- Folk methods of maintaining the purity of the reservoir

- Folk methods of dealing with the problem

- Boiling water and salt

- A solution of baking soda and vinegar

- soda and salt

- Lemon juice or acid

- Alka-Zeltzer

- washing powder

- Vinegar, baking soda and chlorine

- Rock salt

- Alkali-based preparations

- Caustic soda

- How to pump a well with a submersible pump?

- Ways to solve the problem

- Method 2 cleaning the well with a bailer

- Cleaning after drilling with a compressor

- Necessary characteristics of the well for the selection of the optimal method of sand removal

- Possible causes of clogging

- Sand penetration into the casing

- Silting of a non-producing well

- Why can a well become clogged?

- Reason one. Sand got into the casing

- The second reason. Unused well silted up

- First compressor cleaning immediately after drilling

- Common mistakes when flushing a well

- Using a bailer

- Determining the location of the blockage

- Reducing the silting factor of the water intake

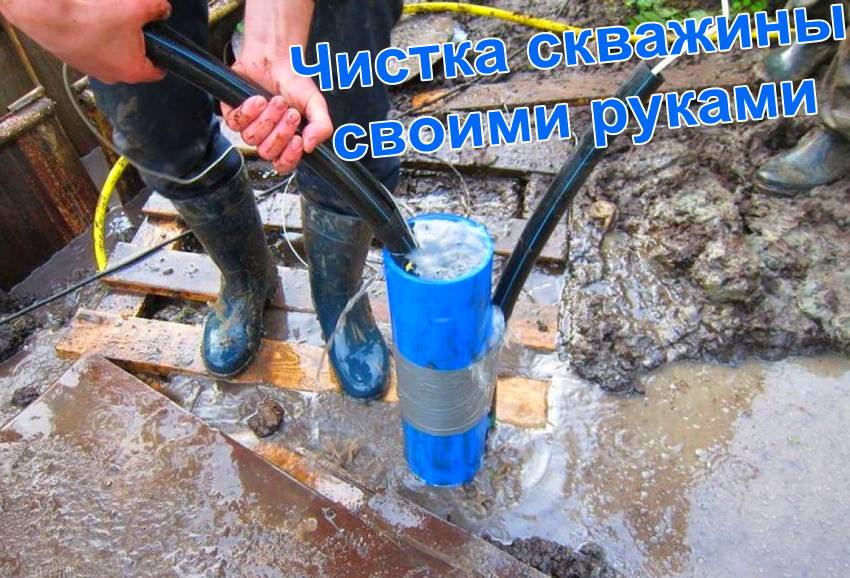

- How to clean a well with your own hands from silt and sand

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

Folk methods of maintaining the purity of the reservoir

To create a natural ecosystem and constantly maintain a garden pond in good condition, experienced summer residents plant the bottom and coastal zone of the pond with plants such as nymphea, elodea, fontinalis, arrowhead, calamus, hornwort, marsh iris, cattail, reeds. In most cases, these are not purchased seedlings at all, but specimens dug up near the nearest river or swamp.

Planting material (rhizomes) is often planted in ceramic pots, which are placed on the bottom. With the approach of winter, the pots are moved deeper so that the plants do not die even if the reservoir freezes completely.

Some summer residents also advise to maintain the natural ecosystem of garden ponds:

- populate water bodies with small river fish (for example, crucian carp), snails or freshwater crustaceans (daphnia);

- keep mesh containers filled with sphagnum moss or peat tablets in water;

- periodically lower a bunch of fresh willow twigs, peeled of leaves, into the pond.

A well-organized garden pond does without frequent labor-intensive cleaning, does not require the use of expensive devices and consumables.

Folk methods of dealing with the problem

If there are no chemicals, and the blockage is insignificant, then you can clean the pipes using folk remedies. They are safe not only for human health, but also for pipes.

Boiling water and salt

A solution of hot water and salt eliminates small plugs. But this method is not suitable for plastic pipes, since the maximum temperature they can withstand is 70 degrees. First, salt is poured into the drain hole, and after 20-30 minutes liquid is poured.

A solution of baking soda and vinegar

This method will allow you to clean the drain system from fatty deposits.200 g of powder is poured into the hole, after which 200 ml of acetic acid is poured there.

To improve the effect, soda can be calcined in a pan to a golden hue. For the reaction to be successful, the hole in the sink must be closed. After 15-20 minutes, the pipe should be washed with hot water under pressure. This method will only help with relatively recent blockages. Old traffic jams require drastic measures.

soda and salt

The drain is cleaned as follows: first, the dry components are mixed (half a glass each). The composition is poured into the drain hole and left for 10-12 hours. After that, the pipe is washed with hot water.

