- Optimal time to drill

- Summer-autumn period

- Drilling in winter

- Choosing a well

- Production of drilling tools

- Option #1 - Spiral and Spoon Drill

- Option # 2 - bailer and glass

- Drilling step by step

- Let's start drilling

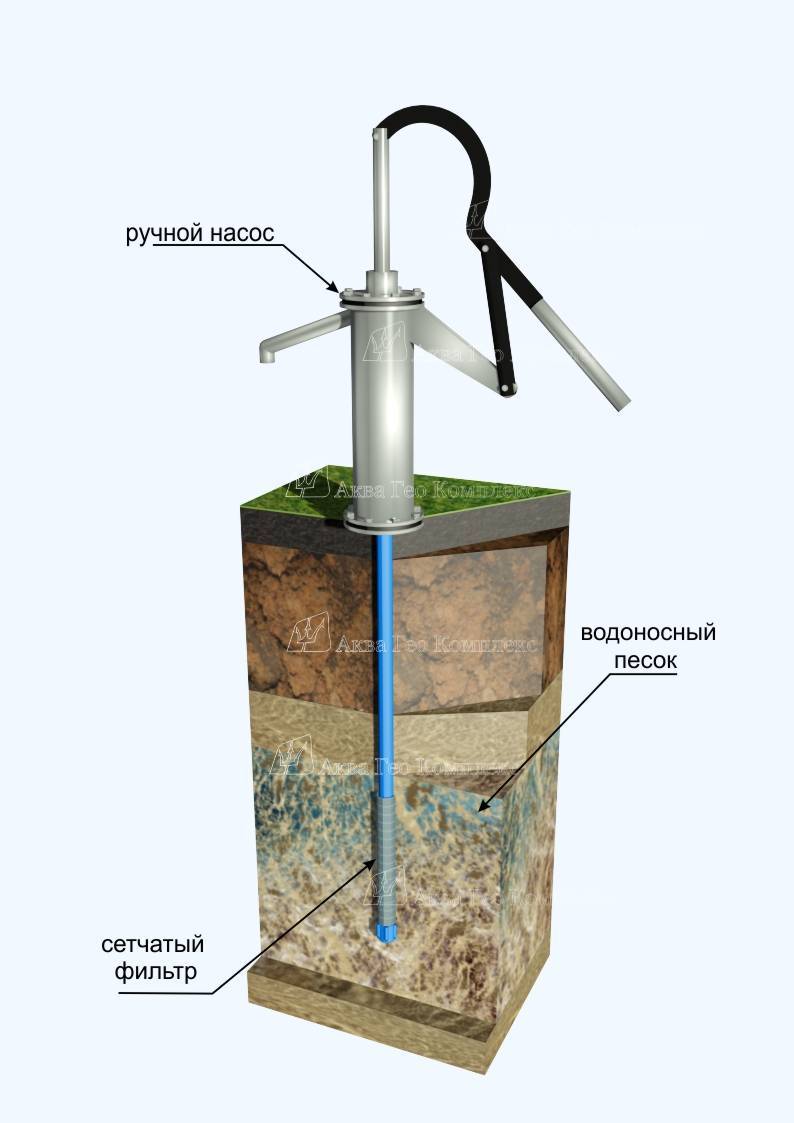

- Abyssinian

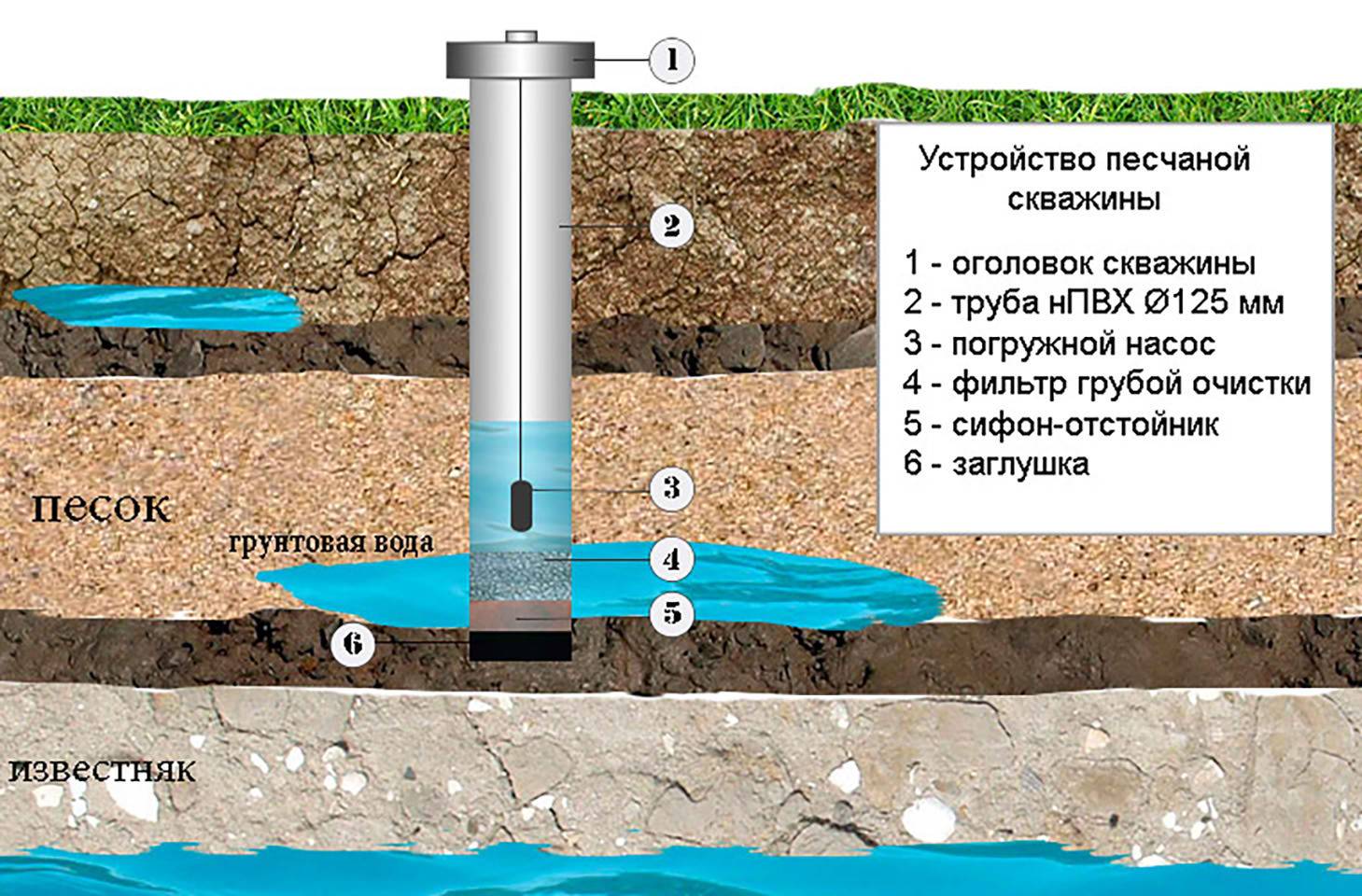

- Well on the sand

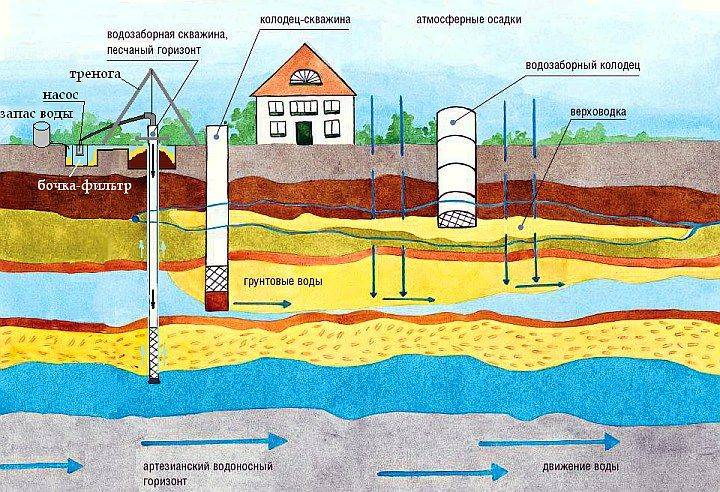

- Artesian

- Methods for self-drilling

- Shock rope

- Auger

- Rotary

- Puncture

- How to drill a well on sand: instructions

- What is a sand well

- Equipment for an autonomous water source

- Sand well for water

- Manual well drilling

- rotary method

- screw method

- The nuances of deepening in floating bases

Optimal time to drill

Having resolved the question of where it is best to drill an aquifer, it is necessary to decide when to drill. Experts believe that each season has its pros and cons for drilling. They agree on one thing: can't drill a well during the spring period.

There are several reasons for this:

- the presence of a flood raises the level of groundwater;

- it is impossible to reliably determine the location and depth of the aquifer;

- spring thaw will make it difficult for drilling equipment to pass.

In most regions of Russia, well drilling is impossible from March to May, in the northern regions from April to mid-June. In arid regions, it is also not recommended to carry out drilling work in the spring, even in the absence of floods, in this case, groundwater is still unstable, their level is noticeably increased.

