- Why wells clog

- How to prevent clogging of the well

- Ways to solve the problem

- Jamming mechanism

- Causes of blockages

- Causes of clogging

- Causes of silting

- Necessary characteristics of the well for the selection of the optimal method of sand removal

- What are we cleaning from?

- sanding

- Silting

- Common mistakes when flushing a well

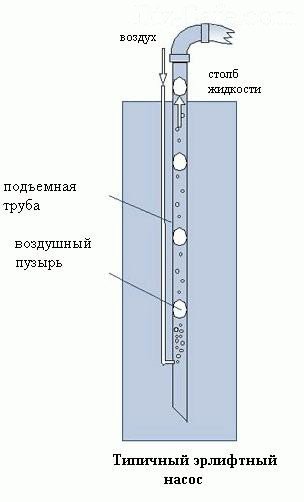

- Method 5 using an airlift

- Do it yourself

- Possible causes of clogging

- No. 1 - sand penetration into the casing

- No. 2 - siltation of a non-operating well

- Conclusions and useful video on the topic

Why wells clog

Cleaning the well is required if it is silted up. A number of reasons may contribute to this.

- The case may be that the pipe was not installed correctly during drilling. The section of the pipe where the water should enter is outside the deep water layer.

- A well may become silted up if it has a high depth vibratory pump equipped with an overhead intake.

- If the pumping of water is weak, then dirt, silt, and stones accumulate in the well. Soon all this is rammed, which significantly limits the water supply. Therefore, if you often use the well and consume a lot of water, the likelihood of silting is reduced.

- If the pipe diameter is larger than the filter diameter, then the pump will not be able to go below a certain depth - this is about 20-25 cm above the filter.

- Finally, siltation can be caused by a rotary pump installed at a depth of less than 10 m. This will cause various particles to settle below the filter and compact there.

How to prevent clogging of the well

All wells have a limited service life. Owners of such water supply systems have to face different problems. The worst thing that can happen is the depletion of the water carrier. In this case, it is necessary to drill a new well or deepen an existing one. This work requires considerable physical and financial costs.

Another thing is if the source is simply clogged. It is easier and more economical to prevent such a nuisance than to turn to the services of specialists later or look for ways to clean the well.

You can extend the life of the source if you follow the following recommendations for well construction:

- Drilling must be carried out in accordance with the technology. In this case, it is necessary to control the integrity of the filter element and the tightness of the pipeline.

- After drilling is completed, the well should be thoroughly flushed.

- From time to time, the well must be protected from dirt and water from the surface. To do this, it is recommended to install a cap and caisson. The top part of the casing can only be used as a temporary solution to maintain high water quality.

- Before use, you must correctly select and install a submersible pump, guided by the required height and debit of the water source.

- It is undesirable to use vibration-type pumping units for supplying liquid.When the equipment vibrates in the siege, it can cause dirt to enter the well. Sand penetrates the hole gradually, accumulating in the source and worsening its condition.

- The water source should not be idle. Experts recommend pumping out about 100 liters of liquid at least twice a month.

By following these rules, you can extend the life of the water source and delay its maintenance and cleaning.

Ways to solve the problem

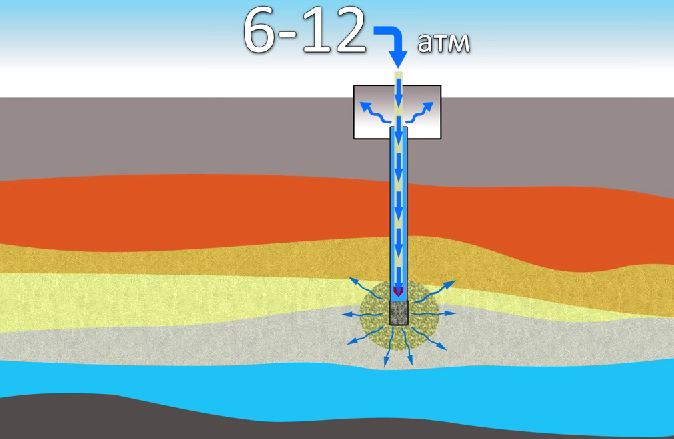

Experts identify three principles for cleaning wells:

- Pumping is a simple way to flush the well with a pump. The use of this method is possible only when the layer of sand has not completely covered the horizontal parts of the filter.