Lemon juice or acid

Acid crystals are poured into the siphon hole, then it is filled with water and vinegar. An acidic environment is created to clean the pipes from limescale. Acid is poured into the pipe in an amount of 100 g, and then 250 ml of boiling water is poured. After 20 minutes, the pipe is washed with boiling water. If lemon juice is used, then it is simply poured into the drain for an hour. Requires 100 ml of liquid.

Alka-Zeltzer

This is a medical preparation, which contains citric acid and acetylsalicylic acid. Additionally, it contains soda.

When interacting with water, these components enter into a chemical reaction. To clean the drain, it is enough to throw 2-3 tablets of the product into it and clog the hole.

The procedure lasts no more than 20 minutes.

washing powder

In this case, a granular agent is required. 2 measuring spoons of powder are poured into the pipe. Next, boiling water is poured into it for 5 minutes.

Vinegar, baking soda and chlorine

Before cleaning with the use of these components, all liquid is removed from the sink.Soda ash and baking soda (50 g each) are poured into the drain, and after half an hour vinegar and chlorine (150 ml each) are poured into it. The hole must be well sealed, otherwise a pungent smell will appear in the room. After 40 minutes, the drain is washed.

Soda and vinegar for cleaning pipes: 6 ways to clean the sewer at home There can be various reasons for clogged pipes. To combat the problem, various store tools are used, for example, Mole. However, you can get rid of it with the means that can be found in ...

Rock salt

You can clean plugs in cast-iron pipes with coarse salt. To obtain the reaction, vinegar essence is additionally required. First, 300 g of salt is poured into the pipe, 2 liters of boiling water are poured, as well as 100 ml of essence. After 30 minutes, the drain is washed. If necessary, the procedure can be repeated.

Alkali-based preparations

Alkaline products clean well with fatty deposits. Popular is the drug KEMI in orange granules

You will have to work with them carefully, as the substance is caustic. To clean the sewer pipe, pour 1 cap of the product into the sink and pour it with hot water

Alkaline-based liquid cleaners are more effective at removing clogs.

Caustic soda

Strong blockage can be cleaned with caustic soda (caustic soda). Powder in the amount of 2-3 is placed in a metal container and 12 liters of liquid (cold) are poured.

The composition is gently stirred for half an hour.

It is important to take precautions so that the composition does not get on the skin or mucous membranes. The powder must be completely dissolved

After that, the bucket is put on fire so that the mixture warms up to 70 degrees.Half of the composition for cleaning is poured into the drain hole and left for 1.5-2 hours. Further, the remaining part of the substance is introduced into the pipe, after which again wait 2 hours.

After the action of soda is completed, the pipeline is washed with hot water.

How to pump a well with a submersible pump?

A more accurate way to clean the well is with a submersible pump. You don't have to work in the mud, because all the water can be drained to a place convenient for you. For this procedure, you need a pump that is designed to pump dirty water. It is desirable that it can suck up solid particles at least up to 5 mm. Then you will remove not only sand from the bottom, but also small pebbles.

To clean the well, it is better to use a submersible pump, it is capable of pumping water with solid particles up to 30 mm in diameter

Consider how in the country you can clean the well using a submersible pump:

- We tie the pump to a strong cable, because during operation it can be sucked into the silt, and the cord that comes with the unit will not always pull the pump out of this trap.

- We lower the unit a couple of times to the bottom of the well and raise it to shake up the sediment.

- We install the pump near the bottom and turn it on.

- If the pump is provided with automation, then it will turn itself off as soon as it pumps out all the water. If there is no such element, it is necessary to control the process so as not to miss the moment of complete pumping. A dry running motor can burn out.

If you do not have a special pump for pumping out dirty water, you can clean the well with a conventional vibration pump, such as "Kid". The course of work is exactly the same as described above. Only periodically this pump must be taken out of the well for flushing with clean water.Vibrating units are not designed for heavily polluted water, therefore, without flushing, they will not withstand such a test and will burn out. By the way, the first sign that the pump is running on wear is the heating of the housing.

Vibratory pumps are not designed for heavily contaminated water, therefore, when cleaning, they must be periodically rinsed with clean water to avoid clogging and overheating.

To flush the system, you will need a container with clean water and empty. Put hoses in containers and turn on the unit.

Ways to solve the problem

Experts identify three principles for cleaning wells:

- Pumping is a simple way to flush the well with a pump. The use of this method is possible only when the layer of sand has not completely covered the horizontal parts of the filter.

- Flushing with circulating fluid - supplying water through a hose into a well at high pressure. Sand and clay under the action of the jet is washed away and the surface rises through the production pipe. Disadvantages - the possibility of damage to the filter, a large volume of circulating water, the release of a large amount of sand.

