- Causes of breakdowns and their elimination

- Problem # 1 - lack of traction in the column

- Problem #2 - Difficulties with water pressure

- Problem #3 - insufficient gas pressure

- Problem # 4 - no ignition when turned on

- Problem # 5 - the presence of blockages in the tubes

- The wick does not light up

- Electronics failures

- If the geyser goes out during operation

- Prevention methods

- Lights up but dims

- How to repair boiler codes?

- Boiler overheat error

- Low system pressure

- There is no gas boiler draft

- The boiler does not ignite the flame when ignited

- The boiler is kindled, but the flame immediately goes out

- The panel gives incorrect errors

- Geyser flame adjustment

- Troubleshooting due to which the geyser does not ignite

- Not enough charge

- More about batteries

- Battery Tips

- The general structure of a household column

Causes of breakdowns and their elimination

Despite the simplicity of design, unpretentiousness in operation, the flow heater is not immune from breakdowns. If the geyser of the Vector brand does not turn on, do not panic. There can be several reasons for the problem, and most of them can be fixed on your own.

Problem # 1 - lack of traction in the column

The lack of draft indicates that the products of combustion cannot be quickly removed from the room. This poses a danger to users, so the sensor turns off the geyser.

Sometimes the burner ignites, but immediately goes out. This can happen when there is not enough air to burn the gas - the flame goes out due to a lack of oxygen to support combustion.

In any case, you first need to check the draft by bringing a burning match to a special hole on the column body. If the flame is directed inward, then the chimney is working normally, the combustion products will be quickly removed, and the cause of the malfunction is different. If the flame remains motionless, directed upwards or towards the user, then it is worth carefully inspecting the chimney, cleaning it.

Soot gets into the air along with the products of combustion. It gradually settles on the walls of the chimney, narrowing its opening. As a result, traction is lost. The problem is solved by thorough cleaning of the chimney

Problem #2 - Difficulties with water pressure

Another reason why household gas does not ignite brand column Vector, there may be a low pressure of cold water or its complete absence. Before you start looking for a solution to the problem, you need to make sure that cold water is supplied without interruption, evaluate its pressure. If there is insufficient water pressure in the system, the solution may be to install a pump or replace old, clogged pipes.

If there are no problems with the water supply, it is worth moving on to inspecting the column. The solution to the issue may be to adjust the water supply to the column. To do this, the corresponding valve must be fully opened.

Another cause of insufficient water pressure in the column is a clogged filter.To inspect it, it is necessary to shut off the water and gas supply with valves, unscrew the nuts, rinse the grid. If cleaning fails, the filter will have to be replaced.

It will take a few minutes to inspect the filter. However, in some cases, one flush is not enough, a complete replacement of the part is required.

Problem #3 - insufficient gas pressure

Sometimes the gas pressure is not enough to ignite the flow column, its normal operation. However, this problem cannot be solved on its own. You need to contact the gas service.

Problem # 4 - no ignition when turned on

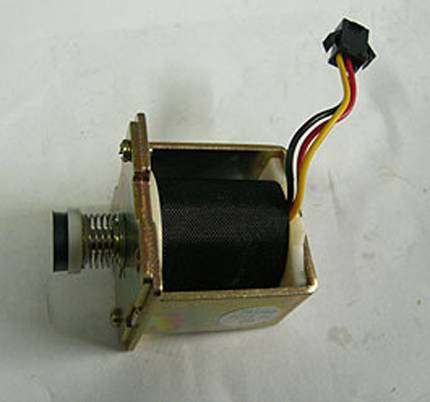

The presence of an electric ignition system ensures the comfort of using the gas column, eliminates the use of a wick that is constantly on fire. However, it is this element that can cause a malfunction of the device.

When the tap is opened, automatic ignition should work. This action is accompanied by a characteristic crack. If the ignition does not work or the spark is too weak to ignite the gas, the column will not be able to connect. Replacing the batteries will solve this problem.

Batteries are required for the smooth operation of an instantaneous water heater. When the batteries are discharged, the electric ignition does not work, the column does not turn on

Problem # 5 - the presence of blockages in the tubes

Water and gas pass through the gas column Vector in the process of operation. The use of filters allows you to clean them from unnecessary impurities. However, the presence of blockages can cause the device to simply not turn on.

However, the filter is not always able to bring the water to an ideal state. Soluble salts get inside the heater together with the liquid, settle on the walls of the heat exchanger.As a result, the patency of thin tubes is impaired.

Specialists remove scale with the help of specialized reagents. A home master can deal with it using a solution of citric acid or vinegar. To clean the heat exchanger, you need to remove it, place it in a warm solution with the addition of vinegar. You can also use special purchased products - "chemistry" designed to clean heat exchangers.

It is better to entrust the elimination of blockage of the heat exchanger to qualified craftsmen, since the tubes are fragile and, in the absence of specialized skills, they are easy to damage

We discussed in detail about cleaning and repairing the heat exchanger in the next article.

The wick does not light up

If the column ignites, but very badly, then there may be several reasons. Let's consider each of them:

- If the piezoelectric element does not work, then in the Astra and Zerten models there may be problems with the igniter. The wick should always burn, and it works when the tap is opened or when the corresponding button is pressed. If the element does not work, the wick does not burn, then the jets of the column could become clogged. To do this, disassemble the device, remove the metal protection or casing and clean the blockage of the jet. It is better to do this with a thin wire. Usually, after cleaning the jet, the column works fine. This is one of the reasons why the Astra gas column and other similar devices do not light up.