- Flushing with circulating fluid - supplying water through a hose into a well at high pressure. Sand and clay under the action of the jet is washed away and the surface rises through the production pipe. Disadvantages - the possibility of damage to the filter, a large volume of circulating water, the release of a large amount of sand.

- Blowing with compressed air is a coarse cleaning system, carried out by an airlift. Airlift is a special apparatus consisting of a compressor and a hose through which air is supplied to the well at a pressure of 10 to 15 atm. A high pressure is created in the barrel, pushing out particles of silt and sand. This method is suitable for wells with a depth of 30 to 40 m.

These principles are the basis for a large number of methods for cleaning wells.

Jamming mechanism

Having connected two rods together, it is necessary to install worm screws on them and lower the structure to the bottom of the well. There is always a gutter at the bottom of the well, into which you need to insert screws and advance to the end of the downpipe

Additional rods are added to the structure as needed, however it is important to remember that each of them can only be turned clockwise one turn to prevent unscrewing the structure

Under the influence of slow forward movements of the drain cleaner, the plug will move along the drain, as evidenced by the resumption of water flow and the appearance of water in the nearest inspection well. However, this is not the end of sewer cleaning. With the help of the remaining nozzles, it is necessary to thoroughly clean the drain pipe - its underground section, in order to prevent a recurrence of the situation in the near future.

If everything is done correctly, the emergency gang will probably not be needed, besides, this method is quite simple and does not take much time, if, of course, there is a drain cleaner at hand. If there were no special equipment and devices, perhaps the emergency gang will be the best solution until the sewer drains are completely clogged?

Causes of blockages

Water coming from the central water supply does not always require additional treatment. Usually special services take care of this, and people can simply put the filter on the tap. But the water and the well itself are not automatically cleaned by services. People need to independently control the quality of the liquid and get rid of sand impurities in it.

Before cleaning the well, you should study the theory well

Clogging can occur for several reasons:

- Intermittent use. Summer residents often face this. In summer, they use water more often than in autumn or spring, and in winter they do not take water at all. Without using water all winter, sediment forms in it and dirt accumulates.This leads to clogged filters.

- Various environmental debris (leaves, sand, sediment mixed with dust) can get into the water.

- If the edges of the water intake source began to collapse, and debris began to enter the water through the mouth.

- Incorrect installation or use (maintenance cleaning has not been carried out for a long time). The filter may become silted if its diameter is smaller than that of the pipe.

- Soil mobility.

Cleaning is possible in several ways, using additional equipment or solutions.

Causes of clogging

The most common option is an error when drilling the well itself and incorrect installation of well rings. Moreover, the part of the hole intended for water inflow is located in a place where the liquid enters weakly or exits outside the aquifer.

The next reason is that the filter for purifying water from a well does not cope with its function. Usually devices are installed in wells, some of which are mounted only superficially. This means that lime litter, silt and iron particles settle at the bottom. Over time, the dirt is compressed and blocks the access of water to the surface.

The well can become clogged if an ordinary filtering device is smaller in diameter than the circumference of the pipe. In this case, the pump can only be lowered 30 cm above the filter. A rotary water pump for a well can cause heavy pollution. Due to its limited activity (10 m deep), the particles settle on the bottom, creating a blockage.

Insufficient filtration is the main contributor to well contamination. But even the most powerful filter is not able to capture the smallest particles that cause clogging.From time to time the borehole will need to be cleaned. But in order to more or less extend the period of action, a coarse water filter with two pipes is used. In this case, you will have to temporarily remove the pump itself. In addition, the device is not suitable for too deep wells.

Causes of silting

An alarm signal that should alert the owner of the device is a decrease in water pressure. After that, a brief stagnation is usually formed, accompanied by a characteristic gurgling, then muddy water is ejected and, as a result, the system stops working.

Silting occurs for several reasons:

- When drilling a well, the installation of the pipe was performed incorrectly. Not in the aquifer or in the weakly aquifer is the place where water enters the device - a waste during drilling.

- The internal arrangement of the structure also plays an important role. Due to the leakage of casing pipes, grains of sand enter the source from the side and from above through the cracks. Thus, the source is filled with sand.