- Blowing with compressed air is a coarse cleaning system, carried out by an airlift. Airlift is a special apparatus consisting of a compressor and a hose through which air is supplied to the well at a pressure of 10 to 15 atm. A high pressure is created in the barrel, pushing out particles of silt and sand. This method is suitable for wells with a depth of 30 to 40 m.

These principles are the basis for a large number of methods for cleaning wells.

Method 2 cleaning the well with a bailer

If the well is slightly clogged, and at the same time shallow in itself, a bailer can be used. In other cases, its application will be ineffective. If the depth is within 30m or more, you will also need a winch, and this method of cleaning will require considerable effort from two strong men.

Bailer - a piece of pipe on a cable with a mesh in the upper part and a hole in the bottom. It sinks to the bottom, then rises to a height of 0.5 m and drops sharply. Water is drawn inside, inside the cylinder there is a ball of metal, which after a couple of seconds rises, and then falls and closes the hole. Such a cycle of raising-lowering is repeated three or four times, then the bailer is raised and cleared of sand. To make it more convenient, you can use a tripod. At a time, about 0.5 kg of sand enters the cylinder, so by cleaning in this way, you can find out how quickly the well becomes clogged.

Photo and diagram of the bailer device. Reviews about this method of cleaning the well are both positive and negative. For some, this method of cleaning seems to be very time-consuming and inefficient, someone only uses it. If you can make a bailer yourself, such cleaning will not require extra expenses, and this is already a plus.

A bailer with a ball valve can be made independently or bought ready-made in a store.

This is interesting: Design of a bedroom with a loggia - we learn in detail

Cleaning after drilling with a compressor

Immediately after drilling and installation of casing pipes, even before the start of regular operation, it is necessary to clean the well from clay, sand and debris that has fallen during the work.The first cleaning of the well (claying) is carried out before the appearance of potable water, and can be carried out over a long period of time, from several hours to several weeks. For independent work you will need:

- Air compressor (power not less than 12 atmospheres).

- A set of pipes, the diameter of which allows them to be freely immersed in the casing, and the total length to reach the bottom.

- An adapter from a pipe diameter to a compressor hose. Well cleaning is performed as follows:

- The pipes are connected and plunged into the shaft to the bottom level, while the upper part should protrude 20-30 cm above the ground.

- The upper part of the pipe is fixed with a rope, since during operation the pressure will try to push it out of the shaft.

- Using an adapter, a compressor hose is connected to the pipe and air is supplied under pressure. As a result, sand and clay rise from the bottom and are pushed along with the liquid into the wall between the casing and the inner pipe.

The ejection of water occurs under high pressure. It must be taken into account that the site around the well will be contaminated on an area of at least several square meters, and measures should be taken in advance to protect people, soil and equipment from dirt.

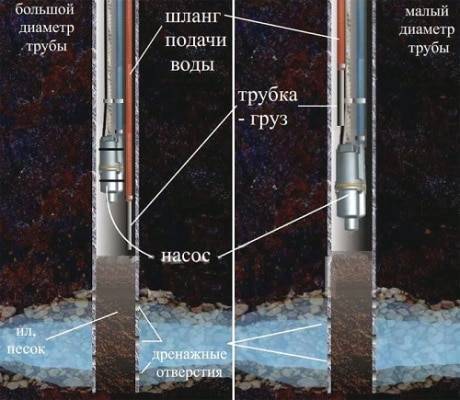

Necessary characteristics of the well for the selection of the optimal method of sand removal

To obtain a guaranteed result, it is necessary to know some well parameters: depth, flow rate, water level, type of well device (straight bore or with a filter whose inner diameter is smaller than the diameter of the main bore). All this data can be found in the well passport, which is issued by some companies.The choice of a submersible pump with which cleaning will take place depends on the indicators.

The flow rate of the well must exceed the productivity of the vibrating pump. If there is no well passport, then the well flow rate can be calculated independently. This will require a measuring tank, the volume of which is known. Using a pump lowered to the very bottom, pump out all the water, wait for the water level to recover and repeat the procedure again. By dividing the volume of water produced by the time it took to pump out, we obtain the necessary data.

The table below will help determine the performance of vibration pumps using popular models as an example:

| Name of the electric pump | Cost (in rubles) | Depth (in meters) | Productivity (liters per second) | Productivity (liters per hour) |

|---|---|---|---|---|

| Typhoon-2 | 2200 | 40 | 0,25 | 900 |

| Creek-1 | 1000 | 40 | 0,12 | 432 |

| Aquarius-3 | 1800 | 40 | 0,12 | 432 |

| Shower | 2100 | 40 | 0,16 | 576 |

All data for the table (with the exception of the last column) were taken from the accompanying documentation for the indicated models. Knowing the performance of these pumps, you can easily choose a model that will help clean the well without the risk of damaging it.