- Another case is automatic speakers that light up for a long time. The automatic column ignition system is battery operated. When the faucet is opened, the device is triggered and a powerful spark is formed, which ignites the burner of the column.If there is no spark, then it is worth trying to replace the batteries, but it is better to install batteries.

- The generator of the hydrodynamic system may also fail. The generator rotates when water passes through it. The unit, during rotation, generates a current, from which a spark is then formed. If this is the reason why the geyser does not light up, then it is better to entrust the repair to professionals.

Electronics failures

The presence in modern models of a large presence of electronic components, on the one hand, ensures high safety of the device and ease of use, on the other hand, complicates troubleshooting and subsequent repairs.

The causes of electronics malfunction are mainly related to the influence of external factors - voltage drops in the network, lightning discharges that have fallen into the main gas pipes and water from leaks inside the device getting on the boards. In addition, the failure of individual electronic components due to failures in the electronics itself cannot be ruled out.

The reason that the geyser vector does not light up may be a malfunction of the electronics, and the following situations may occur:

- Lack of spark during ignition;

- Extinguished digital scoreboard;

- The device does not start the first time;

- When working, it constantly shows an alarm signal;

- The protection system is constantly working;

- The device turns on, then turns off again;

- Diagnosing a breakdown usually begins with checking the batteries, old or dead batteries must be replaced with new ones. If there are traces of electrolyte coming out to the terminals, they must be cleaned.

If this operation did not lead to troubleshooting the device, you must call the wizard to check the electronic unit. Most often, in such models, the electronics unit cannot be repaired, it is simply replaced with a new one. During the replacement of the block, the master must examine all the nodes of the device, and when connecting a new block, in addition, test the system and configure its parameters

Particular attention is paid to the presence of leaks at the joints of the nodes and the integrity of the heat exchanger

If the geyser goes out during operation

There is no traction.

If the window is tightly closed in the room, there is no inflow of fresh air, the column overheats and the automation is activated, which turns it off. If after that you opened the window, after 10 minutes you turned on the column, and it works, then the reason has been found.

The draft also decreases when the ventilation duct is clogged. To check the draft, you need to open the window and close the channel with a sheet of paper: if the sheet is held, then the draft is normal. You can also check it with a match lit near the exhaust channel: if the flame becomes horizontal, then the draft is good, if not, then you need to clean the channel.

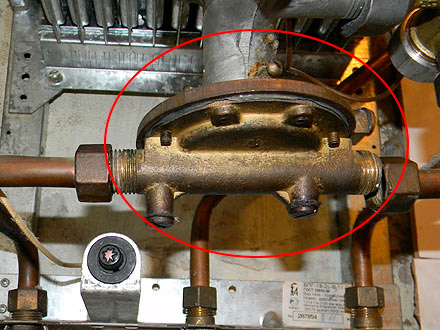

Water node malfunctions.

The burner in the geyser can also go out in case of insufficient water pressure. The reason for this may be a clogged strainer. To clean it, you need to unscrew the water supply and clean the mesh.

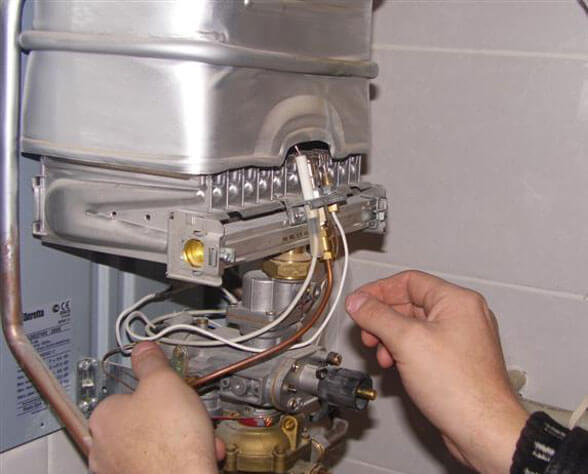

Fix leaks in connections.

A tap must be installed on the pipe that supplies water to the gas column radiator, and a tap must also be installed on the pipe through which gas is supplied.All plumbing connections are made with union nuts, and sealing is done with rubber gaskets.

From the temperature difference and over time, the elasticity of the gaskets decreases - this leads to the fact that water flows from the joints. Gaskets need to be replaced periodically. If one gasket is not enough and water flows from the connection, then two gaskets must be installed.

We clean the igniter.

After some time, the igniter becomes clogged with soot, the flame of the wick decreases, and the gas coming out of the burner does not immediately ignite. If gas builds up, an explosion may occur. To prevent it, it is urgent to clean the igniter.

Air holes need to be cleaned. To do this, the jet is removed and the nozzle is cleaned with a thin wire. Some speakers have automatic electric ignition, but it has drawbacks: with low water pressure, it works unstably, the batteries need to be changed periodically.

Prevention methods

In order not to have to fiddle with the unit too often or constantly call the repair service, you should adhere to the following rules:

- Set the temperature at the optimum level so that there is no need to dilute the water, then the scale will not appear so quickly. In order not to have to adjust the column every season, it is preferable to choose a model that remembers the setting for winter and summer modes.

- To remove salts from water with high hardness, you can install an electromagnetic system that will purify the liquid.

- Regular cleaning of the chimney and parts of the water heating system is necessary.

- Modern speakers that have a built-in electronic controller are best connected to the network through a stabilizer and not turned off at night.

- If the hose length exceeds 3 meters, then the pressure during the gas supply will greatly decrease.

