- Power outages

- Why does the heating boiler click. Why the heating boiler is noisy, we understand together

- Why does a gas boiler make noise when heated?

- Faulty fan located above the burner

- Scale in the heat exchanger

- Water doesn't heat up well

- Reason 1. Insufficient speaker power

- Reason 2. The column is clogged

- Cause 3. Damaged column water assembly membrane

- Cause 4. Incorrectly installed water inlet-outlet hoses

- Peculiarities

- Possible reasons

- If the stove burner does not ignite

- The main reasons for the unstable operation of the boiler

- Possible malfunctions of the gas fireplace

- What to do if the gas boiler goes out

- Safe operation guarantee

- Heating boilers Conord

- Automation AGU-T-M (Russia)

- Automation Euro SIT (Italy)

- Honeywell (USA)

- Crashes during abrupt regassing

- Clogged filter

- Electrical circuit problems

- Other problems of gas boilers

- Conclusions and useful video on the topic

Power outages

It happens that the voltage in the electrical network drops below the permissible level. At the same time, the boiler immediately goes out, since modern automation can detect low voltage. When the power supply is restored, the same automation will turn on the burner, so that most of these failures can go unnoticed.However, this mode of operation is harmful to electronics, so it can fail over time. So if suddenly the gas does not light up when voltage appears in the network, perhaps something has happened to the automation. To avoid this scenario, it is better to buy a voltage stabilizer.

Why does the heating boiler click. Why the heating boiler is noisy, we understand together

A recently purchased gas boiler operates quietly, barely noticeable to a person. If the unit suddenly starts making noise during operation, this is a direct sign of the appearance of the first malfunctions in the system.

The fan is out of order, the walls of the heat exchanger are clogged with scale, the components of the apparatus are worn out or the boiler is incorrectly configured - all these reasons lead to the fact that the device squeaks, knocks, buzzes or makes clicks.

Why does a gas boiler make noise when heated?

Exists many reasonscausing alarming noise in the gas boiler. Every failure requires a different approach for its elimination.

Faulty fan located above the burner

The fan provides blowing in the system for removal and removal of smoke, and also cleans the residues of gas combustion products. Common Cause fan failure is operating time.The longer the boiler works, the more parts of the system wear out.

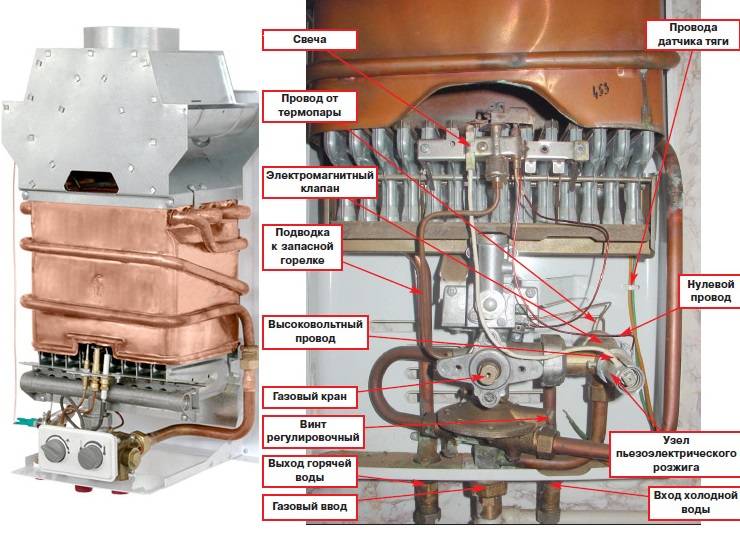

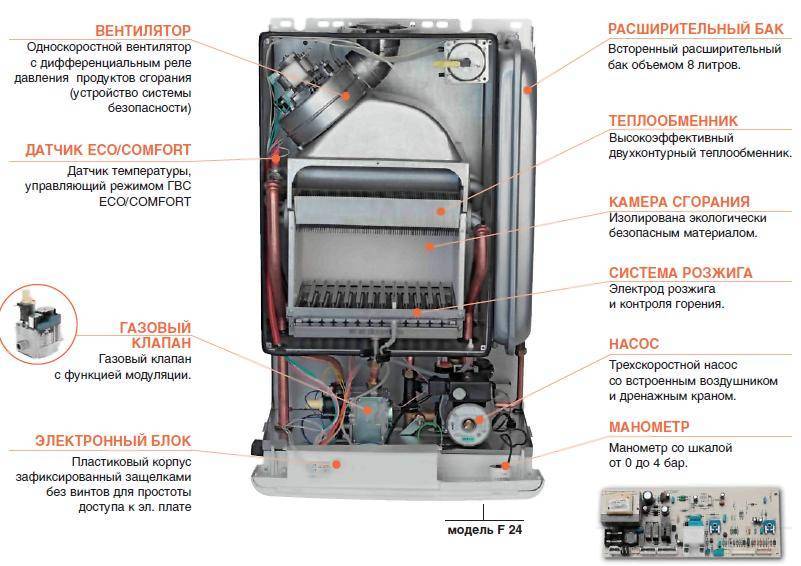

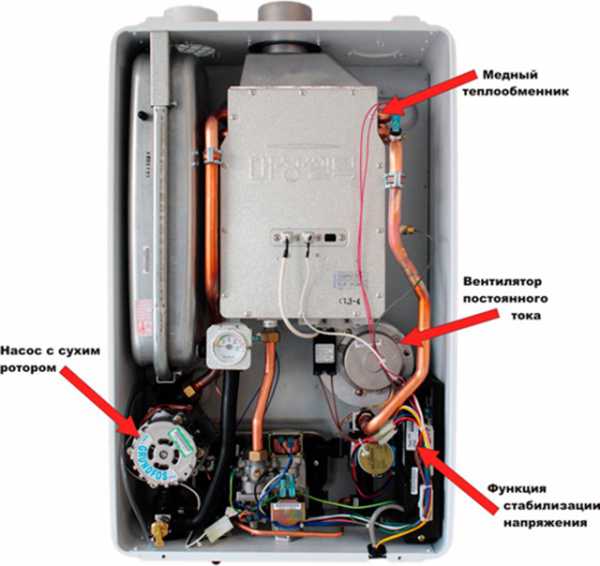

Photo 1. It looks like a fan in a gas boiler. If it breaks, it can cause unpleasant noise coming from the heating device.

