem areas

If everything is in order with the fuses, the voltage in the control zones remains at around 220 volts, it is worth checking the control electronics and the gas generator. When the fuses blow, test the operation of the pump, priority valve, fan and instrument wiring for a short circuit. It is recommended to change the blown fuses and check the operation of the boiler again. There are situations when parts burn out again immediately after replacement, then it is worth turning off the high-voltage sections of the boiler in sequence to identify problem areas.

It is important to prevent problems in time and call specialists for a preventive check of the device several times a year.

The principle of operation of the boiler

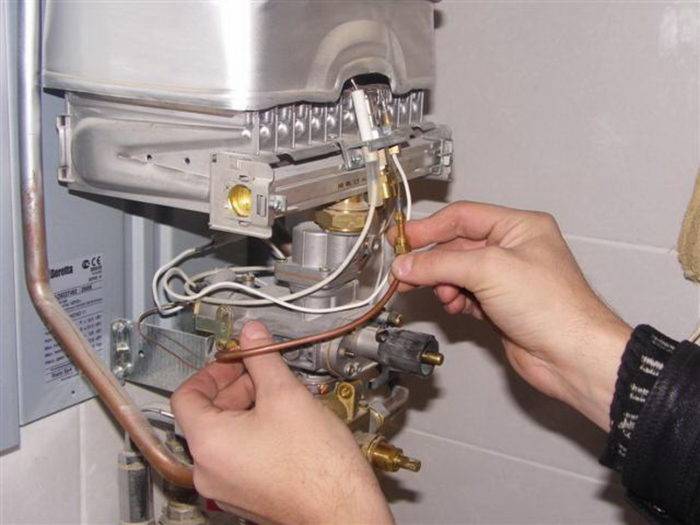

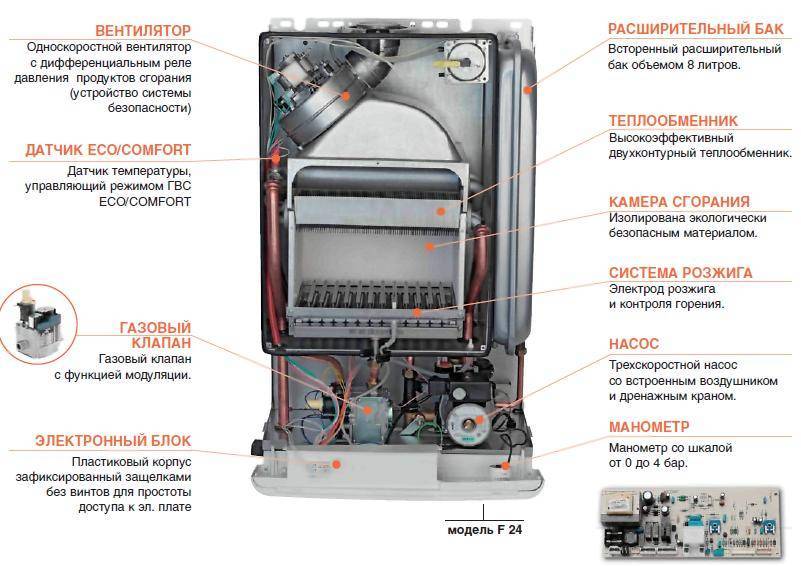

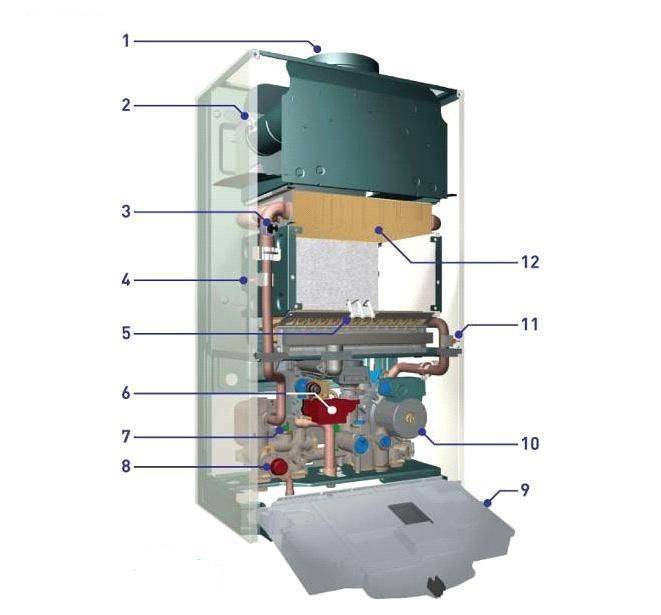

To understand the causes of the breakdown, you need to understand how the boiler works. Double-circuit devices "Ariston", "Baksi" and other models have several blocks.Ignition and combustion take place in the gas node, the water node is responsible for the water supply and pressure in the line. The chimney block brings the products of combustion to the street.

