- Technical specifications

- Power connection

- Best Answers

- How electronically controlled circulation pumps should work

- How to disassemble Grundfos

- Actions for prevention

- How to disassemble the heating circulation pump?

- Exploitation

- Actions for prevention

- The device is so hot that the boiler is not needed Why is the pump in the house heating system heating up

- Grundfos UPS pump, selection. selection table.

- Operation of the circulation pump

- Two main characteristics of the circulation pump

- Connecting pipe diameter

- Power

- How to disassemble the circulation pump

- Grundfos Service

- 2 Sololift installation repair

- Circulation pump repair

- How to protect the pump from malfunction?

- Why is the heating pump heating up

- Exploitation

Technical specifications

When deciding how to choose a circulation pump for a heating system, consider its physical and technical characteristics, the main of which are:

- throughput. Measured in cubic meters per hour or liters per minute, it shows the volume of liquid that the electric pump pumps per unit time, the flow rate is greater, the higher the flow rate. The indicator depends on the diameter of the pipeline used and can reach values up to 15 cubic meters / hour.

- Head.The value is measured in meters of water column and indicates the height to which the electric pump can push liquid through a vertically installed pipeline. The maximum head of the circulation pump for varieties with a wet rotor is about 17 meters, although there may be units with higher pressure characteristics, but they are inefficient in operation (they have large overall dimensions and are too expensive).

- Temperature Range. It is clear that in the heating system, pumping equipment must withstand the maximum heating temperature of the coolant with a margin, commonly used modifications are designed for a maximum temperature of up to 110º C, some types can work with liquids with temperatures up to + 130º C.

- Noise level. Basically, for use in individual homes, devices with a low noise level are chosen, pumping equipment with a wet rotor has such features, the noise characteristics of which do not exceed 35 - 40 dB.

- Compound. In residential individual houses, a heating main of a small section up to 1.5 inches is used - in this case, all pumping equipment is installed in the main through threaded connections (designed for pipelines with a diameter of up to 2 inches). The outlet fittings of most household electric pumps are equipped with external threads and are easily integrated into the line using American couplings.

- Dimensional parameters. The installation length is the main indicator of the device when built into the pipeline (for circular types, the standard sizes are 130 and 180 mm.), The diameter of the inlet and outlet pipes is also taken into account (standard 1 and 1.25 inches).

- Protection class.According to the international classification, the standard class of protection for pumping equipment of heating systems is IP44 - this means that the unit is protected from solid mechanical particles with a diameter of more than 1 millimeter (the first digit in the marking) from entering the housing, and its electrical part is completely closed from drops and splashes, flying at any angle.

In the characteristics of many centrifugal electric pumps for water supply systems, such a parameter as particle size is also indicated. For pumping devices of a closed heating system, this factor does not play any role (if the materials of the pipeline and plumbing fittings have not been destroyed) - the liquid in a closed pipeline is always in a consistently clean state.

For this reason (an open liquid-cooled rotor is designed for a clean coolant), wet rotor electric pumps are not used in the hot water supply lines of individual houses, where the intake is from wells or wells.

Fig.7 An example of a symbol for Grundfos electric pumps

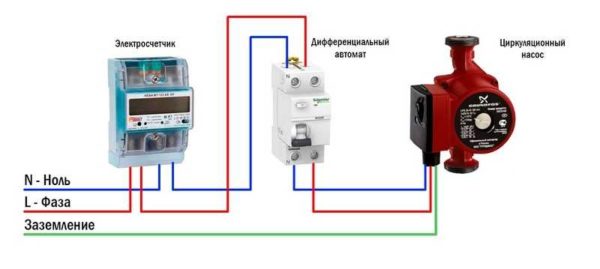

Power connection

Circulation pumps operate from a 220 V network. The connection is standard, a separate power line with a circuit breaker is desirable. Three wires are required for connection - phase, zero and ground.

Electrical connection diagram of the circulation pump

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power cable. It can also be connected via a terminal block or directly with a cable to the terminals.

