- Rinsing with gas-air mixture

- Cleaning methods

- Bailer cleaning

- Water cleaning

- Air pumping

- The easiest way to clean

- Causes of silting

- How to clean the well from silt with your own hands

- The main causes of clogging of wells for water

- Methods for determining well failure

- Causes of well clogging

- Preventive measures to prevent well contamination

- Cleaning with a bailer

- Making a bailer

- Bailer cleaning technology

- Video

- Professional flushing of wells

- Methods for self-cleaning from silt and sand

- Pumping out by pumping apparatus

- Flushing with pressure equipment

- Application of the bailer

- Purge water intake structure

- Chemical cleaning method

- Septic tanks with soil aftertreatment

- Cleaning Recommendations

- First compressor cleaning immediately after drilling

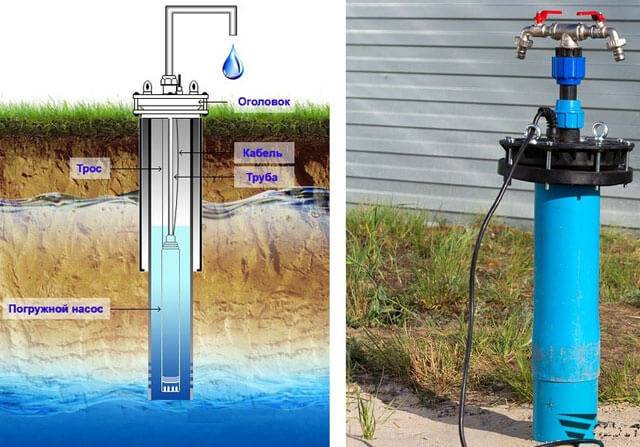

- 1 Why is the water source clogged

- In what situations it may be necessary to disinfect the water in the well

- Peculiarities

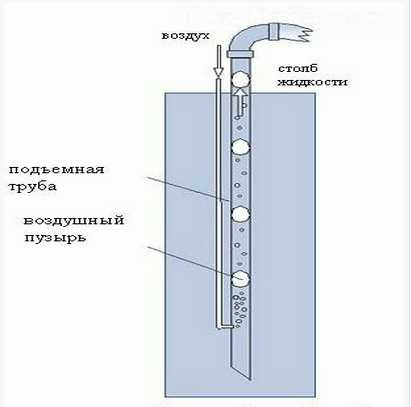

Rinsing with gas-air mixture

The cleaning method using a gas-air mixture is called bubbling. In this case, the well is purged with a compressor. At the same time, a spray gun is lowered to the bottom of the well so that it is located in the thickness of silt or sand. Then compressed air is supplied by a powerful compressor.

The resulting bubbles rise to the surface, dragging contaminants with them. To ensure the removal of dirty water, flushing liquid is constantly added to the source manually or using a hose. You can use a closed circulation of water between it and a pre-prepared container.

Specialists do not consider the combined method of flushing with simultaneous blowing of the well with compressed air effective and productive. The fact is that this process is moving slowly and it may take several days or weeks to complete it if the pollution is severe.

Bubbling has advantages over alternative methods:

- Sometimes it is the only option for cleaning the source and filter if pumping with water has been unsuccessful.

- The implementation of effective methods of cleaning from sand using a bailer or silt deposits by water hammer is accompanied by the creation of serious vibrations that can damage the filter made of fine mesh. Even more likely is the failure or collapse of fragile, worn steel or plastic casing. As a result, the source can be completely disabled.

- Knowing how to blow a well with a compressor using a gas-air mixture, you should not be afraid of trouble. This method is the most gentle technology that will not cause any damage.

Cleaning methods

Before we begin, it is worth discussing one important point ...

In most cases everything is possible clean it up like a great way - with the help of chemistry, which is poured to the bottom of the well. Chemicals get on the surface of the filter and, as a rule, simply corrode garbage, silt, salts and other layers in a couple of days.

It would seem convenient, quick and simple, but only here it is worth thinking about two points:

- After such purification, your water will not be drunk or used for cooking (at least a month). Because it will be necessary to wait until the remnants of chemistry are completely washed off with water.

- The method itself is unpleasant, because the aquifer and the entire ecosystem as a whole are polluted.

Of course, how to clean the filter in the well is up to you, of course, but we do not recommend the method of working with chemicals.

This is what it looks like well filter

Let's take a look at other options.