- There is little water coming from the well. Silting occurs due to sedimentation at the bottom of the system of silt, small particles of clay and rust from the pipe, they are gradually compacted, which reduces the flow rate of the well. If the water consumption is large and frequent use reduces the risk of silting.

- If during the year it is not possible to create a pumping of water in a constant mode, then it is recommended to use the well as much as possible in the summer. Perhaps for this purpose it is necessary to turn on the pump for a long time, which will allow water to be driven away, freeing the well from clay and rust.

But at the same time, one should not forget that particles of fine sand can slightly affect the operation of the well, particles of coarse sand do not have such an effect on the quality of its work.

- For water supply, rotary pumps are used, which draw water, if the depth is not more than 8 meters, this leads to the settling of fine particles below this level. To clean such a well, you need to use a vibration pump periodically, while it must be gradually lowered to the very bottom in the process of pumping the device.

- The presence of a filter of a smaller diameter than the main pipe. As a result, the pump can sink 20 to 30 centimeters higher than the top edge of the filter. Over time, the filter is filled with deposits that poorly pass water. Cleaning of this design is done with a vibration pump, the diameter of which is smaller and has a lower water intake.

- The use of a vibration pump, which has an upper water intake.

- In any well, there is always a filter, which is a small hole located in the layer where water comes from. Most often, this is at the bottom of the first pipe. Such a filter passes solid particles passing through these holes and water.

- Sometimes specially made filters for wells are mounted, which are two pipes of different diameters with drilled holes in them. The wire spiral is wound tightly between the pipes. The disadvantage of such a device is that the inner diameter of the main shaft is larger than the inner diameter of the filter, which does not allow the vibration pump to be lowered to the bottom, and makes it difficult to clean it with such a device having standard dimensions.

Before you clean the well, you need to determine the causes of breakdowns.

They may be:

- Sand began to come out of the well, which is the first sign of siltation, but it can appear in large quantities in the water for other reasons.

- Decreased debit, its potential.This is the volume of water restored in the well per hour.

- The water became cloudy, there was an unpleasant smell.

- Problems can arise from irregular operation, mistakes made during drilling and construction. A change in the direction of aquifers, then the cause will be natural.

- Lack of defense mechanisms. In this case, debris may enter the mouth.

- Causes may be lack of maintenance, incorrect operation of the pump.

There are two main types:

- With filter.

- With a straight stem.

You can set up the work of the structure in the following ways:

- Rinse.

- Upgrade.

- Blow out.

Necessary characteristics of the well for the selection of the optimal method of sand removal

To obtain a guaranteed result, it is necessary to know some well parameters: depth, flow rate, water level, type of well device (straight bore or with a filter whose inner diameter is smaller than the diameter of the main bore). All this data can be found in the well passport, which is issued by some companies. The choice of a submersible pump with which cleaning will take place depends on the indicators.

The flow rate of the well must exceed the productivity of the vibrating pump. If there is no well passport, then the well flow rate can be calculated independently. This will require a measuring tank, the volume of which is known. Using a pump lowered to the very bottom, pump out all the water, wait for the water level to recover and repeat the procedure again. By dividing the volume of water produced by the time it took to pump out, we obtain the necessary data.

The table below will help determine the performance of vibration pumps using popular models as an example:

| Name of the electric pump | Cost (in rubles) | Depth (in meters) | Productivity (liters per second) | Productivity (liters per hour) |

|---|---|---|---|---|

| Typhoon-2 | 2200 | 40 | 0,25 | 900 |

| Creek-1 | 1000 | 40 | 0,12 | 432 |

| Aquarius-3 | 1800 | 40 | 0,12 | 432 |

| Shower | 2100 | 40 | 0,16 | 576 |

All data for the table (with the exception of the last column) were taken from the accompanying documentation for the indicated models. Knowing the performance of these pumps, you can easily choose a model that will help clean the well without the risk of damaging it.

What are we cleaning from?

In order to choose an effective way to clean the well and quickly eliminate the problem, it is necessary to accurately determine the type of contamination. Experts note several types of pollution, each of which should be familiarized.