Drilling a well in the spring is possible if exploratory drilling was carried out in the summer-autumn period and the depth of the aquifer is known exactly

Summer-autumn period

The best time for a well device is July-September. At this time, the level of perched water is at a minimum, which means that it is possible to accurately determine the optimal horizon for a future well.

Also, the advantages of drilling in the summer-autumn period include:

- dryness and stability of the soil;

- the possibility of access to special equipment;

- comfortable temperature for drilling operations.

Many site owners prefer to start work on arranging wells in the fall after harvesting, so that special equipment does not damage the plantings, and when flushing the well, crops are not flooded with pollution.

When planning the construction of a well for the period August-early September, please note that at this time the drilling companies are busy, so it is necessary to agree on a date in advance.

Drilling in winter

Winter is an ideal time for drilling artesian and sand wells to groundwater. In this case, the risk of misidentification of the aquifer is minimized, since perch water does not interfere with the determination of the level of groundwater.

Modern technology easily copes with frozen soil, while at the same time harming the relief of your site to a minimum.

Flushing the well must be done, it is performed not only for the sake of pumping muddy water. The soil collapsed during drilling can clog the pump and instantly disable it. Therefore, inexpensive vibration units such as the Brook are chosen for pumping, which it will not be a pity to part with immediately.

An important factor: in winter, the number of clients from drilling firms decreases, which means that the cost of drilling operations decreases.

In winter, special equipment does not spoil the landscape of the site, does not harm lawns and green spaces, the soil remaining after drilling will shrink and work on its cleaning in the spring will be minimized

Choosing a well

Before deciding how to drill a well at home, you need to understand that water is different and, accordingly, different wells. The lower the water level, the higher the costs.

But at the same time, the deeper the water is, the more it is of high quality and suitable for drinking. Let's look at the types of wells and after that you will determine what is right for you and how to drill a well yourself.

Choosing a well

So:

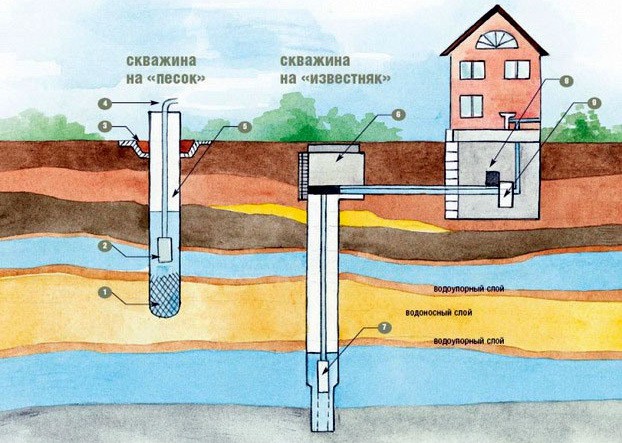

- Well on the sand filter. This design consists of a pipe of the order of 100 mm and is immersed in the ground to a depth of up to 30 meters. From the soil side, a metal mesh is attached to the pipe, which serves as a filter. The service life of the well reaches 15 years.

Only in such a design there may not be high-quality water, it is simply not far from the ground level and untreated sewage can penetrate there; - Artesian well without filter. The depth of which can reach 100 meters, and the water here will be of better quality. The service life reaches up to 100 years.

Now let's move on to the question of how to drill a well in a well.

Production of drilling tools

As mentioned earlier, drilling tools can be made on your own, borrowed from friends, or purchased commercially.

Sometimes a drilling rig can be rented. However, the goal of self-drilling is usually to keep costs as low as possible. The easiest way to drill cheaply is to make tools from scrap materials.

The diagram shows the arrangement of various drilling tools. With the help of a chisel, especially hard soil can be loosened, and then it is removed with a drill, bailer or other device.

Option #1 - Spiral and Spoon Drill

Manual drilling can be done with a spiral or spoon drill. For the manufacture of a spiral model, a thick pointed rod is taken, to which knives are welded. They can be made from a steel disk cut in half. The edge of the disk is sharpened, and then the knives are welded to the base at a distance of about 200 mm from its edge.

A do-it-yourself drill for auger drilling can be of different designs. Its obligatory elements are knives with pointed edges and a chisel installed at the bottom.

Knives should be located at an angle to the horizontal. An angle of about 20 degrees is considered optimal. Both knives are placed opposite each other. Of course, the diameter of the drill should not exceed the diameter of the casing. Usually a disc with a diameter of about 100 mm is suitable. The knives of the finished drill should be sharpened sharply, this will facilitate and speed up drilling.

Another version of the spiral drill can be made from a rod and a strip of tool steel. The width of the strip can vary between 100-150 mm.