Other causes of breakdowns:

- fan usually located above the burner. Constantly being exposed to high temperatures, the bearing grease burns out. This causes rapid wear.

- Fan full of dust and residues from gas processing.

- Manufacturing defects.

Reference.There are characteristic sounds that signal a malfunction of the device. Listen to the work of the boiler. If he publishes clicking sounds at short intervals - The reason is the fan.

For to renovatefan, should be manipulated:

- To start inspect fan and clean it from the inside: the main blades are located on the inside of the housing, it is necessary to free them from accumulated dust and dirt, and then lubricate the bearings.

- If the problem persists and the boiler is still noisy, you can replace valves with ball valves or install a rubber gasket.

- If the previous measures did not help, then you should reinstall cooler. To do this, you need to call the master and replace the worn-out device with a new one.

Scale in the heat exchanger

The heat exchanger is a component of the boiler playing the role of an intermediary between the thermal energy of gas and waterwhich is heated by it. Because of it, scale appears and lime collects both on the walls of the radiator pipes and in the entire heating system.

Photo 2. Heat exchanger from a gas boiler

Water doesn't heat up well

Reason 1. Insufficient speaker power

Perhaps you often need to simultaneously supply water to the kitchen and bathroom, and the column does not have time to warm up such a volume.

Solution:

- Choose a unit with more power.

- Turn on hot water in different rooms alternately.

Reason 2. The column is clogged

Blockage can occur in the burner or heat exchanger due to excess soot. It will be signaled by a red-white color of the flame with normal water pressure.

The solution is to clean the column, preferably with the help of a specialist.

Cause 3. Damaged column water assembly membrane

If at first there is water of an acceptable temperature, but gradually it becomes colder, the flame of the column is blue, and the light is weak, then the problem is in the integrity of the membrane. Cold water is wedged into the hot stream, and the outlet temperature drops.

The solution is to replace the membrane.

Cause 4. Incorrectly installed water inlet-outlet hoses

If you just turned on a new column, and there was still no hot water, it is likely that errors were made during installation.

The solution is to switch the hoses.