Possible causes of clogging

Choice self-cleaning methods construction depends on the possible causes of the problem. For example, if the well is not flushed completely, dirt particles may remain in it and the pump will not be able to work as efficiently as possible.

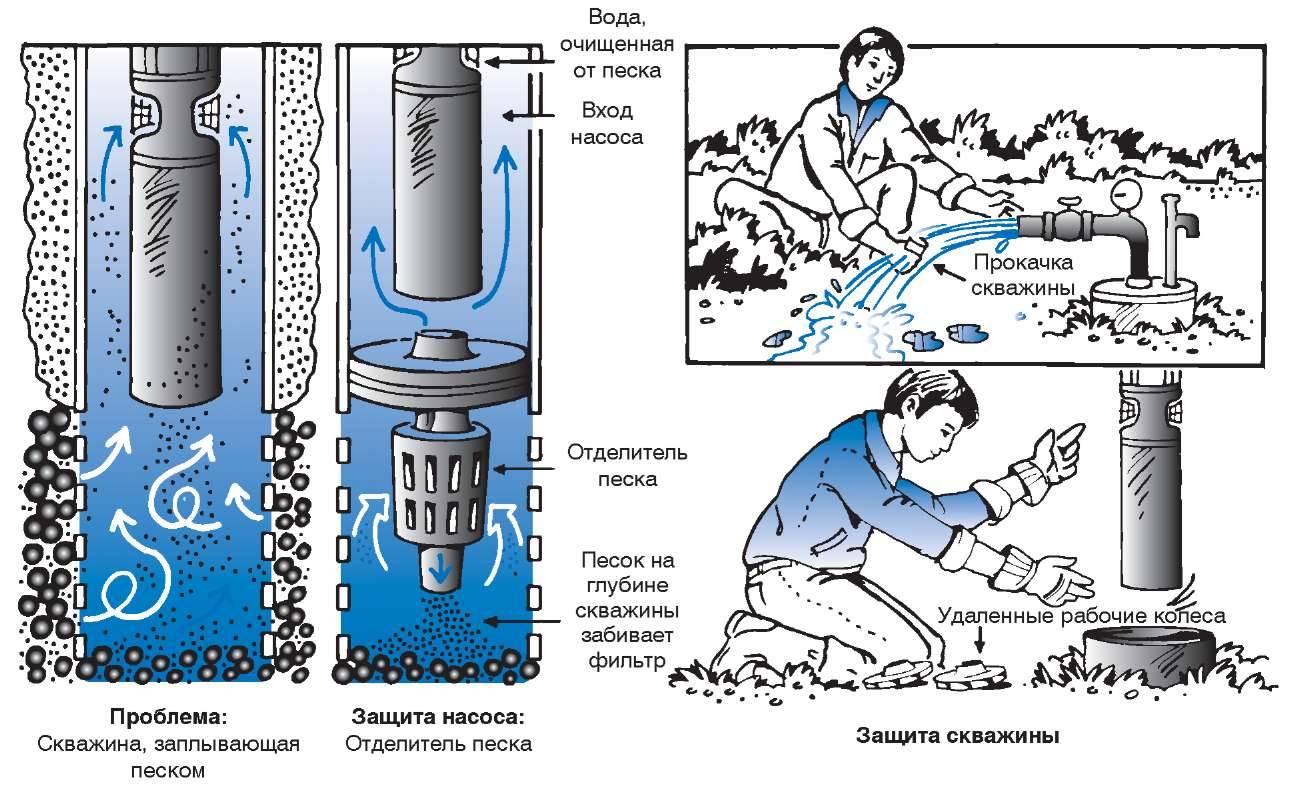

Sand penetration into the casing

Most often, sand accumulation is observed in shallow structures, in which the water carrier is in a layer of gravel and sand.

If the water source has been arranged correctly, sand particles enter the casing in an insignificant amount.

The main reasons for the decrease in the productivity of the water source:

- grains of sand fall from the surface - the tightness of the caisson or head is broken;

- incorrectly selected filter element;

- the filter is broken

- leakage of casing sections due to insufficient thread tightening, poor quality welding, corrosion or damage to plastic elements.

Solving such problems is easier than fixing a breakdown when the well silted up. Fine sand particles pass through the filter, but they are easier to remove than coarse sand. In addition, some of them are washed out in the process of raising the liquid level.

Silting of a non-producing well

Well cleaning is a must. The fact is that particles of clay, calcium deposits, corrosion, etc. gradually accumulate in the soil thickness in the filter area.

If the amount of these fractions exceeds the norm, the pores of the water carrier and the cells of the filter element begin to clog. As a result, it becomes more difficult for the liquid to pass through the trunk, the debit of the water source decreases, and the process of siltation begins, which can cause the complete disappearance of water.