As soon as you start the boiler, a pump is activated that pumps water into the system. The gas valve opens. The liquid circulates through the tubes of the heat exchanger, and the burner evenly warms up its body. Sensors control the heating process. As soon as the temperature reaches the set temperature, the gas supply is turned off, heating stops.

When the mixer is opened, the flow sensor is triggered. It gives a signal to the board to switch the three-way valve to DHW heating. When the mixer closes, the valve switches to the heating system. Some models are equipped with a "quick start" mode. Then the valve periodically switches, heats up both the first and the second heat exchanger.

Error 2E (the first three indicators flash)

The logic of the error is that the flow temperature rises too fast, i.e. the coolant at the outlet of the heat exchanger heats up too quickly and to prevent emergency overheating, the operation of the boiler is blocked for two minutes. The main reason for this behavior of the boiler may be poor circulation of the coolant. The most common causes of poor circulation are:

-

malfunction of the circulation pump or insufficient performance

-

heat exchanger clogged with dirt or scale

-

air in the heating system

In this article, we examined the most common malfunctions of Buderus gas boilers. A complete list of errors is contained in the equipment manual. Modern gas engines are designed so that the elements are as accessible as possible for ease of service.Some errors can be corrected by the user himself, for example, make up the boiler or inspect the chimney for blockages.

Doing any self-diagnosis actions should be done only in case of urgent need in compliance with precautionary and safety measures. If you do not have an idea about the principles of operation and the device of a gas boiler, it is better to call a qualified specialist

The Buderus company posts informative videos in which the specialist talks, including about the boiler errors that occur.

Dilemmas with cravings

If before the incident the equipment was operating normally, but now the fuel supply is blocked due to the automatic valve, there may be several reasons at the same time (and separately).

The most common reason for the attenuation of a gas boiler in a private house is the reduction or disappearance of traction.

The first step here is to check the traction. A match or a lighter is brought to the viewing window.

If the fire deviates away from the combustion compartment, then the thrust is normal. With a vertical static flame, it is absent.

Then the draft in the chimney is studied. A part of the tube attached to the outlet pipe is removed.

The presence of traction is checked in a similar way. With a positive verdict, it is necessary to clean the channels of your boiler. With a negative - the chimney itself.

Soot deposits, combustion products, leaves and other debris can accumulate in it.

If pollution is concentrated at the entrance, cleaning operations are carried out independently. In case of problems in the upper zone, the intervention of craftsmen with professional tools is necessary.

Also, private houses are characterized by such a dilemma as reverse thrust.And often the gas boiler goes out in strong winds if the chimney is not protected by a deflector. Because of this, the exit of smoke through the pipe to the outside is blocked, it returns to the combustion chamber and knocks down the flame.

If the specified protection is available, then such a thrust is formed due to two factors:

- blockage in the chimney inside the building,

- pollution in the outer zone of the chimney.

The methods for solving the problem are as follows:

- Installation of a protective cap (deflector) at the end of the chimney.

- Extension of this pipe by 1-2 m.

Problems of solid fuel boilers

Most often, these devices are “pleasant” with the fact that they begin to flow. This difficulty arises when:

- Overheating, due to which the water boils, and a fistula appears on the heat exchanger. Repair of boilers involves the replacement of the heat exchanger.

- Too low water temperature (less than 60 °C) in the return line. This leads to the appearance of condensate, which corrodes the heat exchanger. Because of this, a fistula is formed, and the coolant begins to flow. In this case, the leak occurs due to improper organization of the heating system at home.

In general, most problems, including leaks and fistulas, arise due to improper installation of the unit and errors in the organization of the chimney, into which the wind easily blows. Such errors also cause accelerated circulation of antifreeze (which means that its volume does not correspond to the manufacturer's standard), breakdown of the pump and other piping units, a fall or excessive increase in thrust.

As for noise, poor fan operation and automation, these problems have the same origin as in the case of a gas boiler that is easy to maintain.

Reasons why the gas boiler does not turn on

one.The absence or deterioration of the natural draft of the chimney is the first reason why the boiler does not turn on.