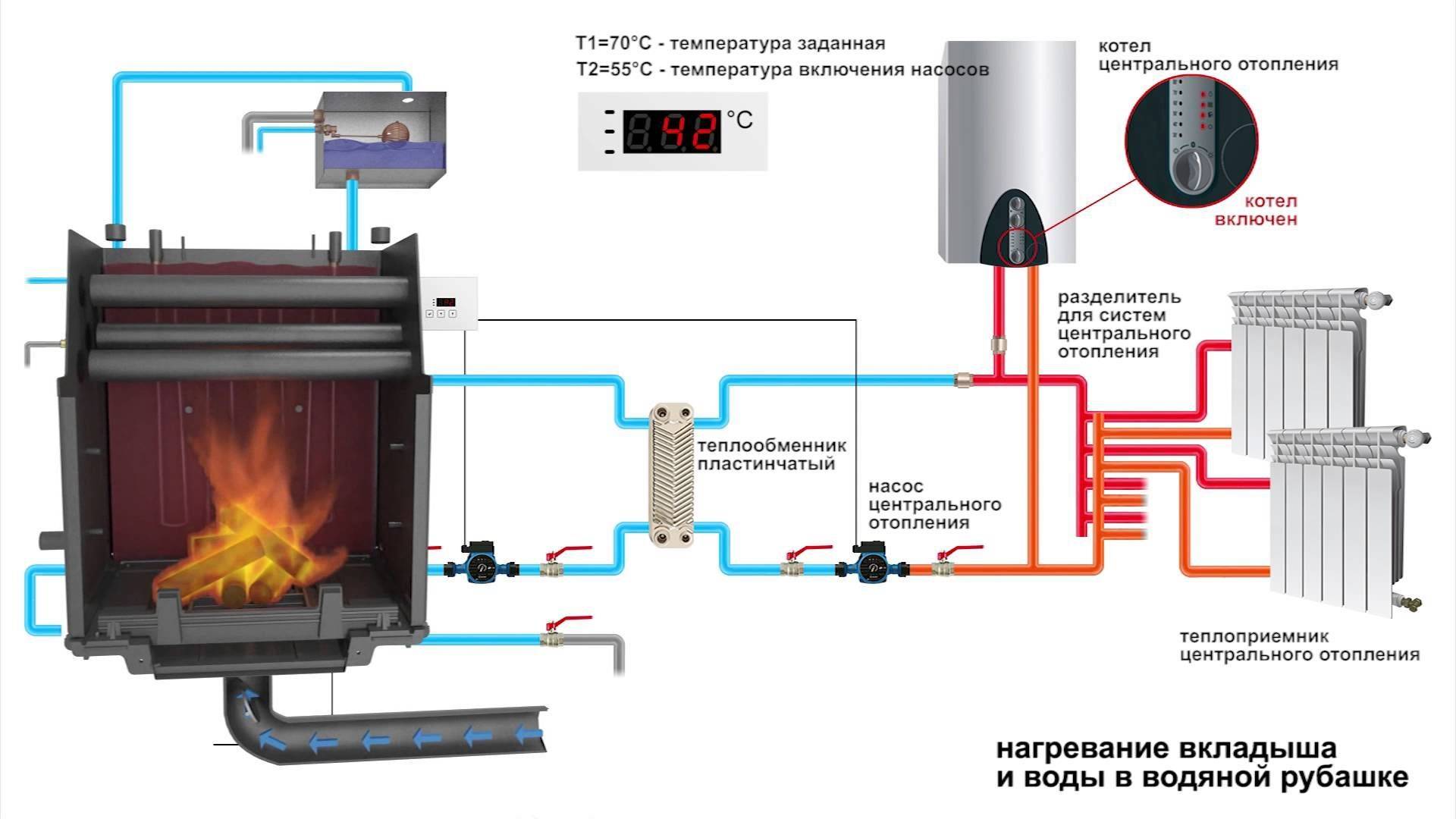

Peculiarities

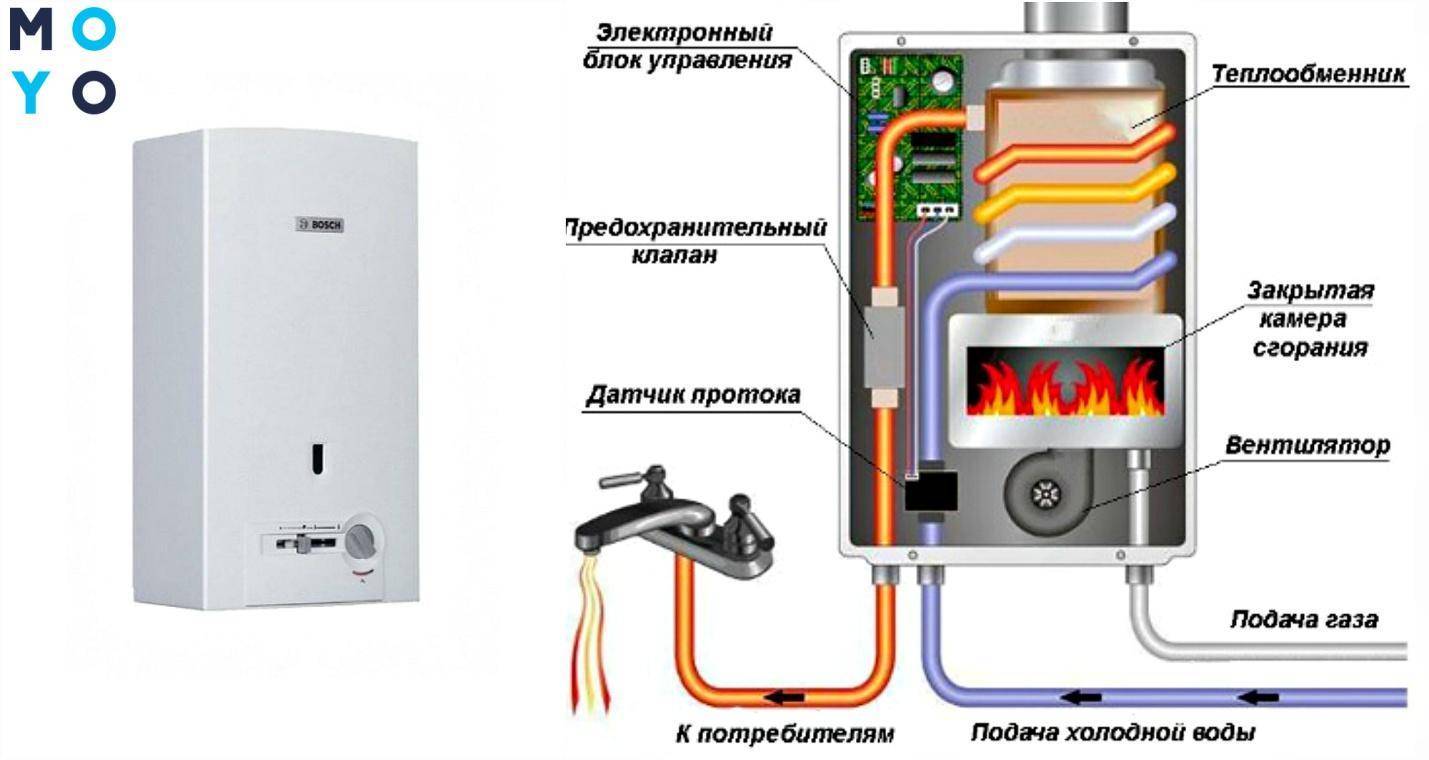

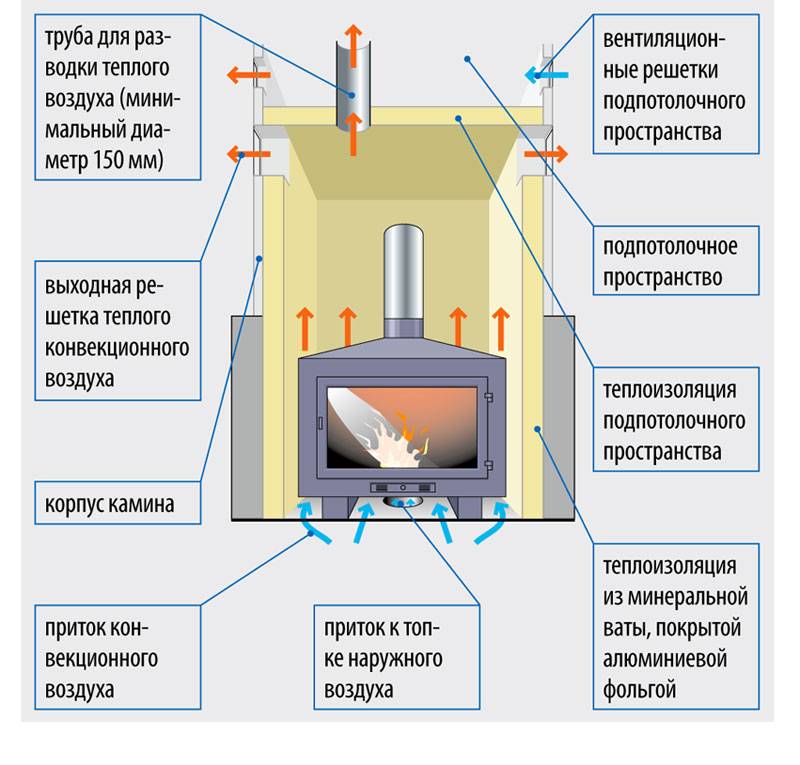

In order to turn on a gas boiler, you need to know its device well, as well as system features.

The first step is to consider the design of a standard AGV.

- Boiler equipped with autonomous gas heater. This is a tank that is located in the casing.

- The pipe that is inside this tank. It burns gas, which heats up the water. The products of combustion that are formed inside go outside through the chimney.

- Heating appliances. For example, hot water flows into the heating circuit. Then it circulates through all pipes. When the water cools, it goes back to warm up. All this is a closed gravity heating system.

- Expansion tank, which is installed from above, above the gas boiler. It allows water, which expands when heated, to rise to the top.

- Pump. It is located behind the gas boiler, which allows you to effectively pump water through the entire system. The speed of movement of the coolant throughout the system can be increased and decreased. All these processes are controlled by automation.