- When the column is running, it is better to open the window, such a simple way will allow you to get a lot of air for the normal functioning of the unit.

- The chimney and quickly dusty parts of the column should be periodically checked for dirt, cobwebs and the like and get rid of them with brushes and a vacuum cleaner.

Signs that an unscheduled preventive maintenance and technical inspection from a specialist was required:

Signs that an unscheduled preventive maintenance and technical inspection from a specialist was required:

- the pressure in the water supply is normal, but the heat exchanger still works for a small amount of time;

- the unit is constantly turned off or does not function in principle, although the supply of gas and water is carried out in the optimal mode;

- often, for no reason, thermal protection is triggered, provoking a shutdown of the working system;

- the heating of the water is reduced, although there are no noticeable violations of the work.

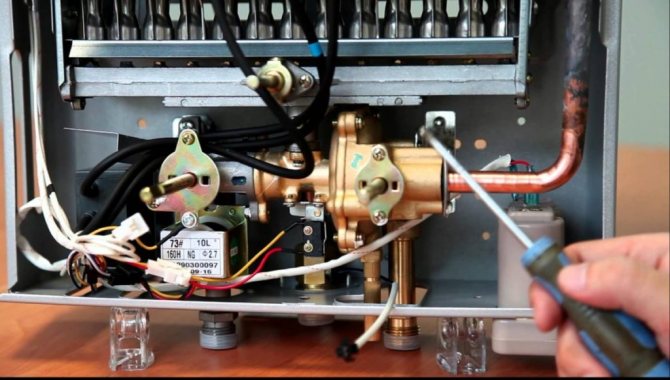

To check the column from the inside, you need to remove the upper case. This is done using a Phillips screwdriver, which unscrews the screw located on the handle for attaching the gas blocking valve.

The handle itself is removed by pulling on itself. Then, with a flat screwdriver, the screws for securing the case are removed, after which it can be removed.

The main tasks in scheduled maintenance are to check the overall performance, inspect the column inside and out to find places that need to be cleaned from dust and dirt, and assess the condition of the heat exchanger as accurately as possible.

Periodic preventive maintenance and checks allow you to increase the life of the device due to the timely detection of problems in the functioning of the column.

The work itself should usually be carried out once a year, but if the column is already old and often junk, then if it is impossible to replace it, checks should be arranged more often.

It is better to trust the annual check to professionals from specialized gas services, as they will be able to determine exactly what condition the unit is in.

Quality maintenance usually includes a complete disassembly of all equipment, looking for defects and areas of damage that can cause interruptions in the operation of the dispenser.

Also, each main part is cleaned (wet and dry cleaning), adjustment of all components of the gas water heater or bringing them to their original position, reconnecting and testing readiness for operation.

Lights up but dims

Let's consider several moments when the column decays some time after ignition and what are the ways to solve this problem:

One of the reasons is insufficient draft due to the lack of air movement inside the room where the device is located.

Traction test

This happens when windows and doors are tightly closed. For this reason, the protective relay overheats, the overheating sensor is triggered.

You can eliminate it by opening a window or window, creating a draft in the room. The gas heater burns a very large amount of oxygen during operation, so a constant supply of fresh air is required for its operation.

The second reason for the attenuation of the column may be insufficient holding time of the ignition button. It should be held for at least 20 seconds, if you hold it for a shorter time, the column will go out.

A malfunction of the combustion products removal sensor is the next point. To check the sensor, you need to ring it by connecting two terminals.Normally, the resistance should show infinity. If the reading is different, the sensor will need to be replaced.

Strong pressure of cold water, and low hot - this situation also often causes the water heater to fade. This happens when you open a cold tap using hot water. To eliminate this problem, it is necessary to adjust the water supply in such a way that you do not have to open cold water in order to dilute the hot one. In addition, this is an incorrect operation of the device, which can lead to damage to the heater.

High water pressure can lead to damping. This problem is especially typical for the Lux Eco model, which is designed to work with low water pressure. At the same time, the strong pressure of the duct bends the membrane of the water unit, the membrane shifts the stem in the gas supply. It is required to adjust the gas supply or, if possible, adjust the water pressure.

The temperature sensor has tripped, which protects the device from overheating.

Column Temperature Sensor Vector

For some time after ignition, the heater works, then it fades again. If you try to immediately turn on the device, there will be no result. After a while, about 25 minutes, the burner lights up, but then goes out again. The problem is that the sensor is too sensitive. In this case, only its replacement will help.

Poor contact between thermocouple and solenoid valve.

If the thermocouple is in good condition, it is necessary to clean the contacts and the automation unit.

The design of the igniter itself (the device for generating an electric spark).The electrode is mounted in such a way that the spark falls on the comb, which is welded to the edge of the gas burner at a distance of about 12 mm from its outlet. Provided that the gas supply is adjusted to low water pressure, the gas leaves the burner in a small volume and at a low speed.

Given the fact that a small reverse thrust is almost always formed inside the system, a weak level of gas goes down under the pressure of this thrust, not reaching the spark. This situation can be corrected by bending the electrode from the comb to a level at which the spark falls not on the comb, but through the gas exactly in the center of the burner. After performing such manipulations, the device almost always ignites, ignition is fast, stable and soft.

The formation of holes between the flue pipe, the connecting pipes of the flue device and the chimney, between individual sections of the flue pipe. It is determined visually, to eliminate it is required to seal the gaps with self-adhesive heat-resistant tape or other materials that are resistant to high temperatures.

How to repair boiler codes?