2. Malfunction or damage to the gas meter.

3. Clogging of the gas filter also stops the operation of the boiler.

4. Decrease or lack of pressure in the line.

5. Power outage or wiring damage.

6. The presence of a short-term excess of air due to a draft in the house.

7. Problems in the heating system.

8. Damage to draft sensor or thermocouple.

9. If the boiler display does not work, then the controller fuse is blown.

10. Soot contamination of the photocell of the flame control sensor.

See: 7 reasons for pressure drop in a gas boiler

To understand the reasons why the gas boiler does not ignite or goes out, it is important to understand the principle of the system. An analysis of the most common practical situations - why the boiler does not turn on and does not light up, and recommendations for repair - are presented in the material

Pump not working well

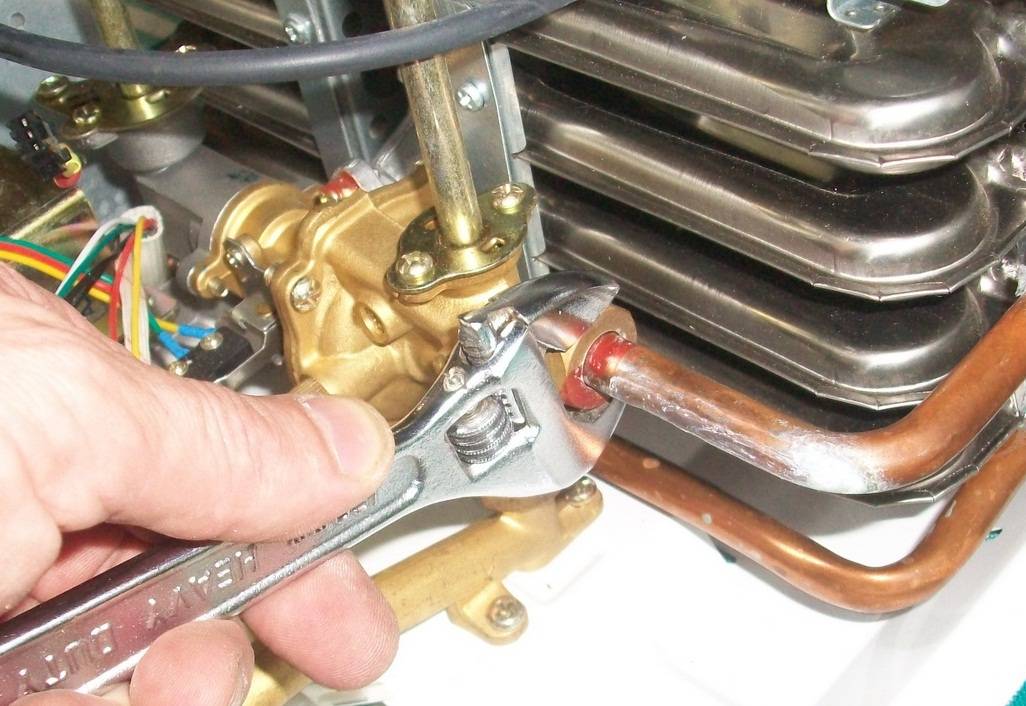

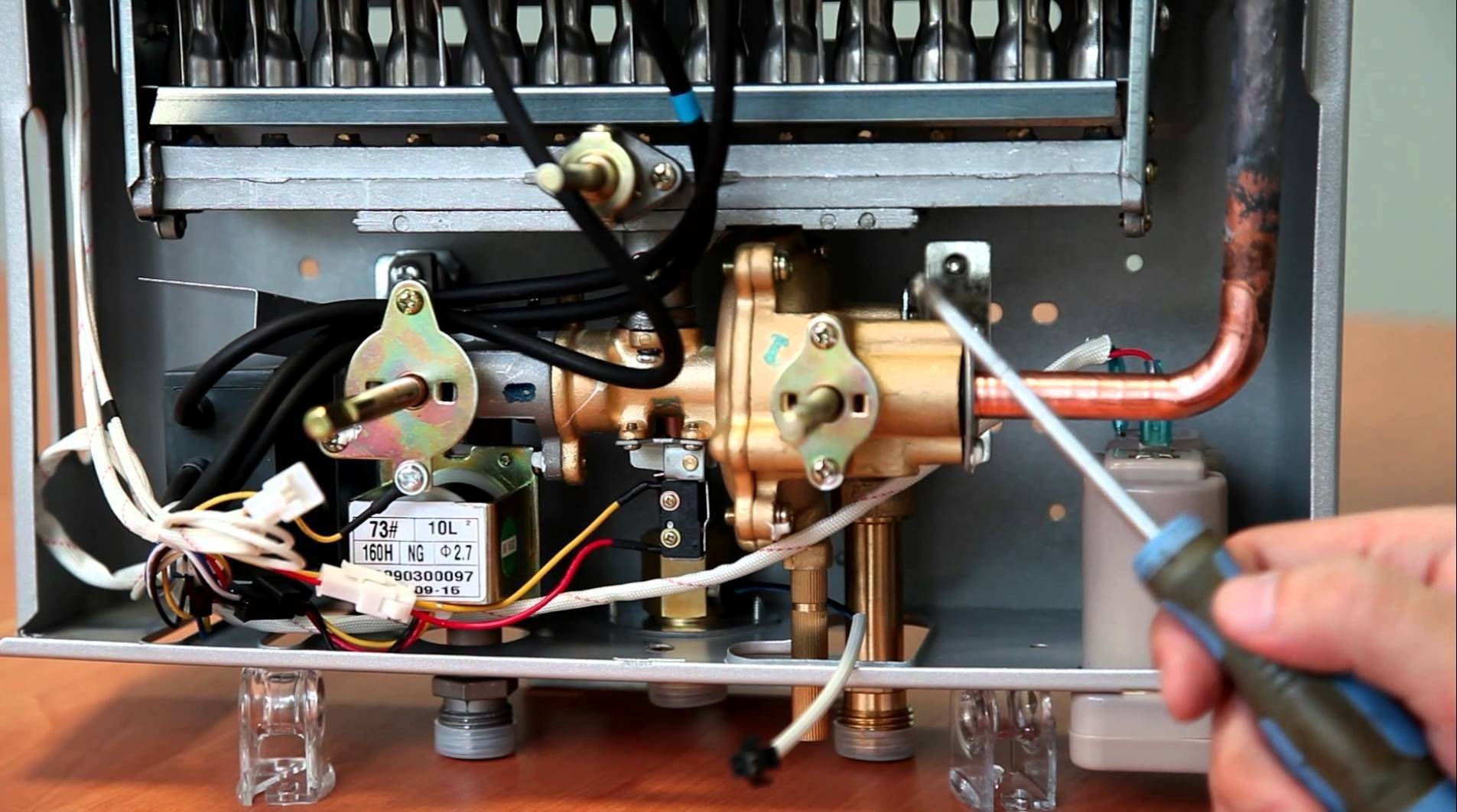

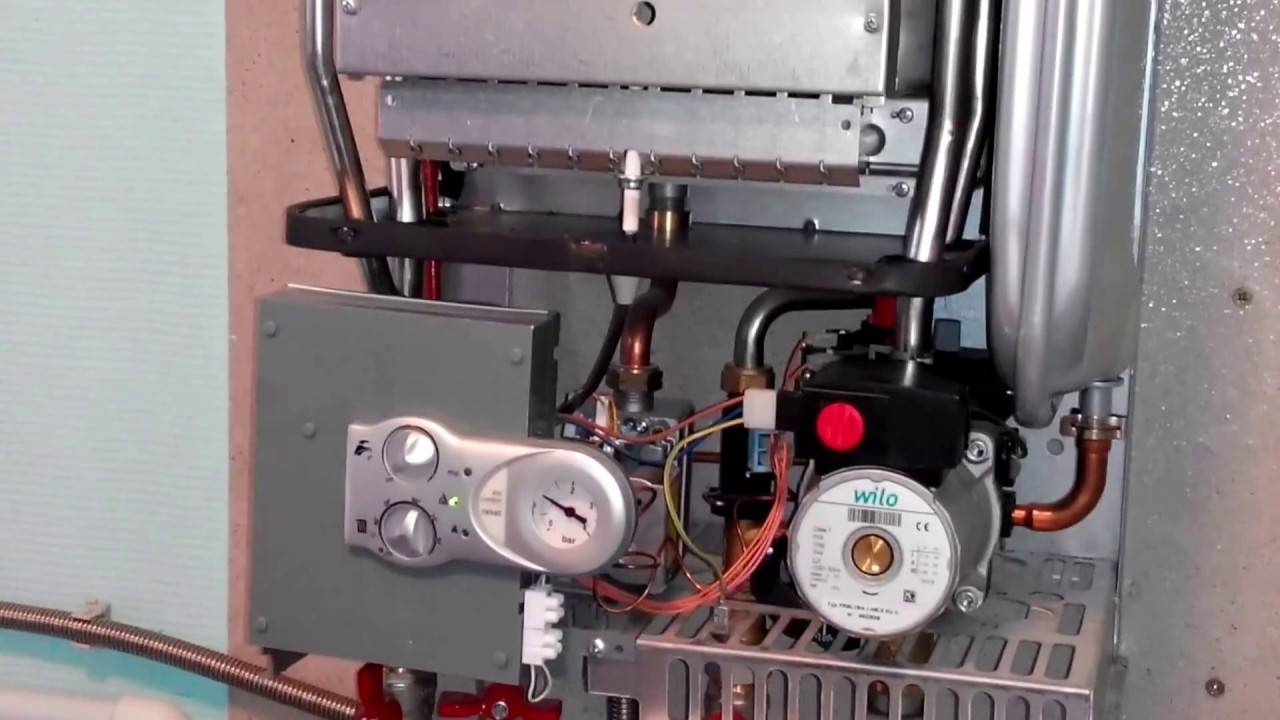

Users of gas boilers sometimes face various problems in the operation of the pumping unit. Such equipment stops pumping water if the rotor fails or a significant amount of air has accumulated in the inside. To exclude such a breakdown, it is necessary to unscrew the nut from the unit and drain the water, after which the axis is forcibly scrolled with a flat screwdriver.