Such heating devices have both disadvantages and advantages.

Among the advantages, the following points can be noted.

- AGVs are safe and reliable in operation, completely independent of electricity, they have the ability to install automatic blocking.

- Consists of different types of water heaters. This includes both floor and wall structures.

- Such units are quite simple, they are easy to repair and maintain.

- They are not very expensive, besides, such models are very economical.

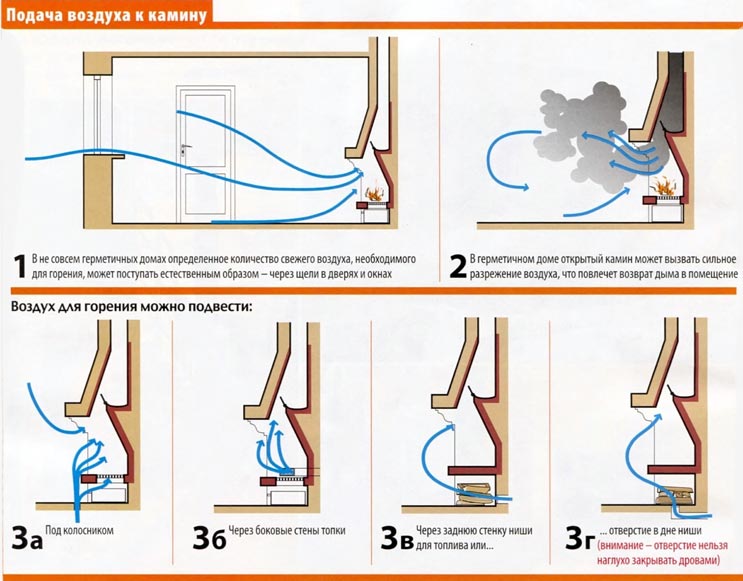

Possible reasons

In the case of incorrectly connected pipes, the water heater protection system itself shuts off the gas supply, which is why it does not turn on. The pipe connection scheme is very simple:

The gas supply pipe is connected on the left, the cold water supply pipe is connected in the center, and the hot water outlet pipe is connected on the right.

It is also necessary to make sure that all gas supply valves are in the open position. It may well be that after installing new equipment, you simply forgot to turn on one of them. All faucets with yellow handles must be open.

