- Noise source in the boiler

- Reason 1: Water saturation in the system

- Why is this noise dangerous?

- How to get rid of it?

- Reason 2: lime deposits

- How to get rid?

- What to do to eliminate the hum?

- How to care for an autonomous heating system

- Fault reporting procedure

- Why does the speaker crackle and click?

- Why does the gas meter click

- How to eliminate the hum of the boiler when hot water is turned on

- The gas meter beeps - what to do, whether to call the master?

- The counter does not work correctly or is broken?

- If you have

- The button is turned on, but the ignition does not work

- One or all spark plugs spark

- You release the button and the ignition fires

- Shooting and tapping radiators

- Conclusion

Noise source in the boiler

The noise in the boiler may have some differences:

- Uniform monotonous.

- Uneven, crackling.

In this case, the first type may occur even during the operation of a new boiler, but the second may appear after some time of operation. What can be the reasons for their occurrence?

Reason 1: Water saturation in the system

Let's try to figure out why the heating boiler is noisy?

As follows from practice, most often those installations that are connected to an open-type heating system make a sound.The reason may be the saturation of the water that circulates in the system with oxygen. It is released when water is heated and forms small bubbles, while the process is accompanied by a characteristic sound (you can recall, as an example, the process of boiling water in a kettle).

Why is this noise dangerous?

This process does not pose a danger to the boiler and the heating system. No defects or threats to work will also happen. But, it can create discomfort in living rooms.

How to get rid of it?

The only option would be to change the type of system from open to closed.

The process does not require time and investment, and an additional positive point will be the additional possibility of protecting the metal components of the structure from corrosion.

At the same time, changing the type of system will not affect the possibility of its functioning without a pump. The process of changing the type of system consists in installing air vents on the boiler and changing the expansion tank to a membrane one.

You can also install an automatic make-up system and a weather-sensitive automatic system, which will make the use of the unit more economical and comfortable.

Reason 2: lime deposits

Another thing is when an extraneous sound does not appear immediately, but after a certain period of time. Let's try to figure out why the boiler makes noise in this case?

The thing is that lime deposits lead to noise. They form on the walls of the heat exchanger after a certain period of operation.

Such deposits lead to the fact that the temperature of the internal walls of the heat exchanger begins to increase, which also affects the wear resistance and durability of the structure.

The characteristic sounds that a boiler with deposits has formed are not only noise, but also strong clicks and knocks (they appear with heavy deposits).

How to get rid?

Only cleaning the heat exchanger from formations will help get rid of this type of noise.

Tip: craftsmen advise periodically washing the parts of the heat exchanger in a 4% vinegar solution. It is better to do this after removing the heat exchanger, and be sure to rinse the parts with clean water.

From the foregoing, we can conclude that there are actually not many reasons for the noise of a heating boiler, and they can be easily diagnosed and eliminated.

The video below shows how the Beretta Ciao boiler makes noise - watch it and pay attention if your equipment behaves in this way. If it was not possible to fix the boiler noise problem on your own, we strongly recommend that you do not delay and contact the specialists, because the consequences can be deplorable. The contact form is located at the bottom right of the page - write, do not be shy

The contact form is located at the bottom right of the page - write, do not be shy

If it was not possible to fix the boiler noise problem on your own, we strongly recommend that you do not delay and contact the specialists, because the consequences can be deplorable. The contact form is located at the bottom right of the page - write, do not be shy.

We hope that the material was useful to you. We will be very grateful if you click on the buttons of social networks. They are located a little lower. Let your friends learn how to deal with these malfunctions.

We invite you to our VK group and wish you a good day!

Hello dear readers.Why is the gas boiler noisy? This question is very relevant for the owners of this equipment.

Noises in a gas boiler may reflect difficulties in the heating network. It is necessary to quickly identify the causes and eliminate problems, otherwise the equipment may completely fail.

What to do to eliminate the hum?

Not all valves provoke a hum. The cause of noise can be mixers or faucets of outdated designs, with valves, as well as half-turn crane boxes.

Modern ball valves or joystick-type mixers do not have gaskets in their design. Therefore, they cannot enter into resonance with water pipes.

To get rid of the noise, sometimes there is no need to buy a new faucet. Often it is enough to dismantle the crane box, remove the gasket and correct it or replace it. Such elements often hang freely on the stem or have tapered edges.