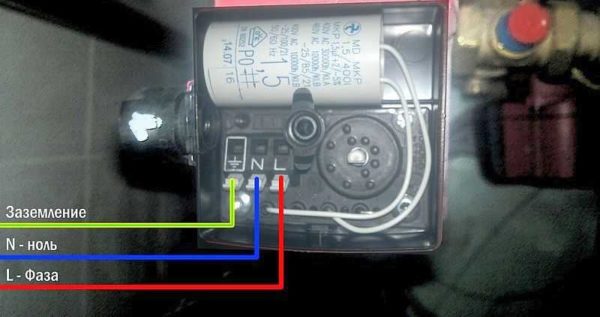

The terminals are located under a plastic cover. We remove it by unscrewing a few bolts, we find three connectors.They are usually signed (pictograms are applied N - neutral wire, L - phase, and "earth" has an international designation), it is difficult to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - put a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pull” electricity to a maximum of 250-300 watts. But when organizing, you need to calculate everything and select the capacity of the batteries. The disadvantage of such a system is the need to ensure that the batteries are not discharged.

How to connect a circulator to electricity through a stabilizer

Hello. My situation is that a 25 x 60 pump stands right after the 6 kW electric boiler, then the line from the 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, the branch goes up, then 4 m, down, rings the house of 50 sq. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bath branch 40 mm up, leaves the bath, enters the 2nd floor of the house 40 sq. m. (there are two cast-iron radiators) and returns to the bath in the return line; the heat did not go to the second floor; the idea to install a second pump in the bath for supply after a branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Best Answers

marat musin:

LOOK AT THE PASSPORT WHAT LIQUID SHOULD BE FILLED

******:

It looks like it works dry or there is no water flow in it.

Vladimir Petrov:

Check the system, it looks like you just have a bad flow of water into a new branch or not at all. Did you clean the filter, maybe that's the problem. Or on a new branch of a pipe of small diameter. And also check you put it correctly there is an arrow in the direction of the water

Viktorij Lashhehova:

❝Actually, what could be the problem? ❞If there were financial disagreements when settling with the contractor, then you need to resolve them and after that everything will work correctly for you.

Rocked Like a Tsap:

It looks like the pump rotor is not spinning. On the end of the pump there is a plug with a slot for a screwdriver. Unscrew this plug and tap on the rotor axis with a metal object (for example, with the same screwdriver) ... I had a similar situation last year and after a few light blows with a screwdriver, the pump started working and is still working.

How electronically controlled circulation pumps should work

Models with electronic type of heating have two types of speed control: manual and automatic. Manual regulation involves setting the power of the device at the desired level. There is no pressure drop adjustment.

Photo 1. Control circuit of the DAB EVOSTA circulation pump with electronic regulation. The choice of an operating mode becomes one button.

In the case of automatic control, the decrease or increase in speed is carried out by the system itself and directly depends on the temperature in the pipeline. The autopilot itself determines the optimal level of performance and, if necessary, reduces power consumption without compromising performance.

Important! Automatic pump speed reduction is only possible after the system has been hydraulically balanced

How to disassemble Grundfos

Before that, it should be disconnected from the power supply and drain the water from the internal cavities and tubes. You should start disassembling the device from the switch box, after which a visual inspection of the internal components is performed. Thus, it is possible to find a burnt or failed part. In a situation where all the components in this part of the apparatus are in good order, disassembly should be continued.

Grundfos deep-well pumps are disassembled as follows:

- The body is firmly clamped in a vise. This is best done using two halves of a steel pipe of the appropriate diameter. This eliminates the possibility of deformation of the body of the device.

- If you cannot unscrew the cover with your hands, the threaded seam should be lubricated with a special liquid. Often, silt and dirt accumulate at the junction of the cover and the body itself, making it difficult to turn the thread.

- After removing the cover, remove the rotor from the working chamber.

When disassembling, the pump motor must be in a vertical position. In this case, leakage of lubricating oil from it can be avoided.

Actions for prevention

In working condition, monitor the level of heating of the engine. If it seems too high for you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in the case of a discrepancy between the force of pressure

Also, to protect pumping equipment from sudden failure, it is recommended to carry out preventive maintenance of the unit, which will include the following actions:

- Regular external inspection of the pump housing and its careful listening in the operating mode.So you can check the performance of the pump and the tightness of the housing.