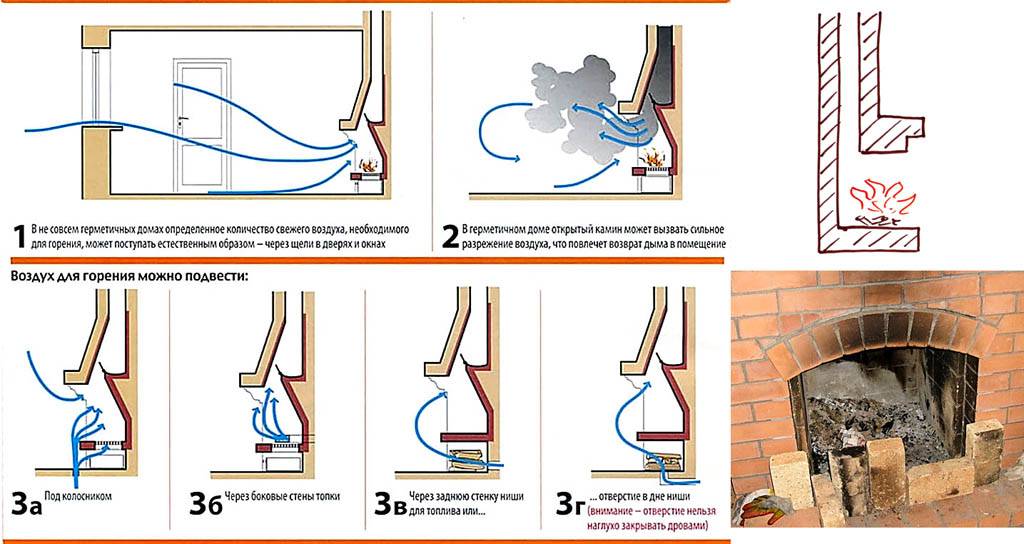

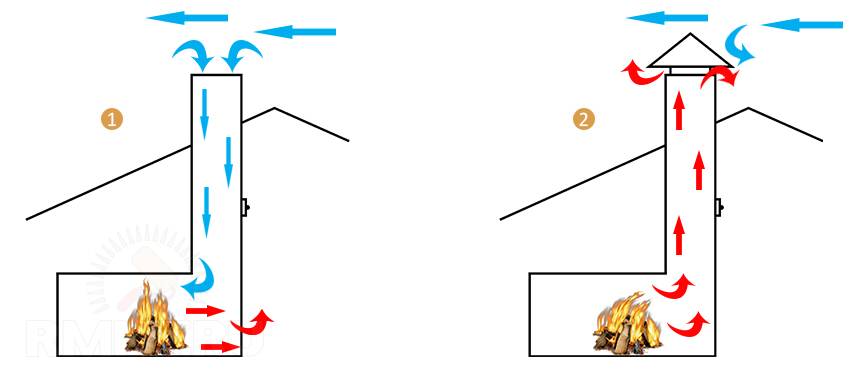

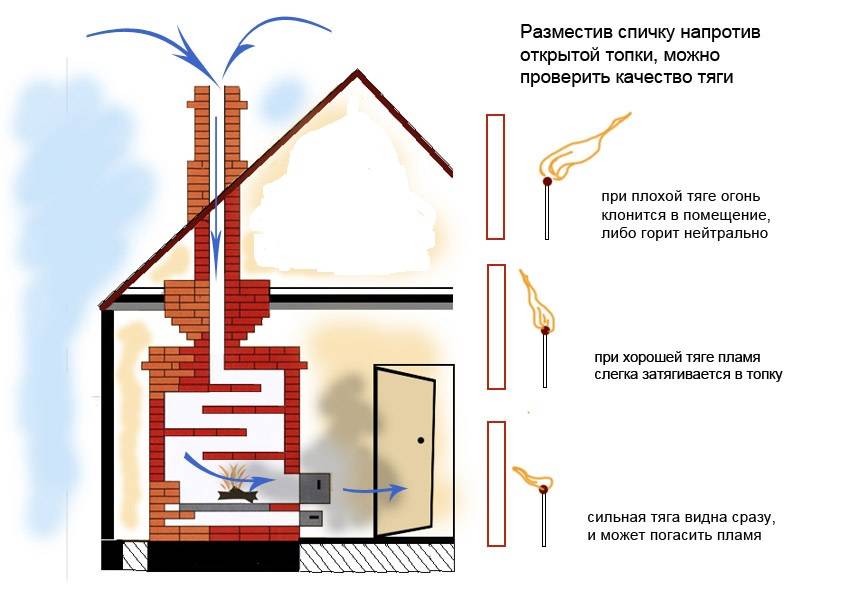

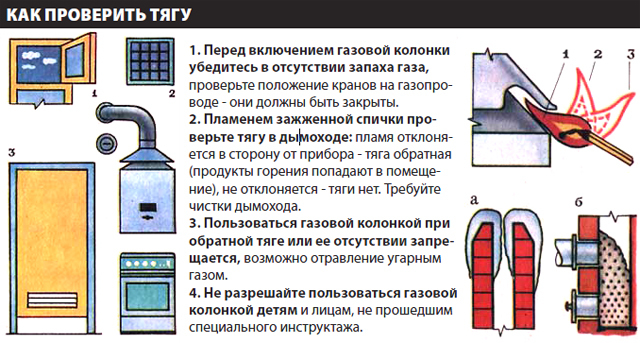

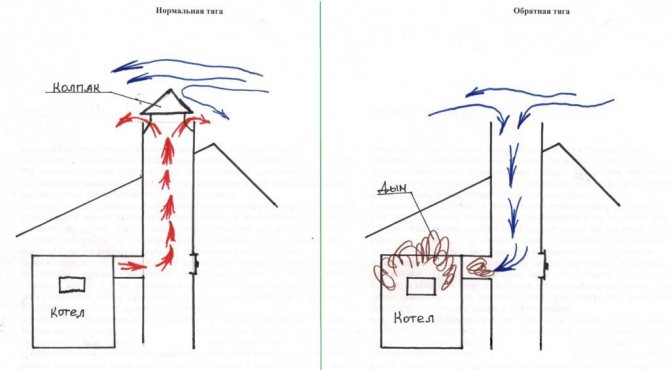

No or poor draft in the chimney.

Accumulated soot, construction debris or other foreign objects that have entered the chimney can prevent the removal of combustion products through the chimney, which creates a danger not only to health, but also to the lives of residents.

A cooker hood that is too powerful can also cause draft failure, making it impossible to turn on. The air flow does not go up through the duct, but is drawn into the room by the hood, creating a draft, due to which the protection is triggered and the column goes out. In this case, it is necessary to reduce the power of the hood or completely remove it.

The presence of draft in the chimney can be easily checked by yourself. To do this, you just need to bring a burning match to the inlet. If its flame rushes in the direction of the hole, then the chimney is working properly. Otherwise, you will have to look for the reason why there is no traction. As you can see, an ordinary match can help eliminate a dangerous malfunction and protect your household from carbon monoxide poisoning.

If there is no draft, make sure that there are no obstacles above the outlet of the ventilation shaft, such as a satellite dish. In this case, the problem is completely solved without seeking help from specialists.

If no external circumstances interfere with the correct operation of the chimney, then, definitely, you are dealing with its pollution. What to do in this situation? Of course, you can try to clean it yourself, but there is a possibility of damage to the branches from neighboring apartments.

Increased relay sensitivity.

The most likely cause of the malfunction is the increased sensitivity of the thermal relay, the protection of which is triggered by overheating, stops the gas supply and the column goes out.