Loose hanging gasket should be replaced. A deformed, irregular shape can be cut with scissors. Then the faucet box should be assembled and installed in the water supply. If the repair is done correctly, then there should be no more noise.

The simplest solution for an obsolete valve design is to replace it with a newer ball valve model. High-quality ball structures cause fewer problems during the operation of the water supply system.

The same advice can be given for obsolete faucets. Replacing the old faucet with a new model with one lever is the best solution to the problem.

How to care for an autonomous heating system

Autonomous heating requires constant attention. Emergency repair of the circulation pump will cause a lot of inconvenience.

- Joints and joints must be waterproof.

- Gaskets and bearings contain a sufficient amount of grease.

- A special device will help evaluate the connection and compliance with the mains.

- Trial activation will detect extraneous sounds and malfunctions in the system in advance. The engine must run without vibration and noise.

- Prolonged downtime is harmful to the pump. In the warm season, it is necessary to turn on the system once a month for 15-20 minutes.

- Running the device without water in the pipes will cause serious damage. It is also necessary to monitor the normal circulation of the liquid, do not block the valves near the pump.

- The filter must be free of contaminants. In its absence, only clean water is poured into the system.

- Limescale disrupts the operation of the shaft. It must be removed periodically or try to use a less hard liquid for the device.

Fault reporting procedure

Having decided to check how much a personal gas meter winds, and suspecting something was wrong, most users contact the gas service. There are a number of nuances in this procedure, knowing which you can save your money and nerves.

An analysis of judicial practice shows that court cases do not always end in favor of the consumer. The reason for this is the inability to prove the fact of contacting the gas service

Consider the situation

The owner of the apartment noticed that the new gas meter winds much more than the old one, does not work correctly or is faulty and turned to the gas workers. Calls to the gas service are ignored

The experts don't come.

A week or even a month later, the inspector comes with a check and discovers a malfunction.An act is drawn up and soon an invoice arrives for paying for gas for the past six months at an average tariff with inflated norms. Having no desire to contact the courts, most consumers pay the receipt, because they understand that the balance of rights is shifted towards the gas workers, and not the consumers.

And here is another example. You found a problem and called 04. The check came to you, identified and fixed the problem. Later, you will receive an invoice for gas payment at average rates for the past six months. In any situation, consumers are advised to be vigilant and take a number of preventive measures.

Algorithm of actions to avoid unnecessary financial expenses:

- report a malfunction to the organization that sends you payments (contact details are indicated on the receipts);

- during communication with a representative of the gas service, find out if your appeal is recorded and in what form;

- the best solution is to report the malfunction of the meter in writing;

- when the gas workers come to you with a check, find out if their visit is a reaction to your application or is it a scheduled check (if you don’t get a clear answer, call the gas service).

Try to protect yourself from trouble in advance.

You will learn how the gas flow meter is installed from the following article, which details all the nuances of installation and connection.

Why does the speaker crackle and click?

Clicking and crackling, another common malfunction of gas flow-through water heating equipment. Breakdown occurs in both automatic and semi-automatic boilers. The following is the nature of the sounds and indicates what exactly can cause them:

- The geyser clicks, but does not ignite - the contacts on the ignition unit are oxidized.The module is not disassembled and needs to be replaced. The catalyst for the fact that the geyser crackles, but does not ignite, can be dead batteries.

- The geyser clicks after the water is turned off - the frog water regulator has failed. Inside the block there is a rod with paws connected to the ignition block. After turning off the water, the spring should return the metal rod to its original position. If the rod is rusted, it may seize. The ignition unit remains on and continues to produce a spark. For this reason, the column cracks after being turned on. A hardened frog membrane can cause a malfunction - it needs to be replaced.

- The piezoelectric element constantly cracks - the contacts are oxidized, which leads to jamming and stable operation.

The noise in the column causes insufficient draft (the flame burns with a hum, changes its color, there is soot), poor air circulation (observed after installing metal-plastic windows in the kitchen), clogging of the burner's ignition wick or overgrowing of the heat exchanger with scale. The malfunction is found by elimination during the next column maintenance.

Why does the gas boiler hum and/or whistle?

There are times when the boiler interferes with its emitted noise. The burner makes a noise similar to that of a jet aircraft. The gas boiler is noisy and can be heard throughout the house. It naturally interferes with sleep, especially turning on after a pause. How to reduce the noise emitted by a gas boiler?