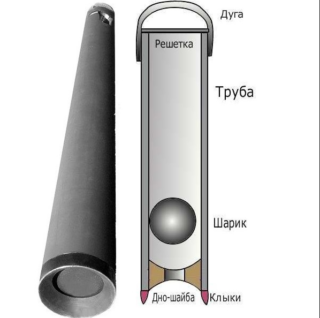

Bailer cleaning

This is a very effective and relatively simple technology that is used quite often for wells up to 40 meters deep.

A bailer is a piece of heavy metal pipe 60 centimeters long and slightly smaller in diameter than the diameter of the main pipe in the well. The bottom of the bailer consists of a washer with a hole in the center - through it debris and sand from the bottom of the well enters the pipe.

In the middle of such a pipe there is a ball, which has a diameter slightly smaller than the bailer itself. By the way, the inner side of the lower washer exactly repeats the shape of the ball.

The ball can be made of metal, but, as a rule, it is rarely possible to get the right diameter, so they approach the issue a little differently. An ordinary children's rubber ball is bought on the market, which is cut in half. Both halves are filled with small bearings, for example, and then glued together.

Bailer

The device operates very simply.

The bailer on a cable is lowered to the bottom of the well, then slightly lifted and abruptly released.The pipe flies down, while the ball inside the bailer breaks away from the plane of the washer for a few seconds (that is, as if opening a hole in it) and just at that time sand and silt are collected in the bailer.

Then the ball closes the hole, and the pipe gently rises to the surface, where debris is poured out of it, and then the operation is repeated again and again.

The next way.