Steel should be heated and rolled into a spiral, hardened, and then welded to the base. In this case, the distance between the turns of the spiral should be equal to the width of the strip from which it is made. The edge of the spiral is carefully sharpened. It is worth noting that it is not easy to make such a drill at home.

A spiral auger for drilling can be made from a pipe and a steel strip, however, it is not always easy to roll the tape into a spiral, weld and harden the tool at home

To make a spoon drill, you need a metal cylinder. In conditions of self-manufacturing, it is easiest to use a pipe of a suitable diameter, for example, a 108 mm steel pipe.

The length of the product should be about 70 cm, it will be difficult to work with a longer device. On this case, a long and narrow slot should be made, vertical or spiral.

A homemade spoon drill is easiest to make from a piece of pipe of a suitable diameter. The lower edge is folded and sharpened, and a hole is made along the body for cleaning the drill

Two spoon-shaped knives are mounted in the lower part of the body, the cutting edge of which is sharpened. As a result, the soil is destroyed by both horizontal and vertical edges of the drill.

The loosened rock enters the cavity of the drill. Then it is taken out and cleaned through the slot. In addition to knives, a drill is welded along the axis of the device in the lower part of the drill. The diameter of the hole made by such a drill will be slightly larger than the device itself.

Option # 2 - bailer and glass

To make a bailer, it is also easiest to take a metal pipe of a suitable diameter.The wall thickness of the pipe can reach 10 mm, and the length is usually 2-3 meters. This makes the tool heavy enough so that when it hits the ground, it is effectively loosened.

A shoe with a petal valve is attached to the bottom of the bailer. The valve looks like a round plate tightly closing the lower section of the pipe and pressed by a sufficiently powerful spring.

However, a too tight spring is not needed here, otherwise the soil simply will not fall into the bailer. When the bailer is pulled out, the valve will be pressed not only by the spring, but also by the soil collected inside.

The lower edge of the bailer is sharpened inwards. Sometimes sharp pieces of reinforcement or sharpened pieces of triangular metal are welded at the edge.

A protective mesh is made from a thick wire on top and a handle is welded to which a metal cable is attached. A glass is also made in a similar way, only a valve is not needed here, and a slot should be made in the body to clean the device.

Drilling step by step

The above types of wells, in addition to artesian and lime models, involve drilling using various technologies. It could be:

- auger drilling using an appropriate drill;

- core drilling with an annular drill;

- percussion drilling. In this case, drill bits are used that are driven into the soil without removing the soil. The earth is compacted in different directions from the axis of the bit. The tool is hammered with a tripod with a winch;

- rotary percussion drilling. During operation, the soil is washed out with water. The method involves a lot of labor;

- rotary drilling. Mobile drilling rigs are used. They can be small and have a movable hydraulic rotator.

Let's start drilling

If we talk about step-by-step instructions for drilling a water well with your own hands from A to Z, then it looks like this:

- A pit is digging one and a half meters long and the same width. Depth - from 100 to 200 cm. This is necessary to prevent the collapse of the upper layers of the soil. The walls are lined with plywood sheets in the manner of formwork. The bottom is covered with boards. A wooden shield is mounted on top of the pit, on which you can safely walk without fear that the walls of the pit will collapse.

- Technological holes are made in the bottom and cover for the production of work. A drill rod attached to the drilling rig is threaded through them.

- The drill is driven by a special engine with a gearbox or manually. If we are talking about a puncture, a pin is installed on the pin, which is hit with a sledgehammer.

- If the technology involves the parallel installation of casing pipes, work is also carried out through technological holes in wooden shields.

- The soil removed from the well is selected manually. If it is slurry, you need to install a mud pump that will pump it directly from the casing.

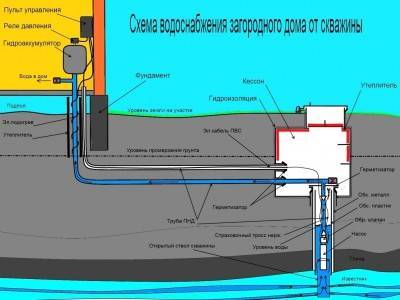

- After drilling is completed and the casing is installed, it is necessary to mount the electrical equipment and start the pump, which should work until the water from the well becomes absolutely clean.

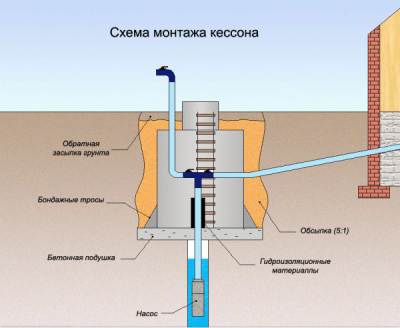

After all stages are completed, a caisson is mounted instead of a protective box. A cap, pumping and filtration equipment is installed, a pipeline is connected. The system is being tested. The equipment depends on the type of well.