Usually, it is not the boiler and the fan installed in it that make noise, but not the correct installation of the chimney. To make the boiler start to make a noisy sound, it is enough to narrow the chimney a little, and you are provided with a sound like at the airport. The solution is to change or expand the chimney.

There are very frequent cases when gas equipment with pressurized burners starts to buzz. The fact is that the fan units are equipped with a stabilization system aimed at regulating the pressure of the gas supplied to the combustion chamber. During operation, such a boiler buzzes like a vacuum cleaner. To minimize the unpleasant buzz, it is better to build a boiler room building away from a residential building, and make good sound insulation for it.

The boiler may begin to hum due to a thick layer of plaque on the inside of the heat exchanger tube. The boiler begins to boil - it makes a sound like the sound of water from a boiling kettle. Clogged primary heat exchanger. You can check this as follows: set the maximum temperature on the boiler and close the return or supply valve so that there is a minimum water flow. When the temperature reaches about 80 degrees, the hum increases. The only way to solve the problem is to clean the heat exchanger.

Cushioning lining - what is it?

Shock-absorbing lining is a rubber sheet 10-12 mm thick or rubber washers of the same thickness. To reduce noise, all connections must be tight, rigid, the chimney must be additionally insulated with thermal insulation (basalt mineral wool, etc.)

It happens that when the ignition button is pressed, a whistle is heard from the pilot burner nozzle. If air has appeared in the gas pipeline or gas fitting, it is necessary to unscrew the nut at the junction of the gas pipe to the gas fitting, press the ignition button, after loosening the tube, bleed the air that has appeared until the smell of gas appears. Tighten the nut.

If there is a flame separation, then the gas pressure of the ignition burner should be adjusted with the adjusting screw.There are times when the wrong nozzle is installed, then it just needs to be replaced. This situation takes place in domestic units. The nozzle may also have a factory defect, expressed in the absence of a chamfer along the edges of the holes. When switching to a mode of increased intensity, the gas flow escapes, and the boiler begins to whistle. The only way out in this case is to replace the nozzle.

We should not forget that gas boilers are explosive, therefore, to correct problems, it is better to contact the specialists of Tyumengazservis LLC by phone 8 3452 58-04-04.

Why does the gas meter click

Out of ignorance, I made a project with a counter in the house, and not on the street, it makes terrible sounds during operation, it’s fine during the day, but it interferes with sleep at night, in principle, it has only been in operation for a week, another 100 cubes haven’t “burned out”, so here’s a question for specialists - will he get used to it over time (a neighbor says he also croaked at first), or is it a marriage and you need to go change it?

damn, Vovan, you, as always, give out the most adequate advice

in short, I looked on the internet - if you change the meter, you will have to redo the eyeliner, because all manufacturers have different ways, this is crap and loot that is not commensurate with the cost of the meter (bureaucrats / welders / sealers), I’ll wait a couple of weeks, let it wrap

How to eliminate the hum of the boiler when hot water is turned on

In the event of noise from the boiler, you can resort to the following measures:

- call a master specializing in the repair and maintenance of gas boilers;

- try to find the cause of the problem yourself. To do this, it is necessary to diagnose all the nodes of the system - from the gas pipe to radiators and hot water taps;

- clean the system with suitable products. You can use special factory chemicals or folk remedies such as vinegar and citric acid;

- check the pressure in the system, and if possible adjust it to the optimum level.

Do not interfere with the operation of the equipment in the absence of professional skills. This entails a serious danger to others. Work with gas equipment should be trusted only by specialized craftsmen. It is best to contact a service center recommended by the boiler manufacturer.

Climate technology Boiler

The gas meter beeps - what to do, whether to call the master?

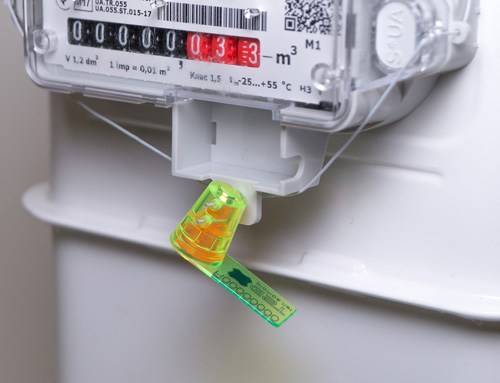

You had such a problem, and you immediately thought about what would be more profitable - to repair an existing gas meter or buy a new one? Here it is necessary to remember that the control counter is in your full property. Based on this, all current financial costs related to its verification, installation and replacement are borne only by you. Therefore, the only option that can be dispensed with without calling a specialist from the gas office is a thorough visual inspection of your device:

If you notice something suspicious, such as debris or old leaves with last year's grass on its body, then you can carefully remove all this yourself and clean the counter with a soft brush.