Boiler overheat error

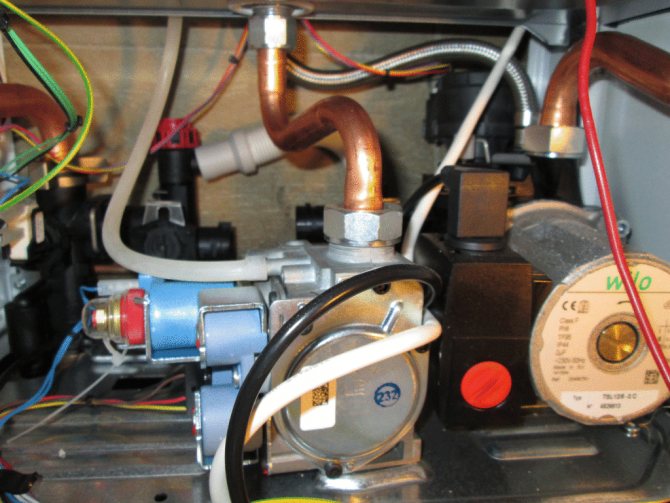

A gas boiler malfunction in the form of overheating may occur due to lack of circulation. In this case, you need to check the pump and filter. Maybe the overheating thermostat is broken.

Low system pressure

If the pressure does not rise when the boiler is heated, then the tightness of the system may simply be broken and the connections must be tightened, after which a little pressure should be added. If this problem arose almost immediately after installing the boiler, then you just need to remove the air through the automatic air vent and add a little water.

There is no gas boiler draft

If the boiler has an open combustion chamber, it is enough to see if it is clogged with something. If the combustion chamber is closed, then condensate drips from the outer pipe, getting into the inner one and freezing, in the winter season, it turns into an icicle, blocking the access of air to the boiler. To eliminate this problem, it is necessary to pour the formed icicle with hot water. Another foreign object can also get into the chimney.

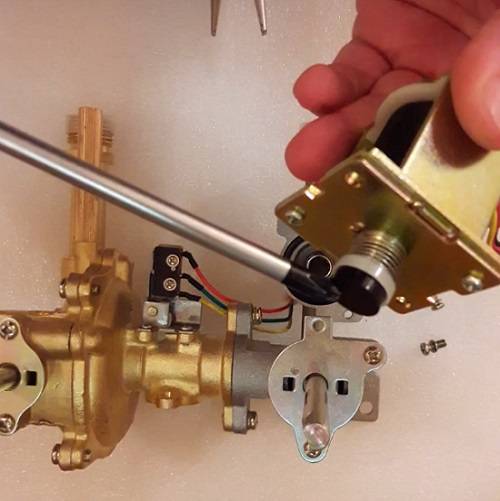

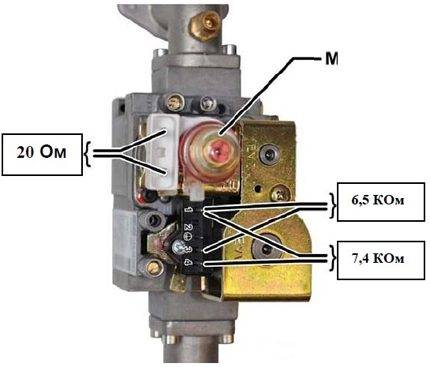

The boiler does not ignite the flame when ignited

This indicates a malfunction of the gas valve in the boiler. To verify this, you can unscrew the hose and see if gas is supplied. If there is gas, then you should call a specialist who will replace this valve.

The boiler is kindled, but the flame immediately goes out

In this case, the panel may show a malfunction of the gas boiler in the form of a lack of ionization current. You need to check this by turning on the boiler again, turning the plug over, thereby changing the phases. If nothing has changed, then the operation of the ionization current may be disrupted due to any electrical work in the house. If the boiler periodically extinguishes the flame, then this is due to power surges and a stabilizer is needed.

The panel gives incorrect errors

Sometimes electronic board errors can occur. This happens from bad electricity and poor-quality power supply. From this, some parasitic charges arise on the boards, due to which such errors are observed. To eliminate this, you need to disconnect the boiler from the network and let it stand for about 30 minutes. The capacitors will discharge during this time and these unnecessary charges will disappear. After that, the boiler should work well.

In general, that's all. If the material was useful, do not forget to share it by clicking on the social media buttons below this text.

Also find out how to choose the right gas boiler so that there are no problems in the future:

Read also:

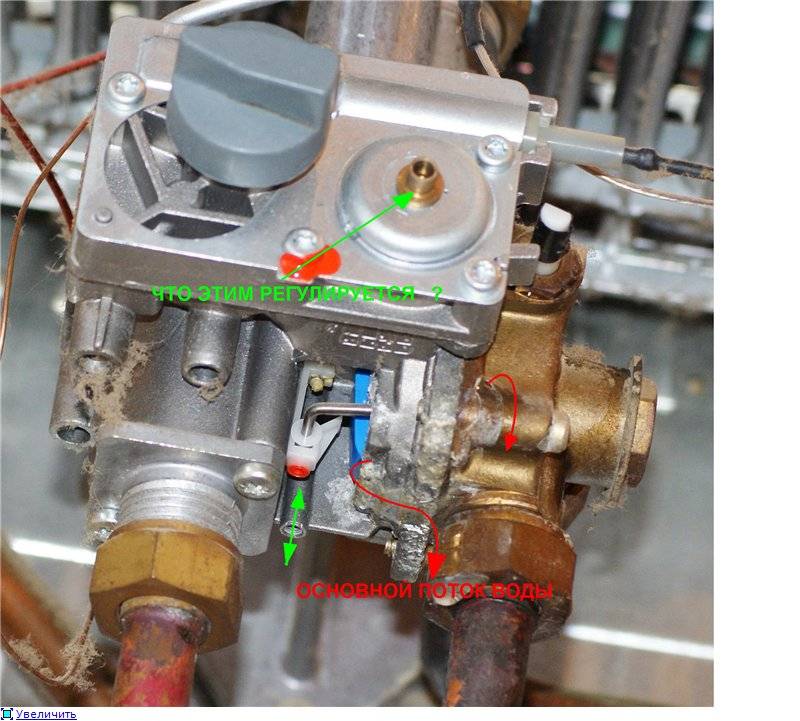

Geyser flame adjustment

Another way to adjust the water heater is to change the gas supply to the burner. This is done by adjusting the flame. On the body of automatic and semi-automatic hot water boilers there is a gas adjustment knob that reduces and increases the supply of blue fuel. The power of the column depends on this lever.

With an increase in the flame, the heating occurs more intensively, the gas consumption increases. Experts recommend changing the gas flow rate to fine-tune the burner flame. After choosing the intensity of combustion, for additional adjustments, use the knob for changing the water pressure. Another way to change the combustion temperature is to change the winter-summer mode.

To reduce gas costs in semi-automatic models, you can adjust the igniter. The adjustment of the wick is carried out by means of a special bolt on the pilot burner. Changes must be made carefully. If the pilot flame is reduced too much, this will cause the water heater to refuse to work. A strong increase in the intensity of the flame will lead to a significant waste of gas.

The column refers to complex gas equipment. Fine-tuning and maintenance must be performed by a licensed wizard. You can independently change the intensity of the water flow and gas pressure by adjusting the operating mode of the water heater for yourself.

Troubleshooting due to which the geyser does not ignite

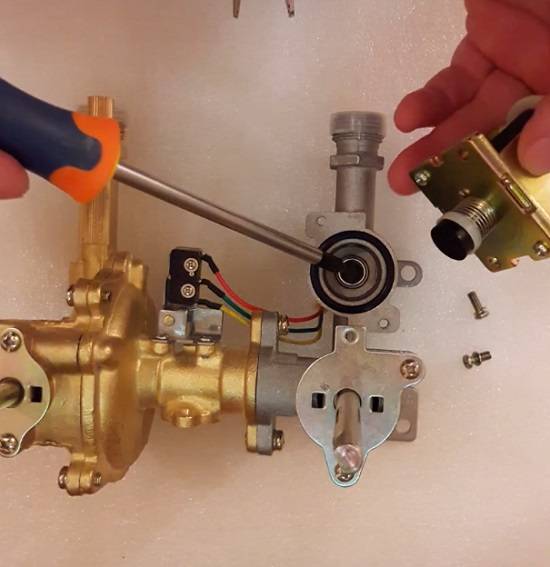

There is a turbocharged geyser with electric ignition. When hot water is turned on, the column clicks, but does not light up.An electric discharge is heard, the fan turns on.

The first step is to inspect, for this we remove the column cover. It is mounted on four bolts: two from the bottom, two from the top. We also remove the knobs for the flame regulator, temperature, winter-summer mode. On examination, everything seems to be intact, the wires have not burned out anywhere, water does not leak anywhere.

The principle of operation is that when a water flow appears, the gas valve is activated, an electric discharge is created, the gas is ignited, and at the same time the fan is turned on to pull the spent combustion products out into the street. If the water pressure is insufficient or the hood does not work, the gas goes out, the column turns off.