Abyssinian

The upper water layers are suitable for irrigation, but are not used for domestic use. This is due to pollution that penetrates the soil with floods.Such a well has a depth of less than 10 meters. Water must pass through a multi-stage filtration system. Only in this case, the liquid turns from technical into drinking.

A hand pump can be used as pumping equipment. It is allowed to use any type of electrical equipment (submersible, surface). The pumping station does not have to have a large capacity, and this makes the well the most inexpensive. It is advisable to equip a storage tank into which the daily supply of water is pumped.

Well on the sand

At a depth of 10-40 meters, there are layers in which water undergoes natural filtration. Passing through the sand, it is cleared of part of the impurities. It does not contain large inclusions, clay and a number of chemical compounds. For domestic purposes and for irrigation of crops, such water can be used, but additional filtration is required to make it suitable for food use.

The best option for electrical equipment is a pump. Surface pumping stations are also used. If the depth is more than 10 meters, the use of an ejector is allowed, which will increase the performance of the pump, accelerating the flow of produced water in the pipeline.

Artesian

These are wells with absolutely pure water, enriched by nature in limestone cut ground plates. Depth may vary from 100 to 350 meters depending on the location of the site, the geological features of the soil and the terrain. Water does not require filtration. The threat is contaminants that can get inside the casing from the outside. The minerals contained in the solution are beneficial to humans.

It is necessary to install a submersible pump for the well.It can be a centrifugal or vibration type device. The latter is preferable, since it breaks less often, and its performance is greater. The main thing is that the pump has a coarse pump that prevents solid particles from entering the working chamber.

Methods for self-drilling

To drill a well for water in a country house, a personal plot, a rural courtyard, it must be taken into account that there are three ranges of depths at which aquifers occur:

- Abyssinian well. Before the water will have to drill from one and a half to 10 meters.

- On the sand. To make a well of this type, you need to pierce the soil to a mark in the range from 12 to 50 m.

- Artesian source. 100-350 meters. The deepest well, but with the purest drinking water.

In this case, each time a separate type of drilling rig is used. The determining factor is the chosen method of drilling operations.