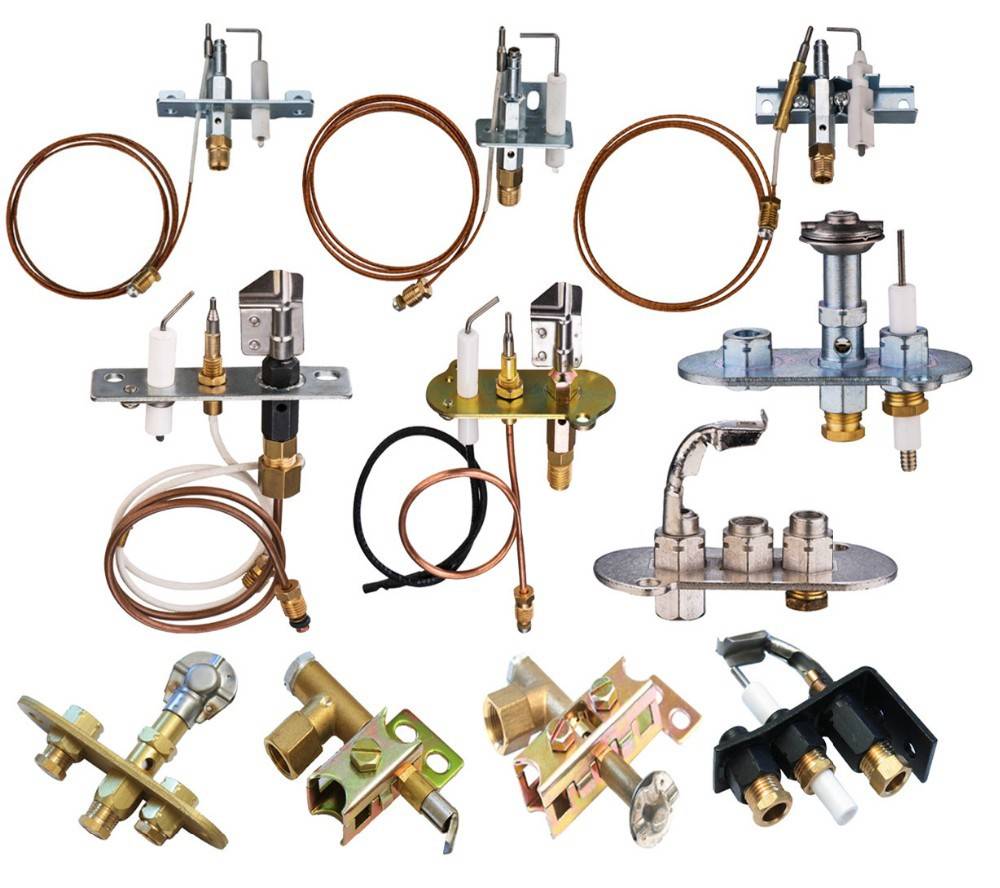

If the stove burner does not ignite

If, after pressing the ignition button, the flame burns, but after a minute of warming up and after releasing the button it goes out, the reason lies in a malfunction of the security system. To begin with, it makes sense to make sure that the flame sensor is installed correctly. It should be in a flame and warm up well. If the fire goes out and the installation is correct, it is likely that the safety device itself has failed, it must be changed.

There are two types of devices in gas stoves:

- the first - the sensor - is a copper flask with a liquid or gas.As the temperature rises, the liquid/gas expands or evaporates. This leads to an increase in pressure, which is transmitted through a thin copper tube to the valve. This is what keeps it open. Here, breakdowns are caused by the loss of tightness of the flask, which is why the burner does not want to ignite. The only way out is to replace the bulb;

- the second is a thermocouple. Such a sensor generates electricity when heated. Through the wires, it is fed to an electromagnet that holds the valve open. Here, breakdowns consist in damage to the wires, which is why the thermocouple is not able to contact the electromagnet. Plus, just like on the hob, as I mentioned above, the thermocouple itself and the electromagnet can burn out.

The main reasons for the unstable operation of the boiler

Even the most modern technology breaks down from time to time. In such a situation, the owner needs to identify the cause of the malfunction and carry out a quality repair. It is impossible if you use cheap spare parts for heating boilers.

Most often, the equipment stops working for the following reasons:

- Violation of the rules of operation. Before using the device, users often do not even read the instructions for use. As a result, this leads to the fact that pretty soon the installation begins to demand attention. Often, the installation of the device is carried out independently, even if there is no experience in this matter. This is done to save money and not pay for the services of a specialist. To avoid malfunctions of the device, the best solution would be to invest in the services of a master who can properly install the boiler.

- Unstable voltage. In the private sector, this is one of the main reasons leading to equipment failure.It can occur due to severe wear of the electrical network. Also, the cause of jumping voltage indicators can also be intensive construction ongoing in adjacent areas, using several welding machines and the use of home-made heaters.

- Insufficient gas purification. When using a boiler operating on such an energy carrier, the contamination of the "blue" fuel can lead to disturbances in the operation of the installation. When the gas is dirty, it contains small solid fractions, as well as water droplets. This provokes a situation of incomplete combustion of fuel. As a result, deposits in the form of soot form in the boiler burner.

- Low water quality. If a boiler-based heating system uses water of poor quality as a heating medium, then over time the efficiency of the installation will decrease. In addition, this has a bad effect on the service life of the heat exchanger and the device as a whole.

Possible malfunctions of the gas fireplace

Over the years of operation, failures may occur in the operation of heating equipment. Common breakdowns:

- When you try to light the fireplace, the igniter immediately goes out. The reason is the wear of the thermocouple, which heats up from the wick and keeps the gas supply valve open.

- The fireplace does not light up at all. The reason is a problem with the contact of the electrical circuit.