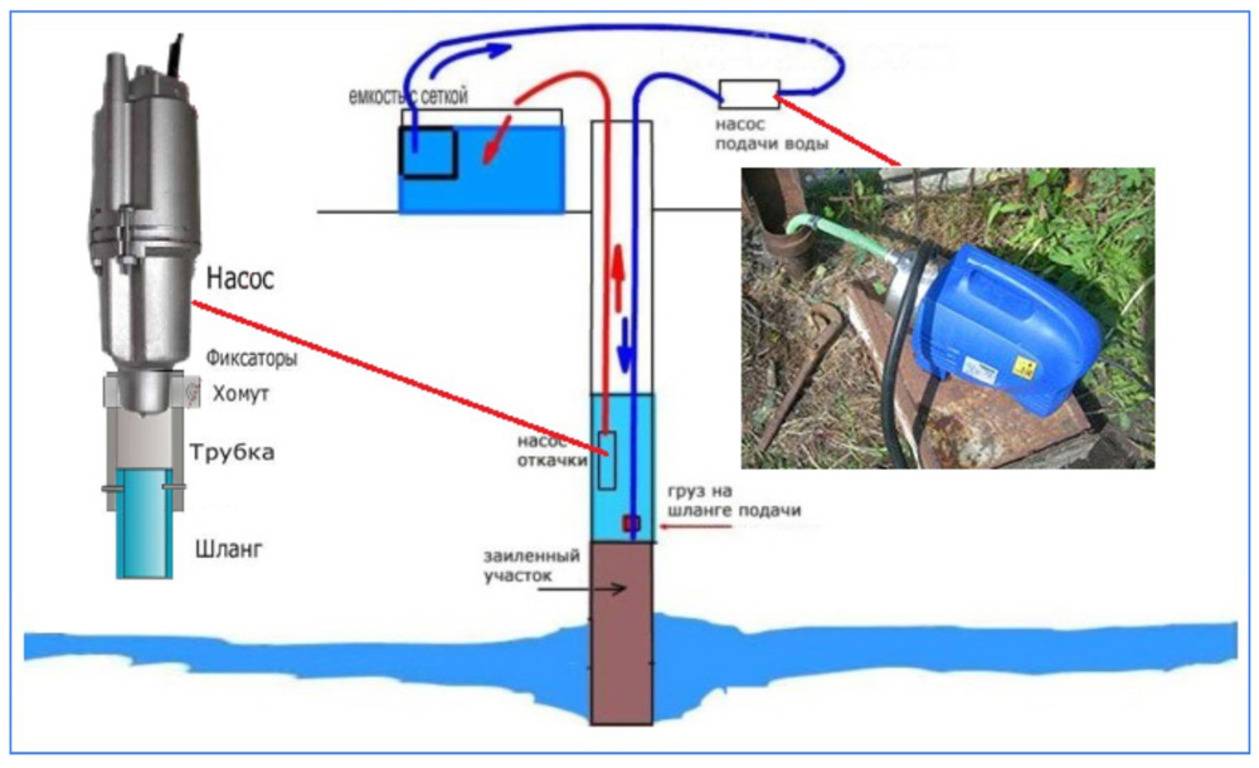

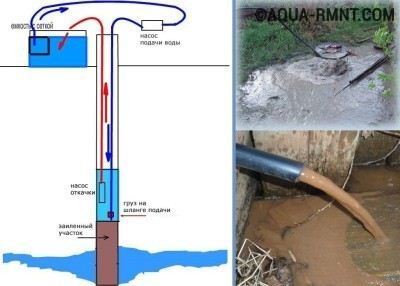

Water cleaning

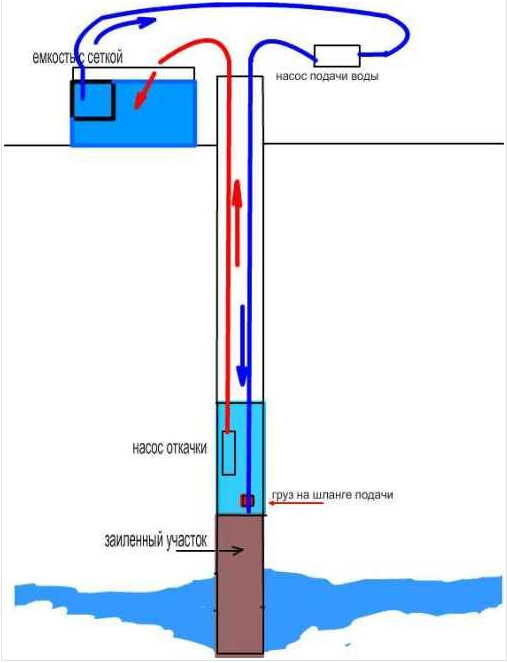

This method is carried out using two pumps - one that already supplies water from the well to the surface, and an additional one - ground, which will supply water under pressure to the bottom of the pit.

That is, it turns out that due to the increased circulation of water, water with a high content of sand and small debris enters the pump, which is located at a depth. After some time of such pumping, the percentage of foreign substances in the water will become much lower, or the garbage will disappear altogether.

Water cleaning scheme

The technology is good to use when you need to clean the bottom of silt, sand or other similar debris.

Everything is done very simply:

- A water tank is installed near the well;

- A small container with a mesh is lowered into the tank, which will act as a filter. It may well be an ordinary bucket;

- A hose is pulled from a bucket to one ground pump;

- Another hose is laid from the same pump to the bottom of the well;

- Start the water supply to the well and at the same time turn on the pump for pumping water from the bottom. The circulation effect has been created. Cleaning has started.

Such is the instruction - as you can see, there is nothing complicated.

Air pumping

Scheme of cleaning with air pressure

In fact, here the principle of operation is quite similar to the previous method.Air is supplied to the barrel through a hose with the help of a compressor under a pressure of 10-15 atmospheres, which raises layers of sand from the bottom.

Then these layers gradually come to the surface with the help of a water pump.

Here it is only important to ensure that the air pressure does not spoil the equipment itself (pump, filter) in the barrel - after all, the pressure is decent

An example of a simple compressor

And one more technology, which is great to use in the country, where there is no additional equipment other than the water supply pump itself.

So to say - "economy option".

The easiest way to clean

The method lies in the fact that next to the pump, the soil is loosened with a piece of conventional reinforcement. The metal is tied to a cable or rope (make sure that they do not break - otherwise the reinforcement will remain in the trunk) and sinks to the bottom.

Then the cable must be sharply raised and lowered so that the reinforcement seems to loosen the ground.

Here, too, the principle is simple - layers of sand and silt will leave with water through the pumping pump.

Such are the technologies.

Let's summarize.

Causes of silting

An alarm signal that should alert the owner of the device is a decrease in water pressure. After that, a brief stagnation is usually formed, accompanied by a characteristic gurgling, then muddy water is ejected and, as a result, the system stops working.

Silting occurs for several reasons:

- When drilling a well, the installation of the pipe was performed incorrectly. Not in the aquifer or in the weakly aquifer is the place where water enters the device - a waste during drilling.

- The internal arrangement of the structure also plays an important role. Due to the leakage of casing pipes, grains of sand enter the source from the side and from above through the cracks. Thus, the source is filled with sand.

- There is little water coming from the well. Silting occurs due to sedimentation at the bottom of the system of silt, small particles of clay and rust from the pipe, they are gradually compacted, which reduces the flow rate of the well. If the water consumption is large and frequent use reduces the risk of silting.