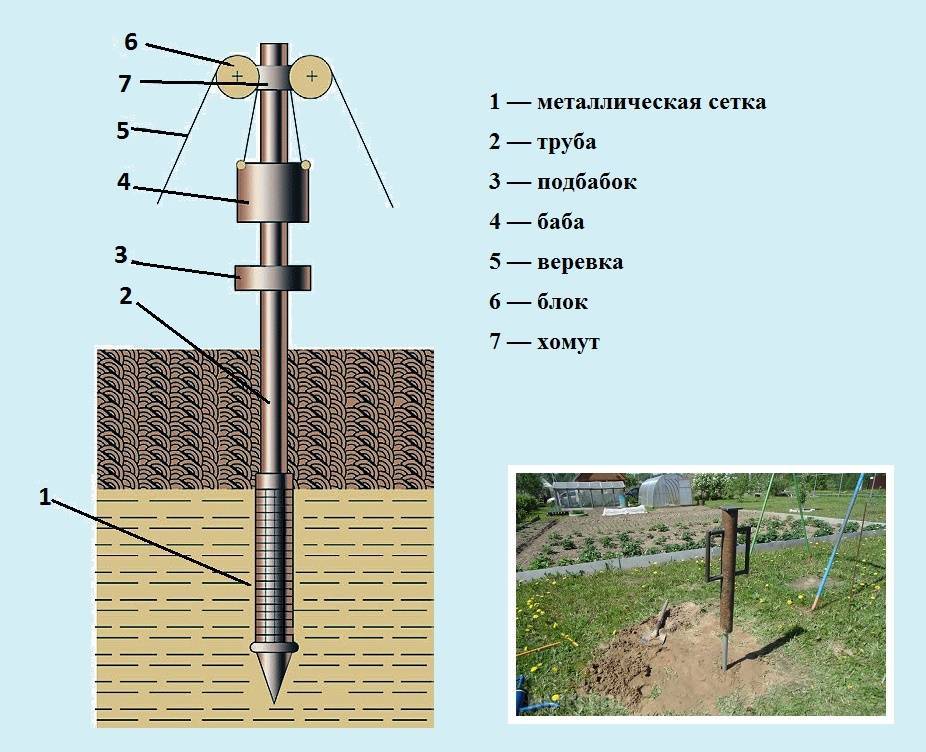

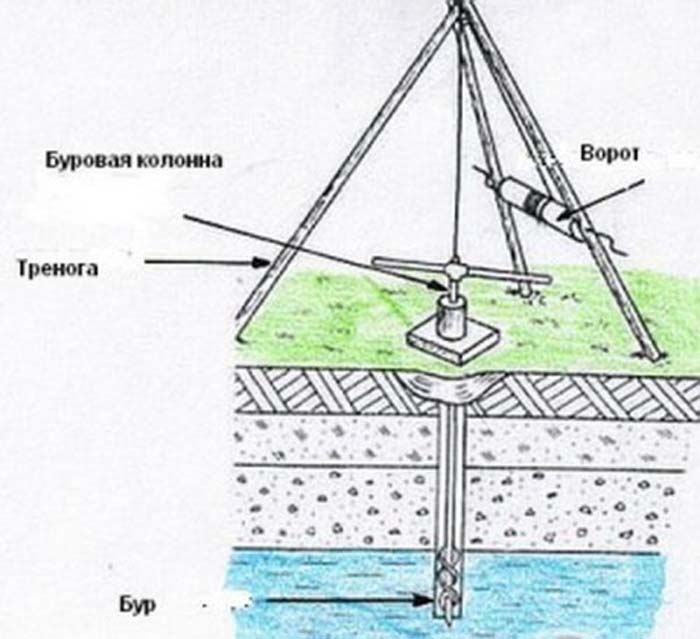

Shock rope

With such drilling of wells for water, the technology of the process involves raising the pipe with three cutters to a height. After that, being weighted with a load, it descends, and crushes the rock under its own weight. Another device necessary for extracting crushed soil is a bailer. All of the above can be bought or made with your own hands.

But before drilling do-it-yourself well you will have to use a garden or fishing drill to make the primary recess. You will also need a metal profile tripod, a cable and a system of blocks. The drummer can be lifted with a manual or automated winch. The use of an electric motor will speed up the process.

Auger

This technology of drilling wells under water involves the use of a drill, which is a rod with a helical blade. A pipe with a diameter of 10 cm is used as the first element. A blade is welded onto it, the outer edges of which form a diameter of 20 cm. To make one turn, a sheet metal circle is used.

A cut is made from the center along the radius, and a hole equal to the diameter of the pipe is cut along the axis. The design is “divorced” so that a screw is formed that needs to be welded. To drill a well in the country with your own hands using an auger, you need a device that will serve as a drive.

It could be a metal handle. The main thing is that it can be disconnected. As the drill deepens into the ground, it is increased by adding another section. The fastening is welded, reliable, so that the elements do not come apart during the work. After the procedure is completed, the entire structure is removed, and casing pipes are lowered into the shaft.

Rotary

Such drilling of a well in the country is not the cheapest option, but the most effective. The essence of the method is the combination of two technologies (shock and screw). The main element that receives the load is the crown, which is fixed on the pipe. As it sinks into the ground, sections are added.

Before you make a well, you need to take care of the water supply inside the drill. This will soften the ground, which will extend the life of the crown. This method will speed up the drilling process. You will also need a special installation that will rotate, raise and lower the drill with a crown.

Puncture

This is a separate technology that allows you to penetrate the ground horizontally.This is necessary for laying pipelines, cables and other communication systems under roads, buildings, in places where it is impossible to dig a trench. At its core, this is an auger method, but it is used for drilling horizontally.

The pit is dug, the installation is installed, the drilling process begins with periodic sampling of rock from the pit. If water in the country can be obtained from a well separated by an obstacle, a puncture is made, a horizontal casing pipe is laid, and a pipeline is pulled. Everything can be done with your own hands.

How to drill a well on sand: instructions

How to drill a well for drinking water if water-bearing sand lies to a depth of 40 m? Sand holes can be punched by hand, but this will require too much time and hard physical labor. The best way is to use small-sized equipment and select a drill according to the type and density of the soil.

Unlike wells that can be drilled by hand, sand springs require careful preparation. It is difficult to find a place for slaughter on your own. Specialists who are engaged in the arrangement of water intakes usually have accurate information about the depth and saturation of water-bearing sands and use special maps.

At the selected site, the installation is assembled. Before assembly in the ground, three holes are dug on the site:

Pit, which must be sheathed from the inside with rough boards, or tighten the bottom and walls with a strong plastic film.

Two slurry wells connected by a liquid overflow trench. The first tank is a filter in which the clay solution settles. From the second, water is fed under pressure into the barrel during drilling.

Hoses are being prepared: one for water supply, the other for outlet. After the assembly of the installation, they begin to clog the well.

You can drill such a well under water with your own hands in different ways: in soft rocks, a spiral drill, a glass are attached to the installation. In hard stony soils, a rotary method is used: they are drilled with a chisel and the mine is flushed with a clay solution.