- Ensure that all external pump fasteners are properly lubricated. This will make it easier to disassemble the pump if repairs are needed.

- It is also worth observing some rules when installing the pump unit for the first time. This will help to avoid repairs in the future:

- So, when you first connect the pump to the heating network, you should turn on the unit only if there is water in the system. Moreover, its actual volume must correspond to that indicated in the technical passport.

- It is also worth checking the pressure of the coolant in a closed circuit here. It must also correspond to that stated in the technical specifications of the unit.

- In working condition, monitor the level of heating of the engine. If it seems too high for you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in case of a mismatch in the pressure force.

- Also, make sure that there is an earth connection between the pump and the terminals when connecting the pump. Here, in the terminal box, check the absence of moisture and the reliability of fixing all wiring.

- A working pump should not give even minimal leaks. Particularly noteworthy are the junctions of the inlet and outlet pipes of the heating system with the pump housing.

How to disassemble the heating circulation pump?

Before dismantling the device, it is necessary to perform a number of preparatory steps.

First of all, we check whether there is a voltage supply to the terminals of the device. The indicator will help in this matter.

Often the repair of the heating pump is preceded by blocking the fan. During use, due to chemical impurities in the coolant, salts are deposited on the fan.Turning the shaft with a screwdriver, the system will work again.

If these actions do not solve the problem, make sure that your circulation unit is generally disassembled. Some models are simply not recoverable. The question of repairing a heating pump with your own hands is presented in detail in the video.

Preparatory steps before dismantling the equipment: de-energize the heater; close the bypass, but do not stop the circulation of water; install a backup pump (in case of lengthy repairs); direct disassembly of the pump.

When purchasing heating equipment, check the possibility of repairing the heating unit at home on your own. Ask the consultant if spare parts for the device are available for sale. Sometimes it's easier to install a new device than to deal with exhausting troubleshooting.

Interesting on the topic:

- Is there any harm from infrared radiation?

- Electric boiler automation

- Using the air conditioner for heating

- Renewable energy for heating: th.

Comments on the article:

gennady. 03/10/2016 at 21:27

well, what if the gasket in the pump itself is not round, but flat with a shoulder along the edge. where should the bead point during assembly? pump oasis 25/2

Alexei. 03/29/2016 at 16:48

Exploitation

At the next start of the pump during the season, be sure to check the tightness of the entire system, the absence of extraneous noise in the operation of the pump and the presence of lubrication at the connecting points of the housing

At the next start of the pump during the season, be sure to check the tightness of the entire system, the absence of extraneous noise in the operation of the pump and the presence of lubrication at the connecting points of the housing.

If you still have to repair the pump, then prepare a bypass.This is a piece of bypass pipe that will close the circuit for the duration of the repair work.

Important: it is not recommended to repair the pump on weight by disconnecting it from one of the nozzles. The heating pipe may break, especially if it is plastic

If you have to open the pump housing, and the bolts are stubborn, then you can use a special tool called "liquid keys". It must be applied to the fasteners and after a while the bolt will succumb to the action of a screwdriver.

And most importantly: do not open the pump yourself if its warranty period has not yet expired. It is better to contact the service center in this case.

In addition, in complex cases, it may be cheaper to buy a new pump than to find accessories or parts for it.

Actions for prevention

In working condition, monitor the level of heating of the engine. If it seems too high for you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in the case of a discrepancy between the force of pressure

Also, to protect pumping equipment from sudden failure, it is recommended to carry out preventive maintenance of the unit, which will include the following actions:

- Regular external inspection of the pump housing and its careful listening in the operating mode. So you can check the performance of the pump and the tightness of the housing.

- Ensure that all external pump fasteners are properly lubricated. This will make it easier to disassemble the pump if repairs are needed.

- It is also worth observing some rules when installing the pump unit for the first time. This will help to avoid repairs in the future:

- So, when you first connect the pump to the heating network, you should turn on the unit only if there is water in the system. Moreover, its actual volume must correspond to that indicated in the technical passport.

- It is also worth checking the pressure of the coolant in a closed circuit here. It must also correspond to that stated in the technical specifications of the unit.