- If during the year it is not possible to create a pumping of water in a constant mode, then it is recommended to use the well as much as possible in the summer. Perhaps for this purpose it is necessary to turn on the pump for a long time, which will allow water to be driven away, freeing the well from clay and rust.

But at the same time, one should not forget that particles of fine sand can slightly affect the operation of the well, particles of coarse sand do not have such an effect on the quality of its work.

- For water supply, rotary pumps are used, which draw water, if the depth is not more than 8 meters, this leads to the settling of fine particles below this level. To clean such a well, you need to use a vibration pump periodically, while it must be gradually lowered to the very bottom in the process of pumping the device.

- The presence of a filter of a smaller diameter than the main pipe. As a result, the pump can sink 20 to 30 centimeters higher than the top edge of the filter. Over time, the filter is filled with deposits that poorly pass water. Cleaning of this design is done with a vibration pump, the diameter of which is smaller and has a lower water intake.

- The use of a vibration pump, which has an upper water intake.

- In any well, there is always a filter, which is a small hole located in the layer where water comes from. Most often, this is at the bottom of the first pipe.Such a filter passes solid particles passing through these holes and water.

- Sometimes specially made filters for wells are mounted, which are two pipes of different diameters with drilled holes in them. The wire spiral is wound tightly between the pipes. The disadvantage of such a device is that the inner diameter of the main shaft is larger than the inner diameter of the filter, which does not allow the vibration pump to be lowered to the bottom, and makes it difficult to clean it with such a device having standard dimensions.

Before you clean the well, you need to determine the causes of breakdowns.

They may be:

- Sand began to come out of the well, which is the first sign of siltation, but it can appear in large quantities in the water for other reasons.

- Decreased debit, its potential. This is the volume of water restored in the well per hour.

- The water became cloudy, there was an unpleasant smell.

- Problems can arise from irregular operation, mistakes made during drilling and construction. A change in the direction of aquifers, then the cause will be natural.

- Lack of defense mechanisms. In this case, debris may enter the mouth.

- Causes may be lack of maintenance, incorrect operation of the pump.

There are two main types:

- With filter.

- With a straight stem.

You can set up the work of the structure in the following ways:

- Rinse.

- Upgrade.

- Blow out.

How to clean the well from silt with your own hands

There are several ways to clean the well and prevent further silting. There are also special mechanisms and substances for cleaning.

A water compressor can be used, and with its help deposits of sand and silt are easily removed by a jet of water under pressure. There is an air compressor that is used to remove soft particles such as sludge. Another way to clean the well from silt is to blow the pipe along its entire length with a vacuum plug. To clean the well, the so-called explosion is used - an artificially induced short circuit, as a result of which a bottle of gunpowder lowered to the bottom of the well explodes. As a result, the blast breaks the blockage at the bottom of the well, and it is easy to pump it out with a pump along with water.

Acid can be used to clear the blockage, but it must be used with caution, as it can damage the filter or even the pipe itself. Therefore, you must strictly adhere to the instructions and observe the proportions of the solution that are indicated in it. Acid must be injected into the well pipe at one time and left in the well for 2 days, and then pump water until the bottom is completely cleaned

Acid must be injected into the well pipe at one time and left in the well for 2 days, and then pump water until the bottom is completely cleaned.

If your well water comes with sand, this problem needs to be addressed as soon as possible. Silting, sanding - no matter how the professionals call the problem, if you really want to, you can clean your well yourself with some effort. When filled with a creamy viscous substance. It can have a different origin - from mineral to organic. When sanding, as the name of the phenomenon implies, sand passes into the source. As a result, the water from the well is dirty. And such water with sand is suitable only for household needs, and even then not for everyone.

Therefore, it is very important to correct the problem in a timely manner and return the well to its normal state. To do this, you first need to figure out why the water comes with sand

The main causes of clogging of wells for water

Often the well becomes clogged due to damage to the casing

Often the well becomes clogged due to damage to the casing

Sources are silted up in the following cases:

- During installation, the workers forgot to isolate the bottom layer of soil. Usually coarse gravel is used so that the dirt does not rise during the operation of the pump.

- Incorrect pump selection. The vibration type creates strong vibrations, due to which small particles of dirt are set in motion and enter the house along with the liquid. Its residues settle on the mesh filter or in the equipment case.