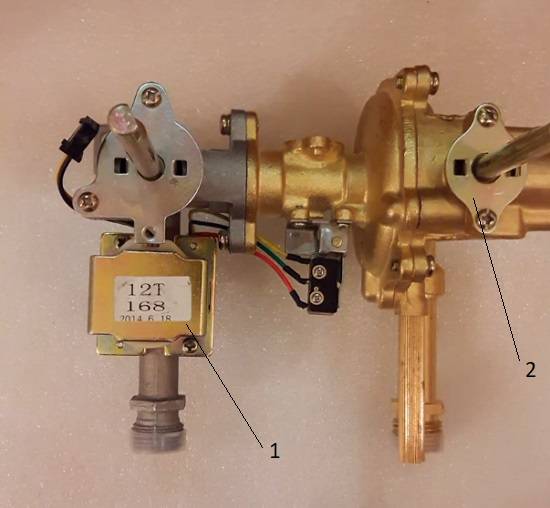

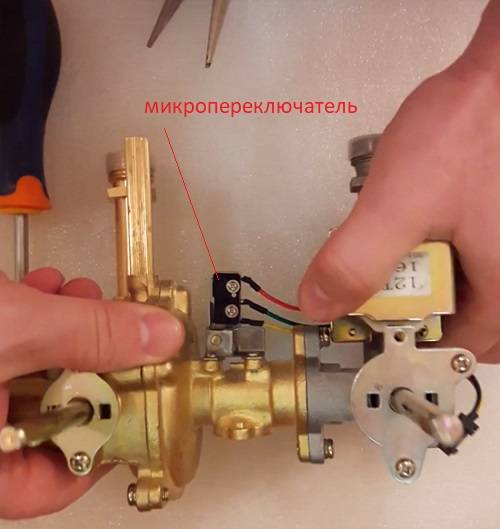

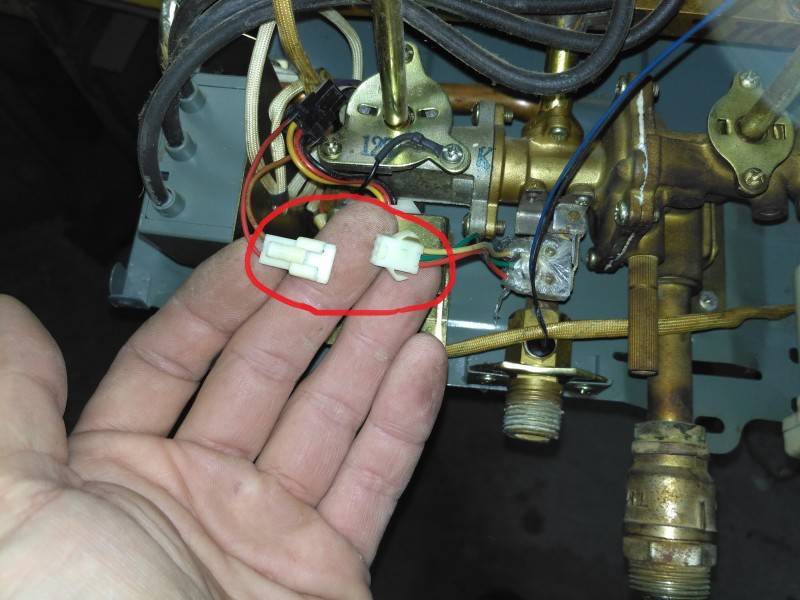

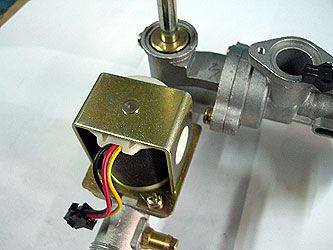

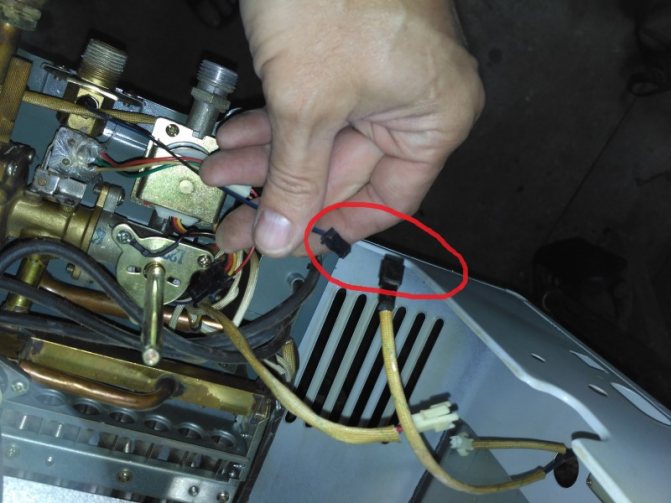

So, open the faucet and see what happens. Water rustled through the tubes of the heat exchanger, the electrodes gave a discharge, the fan turned on, but the gas did not ignite. Let's check if the relay (microswitch) is working, which works with sufficient water pressure and opens the gas supply valve. To do this, turn the tap again, the relay tongue should move away.

It works, which means that the pressure is sufficient for the operation of the gas column. Now let's check the operation of the gas valve. To do this, use a screwdriver to move the same tongue without opening the water. If there is a spark on the electrodes and the fan starts, then the gas valve is working.

The fault was found quite quickly, the ignition electrode did not spark. There are two of them: extreme. The one in the center is the control one, in the absence of a flame, it turns off the gas supply.

Not enough charge

When you open the water, you observe a normal flow, when you turn it on, there is a characteristic click, a spark is formed and everything in general is visually good. But there is one noticeable point: the burner itself in the gas column does not ignite. If you look out the window, there is no flame. This is the reason why there is no hot water. The owner does not have hot water, because of this fact there is a lot of inconvenience. This cause must be eliminated as soon as possible.

The reason for the malfunction and lack of hot water lies in a completely simple phenomenon. When the batteries stop working, the column stops functioning. It does not heat up and therefore the hot water supply stops.

The charge of the battery in the last stages is only enough for the formation of a spark. Therefore, visually you observe a spark, there is also a noticeable click. But the energy of the battery is not enough to ignite the burner itself.

Replacing the batteries yourself is not difficult. To do this, open the box with batteries and pull them out. Next, you should replace with new high-quality powerful batteries.

More about batteries

Battery polarity matters. If you insert batteries without taking into account their polarity, the column will not light up. Batteries can sometimes get stuck in the box, so keep an eye on them.

Batteries are replaced with new functioning batteries subject to two main criteria:

- the polarity of the batteries must be taken into account;

- the closing of the box, which is intended for batteries, should be done until a characteristic click.

Batteries used in gas water heaters must be standard D (in other words, barrel batteries). Salt options are not suitable because they have the ability to quickly fail.In most cases, alkaline batteries are used for gas water heaters. In another way they are called alkaline batteries.

Often there are cases when a person purchases batteries, but they do not light the column. Here, too, several questions arise, why even new batteries cannot cope with their functions. At this stage, the owner may also be embarrassed and look for the cause in a completely different way. In order not to find yourself in such an unpleasant situation, you need to wisely approach the choice of batteries for the functioning of the gas column. A few tips to keep in mind..