In all other cases, when the device has a normal appearance, but a squeak is heard from its body, it will be necessary to immediately apply for a gas master call. And before his arrival, it is advisable to cut off the flow of gas to your apartment or house.

When buying a new control device that will keep records of the consumed gas, each gas consumer must obtain a new registration certificate for this device without fail. This paper must be immediately registered with the serving local gas organization. When registering, a staff member will notify you of the date when the first check will be carried out. These periods vary greatly in different regions and can be every five years, and in some cases even more - from eight to ten years. We wish you that your metering devices rarely break down and do not cause you any unnecessary problems, because they are created for other purposes!

The counter does not work correctly or is broken?

You can independently check whether the counter really winds a lot.

To make sure that the account device does not deceive you, you need to:

- turn off all gas appliances in the house and check if the meter is winding (if so, then there is a gas leak or your meter was illegally connected);

- run the gas appliance at full power for 15 minutes, and compare the readings obtained with the passport data of the device;

- if the gas meter is equipped with an electronic display, and even when the gas valve is closed, the readings continue to change, then the reason is most likely stray currents.

It is forbidden to perform other manipulations to find the cause.

Most often, stray currents appear due to improper connection of stoves equipped with electric ignition from neighbors. Another reason is the use of special gas outlets.

No matter how carefully the “craftsmen” try to hide the traces of interference in the operation of the accounting device, experts experienced in the field of verification will be able to detect them.If the fact of violation of the body and design of the device is detected, the device will be recognized as faulty, and its owner will receive a considerable fine.

Most often, if it is noticed that the meter readings do not correspond to reality, consumers are in a hurry to give gas metering devices for verification. As a result, most often it turns out that the counters are working.

The main reasons on the basis of which the gas meter winds unreasonably much:

- problem with gas equipment;

- a leak;

- nearby electrical appliances.

In the first case, you need to calculate how many cubic meters of gas you use per month. If a single-circuit gas boiler is installed in the house, in which only one heat exchanger is involved, while the consumption of blue fuel is 10-20 cubic meters, then the reasons for such a huge consumption should be analyzed.

First, it is recommended to check the energy efficiency in terms of heat retention. Warming the house can solve this problem and gas consumption will be significantly reduced.

Membrane gas meters are used in private houses and apartments, which provide accurate data. These devices are easy to use

One of the most common reasons for winding extra cubes is a leak. Therefore, it is worth checking the system even if there is no smell. After all, with a leak, the smell of gas may not be felt.

You can check for leaks yourself. To do this, coat all connections and the gas valve with soapy water. The presence of a leak is indicated by emerging bubbles. In this case, urgently need to call the emergency gas service.

If you find a leak, turn off the gas. It is forbidden to use the stove

What to do if you find that the gas meter winds a lot:

- it is strictly forbidden to open the counter, interfere with its work and break the seal;

- after arrival, the repair team is obliged to attest to the safety of the seal;

- depending on the result of the inspection, the device can be dismantled and taken away for testing;

- if there is no leakage of blue fuel, before the arrival of the gas service, you can safely use gas appliances.

If the meter is beyond repair, then you are required to issue a document according to which you are shown the replacement of the meter.

Carefully monitor the representatives of the gas service so that during the inspection they themselves do not damage the seal, and the blame for this is not shifted to you. This happens quite often. The foremen then extort money from the tenants to "fix" the issue.

For the period during which you do not take readings from the gas flow meter, the payment for gas is carried out in accordance with the generally accepted agreement for the supply of blue fuel. Most often, this is the average gas consumption rate, which is calculated from the day you contact the gas service.

If a malfunction of the gas meter during the check was discovered by gas workers, then the monthly fee is recalculated for the previous six months. In both cases, consumption standards are overstated.

To avoid such a situation, the consumer should carefully monitor the operation of the gas meter and equipment. Responsibility for the serviceability of all appliances in a residential area lies with its owners.