If the amount of these fractions exceeds the norm, the pores of the water carrier and the cells of the filter element begin to clog. As a result, it becomes more difficult for the liquid to pass through the trunk, the debit of the water source decreases, and the process of siltation begins, which can cause the complete disappearance of water.

In actively exploited wells, this process is slow and can last up to several decades. If the artesian source is not pumped periodically, it can become silted up in 1-2 years.

Why can a well become clogged?

To understand the causes of the problem and choose the appropriate cleaning method, you need to familiarize yourself with the types of clogging.

Reason one. Sand got into the casing

This is a common problem in shallow sand wells with an aquifer located in a sand and gravel layer. If the well is properly equipped, sand will enter the casing in minimal volumes.

With a decrease in well productivity and the presence of grains of sand in the water, the problem may be:

- ingress of sand from the surface (due to leakage of the caisson, cap);

- broken tightness between casing elements;

- incorrectly selected filter (with too large cells);

- violation of the integrity of the filter.

It is impossible to eliminate leaks inside the well. Fine sand, constantly penetrating through the filter, is easily removed (especially since it is partially washed out when lifting). But when coarse sand enters, everything is somewhat more complicated, the well can simply “swim” over time

That is why it is necessary to choose a filter and mount casing elements with special attention.

The installation of a sand separator in the casing pipe significantly reduces the sanding of the filter and extends the service life of the well on the sand

The second reason. Unused well silted up

Over time, particles of rocks, rust, clay, and calcium deposits accumulate in the ground near the filter. With an excessive amount of them, the filter cells and pores in the aquifer are clogged, and therefore it will be more difficult for water to enter. The flow rate of the source decreases, it silts up to the complete disappearance of water. If the well is used regularly, then this process slows down and can take decades, and if not, then siltation may take one to two years.

In the case of timely cleaning of the well from sludge (that is, before the water disappears completely), the source can most likely acquire a “second life”. Water supply will be maintained in sufficient volumes for the residents of the house.

Water entering the well through the filter carries with it small particles of silt. There is silting of the soil near the filter. Calcium salts also accumulate in the suction zone if the water hardness is high.

First compressor cleaning immediately after drilling

As soon as the well is drilled, it must immediately be cleaned, because not only water will flow into the pipes from the aquifer, but also all the debris that is in it. Installed filters cannot trap the smallest particles, from which the water becomes cloudy and unsuitable for drinking. Depending on the depth of the well, the flushing process after drilling can take from 10 hours to several weeks.

If drilling was carried out by specialists, then they flush the system using a flushing unit. If you drilled the well yourself, you will also have to clean it of dirt yourself. To do this, you will need a compressor with a capacity of at least 12 atm and several pipes that must be connected to each other and inserted into the well so that they reach the bottom. In this case, the diameter of the pipes must be smaller than the diameter of the well so that there is an empty space between them.

The compressor forces air into the well at high pressure, so dirty water can fly out at high speed and splatter everything around

Let's consider step by step how to clean the well yourself using a compressor:

We insert pipes into the well.It is desirable to strengthen the top with a rope, because under high water pressure the structure can bulge upward. We put a vacuum adapter on the pipe, fixing it with self-tapping screws. We pump up the compressor to maximum pressure. We put the compressor hose on the adapter. pumping.

Air under pressure will push dirty water through the annulus. Therefore, do not be surprised if everything around is filled with mud.

If air does not achieve clean water, repeat the procedure, replacing the air purge with a water purge, using the same piping system with an adapter. To do this, find some large barrel, put it next to the compressor and fill it with water.

Using a water compressor, drive this water at maximum pressure into the well. But be careful, because heaps of dirt pushed out by this water will fly at you. Clean the well until the tank is dry. Then, flushing should be repeated until dirt is no longer ejected from the annulus.

With the help of blowing and flushing, the well is cleaned of silt or sand. But salt deposits on the filter cannot be knocked out in this way.

4

Bailer - an elementary device for extracting sand

If the farm does not have a vibration pump, it is possible to clean a well up to 30 m deep in another way, involving the use of a device called a bailer. It is a one and a half meter piece of metal pipe with an eye lever on one side and a valve on the second.

Bailers are sold in hardware stores. If desired, they are easy to make with your own hands.The function of the valve in such designs is performed by a heavy steel ball. He is held by the puck. It is fixed with a threaded connection. The eyelet lever allows you to attach a cable to the fixture.

Additionally, you need to prepare a tripod, on top of which there is a block. Work on cleaning the well with a bailer is carried out by two people. The process implementation algorithm is given below:

A deep pump is drawn from the source. All foreign objects are removed from the pipe, water is pumped out. The bailer is fixed on a strong rope or cable and drops sharply into the well. Sand particles begin to move and enter the bailer through the intake valve, which is opened by a steel ball.