Battery Tips

It is not advisable to choose too cheap. In this case, it is recommended to choose more expensive batteries (normal ones cost about 200 rubles). If you buy cheap ones, then they most likely will not work normally, which means that in the future you will need to overpay

Therefore, purchase initially good quality expensive batteries;

Pay attention to the expiration date of the batteries;

As for brands, Duracell and Energizer brands are preferred.

The battery must be alkaline or lithium.

It will be more informative to use a specific multimeter tester that accurately determines the charge. Everyone can use such a tester, it will not be difficult. This method is convenient and practical to use, and you can buy a battery tester at any store.

Read also:

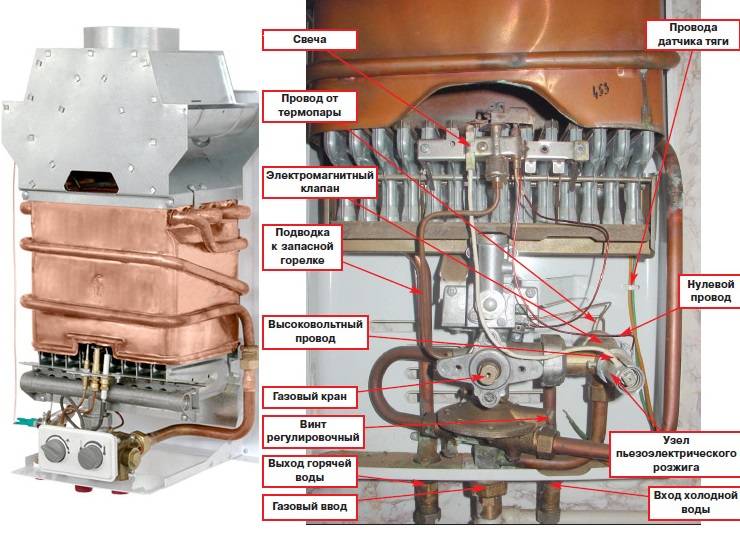

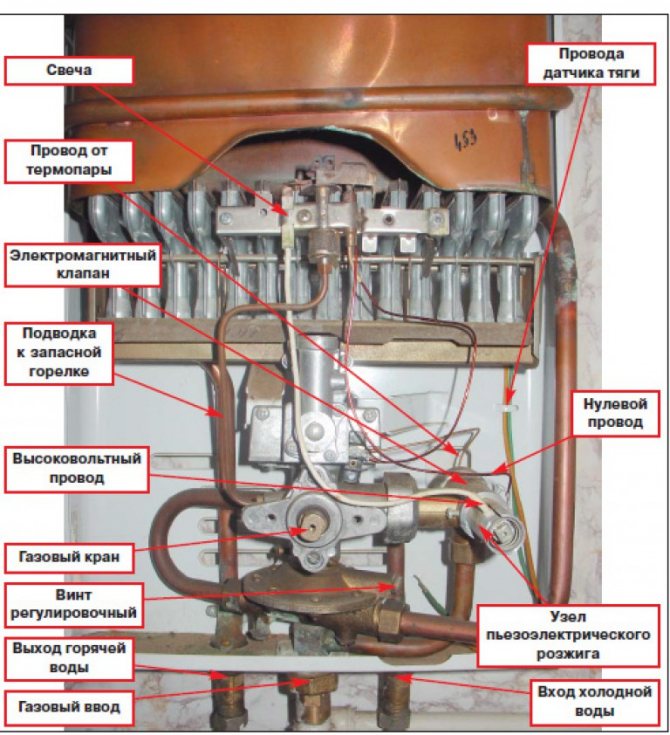

The general structure of a household column

A geyser is a flowing water heater. This means that water passes through it and heats up as it goes.But, before proceeding to an analysis of how a household geyser for heating water is arranged, we recall that its installation and replacement are associated with a centralized gas supply system.

Therefore, it is imperative to submit documents to the gas service of your region along with the corresponding application. You can read about the norms and necessary documents in our other articles, and now let's move on to the device.

Different models of geysers differ from each other, but the general structure of a household geyser looks something like this:

- Gas-burner.

- Igniter / ignition system.

- Exhaust and connection to the chimney.

- Chimney pipe.

- The combustion chamber.

- Fan (on some models).

- Heat exchanger.

- Pipe for gas supply.

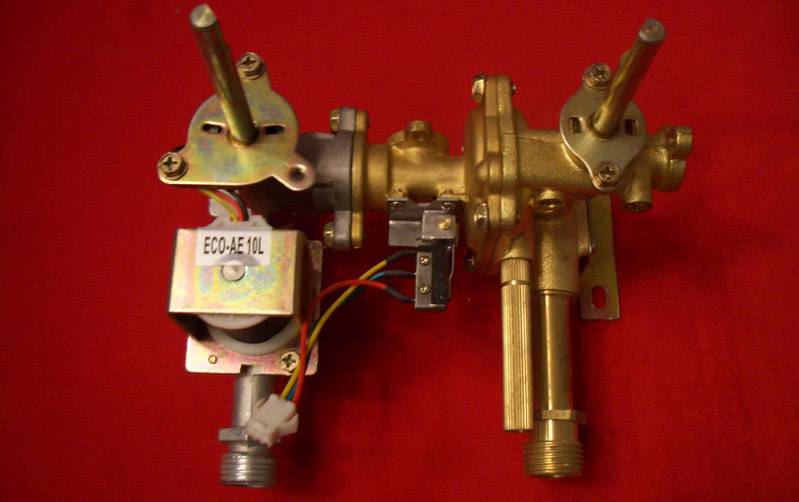

- Water node.