Pump in a gas boiler

Separate equipment requires compliance with installation rules. It is advisable to install the pump before the gas boiler, which will extend the life of the heating system. This rule is associated with the presence of a high temperature regime at the outlet of the boiler, which can cause damage to the device.Of course, the design characteristics of the circulation pump must also be taken into account, as well as the need to mount a filter or sump directly in front of the pump.

Low gas pressure

Even if, in accordance with the factory specifications, the boiler has sufficient power, the device may not gain the required level to heat the coolant due to low gas pressure. The optimal pressure in a low-rise cottage is 1.5-2 atmospheres. For a high-rise house, an indicator of 2-4 atmospheres is considered acceptable.

Pressure can decrease for various reasons. One of the reasons is the decrease in pressure at the inlet to the boiler. If a pressure reducer is used in the system, it is necessary to adjust the device, increase the pressure due to this device.

It is also necessary to check the settings on the gas valve. The pressure on the gas valve must not be lower than that allowed by the regulations. If the valve is set incorrectly, the boiler will not operate at full capacity. The valve setting is usually done by the installer of the boiler.

A clogged gas filter can also cause a pressure drop. To check this factor, it is necessary to unscrew the filter and, if necessary, clean it. Having done all these procedures, the gas boiler should start to turn off.

Why the boiler does not heat water for the heating system

There can be many reasons why a gas boiler does not heat water for heating. The main ones and ways to eliminate these causes will be discussed below.

The boiler turns on, but the heating does not heat.

Possible causes and their elimination:

first of all, you should check whether air has accumulated in the batteries, using taps, you need to remove air from the system.Install an air vent to prevent air build-up.

Faucet to vent their battery

It functions on the principle of an expansion tank, without reducing the pressure in the system. After a long downtime of the unit, check the valve, it may become clogged with scale;

- clogged batteries, what to do in this case? It is necessary to drain the water from the cooled batteries. If you see that water is flowing out with debris, and sometimes black liquid may pour out, you need to flush the system to clean water;

- improperly made connection and piping. The pipe diameter may be incorrectly selected, shut-off valves are incorrectly installed, the heat exchanger is incorrectly connected. Check the manufacturer's recommendations in the instructions and correct the errors;

- at reduced pressure, the unit also does not heat well, add water to the system;

- the appearance of scale in the heat exchanger. It is necessary to flush the heat exchanger from plaque. Not in all models it is easy to remove the heat exchanger from the device. Where this is problematic, you can clean it without removing it. To do this, the boiler must be turned off, cool.

Connect the pump hoses with the filtration system to the inlet and outlet and flush the heat exchanger with a special cleaning fluid. After that, be sure to rinse the boiler with clean water to remove chemical residues, otherwise the remaining particles of the agent can lead to corrosion of the heat exchanger, pipes and radiators.

Flushing the heat exchanger

The use of reagents as additives to the coolant significantly reduces the formation of scale. But not all models are allowed to use antifreeze.Manufacturers Ariston (Ariston), Arderia (Arderia), Navien (Navien), Buderus, Viessmann (Vismann), Electrolux (Electrolux) prohibit the use of antifreeze, recommending the use of distilled water.

In the instructions for the models Rinnai, Baxi (Baxi), Vaillant (Vaillant), Celtic (Celtic), Ferroli (Ferolli), AOGV 11 6, Beretta (Beretta), Bosch (Bosch), Neva Lux, Protherm (Proterm), Junkers, Koreastar (Koreastar), Daewoo is allowed to use antifreeze. It should be noted that not all antifreeze is suitable for these boilers.

- contamination of the heating water filter also becomes the reason why the boiler heats the batteries poorly - clean the filter under a strong stream of water, after turning off and cooling the boiler. If the contamination is strong and cannot be cleaned, replace the filter;

- the heating medium heating temperature is set too low, increase the temperature;

- incorrect operation of the circulation pump or its overheating also becomes the reason why your unit began to heat up the batteries badly, adjust its power;

- wrong battery design. Batteries must correspond to a specific heating mode, since each type of radiator has an individual heat transfer value depending on this mode.

What is a bimetallic plate

An element that has the property of deforming (bending) in one direction under the influence of elevated temperature is called a bimetallic plate. By the name, you can guess that the plate contains two metals. Each of them has its own value of the coefficient of thermal expansion. As a result, when such a plate is heated, one component of it expands by a certain amount, and the second by another.

This leads to a bend, the shape of which depends on the difference in temperature coefficients. The rate of deformation is directly proportional to the change in temperature. When the plate is cooled, it acquires its original position. The plate is a monolithic connection and can work indefinitely.