If you have

They are now equipped with almost all devices, which has a positive effect on ease of use.Let's decide for a start how electric ignition is arranged and works.

Electric ignition consists of four parts:

- transformer (block) operating from the mains for 220 V;

- electrical wire leading from the transformer to the ignition mechanism;

- ceramic candle;

- the ignition button located on the control panel next to the rotary switches.

The mechanism of operation of electric ignition is as follows:

- When the button is pressed, the circuit closes;

- The transformer generates current for the spark;

- The impulse is fed through the wires to the gas burner;

- The ceramic candle produces a spark and the burner ignites.

It is noteworthy that the candle fires on all burners without exception, however, only the one to which the gas goes is ignited.

It is very important to ensure that there is always one voltage in the network - 220 V. You can buy a household voltage stabilizer for your stove, which will save you from unforeseen current surges. Otherwise, short circuits and unstable operation of the network negatively affect the electric ignition, and can cause damage.

If your hob is experiencing the following problems, then the problem is with the ignition:

Otherwise, short circuits and unstable operation of the network negatively affect the electric ignition, and can cause a breakdown. If your hob is experiencing the following problems, then the problem is with the ignition:

- turn on the button, but the ignition does not work;

- sparks one or all spark plugs;

- you release the button, and the ignition works.

The button is turned on, but the ignition does not work

The first and most common cause is contamination of the mechanism button and / or burner with dirt and combustion waste.

. Cooking entails splattering food all over the stove, so this problem is not uncommon.Clean the ignition button, wipe the burner clean, clean the nozzle with a needle or any other thin stick, wait until everything is dry.

One or all spark plugs spark

If the spark plugs on all burners sparkle orange or yellow, work intermittently, then the problem may be in a faulty electric ignition unit. It needs to be replaced, but it is extremely difficult to do it yourself. The block is located in the middle of the panel, it needs to be disassembled, the contacts disconnected, so it is better to trust professionals in this situation. To finally make sure that the fault is in the transformer, do the following:

- in the dark, with the lights off, turn on the ignition button;

- if there is a spark on all burners of the color described above (yellow, orange) - the unit definitely needs to be replaced;

- if the spark is blue, the block is good.

If the integrity of the spark plug is broken or its stem is oxidized, it will sparkle orange or yellow, intermittently. This is solved by replacing the faulty spark plug. However, such problems are quite rare and this is due to the design of the candle itself. It is a steel wire, one millimeter thick, enclosed in porcelain. For a candle to become unusable, it must be in very unfavorable conditions of high humidity or be hit

.

You release the button and the ignition fires

This may be due to a faulty transformer or contact oxidation.

When washing the panel, boiling water, the liquid can penetrate into the middle of the device, onto the contacts. With constant leaks and heat coming from the included burners, the contacts are oxidized. They get rough, can stick together, break.Their technical cleaning and high-quality drying will help.

Shooting and tapping radiators

In metal radiators, sharp sounds sometimes appear that resemble shots. These sounds are a consequence of the expansion of the metal: structural elements made of this material increase during heating and decrease when they cool. To prevent this factor, experts recommend using special insulation for pipes that are located close to the walls.

In addition, these sounds may be the result of improper installation of the structure or a violation of the rules for attaching heating batteries. To prevent this problem, you must strictly follow the installation instructions and the recommendations of specialists:

- the distance between the floor and the radiator should be 14 centimeters;

- from the windowsill, the battery should be located at least 10 centimeters;

- there should be a distance of 5 centimeters between the wall and the battery (a layer of insulation can be placed in it);

- pipes must be installed on a flat vertical surface;

- it is recommended to raise the end with an air vent by a centimeter.

In addition, periodic knocks can be heard in the heating system. Usually their occurrence occurs due to the difference in the diameters of the pipes used in the manufacture of the structure.

To prevent this malfunction, it is recommended to use elements with the same dimensions when installing the system. Instead of a diaphragm, it is better to install a regulator that monitors the pressure drop in the water supply to the heating battery.

The occurrence of extraneous sounds can also signal that the life of some structures has expired.You should diagnose the condition of the heating system and, if necessary, replace the radiator with your own hands or ask for help from specialists.

Conclusion

Whatever boiler is in your house, carry out its correct installation. Service this machine regularly. Eliminate dirt and scale from its components. Thanks to these operations, the boiler will work for a long time, efficiently and safely.