Then the pipe is lifted up. At the same time, the ball clogs it, preventing the “captured” contaminants from falling out back. On the surface of the earth, the bailer is freed from sand particles and again lowered into the well. This operation is repeated several times.

The described technique is ideal for cleaning the casing from small compacted deposits and pebbles, large volumes of sand. But it is not suitable for removing silt from the well. The method described in the next section helps to cope with such sediment.

Common mistakes when flushing a well

Inexperienced well owners often make the mistake of ignoring well flushing after drilling is complete. As a result, the water in the working remains untreated, which makes its use limited. One of the most common mistakes when flushing a well with a pump is its incorrect hanging height.

The pump must not be allowed to touch the bottom, in which case the cleaning will not be effective: the pump will not be able to capture silt particles under its body. As a result, silt will remain at the bottom of the well, blocking access to the aquifer and deteriorating water quality.

In addition, a too low position of the pump can lead to the fact that the equipment "burrows" in the sludge and it will be problematic to get it out of there. It also happens that the pump gets stuck in the wellbore. This can be avoided if a thin but strong cable is used for immersion, and when pulling the pump back, do not make sudden movements, but gently swing the cable to lift the pump from the well.

Another mistake is improperly organized drainage. Contaminated water coming from the well should be diverted as far as possible from the mouth. Otherwise, there is a risk that it will again enter the source, which will lead to an increase in the flushing period, and hence additional financial costs. For the organization of drainage, it is best to use durable fire hoses.

It is important to flush the well before clean water comes out of it. Putting an uncleaned well into operation is prohibited! This will lead to damage to pumping equipment and problems in the operation of the well in the future.

Using a bailer

Most often used to remove sand deposits from the structure. Please note that it will take effort to make blows with a piece of pipe. In addition, if the well is not deep and there is little debris, a bailer will come in handy. And if the depth of the structure is about 30 m, then a winch will be required to perform lifting work.