- Breakage inside the well. There have been cases when using a plastic casing pipe, it was exposed to quicksands - moving sands from the aquifer. At depths below 25 meters, the plastic is ineffective and often bursts, allowing dirt to enter the pipe.

- Wrong well design. When drilling, workers violate the conditions of the project, so the productivity of the source is less than expected.

- Overgrowing of the filter with silt, clay, salt deposits or iron ions.

- Filter breakage due to high water velocity.

- Replacing the sand layer with clay due to ground movements. As a result, the filling of the well deteriorates or the water disappears altogether.

- Incorrect source operation. Silting can occur in the interval of 2 - 3 months if it has not been pumped. Depending on the condition of the filter and the composition of the soil, this process can take up to a year.

Not always poor water supply is associated with the condition of the well. Depreciation of pumping equipment is one of the reasons for the drop in pressure.In submersible units, due to the sanding of the source, the working blades are erased and the productivity drops by 25 - 30%.

Methods for determining well failure

Specialized firms use a video diagnostic method that allows you to view each area on a computer monitor. After that, an estimate is made for the required amount of work. The method is error-free, but only the company's specialists have cameras that can work underwater.

You can independently determine the breakdown only by examining each individual unit - the pump control unit, the unit itself, pipe connections, the well and its components. If water is found in the caisson, the pump may have closed due to depressurization. In the winter season, ice accumulates on the inner walls of the pipes, the operation of the water intake system is disrupted.

Causes of well clogging

To save yourself from frequent cleaning of the well, you need to know exactly the reasons why the water is silting. There are several such reasons:

- irregular water intake;

- poor external insulation;

- installation errors;

- change in the direction of aquifers.

Well cleaning with a pump.

If the cottage is used only in warm season, in winter, the bottom of the well is covered with sand, silt and a layer of rust from metal pipes, which clogs the filters as a result. In such conditions, cleaning should be done as often as possible, otherwise you cannot do without the intervention of professionals.

Particular attention should be paid to protecting the wellhead from debris, and this should be done even during construction.To avoid mistakes during drilling and installation of the water intake system, which are also often the main cause of silting, it is necessary to start building a well only after a thorough study of the technology, or hire an experienced craftsman to work

Cleaning is recommended when the first signs of clogging appear - the presence of sediment in the water tank or a decrease in pressure. The sooner the blockage is cleared, the less time it will take. There are several ways to clean the well, each of which is effective in its own way:

- compressor purge;

- flushing with a pump;

- bailer cleaning;

- chemical cleaning.

Preventive measures to prevent well contamination

- After drilling, flush the borehole with plenty of water until the turbidity disappears.

- Protect the source from contamination by making a cap or installing a caisson. For temporary protection, the shaft can be sealed from above.

- Install the pump in the water intake chamber in accordance with the requirements of the product manufacturer and taking into account the debit of the source.

- Do not use the vibration pump to pump out water. Vibration causes the penetration of small particles of soil into the shaft and siltation of the source. Such devices can be used for a short time, and for long-term operation, install a centrifugal pump in the source.

- The well must be used at all times. If it is operated occasionally, pump out at least once every 2 months at least 100 liters of water.

Cleaning with a bailer

This is the most effective way of cleaning, requiring a lot of time and effort. The bailer allows you to bring even the most neglected wells back to life, clean them of silt and small stones

You can make the bailer yourself, using improvised materials and fitting it to the size of the well. But you should pay attention to the fact that you need to clean not only the well itself, but also the water. It is obligatory to clean water from manganese and iron, because the deposits of these impurities have a very detrimental effect on human health.

Borehole cleaning

Making a bailer

If you intend to make a bailer yourself, you will need a metal pipe 70 cm long and Ø5 cm. You also need to find a metal ball Ø4 cm. Make the bottom of the pipe in the form of a thick washer.

It is desirable that the bottom of the washer looks like a return funnel. Next, take a washer and weld it to the bottom of the pipe, and attach a metal grate on top so that the ball cannot pop out. Weld an arcuate handle above the grate, a cable will be attached to it in the future. To increase the efficiency of the bailer, attach several metal “fangs” near the washer, which will loosen the silt.

But we did not mention one important aspect - where to find such a ball so that it fits the size of the bailer? To get the ball, you can:

- by ordering its manufacture to a professional (blacksmith or locksmith);

- buying it in the store;

- by doing it by hand.