- In working condition, monitor the level of heating of the engine. If it seems too high for you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in case of a mismatch in the pressure force.

- Also, make sure that there is an earth connection between the pump and the terminals when connecting the pump. Here, in the terminal box, check the absence of moisture and the reliability of fixing all wiring.

- A working pump should not give even minimal leaks. Particularly noteworthy are the junctions of the inlet and outlet pipes of the heating system with the pump housing.

The device is so hot that the boiler is not needed Why is the pump in the house heating system heating up

Improper operation of the circulation pump leads to various problems, including overheating.

Due to overheating, pumping equipment may fail, which will lead to a shutdown of the entire heating system. This is especially dangerous in winter.

contact

The purpose of installing such a device is to pump fluids in the heating system and create pressure. These processes help to heat the heating device, but not critical.

The temperature of the circulation unit and pipes should be approximately the same. If the deviation is large, then this is already overheating of the device.

Grundfos UPS pump, selection.selection table.

If we want to choose the right Grundfos circulation pump UPS, for starters, you need to decide on such characteristics as head = H in meters, and flow rate = Q in cubic meters. Then you need to calculate how much heat you need to heat your area.

For this, a boiler with a capacity is initially selected based on the parameters of the house. The calculation is not easy, you will need the size of the area, you will have to take into account the number of radiators in the system, take into account the insulation of the house, decide on the installation of windows, ceiling height, and so on and so forth. We advise that it is better to leave the calculation at the mercy of specialists and experienced installers.

As a result of the calculations, we will obtain the desired values, with the help of which, according to the graphs of the hydraulic curves, we select the pump. But for simplicity, you can use the pump selection table depending on the area of \u200b\u200bthe house. In addition, as we know, the Grundfos UPS pump has three speeds, with which we will adjust the pump to our system.

| Heated area (m2) | Productivity (m3/hour) | Brands Grundfos UPS |

| 80 – 240 | 0.5 to 2.5 | UPS 25 - 40 |

| 100 – 265 | 0.5 to 2.5 | UPS 32 - 40 |

| 140 – 270 | 0.5 to 2.7 | UPS 25 - 60 |

| 165 – 310 | 0.5 to 2.7 | UPS 32 - 60 |

As can be seen from the table below, the owner two-storey house with area 100-265 m2, a Grundfos UPS 32/40 or UPS 32/60 heating pump is recommended in the presence of water heated floors. The decision to consult with your heating system installers is welcome, they know your system more accurately and, based on experience, will suggest the best grundfos pump size. You can also choose a UPS pump based on the known boiler power according to the table below:

The rule does not work in this matter - the more powerful the better, since an oversized pump in terms of hydraulic indicators, firstly, consumes more electricity, which leads to low energy efficiency. Secondly, the piping system can make noise, causing significant discomfort to your household. On the video, the legendary pump Grundfos UPS 25-40 180.

Operation of the circulation pump

Some rules must be observed during the operation of the pump, including such as:

- The pump should not work if there is no water in the heating system.

- The pump must not be allowed to run at zero flow.

- A certain range of allowable flow rates must be respected during pump operation. The pump may fail if the water supply is too low or too high.

- If the pump is idle for a rather long period of time, then for its prevention it will be necessary to turn it on at least once a month for 10-15 minutes. If this is not done, then some components of the pump may oxidize.

- For normal operation of the pump, the temperature of the coolant in the heating system should not be higher than +65 degrees. This is necessary in order to prevent hard salts from precipitating.

Temperature at the inlet and outlet of the circulation pump

- First, you need to make sure that there are no various vibrations or the heating pump is noisy.

- Check how the circulation pump works, based on its pressure-flow characteristics.

- Check if there is no excessive heating of the electric pump motor.

- Check visually if there is grounding on the pump housing.

- Check if there are no leaks in the places where the pump is attached to the pipeline.If a small leak is observed, then it will be necessary to replace the gaskets or tighten the connecting components.

- Check how well the electrical wires are connected to each other in the terminal block.

Two main characteristics of the circulation pump

With a long list of technical specifications for heat pumps, there are two main ones. This is the diameter of the connection pipes and the power of the "accelerator". These two numbers are considered decisive and are indicated in the name.