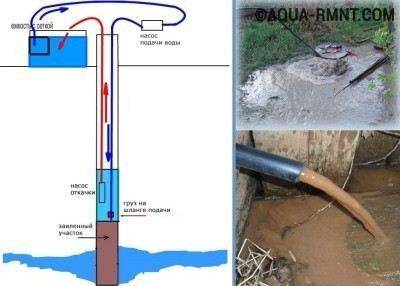

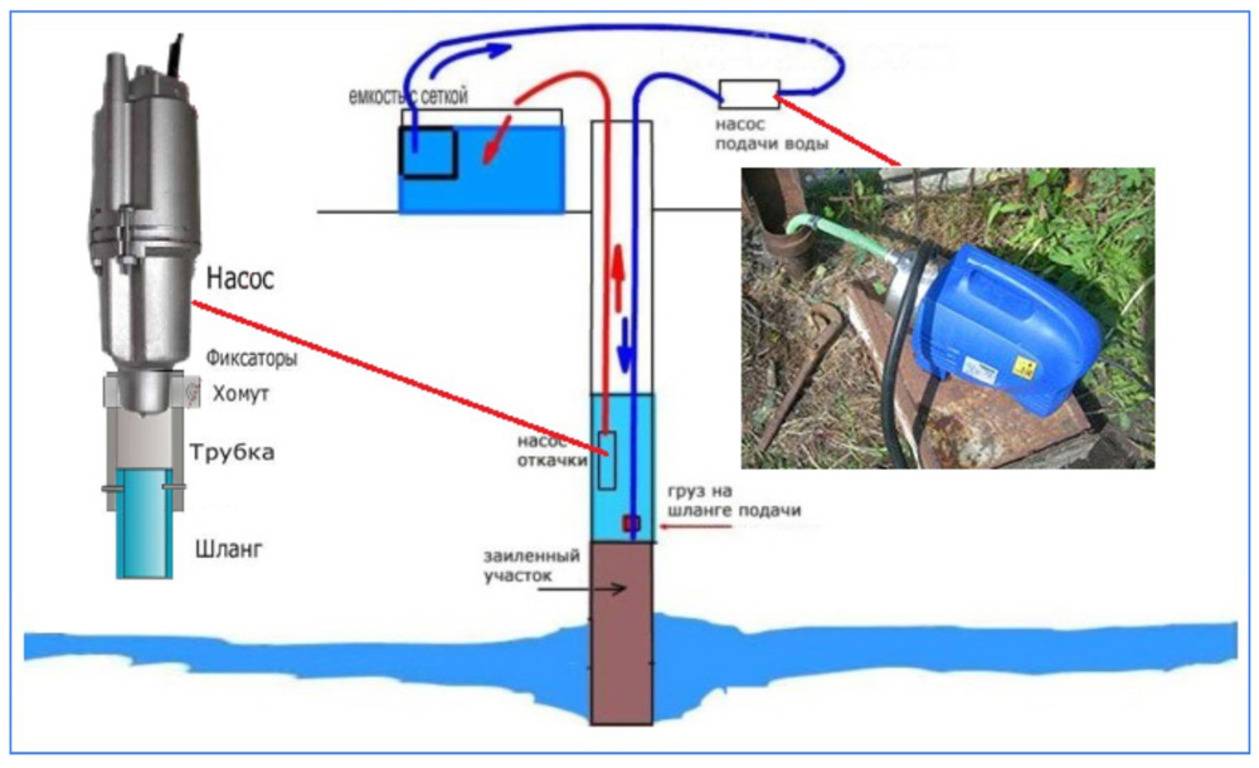

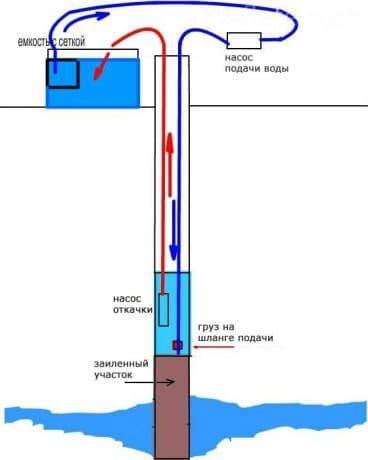

For a very deep well, a mechanized cleaning method is more effective.Water cleaning is optimized thanks to two pumps working simultaneously.

As a rule, deep, located at the very bottom. The pump has a lower hydraulic intake. Silt and mud deposits go up. The pump also works. This pump delivers liquid from a reservoir under pressure. Sand and silt deposits are shaken up. To ensure that the system works without problems, shake the fluid outlet hose from time to time, control the content of debris.

Of course, the quality of cleaning depends on the choice of devices. For example, at a depth of more than 10 m, it is necessary to use a vibration pump.

Determining the location of the blockage

A clogged pipe is a fairly common problem that you should not panic and look for the plumber's phone number when faced with. You can often do it yourself, saving time and money.

Before cleaning pipes, it is important to understand exactly where the plug has formed. This directly affects the choice of method for solving the problem.

To determine the approximate location of the blockage, open the water and see how it will "leave":

- Water decreases very slowly - most likely, the cork is at a distance of more than a meter from the drain. With such a problem, the most optimal way would be to use a special metal cable.

- The water drops to a certain level, and then everything remains unchanged - the blockage is located in the area from the siphon to the first turn. In this case, it will be enough to use either folk methods or chemical means.

- The liquid does not go away at all - in 90% of cases, the siphon is clogged with fat deposits. The best option to deal with contamination would be manual cleaning of the pipeline.

These are the most common ways to identify the place where the problem has formed.

Most often, traffic jams occur at the first turn of the pipe, its narrowing or connection with the central riser.

Most often, traffic jams occur at the first turn of the pipe, its narrowing or connection with the central riser.

Once you have figured out exactly where the blockage formed, you can begin to eliminate it.

Reducing the silting factor of the water intake

The fact that the well has silted up is not unusual. The extraction of life-giving moisture is carried out from the soil, so that the presence of its particles in it is quite natural. Periodic preventive cleaning of water intakes is mandatory. And in order to reduce their frequency, it is necessary to apply some techniques in the process of drilling and arranging the well to avoid too frequent flushing:

- It is necessary to control the quality of the opening of the well. Depending on the drilling method, it is necessary to obtain confirmation that water-resistant clay is present in the excavated soil after wet sands. This indicates the complete opening of the aquifer.

- At the final casing of the walls of the pit, it is necessary to arrange a bottom gravel filter. To do this, it is necessary to fill the casing with up to 50 kilograms of gravel in a mixture of fine and medium fractions and raise and lower the casing string several times. In this case, the gravel spills onto the outer part of the casing, creating a reliable lock, which plays the role of a coarse groundwater filter.

- The space between the wall of the pit and the wall of the casing along the length of the casing filter should also be backfilled with gravel of the same quality. Thus, the filtering part of the casing will be in a gravel bag, reliably retaining coarse and medium sand fractions.Further backfilling of the inter-wall space can be done with gravel of the middle fraction, and this operation is performed without fail.

- If the well has reached the second aquifer on the sand, it is necessary to isolate the top water, not allowing it to mix with the water of the operated aquifer. To do this, you need to fill the clay castle with a height of at least one meter. A clay solution is used, which is similar in composition to the clay of the water-resistant layer. It should be noted that the prevention of water mixing of neighboring layers is an indispensable condition for issuance under the subsoil law. Yes, and the user does not need dirty top water.