Let's consider the last option in more detail. To make a ball, buy a children's rubber ball that is suitable in size. You also buy hunting shot, the caliber does not matter. Cut the ball into two equal parts and fill each of them with shot, previously mixed with waterproof glue. When the halves are dry, carefully sand them and connect them with the same glue.The reliability and durability of the bailer will depend on the quality of the glue. If you were unable to buy a fraction, then it can be replaced with bearing balls.

Bailer

Bailer cleaning technology

Fasten the bailer to a metal cable and lower it into the well. Having reached the bottom, raise the bailer about half a meter, then sharply lower it. The potential energy of the ball will cause it to remain in its original position, while the lower hole will be open and dirty water and silt will get into it. Soon the ball under its own weight will fall and close the hole. To fill the bailer ½, repeat the procedure about four times. Then slowly pull out the bailer and empty it.

With each such lift, you will remove up to 0.5 kg of dirt and silt from the well.

Video

Practical cleaning tips you can get wells using a vibration pump, a homemade bailer and a compressor by watching the following videos:

Found an error? Select the text with the mouse and click:

ctrl

+

Enter

Do you know that:

Oklahoma farmer Carl Burns developed an unusual variety of colorful corn called Rainbow Corn. The grains on each cob are of different colors and shades: brown, pink, purple, blue, green, etc. This result was achieved through many years of selection of the most colored ordinary varieties and their crossing.

Professional flushing of wells

Direct flush. The supply of fluid for flushing the well is carried out under pressure directly into the wellbore (in this case, silt and clay are washed out through the annulus).

There is also a backwash. In this case, the liquid is supplied, on the contrary, into the annulus and rises up the wellbore with the pressure of water.The method is effective against mechanical impurities, silt, clay, sand. Such cleaning of wells is most often effective after a long idle time of the water intake.

Replacing the filter and installing a new pump to replace the failed one is not an option. Otherwise, the situation will repeat itself. Well flushing is the best option. Terms - from 1 day. Prices for such cleaning of wells from silt and sand start at 3,000 rubles. More details in the section prices for cleaning wells

To calculate the flushing of artesian wells for water at your site, please contact our company. We will promptly process the application and send you a detailed answer.

Methods for self-cleaning from silt and sand

Well flushing with two pumps

There are many ways to clean a downhole rig with your own hands, but any of them belong to three technologies: flushing, pumping or blowing.

Pumping out by pumping apparatus

Cleaning a well with your own hands using a vibration pump is one of the simplest methods. Lower the pressure device to the bottom and start it. All particles of debris that accumulated at the bottom of the mine will rise and be brought out.

This process is not fast, since the casing of the pumping unit is strongly heated from long work, and the device must be stopped from time to time. You also need to periodically run clean water through the system.

The use of vibropumps is possible only in water intakes with a depth of 10 meters or more. It is possible to clean the well with an ordinary pump if the water layer lies no deeper than 40 meters.

Flushing with pressure equipment

There is another method using pressure equipment, but technologically being flushing. This will require two pumps.Do-it-yourself washing of a well from sand is carried out using the following technology:

- A deep pressure unit with a lower water intake is lowered to the bottom. It is needed to pump out the liquid.

- The second pump is used to supply a water stream that agitates the deposits. The liquid can be supplied both from a pre-filled container, and from another water supply source.

- With a constant supply of fresh water, the well structure is washed - all suspensions, even fixed on the walls of the mine, are separated and brought out.

The hose used for drainage must be shaken systematically to avoid damage to the pump.

Application of the bailer

Self-cleaning of water intake structures can be performed using a bailer. This technique is used if the pollution is not too strong, and the depth of the mine is up to 25 meters.

A bailer is a pipe segment on a cable with a mesh and a ball inside.

The download itself is done like this:

- The device is directed to the bottom, and then lifted to a height of 50-70 cm and thrown sharply.

- Water enters the inner part of the pipe under pressure, and the ball goes first up and then down and closes the hole.

- Such actions are performed several times.

- Then the device is pulled out of the shaft and cleaned of dirt.

This simple device can be created with your own hands or bought at a hardware store. It should be noted that one person will not be able to cope with the work. You will need a winch and at least two adult men.

Purge water intake structure

A method that allows you to clean the well from sand and silt on your own, created on the basis of the laws of Archimedes. A well shaft is a reservoir of water.You will need to lower a pipe into it, from the bottom of which air under high pressure comes out through a compressor. As a result, an air-foam mixture is formed in the mine. Together with the water flow, all the garbage accumulated in it rises.

The process of purification by means of a compressor requires constant monitoring. The purge is suspended at the moment when the outflow of water has stopped.