Solving problems with the attenuation of the boiler

If the shutdown of the flame is not caused by malfunctions of the boiler itself, but by other external reasons, you can try to fix the problems yourself. Some models of simple boilers can even be cleaned from soot and soot on their own, but this is a topic for a separate article.

Traction recovery

You can deal with what is clogged - a boiler or a chimney - by disconnecting the corrugated pipe of the exhaust system from the boiler itself. If there is a draft in the pipe, then we solve the problem with the boiler by calling the master. Otherwise, you have to climb onto the roof and look into the pipe. If a blockage is found, it is necessary to remove those foreign fragments that interfere with the passage of smoke.

Cleaning the chimney is a mandatory procedure to prevent its pollution.

If ice is found on the head, it must be carefully chipped off so as not to damage the chimney itself. Be sure to check the cleaning hatches. A sign that cleaning is needed is a large amount of soot and soot being removed from the inside of the canal.

It is still possible to reconcile with the blowing of the channel due to strong wind if this happens once or twice during the entire heating season. But if winds are a frequent occurrence in your area, you should take measures:

- First, you can try to build a pipe.High altitude will prevent the wind from pushing the air back with force.

- Secondly, a competent head configuration can help out, which will close the hole from the side where the winds predominantly blow.

If there is no electricity

A non-volatile boiler in conjunction with a circulation pump consumes not so much. It can be adapted for DC power and switched to battery operation. But for powerful boilers this is not suitable. The only way out is to connect the boiler to an alternative source of electricity, such as a gasoline or diesel generator.

If the gas pressure drops

The first step is to check the gas pipeline in the place where it departs from the main line. The joints, where there are traces of welding, as well as valves and taps, are carefully checked. The specific smell that is given to natural gas at distribution stations will help detect a leak.

The only option is to write an appeal to the appropriate authorities. Contact your neighbors - they most likely have the same problem. Drafting a collective petition will help expedite the decision-making process within the natural gas supplier organization in your area.