- The burner ignites, but works intermittently. The flame is colored yellow. This indicates a clogged main fuel jet.

It is not recommended to clean the jet yourself. All gas fireplaces must be repaired by a professional.If there is no way out, then be sure to turn off the gas, and after performing repair work, check the tightness of the joints with soapy water.

What to do if the gas boiler goes out

When the flame goes out, do not panic. First of all, the gas supply from the main is shut off with a tap at the inlet. The room is ventilated, as the smell of carbon monoxide or pure gas is not always felt by smell.

The next step is to try to determine the cause. The problem of traction is solved independently. Check out the chimney. If necessary, clean it from soot, ice.

For cleaning from burning or replacing the thermocouple, the assembly is removed from the boiler

If the device goes out due to minor malfunctions, you can fix them yourself. To replace the thermocouple, it is necessary to remove the igniter unit from the boiler, unscrew the union nuts with a wrench.

During a power surge in electronic heating devices, fuses often burn

Even a volatile gas appliance can be repaired independently. If it does not turn on, the fuses may have overheated from a power surge. It is necessary to get to the main unit and replace the failed elements.

All other malfunctions of complex components, gas equipment are trusted by specialists. Mistakes made will lead not only to more serious damage, but also life-threatening, since the gas is explosive.

The video tells why the igniter on the gas boiler does not light up or goes out:

Safe operation guarantee

Modern equipment is equipped with several automatic security systems. The gas is supplied under constant pressure. The process of gas supply is controlled by a special sensor. In the event of failures, the gas supply is automatically cut off.

Also in the gas fireplace there are atmospheric sensors that check the condition of the ambient air, evaluating the content of carbon dioxide released during combustion.

When choosing a fireplace, you should pay attention to the fact that European-made equipment is designed for higher pressure than is supplied in domestic systems.

In case of exceeding the norm, the gas supply is stopped. The presence of infrared sensors allows you to monitor the position of the device. If the fireplace tilts or topples over, the fireplace will stop working.

Heating boilers Conord

Rostov plant "Conord" has a rich history and rich experience. Initially, the company was engaged in the repair of road equipment, but in the early 70s it was reoriented to the production of heating equipment.

At the same time, the name "Conord" appeared, which is an abbreviation for the words "Heating Boilers, Non-Standard Equipment, Rostov-on-Don". The newly born plant began its activity with the production of the DON-16 boiler, well-known throughout the USSR.

Heating equipment "Conord"

Today, the Conord plant is a modern enterprise, the technical equipment of which does not remind of its advanced age. Production lines are equipped with the latest high-precision laser machines, imported presses and robots, which allow you to quickly and efficiently produce reliable and affordable devices. The main part of the range is gas water heaters, as well as heating boilers - gas, solid fuel and combined.

The range of boilers is quite diverse. First of all, the products differ in the gas burner device used (for brevity, they are called automation). Three varieties are available.

Automation AGU-T-M (Russia)

- is cheap;

- does not need power supply (a bimetallic plate is used as a temperature sensor);

- does not impose special requirements on operating conditions and is inexpensive to repair (replacing a bimetallic plate - the only "weak link" - costs only 50 rubles).

This type of automation is quite common in our country and its use is not limited to the Conord trademark. You can also see it in such Russian boilers as Mimax and some others.

There is no ignition system in AGU-T-M, so the boiler has to be started with a lighter or a match.

Automation Euro SIT (Italy)

- igniter with safety device (thermocouple);

- sectional burner with Polidoro tubes;

- gas valve SIT;

- temperature sensor;

- thrust sensor.

Unlike AGU-T-M, this automation reacts not only to a gas shutdown, but also to a deterioration in draft in the chimney.

The temperature of the heat carrier is set using a thermostat and maintained automatically by a gas valve.

A piezoelectric spark gap is used to ignite the boiler.

Honeywell (USA)

An economy mode function has been added, to enter which the ignition knob must be turned all the way.

Also, the boilers "Conord" are divided into single-circuit and 2-circuit.

The former are intended for connection only to the heating system, the latter can additionally function as a flowing gas water heater.

Unlike many other boilers with two circuits, "Conord" does not turn off the heating while using hot water. The heat exchanger of the 2nd circuit is heated by the fire tubes. But still, the amount of heat supplied to the heating circuit decreases at this time.

Navien boilers from the largest Korean manufacturer, as a rule, work properly. But still it is a technique, and sometimes it can fail. Consider the types of malfunctions of the Navien boiler, as well as troubleshooting methods.

We will talk about the functions of an inverter for a heating boiler in this topic.

Do you know why double-circuit gas boilers are purchased more often than single-circuit ones? At this link, we will consider the advantages of this type of equipment, as well as the features of installation and selection.

Crashes during abrupt regassing

- The gas injectors are not calibrated correctly.

- Gas filter clogged.

- The gas pressure in the reducer is insufficient.

- Problem with gas lines.

If, when switching to the engine, it starts to "jump", most likely the problem is in a faulty HBO, in this case, switch back to gasoline and continue driving it until the causes of interruptions in the operation of the internal combustion engine are established. Do-it-yourself HBO repair is highly undesirable, unless you are well versed in gas equipment and have all the necessary equipment to carry out repair work. In all other cases, we recommend that you contact the specialists or the service station that installed this HBO.

Thank you for your attention, see you at GBOshnik. Bye!

Clogged filter

When the filtering system becomes clogged, the filling of the system with the coolant decreases, as a result of which a small volume of water inside the boiler warms up too quickly. The boiler switches off and waits for the system to cool down. Then it turns on again, realizing that the return line is still cold.The heat carrier supplied to the heating system through public pipelines is capable of carrying a huge amount of dirt and all kinds of impurities. Therefore, a strainer for water must be installed in front of the circulation pump.