In the course of work, the verticality of the projectile entry and depth are constantly monitored. As you deepen, lengthen the bar. MDRs are equipped with collapsible rods of sufficient length to work at a depth of up to 80 m. Signs of water-bearing sand:

- Washing out of the trunk of a large amount of sand.

- Easy entry of the drill into the rock.

Casing starts after drilling is completed.

Regardless of whether the well was drilled water by hand, or performed slaughter with the help of MBU, it is necessary to equip the source. It is also worth equipping surface wells with a pump.

Arrangement technology:

A caisson (pit) is equipped in the pit for piping the well. The walls are sealed.

Assemble and install the pump group. Submersible devices are lowered into the barrel, a safety cable is fixed on the head. Surface mounted on an elevation, connecting the inlet pipe to the supply hose or pipe.

Perform piping, connect watering hoses.

Drilling wells manually is difficult, long and without guarantees. The price of a mistake is lost time, money invested in the purchase of equipment and its rental. The video shows an example of how faster and more accurately the work is carried out by specialists.

It is important to get qualified help from specialists even before the source is arranged: traditional search methods do not guarantee that there will be water at the planned depth and that it will be enough to provide the site in summer. Masters can accurately predict both the depth and flow rate of the well. A water intake equipped by professionals is guaranteed to serve for decades

A water intake equipped by professionals is guaranteed to serve for decades.

What is a sand well

Answering the question about the features of an autonomous source of water supply on sandy soils, the following distinctive points should be noted:

- work is carried out to the level of the aquifer located under the clay in the sand layer;

- the maximum immersion depth of the drilling tool is no more than 50 m;

- drilling work can be performed independently using a manual or mechanized tool.

A sand well, unlike a limestone (artesian) well, is different:

- much shallower depth, which can even reach 10 m;

- reduced volume of produced water, up to 1 m3/h;

- using cheaper casing pipes of smaller diameter (127 mm).

A well is an artificially drilled mine

A well is an artificially drilled mine

The following options for the location of the aquifer are possible:

- in a cavity formed by an underground stream. As a rule, in this option, the flow rate is increased and the water is cleaner;

- in fine-grained sand. In this case, siltation and a decrease in the service life are possible.

Sand drilling is carried out using the following equipment:

- manual garden yamobur. It has reduced productivity and requires increased physical costs;

- mechanical auger.Allows you to reach the aquifer in the sand layer in a day;

- manual petrol drill. Allows you to speed up and mechanize the process, as well as reduce costs;

- screw installation on the road. High-performance unit, allows you to reach the formation in a couple of hours.

To ensure the purity of the produced water and bring its quality to food standards, it is necessary to use special filters.

The well can be of several types.

The well can be of several types.

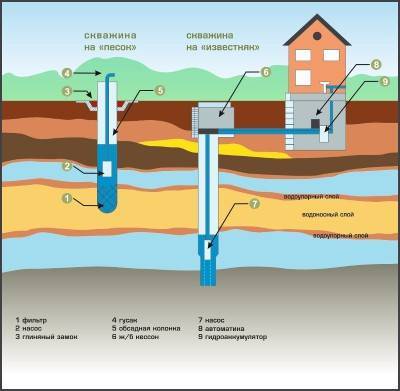

Equipment for an autonomous water source

For well equipment you will need:

- casing pipe (metal, plastic);

- filter;

- pump;

- safety rope;

- waterproofed cable;

- pipe or hose for lifting water;

- valve;

- caisson.

The well is equipped with a filter column, consisting of a filter and a casing pipe. The filter is made from a casing pipe by winding the perforation with a filter mesh. Water is pumped through the casing pipe and the filter is washed.

The pump is preselected. After all, its dimensions must correspond to the diameter of the casing

Also, when choosing a pump, it is important to take into account the debit of the well, the depth of the water, the load on the pump, which depends on the depth of the well itself and its distance from home. If the well depth is more than 9 m, then a downhole pump is used, if less, then a surface self-priming

The submersible pump is lowered into the well fixed on a safety cable or pipe. A cable is attached to the pump, which must be waterproof, and a water pipe (or hose). The diameter of such a pipe can be 25, 40, 50 mm, depending on the flow rate of the well. The pipe is brought to the wellhead and hermetically welded to the head of the caisson.The water supply is regulated by a valve that is installed on the pipe. The caisson is covered with earth from the sides. It is now possible to get to the well only through the manhole cover on the surface of the earth. From the caisson along the trench running water into the house.

Sand well for water

A deeper and more efficient design - a sand well - is designed for the use of special equipment and provides water lifting from a depth of 14 ... 40 m. The hole diameter is 12 ... 16 cm (casing diameter), while the size of the casing pipes is the same throughout. The design is "placed" on waterproof (waterproof) ground and guarantees the supply due to the infiltration of water under pressure through the lower, perforated part of the product. Additional filtration is carried out by a fine-mesh filter, the pressure is provided by a submersible vibration pump.