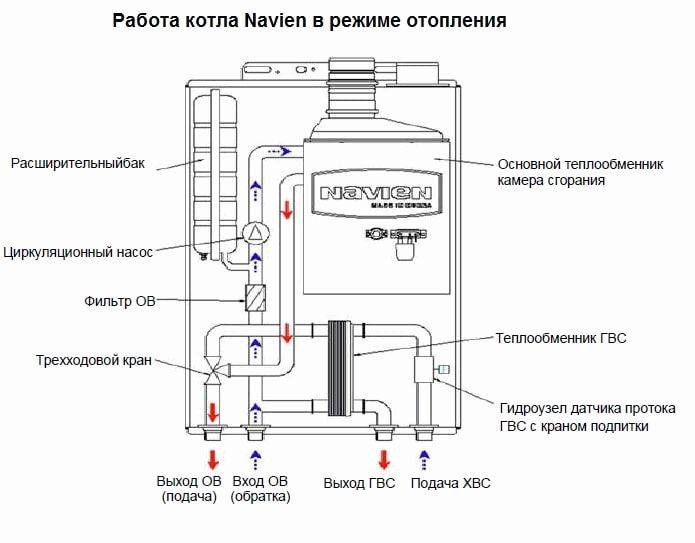

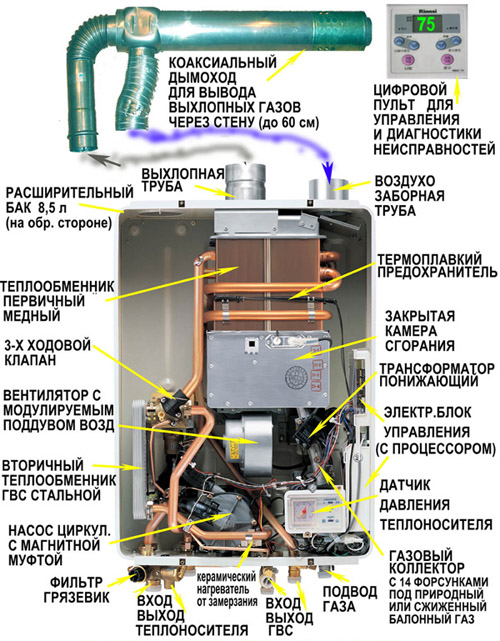

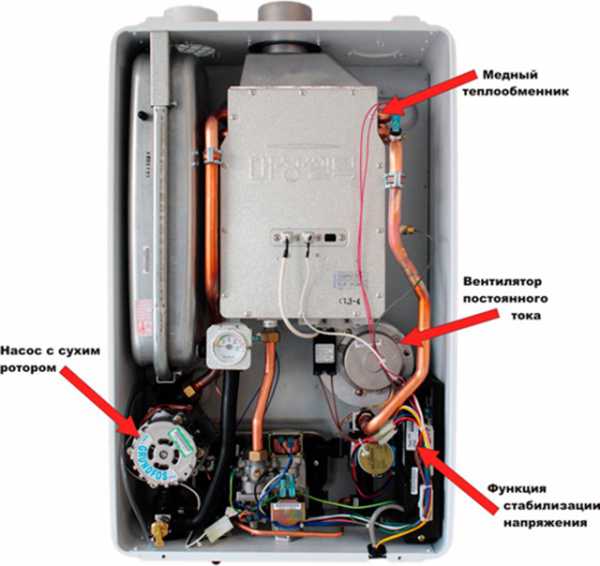

Technical device and principle of operation of the Navien gas boiler

Consider a dual-circuit device gas boiler Navien Deluxe Coaxial.

Navien gas boiler device

The device has two heat exchangers that prepare the heat carrier (main) and domestic hot water (secondary). Gas and cold water supply lines are connected to the corresponding pipes, which enters the heat exchangers, where it is heated to certain temperatures.Then, with the help of a circulation pump, the coolant is sent to the heating system of the house.

All operation of the device is controlled by an electronic unit that provides timely shutdown / on of the burner, which controls the temperature of the water in both circuits by means of special sensors. The control board is protected from power surges, but in areas with frequent or significant power surges, a stabilizer must be used.

Navien boilers have a remote control unit equipped with a display that shows the current mode, temperature, and other operating parameters of the device. In addition, the display shows the error code detected by the control unit in any system of the device.

How to connect and set up

Installation of the boiler does not require any specific actions. Floor devices are installed in a certain place, mounted devices are hung on the wall using a standard hinged rail.

The boiler is hung through damper pads (rubber, foam rubber, etc.) so that the noise during operation does not spread throughout the house. Gas and water pipes, heating system and domestic hot water are connected to the corresponding branch pipes. An air supply and smoke extraction system is also connected (depending on the type of construction).

The boiler is adjusted by bringing the gas pressure to the standard value. To do this, turn off the water supply and adjust the minimum and maximum gas pressure corresponding to operation in different modes with the adjusting screw. Then restart the water supply. During operation, it is necessary to periodically check the condition of the boiler connections with a soapy solution - if they are leaking, bubbles will appear.If noise or other signs of an unplanned change in operating mode appear, turn off the gas supply and check the condition of the equipment.

Brief operating instructions: operation and adjustment

All actions with the boiler are performed using a remote control panel. The water temperature in the heating system is adjusted by pressing the "+" or "-" buttons on the remote control with the "heating" mode selected, which is indicated by a stylized battery image. The display shows the numerical value of the set temperature. It is also possible to set the mode according to the air temperature in the rooms, for which you need to turn on the corresponding designation on the display (the symbol of a house with a thermometer inside). The flashing display shows the desired temperature value, while the constant display shows the actual temperature. Hot water is adjusted in a similar way, you just need to switch the mode.

Common mistakes and causes of problems

Sometimes the boiler displays a special code on the display, indicating an error in the operation of any system. Consider typical errors and codes:

This table shows the common errors of Navien boilers

To solve the problems that have arisen, you should eliminate the source of the malfunction yourself or contact specialists. There are some special requirements that are specified in the instructions. For example, code 10 - an error in the smoke exhaust system - can occur when the system is working properly, just a strong wind has risen outside. In order to avoid errors, you should carefully study the user manual.

Gas boilers Navien — practical and easy-to-use devices, profitable from an economic point of view, with full functionality and capabilities. At relatively low prices, South Korean equipment is optimally suited for harsh Russian conditions, it allows you to create a comfortable temperature in the house, organize the supply of hot water. Installation, operation, maintenance of Navien boilers does not cause any difficulties, all actions are described in detail in the attached instructions. Detected malfunctions or problems that have arisen are promptly eliminated by specialists from service centers.

EMERGENCY STOP OF THE UNIT

- There are the following cases of emergency shutdown of the boiler:

- interruption of the supply of electricity;

- damage to gas fittings or gas pipeline;

- in case of failure or incorrect operation of safety valves;

- if the water flow through the boiler has dropped below the minimum level line;

- in case of defective operation of the steam valve;

- in case of malfunction of automation;

- with an extinguished flame in the furnace during fuel combustion;

- at an elevated water level;

- if the feed pumps are not working;

- when the pressure rises or falls in relation to the norm;

- in case of mechanical damage to the unit, in case of rupture of pipes;

- if cracks or gaps are found in the welds;

- when atypical sound signals appear (crackling, noise, knocking, bumps), etc.

Stopping the heating units involves actions that depend on the type of boiler.

The procedure for emergency shutdown of a gas-fired boiler involves the following manipulations:

- Reduce the gas supply to the burner.