Such a mesh-type device most effectively retains various mechanical contaminants. The lack of full protection causes contaminants to enter the pump and provoke the failure of the rotor. Filters need to be cleaned periodically. For this purpose, the valves that are in front of the filter and behind it are closed, after which the cork above the insert is unscrewed with a key. The filter mesh is washed with running water and carefully installed in its original place.

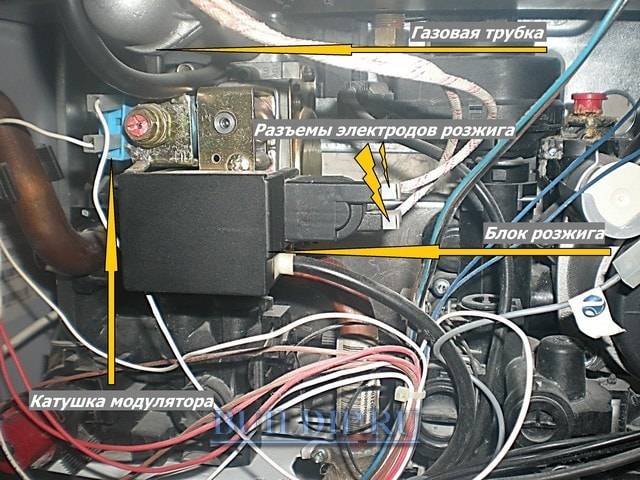

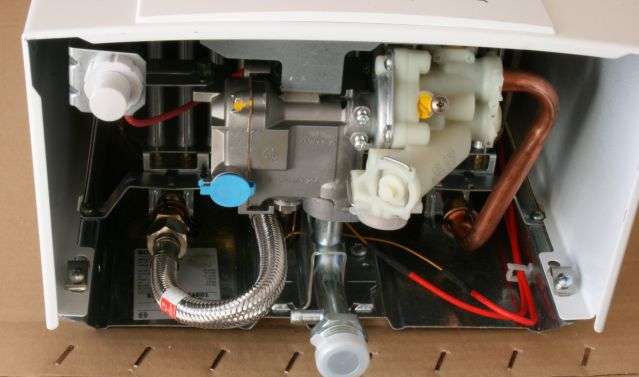

Electrical circuit problems

When the solenoid valve (EMV) makes poor contact with the thermocouple, false indications of no flame are given. Because of this, the fuel supply is blocked.

For this reason, the gas boiler lights up and goes out after a short time or when options are selected.

This is a symptom of a problem in the electrical circuit:

- The thermostat and thermocouple or the vacuum indicator do not contact.

- The thermocouple is outside the flame or does not provide the required voltage.

- The indicated parts and the EMC coil are broken.

These difficulties can be eliminated with your own hands, strictly following this algorithm:

- Consistent check of resistance on indicators and contact devices. The norm is considered to be indicators of 0.3 - 0.5 ohms.

- Cleaning of all oxidized areas with fine sandpaper. Tightening loose contacts.

- Disconnecting the thermocouple from the main unit. Tester connection. Turning on the pilot burner by pressing the release button.

- Voltage measurement.Normalized values: 10 - 50 mV.

If the readings are normal, adjust the position of the thermocouple. In the absence of voltage, the following measures are needed:

- remove the top cover of the main unit,

- thermocouple warms up with the help of a torch,

- pressure is applied to the safety valve, after which it is released.

If the thermocouple does not work correctly, the wire contacts are checked.

If, after pressure and release, the valve is static, it is necessary to remove the complex with contacts and direct a voltage of 220 V to the coil, bypassing the thermostat.

Then the boiler starts up. If problems persist, the EMC coil and thermocouple must be replaced.

Other problems of gas boilers

Almost all wall-mounted boilers are equipped with a panel with a screen or indicators, as well as a control board. If there is no indication, make sure that the boiler is connected to a power source. The connection is checked with a multimeter in the place where the board is connected to the device. When there is no voltage, you can try to connect the device again

Additionally, pay attention to the place where the fuses are located. In standard units, they are located on the board itself or in the connection area. If everything is in order with the fuses, the voltage in the control zones remains at around 220 volts, it is worth checking the control electronics and the gas generator

When the fuses blow, test the operation of the pump, priority valve, fan and instrument wiring for a short circuit. It is recommended to change the blown fuses and check the operation of the boiler again. There are situations when parts burn out again immediately after replacement, then it is worth turning off the high-voltage sections of the boiler in sequence to identify problem areas

If everything is in order with the fuses, the voltage in the control zones remains at around 220 volts, it is worth checking the control electronics and the gas generator. When the fuses blow, test the operation of the pump, priority valve, fan and instrument wiring for a short circuit. It is recommended to change the blown fuses and check the operation of the boiler again. There are situations when parts burn out again immediately after replacement, then it is worth turning off the high-voltage sections of the boiler in sequence to identify problem areas.

It is important to prevent problems in time and call specialists for a preventive check of the device several times a year.

Conclusions and useful video on the topic

How to flush the gas boiler heat exchanger:

Detecting and correcting gas boiler faults:

Gas boilers are high-tech and safe devices. Like all equipment, they have their own expiration date. With timely preventive maintenance, the boiler will last a long time. If the boiler starts to malfunction or work poorly, it is necessary to immediately inspect and diagnose it, to identify the cause of the malfunction.

There are a number of common boiler malfunctions. Sometimes the unit simply refuses to turn on or its operation deteriorates due to a coarse filter that is too dirty. Also, users are faced with the problem of contamination of the heat exchanger and chimney. When carrying out repair work, safety precautions must always be observed.

Do you want to share your own experience in restoring the performance of a gas boiler? Do you have useful information on a topic that is worth sharing with site visitors? Please leave comments in the block form below, post photos, ask questions.