If the well is deep, it is better to use an airlift for blowing - a specialized pneumatic lift that uses compressed air or technical gas.

Chemical cleaning method

If the previous methods did not practically increase the flow rate of the well, then the filters are stuck with hardened iron and lime suspensions. If it is impossible to replace them, it is worth resorting to extreme measures - acid cleaning. This option involves pouring battery acid used for vehicles on the bottom of a well emptied by a pump.

The outlet is tightly closed with a plug and the water intake structure is left for a couple of days. After that, water is pumped out several times. Even after these procedures, it is not suitable for drinking and cooking for a month. The liquid is taken only for technical needs.

Septic tanks with soil aftertreatment

A cheap, simple and advanced analogue of concrete wells are plastic septic tanks with soil aftertreatment. They usually look like barrel-shaped tanks with lids. When choosing a factory septic tank, the number of tanks, the volume and the number of chambers in them should be taken into account. So, at a flow rate of 1 cubic meter of water per day, a single-chamber tank is enough, at a flow rate of 5 cubic meters per day - a two-chamber tank, and at a flow rate above 8 cubic meters per day - a three-chamber tank.The more compartments, the better the wastewater treatment.

Multi-chamber installations provide wastewater treatment for their subsequent discharge into ditches

How it works? In the three-chamber model, wastewater first enters the first chamber, and the heavy fractions sink to the bottom. After some time, they turn into silt. Light particles, together with water, enter the second chamber, where they are processed by bacteria. The purified composition is pumped into the third chamber. There, a filter and a special antiseptic mesh with colonies of bacteria are waiting for him.

Further, purified by 60-70% water enters the filtration field, which is a trench with crushed stone, in which perforated pipes or an infiltrator are laid. Here, wastewater is additionally treated with aerobic bacteria, after which the liquid is drained into a drainage ditch. An integral part of such a treatment system is ventilation pipes (they are needed to provide air access and maintain the vital activity of aerobic bacteria).

It looks like a septic tank with soil aftertreatment in the form of a multi-chamber installation and a filtration field with perforated pipes

How good are these septic tanks? The fact that the water obtained at the end of cleaning can be drained into drainage ditches (but it cannot be used for irrigation and drinking!), For the full operation of the system, energy sources are not needed, and the container needs to be cleaned no more than once every 1-3 years.

For a family of 2-3 people, a single-chamber septic tank with a production volume of several cubic meters is enough.

The disadvantages of septic tanks with soil aftertreatment are:

- inability to use purified water for drinking and irrigation;

- within a radius of 3 m from the filtration field, you cannot grow vegetables and plant fruit trees and shrubs (for a small area, this can play a fatal role).

It should also be remembered that in areas with heavy soil or a high level of groundwater, such a septic tank will not “work”. In order for the system to function, you will have to install an additional container with a drainage pump and build a special dome for additional water treatment on the soil surface. It will be very expensive and ineffective.

Thus, wastewater is still a serious "headache" for owners of private houses. There are not so many purification methods, after which recycled water can be drunk, and they are not cheap. Still, it is easier to dispose of wastewater in small doses using modern environmentally friendly technologies.

Cleaning Recommendations

It may be necessary to use several methods during the cleaning process before a result is obtained. It is usually recommended to start with the simplest method - pumping with a vibration pump. Flushing is done first only when the source is almost dry. If a lot of sand and other deposits have accumulated at the bottom of the well, the use of a bailer is relevant, but this method is applicable only for wells made of steel casing. To clean buildings equipped with plastic pipes, only blowing is used. Water hammer technology is used in particularly difficult cases, when all other methods turned out to be ineffective, there is no sand at the bottom of the well, but water never enters it.

The presence of water on the site solves the issues of watering cultivated plants and gives hope for a harvest

The presence of water on the site solves the issues of watering cultivated plants and gives hope for a harvest

In order not to damage the casing or well filter during cleaning, it is necessary to follow the safety rules:

- do not use cleaning equipment that is larger than the casing diameter;

- personally control the cleaning process, do not leave pumps and devices unattended;

- if the cleaning is inefficient, plastic or metal parts are found in the pumped water, it is urgent to interrupt the process and seek help from specialists.

First compressor cleaning immediately after drilling

As soon as the well is drilled, it must immediately be cleaned, because not only water will flow into the pipes from the aquifer, but also all the debris that is in it. Installed filters cannot trap the smallest particles, from which the water becomes cloudy and unsuitable for drinking. Depending on the depth of the well, the flushing process after drilling can take from 10 hours to several weeks.