- Reduced air supply (draft limitation).

- Closing the valve (faucet) on the gas pipeline.

- Closing the valve on the air duct.

- Checking the furnace for the absence of combustion.

The instruction manual for the boiler Ariston or another brand contains the information necessary to stop the device in the event of an emergency

It is important to execute it step by step and control the correctness of the actions.

If the boiler does not start at all

It may also be that the boiler does not turn on - i.e. there is no flame at all.

The reasons for this may be:

- The simplest is low voltage or other problems in the mains. What to do: you should once again check the connection, the integrity of the wiring, the serviceability of the outlet.

- The electronic control system does not work. Then it is necessary to call the serviceman, since it is almost impossible to fix such malfunctions on your own.

- The burner nozzles are clogged - they can be carefully cleaned at home. The cause of clogging is incomplete combustion of gas and the deposition of soot. Normally, the flame burns blue, and clogging can be identified by the abundance of red, orange and yellow hues in the flame. How to eliminate the cause is shown here.

- Weak pressure in the gas pipeline network, drops. You should clarify the data about a possible accident or temporary failure by calling the service company.

Causes of breakdowns of gas boilers

Autonomous gas heating provides people with comfort and warmth. The “heart” of the entire system can be safely called the boiler, malfunctions in which can adversely affect the operation of the equipment or suspend its operation completely.

Gas boilers can fail for several reasons:

- settings failure;

- damage to shutoff valves;

- the pump does not work;

- poor performance of the hood;

- clogging of the chimney, resulting in the operation of a special draft sensor;

- violation of the rules of operation and safety;

- low quality components;

- power failure due to a drop in gas pressure;

- mechanical damage, etc.

Also, repair of gas boilers is required in case of defects in the controls and protective systems of the unit.

Gas boiler Conord specifications and features

The thickness of the steel sheets used to make the furnace of the Conord boiler is 3 mm. The material has a refractory powder coating, thanks to which the life of the boiler, as the manufacturer assures, is 15 years.

The efficiency of boilers of this brand is 90%.

Such a high rate was achieved due to the installation of turbulators in the fire tubes.

Branch pipes for connection to pipelines are located on the rear panel of the heat generator.

Their diameters are 50 mm or 2 inches (heating circuit connection) and 15 mm or ½ inch (DHW).

The smallest model provides heat generation in the amount of 8 kW. The oldest representative of the line has a capacity of 30 kW. Intermediate values: 10, 12, 16, 20 and 25 kW.

The diameter of the chimney depends on the power of the appliance. For boilers with a heat capacity of up to 12 kW inclusive, it is 115 mm, for more powerful ones - 150 mm.

Heat generators of this brand have built-in expansion tanks with a volume of 8.5 liters. The maximum allowable coolant pressure is 6 atm.

An important feature of the Conord boilers is the ability to operate at a gas pressure in the pipeline of only 0.6 kPa (usually the pressure in the distribution gas pipeline is maintained at 1.3 kPa)

Chimney problems

The health of the chimney is, of course, the main thing to check when you want to find out why the gas boiler is turning off, as many reasons for the malfunction can be associated with it.

Ice formation

Why does frost often form in the chimney? The fact is that hot steam, which, together with the products of combustion, enters the chimney, rises through it, cools and settles on the walls in the form of condensate drops. The condensate freezes over time and turns into a thick layer of ice. As a result, the thrust is greatly reduced, the automation turns on, and the flame in the burner goes out.

The solution to this problem is that the chimney must be cleaned and then insulated so that the condensate does not freeze, but flows down into a special container.

Reverse thrust

This problem often occurs when the wind in the street increases or changes its direction, when air enters the chimney and blows out the flame in the boiler.

This is very dangerous, especially if an old gas boiler with poorly functioning automation is used - combustion products are not removed, but, on the contrary, are pushed into the room by the wind.

What to do in such cases?

- This effect can occur at a certain direction of the air flow and atmospheric pressure, when a vacuum is created at the inlet to the pipe, the wind blows in there, and because of this, the boiler goes out. Sometimes this happens due to the insufficient height of the chimney - you just need to build it up a little so that its top point is 50 cm above the roof ridge:

- Some experts advise installing a variety of tips on the top of the chimney: fungi, umbrellas, deflectors, etc. Such solutions may be suitable for solid fuel stoves, but it is forbidden to put them on a gas chimney;

- Often the flame in the burner of an atmospheric boiler goes out due to poor ventilation. Sometimes it is enough to open a door or a window, and the gas lights up again. In boiler rooms, to improve air exchange, a vent is made at the bottom of the door and covered with a fine mesh;

- Sometimes the cause of a decrease in traction can be a burnout of the pipe. Wind blows into the hole formed and interferes with the normal operation of the chimney. The only obvious solution is to replace the chimney pipe.