- Pipes for water supply.

- A branch pipe for an output of hot water.

- Front panel with controller.

The central element of the column is a gas burner in which gas combustion is maintained, which contributes to heating the water. The burner is installed in the housing, it collects hot combustion products, the purpose of which is to heat water.

The body is made of metal and completely covers the front and sides of the speaker.

It is important that the body material conducts heat well, because the quality of heating depends on the transmission of heat.

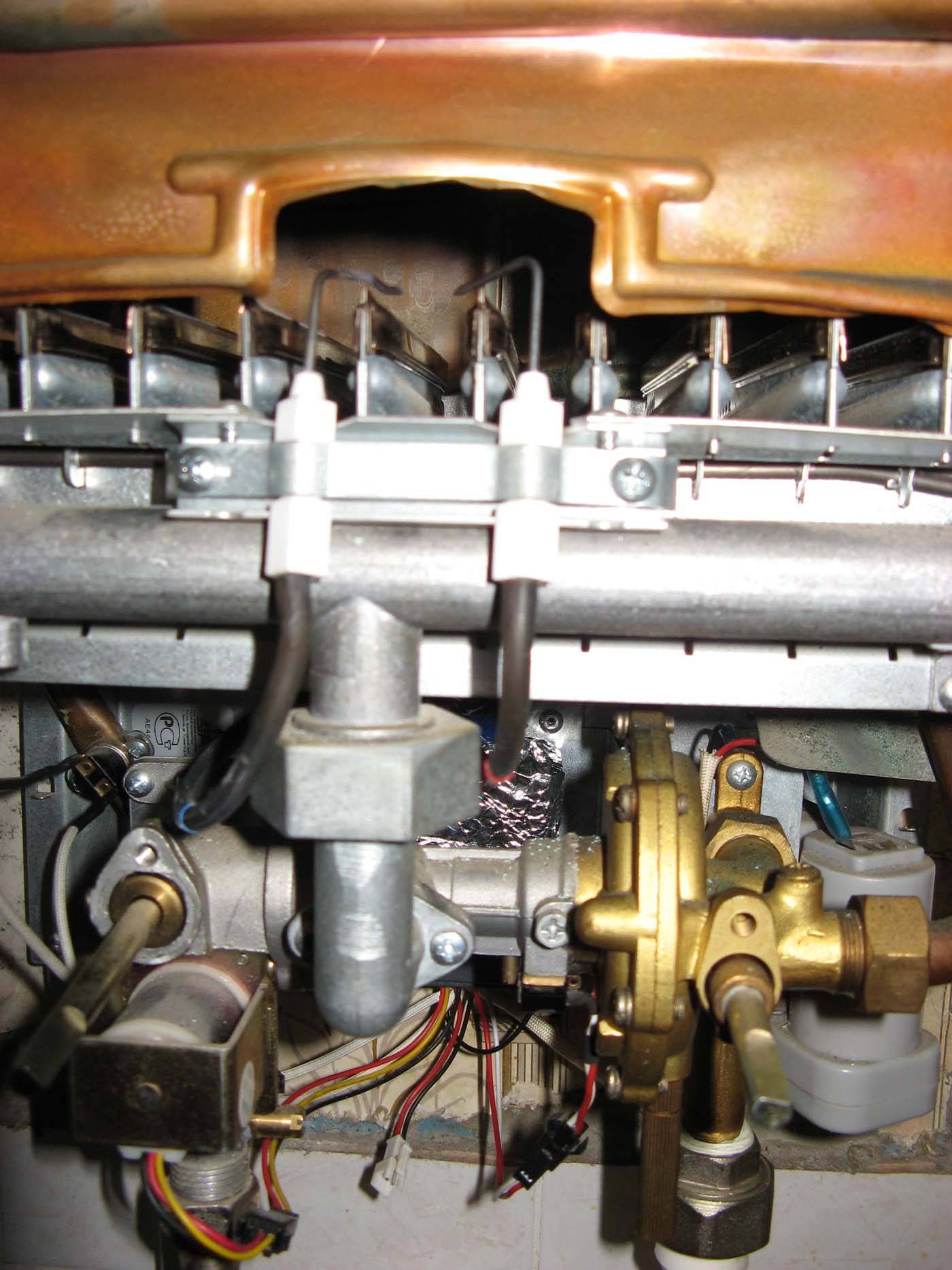

Structural components of the geyser located inside the housing. Closed gas equipment shown here

On top of the apparatus there is an exhaust hood and a chimney through which the products of combustion leave the column and the room. Their device depends on whether the column is open or closed, which will be shown below.

Pipes meander in a coil inside the body, water passes through them under natural pressure and is warmed by hot gases.This whole system of pipes is called a heat exchanger. Below are two pipes: on the right - for receiving cold water from the pipeline, on the left side hot water flows out.

A filter is often installed between the water supply network and the geyser, which regulates the hardness of the water. Without a filter, the column may be covered with scale at high water temperatures. When entering the column, water passes through the water node, which serves as a kind of "connection" between the water flow and the gas flow. We will talk about this connection a little further.

Burning gas burner with electric ignition and flame sensor. Sensors play an important role in the operation of equipment. Let's talk about their functions below.

With the help of another tube, which is also located below, the column is connected to the gas line.

There is also a front panel with a control unit. It is equipped with regulators to control the consumption of gas and water. Depending on the model, these can be simple knobs that need to be turned, or liquid crystal displays where you can see many characteristics of the speaker, or even the nature of its malfunction if the speaker does not work.