- The device of the upper clay and concrete locks at the head of the well has the same goal.

- More often, wells that are operated irregularly are silted up.

The article details how to clean the well, and it is obvious that this is not a problem at all. You can do this work yourself, with a minimum investment of money and time. Good water to you and we advise you to read: Well repair

How to clean a well with your own hands from silt and sand

Owners of plots without power supply will have to solve the issue on their own. Also, owners of old water intakes that have not been used for a long time often face a problem.

Water sources, the depth of which does not exceed 15 m, can be independently pumped without extra expenses. A minimum of equipment is needed, the main thing is to stock up on time and patience.

The most economical option for resolving the issue of how to pump a well with your own hands is to use a conventional bailer and a hand pump to facilitate work and speed up the process. This method is suitable for surface wells, if clay or sandy soil prevails.

You can make a bailer yourself: a tip with a valve with a sharp cutting edge is welded to an ordinary thick-walled pipe. A handle or hook is attached from above so that a pipe filled with silt can be lifted to the surface.

A hand pump is used to facilitate the work. With its help, it is possible to supply water inside the column and suck out the contaminated sludge mass to the surface through a hose. Time and effort are saved: you do not have to manually lift several tens of kilograms to the surface. The pump can be used after removing the bulk of the contaminants with a bailer for final cleaning.

How to clean a well with a bailer:

A bailer is lowered to the bottom of the well. From the water hammer, the valve opens, silt and sand enter the pipe body together with dirty water, the valve closes automatically.

With the help of a winch, a cable, or manually, the filled device is lifted to the surface, the contents are poured out.

The procedure is repeated until the complete removal of contaminants.

Disadvantages of the method: laboriousness, duration of the procedure. Due to the small volume of the device, the cleaning process can take weeks.

How to pump a well from sand with your own hands? The fastest way is with a submersible pump. It makes no sense to buy expensive imported tools for dirty work. It is enough to choose a cheap model. It is better that in the vibration pump the water intake hole is located at the bottom.

For pumping you will need:

Hoses significantly exceeding the depth of the source barrel.

Pump.

Cargo (metal bolt, blank with fastening).

Rope or rope.

A cable is attached to the pump, which must be strong enough to lift the equipment if the pump is sucked into the sand.It is better to use a thin and durable steel cable. After lowering the pump, a hose is lowered in parallel, which will supply water. The pressure will wash away and lift pollution from the bottom.

To soften, loosen the sludge, you can lower the load to the bottom of the well before submerging the pump. During cleaning, it is necessary to periodically lift the equipment, pump clean water - the pump will not break down, overheat or clog.

Express method how to pump a well: water is continuously pumped by a surface pump, silt rises from the bottom at the same time, a submersible pump pumps water to the surface. This way is the fastest.

You will need:

Two pumps: one for supply, the other for the intake of polluted water.

Capacity, at least 150 - 200 liters.

Hoses.

First, a deep pump is connected to fill the pipe with water. Then an external one is connected, the pressure erodes the dirt. The process takes place almost automatically. It is necessary to monitor the water level in the barrel, periodically turn off the pumps to avoid overheating.

Conclusions and useful video on the topic

Methods for cleaning sewer pipes are not limited to those listed. There are many other ways that can be successfully applied in your home. We offer the most interesting materials on the topic.

Overview of popular methods clog cleaning:

There are special cable attachments available in stores, but you can make your own if you follow these tips:

Vantuz is able to save in the most unpleasant situations. How to use it is described below:

There are interesting folk recipes on how to prepare a caustic solution from soda, which is not inferior in efficiency to purchased products. We offer step-by-step video instructions:

All methods of cleaning sewer pipes are good in their own way. It is worth choosing one or more suitable means and using as needed. Do not forget about preventive measures: watch what goes into the sewer, use drain screens and regularly flush the pipes with soda or chemicals.

Clean sewerage is the key to a comfortable life.

Do you know other effective drain cleaning methods and use them successfully? Or maybe you found flaws in the material presented or want to ask a question on the topic of the article? Please write your comments in the box below.

Conclusions and useful video on the topic

Flushing the well with a pump:

What does the process of flushing a well with one pump look like and why it is necessary to take care of the organization of water disposal:

As you can see, flushing a well after drilling is completed is a necessary measure that you cannot do without if you want to get clean water.

Flushing can be done in several ways: one or two pumps or an airlift. The manual method of cleaning with a bailer for primary washing is not advisable due to its low efficiency.

Have something to add, or have questions about the topic? Share your well flushing experience with readers, please leave comments on the publication. The contact form is in the bottom block.