If drilling was carried out by specialists, then they flush the system using a flushing unit. If you drilled the well yourself, you will also have to clean it of dirt yourself. To do this, you will need a compressor with a capacity of at least 12 atm and several pipes that must be connected to each other and inserted into the well so that they reach the bottom. In this case, the diameter of the pipes must be smaller than the diameter of the well so that there is an empty space between them.

The compressor forces air into the well at high pressure, so dirty water can fly out at high speed and splatter everything around

Let's consider step by step how to clean the well yourself using a compressor:

- We insert pipes into the well.It is desirable to strengthen the top with a rope, because under high water pressure the structure can bulge upward.

- We put a vacuum adapter on the pipe, fixing it with self-tapping screws.

- Pump up the compressor to maximum pressure.

- We put the compressor hose on the adapter.

- We turn on the unit and release all the air into the well.

- We repeat the pumping several times.

Air under pressure will push dirty water through the annulus. Therefore, do not be surprised if everything around is filled with mud.

If air does not achieve clean water, repeat the procedure, replacing the air purge with a water purge, using the same piping system with an adapter. To do this, find some large barrel, put it next to the compressor and fill it with water.

Using a water compressor, drive this water at maximum pressure into the well. But be careful, because heaps of dirt pushed out by this water will fly at you. Clean the well until the tank is dry. Then, flushing should be repeated until dirt is no longer ejected from the annulus.

With the help of blowing and flushing, the well is cleaned of silt or sand. But salt deposits on the filter cannot be knocked out in this way.

1 Why is the water source clogged

Pollution of wells in the country is most often observed due to non-compliance rules for their drilling and development. During the construction of wells follows:

- Strictly adhere to the recommended drilling technology, monitor the integrity of the filter and the tightness of the casing.

- Protect the source with a caisson, head from the penetration of debris and surface water into it.

- Flush the well after completion of drilling activities until a clean liquid appears.

- Choosing the right submersible pump And then mount it at the optimum height.

It is undesirable to use vibration pumping equipment for water supply. It contributes to the silting of the soil adjacent to the well and causes sand and clay to enter the source.

When too much of this sediment is collected, the cells of the slotted, perforated or mesh filter and the pores in the aquifer become clogged. It becomes more and more difficult for liquids to move along the mine shaft. As a result, the source is silted up.

If you use the well year-round, the processes described above are much slower. Even old springs with constant operation silt up in 10-15 years, and with seasonal operation - literally in 2-3 years.

In what situations it may be necessary to disinfect the water in the well

One of the causes of well pollution is a violation of the tightness of the walls.

Disinfection of the well includes several stages: cleaning the source shaft and disinfecting the contents. All sources without exception, regardless of the frequency of use and their purpose, must be cleaned.

The main reasons why you need to regularly disinfect:

- the presence of debris, dust and other third-party objects in the well;

- flooding as a result of the spring flood;

- the formation of mucus, fungal and salt deposits, mold on the walls of the mine;

- falling into the source of melt, rain or waste water;

- active use of the well, as a result of which subsidence of the aquifer of the soil is observed;

- penetration into the soil of sewage, products of processing of agricultural and industrial enterprises;

- bodies of dead animals and birds getting into the well.

Peculiarities

A well is a source of water supply not only for a private house, but also for a summer cottage. In regions where there is no centralized water supply, an individual source of drinking water will not only provide high-quality water supply to a dwelling, but will also make it possible to irrigate agricultural land. To obtain high-quality water in the required quantities, the hydraulic structure requires regular preventive and repair work.

Experts identify several signs of clogging of the water source:

- a significant decrease in the volume and pressure of the raised water;

- frequent pressure drops in the system;

- the presence of particles of sand and silt in the water;

- lack of water in the well.

Before starting work on cleaning the well, it is necessary to determine the cause of the malfunction and take measures to eliminate it.

There are several reasons:

- violation of technological standards during drilling and well installation;

- irregular use of the aquifer system;

- natural movement of underground layers of the earth;

- changes in the movement of underground sources;

- installation of low-quality protective structures against the penetration of contaminants from the surface;

- clogging of water filtration equipment;

- weak operation of the pumping unit;

- irregular preventive maintenance.

For high-quality cleaning of the well, experts recommend considering the following parameters:

- soil type;

- well depth;

- casing size;

- productivity of the aquifer;

- availability of power supply systems;

- availability of pumping units and the necessary tools.