The flow rate of such a device is approximately 1.5 cubic meters per hour, while the quality of the water may suffer due to seepage into the sandy layer of the perch, harmful effluents. Often a filter is installed in a set with pumping equipment. With constant use, the well can “work” up to 15 years (in coarse-grained sands), with periodic use it quickly silts up.

Important: during dry periods, water often leaves the sand layers or the level of the aquifer drops significantly.

Manual well drilling

Most often, summer residents are interested in how to drill a well with their own hands, and not just a well. You will need such equipment for drilling wells as a drill, a drilling rig, a winch, rods and casing pipes. The drilling tower is needed for digging a deep well, with its help, the drill with rods is immersed and lifted.

rotary method

The simplest method of arranging a well for water is rotary, carried out by rotating the drill.

Hydro-drilling of shallow wells for water can be carried out without a tower, and the drill string can be removed manually. Drill rods are made from pipes, connecting them together with dowels or threads.

The bar, which will be below all, is additionally equipped with a drill. The cutting nozzles are made of sheet 3 mm steel. When sharpening the cutting edges of the nozzle, it must be taken into account that at the moment of rotation of the drill mechanism, they must cut into the soil in a clockwise direction.

The tower is mounted above the drilling site, it must be higher than the drill rod in order to facilitate the extraction of the rod during lifting. After that, a guide hole is dug for the drill, about two spade bayonets deep.

The first turns of rotation of the drill can be done independently, but with a greater immersion of the pipe, additional forces will be required. If the drill cannot be pulled out the first time, you need to turn it counterclockwise and try to pull it out again.

The deeper the drill goes, the more difficult the movement of the pipes. To facilitate this task, the soil must be softened by watering. When moving the drill down every 50 cm, the drilling structure must be taken out to the surface and cleaned from the soil. The drilling cycle is repeated anew. At the moment the tool handle reaches the ground level, the structure is increased with an additional knee.

As the drill goes deeper, the rotation of the pipe becomes more difficult. Softening the soil with water will help facilitate the work.In the course of moving the drill down every half meter, the drilling structure should be brought to the surface and freed from the soil. The drilling cycle is repeated again. At the stage when the tool handle is level with the ground, the structure is extended with an additional knee.

Since lifting and cleaning the drill takes most of the time, you need to make the most of the design, capturing and lifting up as much of the soil as possible. This is the principle of operation of this installation.

Drilling continues until an aquifer is reached, which is easily determined by the condition of the excavated land. Having passed the aquifer, the drill should be immersed a little deeper until it reaches a layer that is located below the aquifer, waterproof. Reaching this layer will make it possible to ensure the maximum inflow of water into the well.

It is worth noting that manual drilling can only be used to dive to the nearest aquifer, usually it lies at a depth not exceeding 10-20 meters.

In order to pump out dirty liquid, you can use a hand pump or a submersible pump. After two or three buckets of dirty water are pumped out, the aquifer is usually cleared and clean water appears. If this does not happen, the well needs to be deepened by about another 1-2 meters.

screw method

For drilling, an auger rig is often used. The working part of this installation is very much like a garden drill, only much more powerful. It is made from a 100 mm pipe with a pair of screw turns welded onto it having a diameter of 200 mm.In order to make one such turn, you need a round sheet blank with a hole cut in its center, the diameter of which is slightly more than 100 mm.

Then, a cut is made at the workpiece along the radius, after which, at the place of the cut, the edges are parted in two different directions, which are perpendicular to the plane of the workpiece. As the drill sinks deep, the rod on which it is attached increases. The tool is rotated by hand with a long handle made of pipe.

The drill must be removed approximately every 50-70 cm, and due to the fact that the more it goes deep, it will become heavier, so you will need to install a tripod with a winch. Thus, it is possible to drill a well for water in a private house a little deeper than the above methods.

You can also use the manual drilling method, which is based on the use of a conventional drill and a hydraulic pump:

The nuances of deepening in floating bases

When drilling or deepening wells in floating soils, special measures should be taken. The thing is that digging a well with a shovel and a bucket in a floater will not work. This will require effective supporting mechanisms.

It is possible to overcome such a section of soil only with the help of accelerated penetration. To do this, 3-4 sections are mounted at a time, and one more ring will be needed as an additional load. The process of carrying out the work is approximately the same as in the case of sinking in ordinary soil:

- To dig a well in this situation, special equipment is used, which allows you to raise a large amount of sand to the surface. This contributes to an increase in the speed of upsetting the repair rings.

- Be sure to connect the repair and the main trunk.