Connecting pipe diameter

The most important parameter for the installation of the pump, especially with already installed heating systems. This is a numerical value, indicated in millimeters, and showing the diameter of the heating pipes that can be connected to the inlet / outlet pipes.

Please note that taps with threaded threads are made for connection on the body branch pipes

Power

Power in heating systems is the ability to raise water to a certain height or pump head.

In the marking of Grundfos pumps, the power is indicated in meters multiplied by 10 or atmospheres multiplied by 100. That is, Grundfos with the ability to raise water by 5 meters (with a head of 5 meters) will receive the number 50 or 0.5 atm in the marking. (atmospheres).

Example: The circulation pump Wilo Star 30/2, means that the diameter of the connection pipes is 30 mm, the head is 2 meters.

In the Wilo marking, the power is indicated, simply in meters.

Example: Grundfos UPS 25 40 (130 mm), means that the diameter of the connection pipes is 25 mm (1/2 inch), the head is 4 meters. 130 is the installation length of the installation.

How to disassemble the circulation pump

To repair the centrifugal pump installed in the heating circuit, it will be necessary to dismantle it, adhering to the following scheme:

- The electrical part of the apparatus is disconnected from the voltage, for this, the case is removed from the power supply unit.

- Close the valves on the supply and return pipelines or before and after the device, if possible.

- The network water is drained so that when the housing is removed from the pipeline, it is not flooded with water.

- In order to unscrew the case, use a screwdriver - hex. If the bolts boil during operation, they are treated with a special WD tool and after 20 minutes the dismantling operation is repeated

- After disassembly is completed, the cover is removed, under which the rotor with the impeller is located. Usually, it is attached with stoppers or bolts. After that, the passage to the internal structural units of the unit will be opened.

- By carefully inspecting the technical condition of the pump, it will be possible to identify defects and eliminate them.

Grundfos Service

To avoid the above problems, you should follow the rules for operating pumping equipment, as well as carry out its timely maintenance. Installation of Grundfos deep equipment and trial operation is best left to professionals. Before starting pumping stations, always make sure that there is water in them, in order to avoid dry start.

If you use the pump only in the summer season, then the rest of the time it should still be turned on, at least for half an hour every 3-4 weeks. This will avoid problems with the oxidation of its internal parts.

For Grundfos drainage pumps, special attention should be paid to the patency of pipes and nozzles.Since such equipment operates in particularly difficult conditions, entailing a risk of clogging, it is necessary to clean it from time to time with a strong jet of water.

Grundfos equipment (Grundfos) due to its reliability, performance and ease of operation are widely used in all industries.

They are used in the field of housing and communal services in the construction of centralized heating mains, water supply, sewage drainage, servicing agricultural and forestry enterprises, as well as in equipping industrial complexes.

2 Sololift installation repair

A feature of the use of Sololift pumps is that they are installed in places that are below the main sewer line. Therefore, the pumping station pumps wastewater under pressure forcibly. But, despite such serious tasks set for Sololifts, there is nothing complicated in installing a sololift and you can do it yourself. And the correct installation of the device is the key to long-term operation and excludes the quick repair of the Sololift. Proper installation of the installation includes the following points:

- the device is installed exclusively on anti-vibration material;

- only those elements that come with the model are used as fasteners;

- the minimum distance to walls and other plumbing fixtures must be at least 10 mm;

- when connected to a sink, a filter must be installed on the inlet pipe, and in the case of use on other plumbing, a check valve is required.

As for the repair of the Sololift pump, there are many service options, depending on the specific problem. Most often, the following malfunctions occur:

- The engine does not start when the water reaches the start level. If there is such a problem, first of all, it is necessary to check the presence of power in the network and the correct connection. The fuse may also blow. The reason for this is damage to the cable or motor. In this case, the main components are inspected, after which the fuse is replaced. If none of the above helped, you need to check the operation of the pressure switch.

- The motor is noisy, but does not turn the impeller. There can be two reasons for this: the wheel is too tight, or the engine is faulty. In the first case, the repair of the Sololift pump consists in restoring the mobility of the working body. The second option can be fixed exclusively in the service center. There are such centers in Moscow, Sergiev Posad, Orel, Tula, Kaluga, and also in other regions of the country.

- The engine does not turn off by itself. The reason is a leak in the pipeline line, a non-functioning check valve or a faulty pressure switch. The corresponding part needs to be replaced.

- Slow pumping out of fluid when all nodes are operational. First of all, it is necessary to check the tightness of the housing and the absence of leaks on it, if necessary, replace it. Clearing a blockage in the system can also help.

Circulation pump repair

What can be a malfunction of the circulation pump?

Circulation pumps are often installed in private houses and country cottages. With all the variety of models on the market today, the principles of operation of devices are no different. Any malfunction of the heating pump leads to the fact that the entire system stops. There is little pleasant in what happened, because without heat the house will not be comfortable and cozy.

It is important to immediately seek the help of a specialist in a service center, or, if you have the tools and appropriate skills, repair the heating circulation pump with your own hands. In this article, we will give tips on preventing breakdowns, as well as consider the most common damage to heating systems.

How to protect the pump from malfunction?

It is advisable to always maintain the required volume of heat-carrying water in the pipes. Otherwise, the pump will work for wear and tear, both in case of excess water volume, and in case of its shortage.

In order to insure and avoid breakage of rather expensive pumping equipment, it is recommended to follow some basic rules for the operation of equipment of this type:

- Do not turn on the pump without the presence of a coolant in a closed circuit. That is, if there is no water in the pipes of the heating system, then you should not “torment” the pump. So you will provoke an early breakdown of equipment.

- It is advisable to always maintain the required volume of heat-carrying water in the pipes. Otherwise, the pump will work for wear and tear, both in case of excess water volume, and in case of its shortage. For example, if the pump can distill the amount of water from 5 to 105 liters, then the need to work with volumes from 3 to 103 liters will already wear out the working units of the unit, which will lead to its failure.

- In the event of a long downtime of the pump (during the off-season of heating), it is necessary to run the unit once a month in the operating position for at least 15 minutes. This will avoid oxidation of all movable elements of the pump unit.

- Try not to exceed the coolant temperature above 65 degrees Celsius.A higher rate will negatively affect the working and movable parts of the structure.

- At the same time, check the pump housing for leaks more often. If even the slightest leak is observed somewhere, you should immediately identify the malfunction and carry out maintenance of the pump.

Why is the heating pump heating up

When installing a closed-type heating system, a circulation pump is installed on the pipeline. The main task of this device is considered to be the pumping of coolant, water or antifreeze, which ensures quick and uniform heating of all living quarters of a summer house, cottage or any other country house. Thanks to the pump and the automation of the boiler, the user can set the optimal temperature indicators in his home, but sometimes such a device overheats and cannot perform the assigned tasks with high quality. In our article, we will get acquainted with the causes of this phenomenon and methods for solving such a problem.

Exploitation

At the next start of the pump during the season, be sure to check the tightness of the entire system, the absence of extraneous noise in the operation of the pump and the presence of lubrication at the connecting points of the housing

At the next start of the pump during the season, be sure to check the tightness of the entire system, the absence of extraneous noise in the operation of the pump and the presence of lubrication at the connecting points of the housing.

If you still have to repair the pump, then prepare a bypass. This is a piece of bypass pipe that will close the circuit for the duration of the repair work.

Important: it is not recommended to repair the pump on weight by disconnecting it from one of the nozzles. The heating pipe may break, especially if it is plastic.If you have to open the pump housing, and the bolts are stubborn, then you can use a special tool called "liquid keys"

It must be applied to the fasteners and after a while the bolt will succumb to the action of a screwdriver

If you have to open the pump housing, and the bolts are stubborn, then you can use a special tool called "liquid keys". It must be applied to the fasteners and after a while the bolt will succumb to the action of a screwdriver.

And most importantly: do not open the pump yourself if its warranty period has not yet expired. It is better to contact the service center in this case. In addition, in difficult cases, it may be cheaper to buy a new pump than to find accessories or parts for it.

In addition, in complex cases, it may be cheaper to buy a new pump than to find accessories or parts for it.