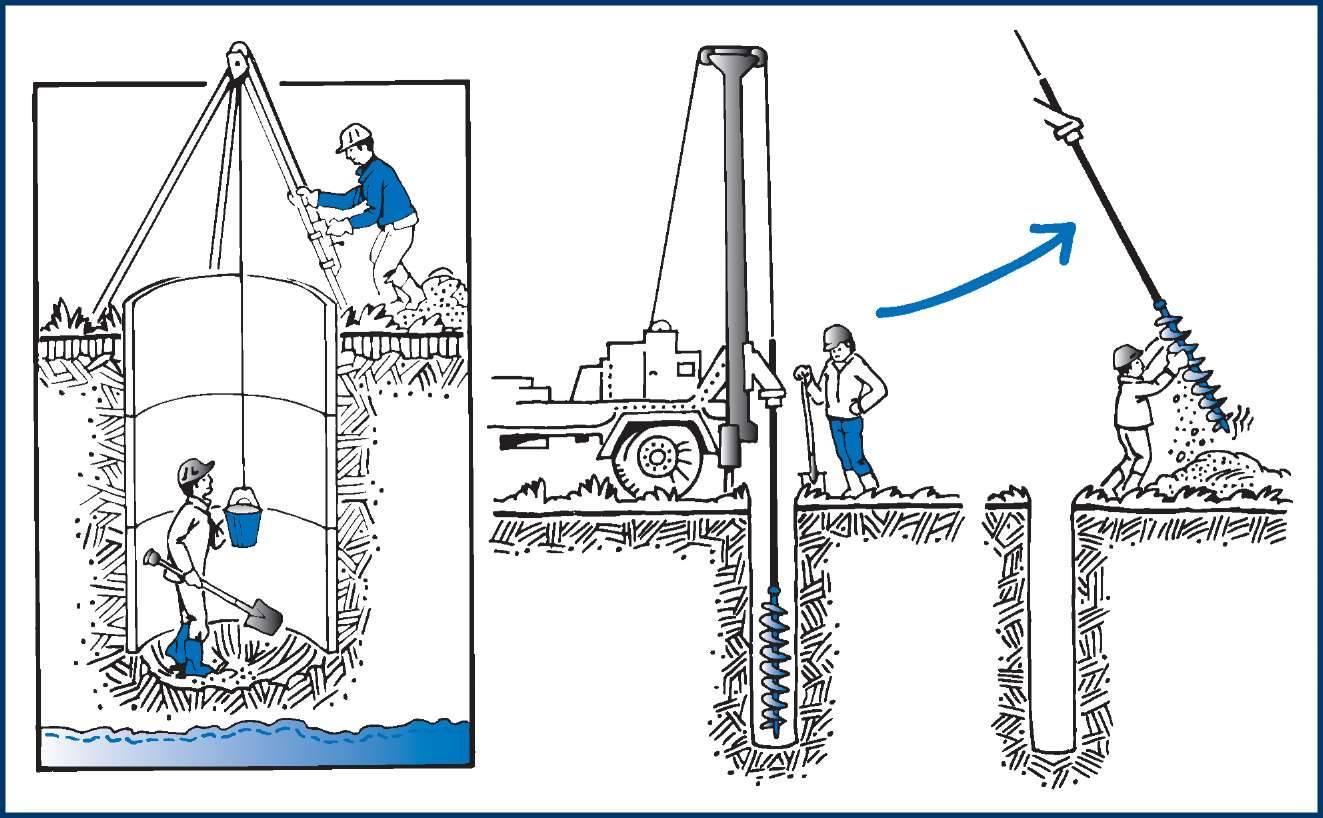

sanding

This is the main problem with shallow sand wells, in which water passes through a layer of sand and gravel.

The reasons:

- leaky structure that allows sand to pass from the soil surface;

- large cells in the filter;

- deformation or breakage of the filter;

- lack of tightness of casing sections;

- corrosion of metal pipes;

- poor-quality installation of the structure (poorly twisted thread, violation of the welding technology of the structure).

Silting

Clogging of pores in the aquifer and filter cells with clay particles, rust, sedimentary rocks and calcium deposits during irregular use of the well. Silting leads to a decrease in the volume of water, and after a short period of time to complete drying of the source.Regular pumping of water makes it possible to use wells for several decades, and timely cleaning of filters from silt will increase the volume of water and prevent clogging of the water supply system.

Special attention should be paid to the buildup process. Swinging - cleaning the bottom of the well after drilling from lime and rusty water

The first well water contains high levels of contaminants and is undrinkable. Refusal to clean up the source will lead to siltation. Professional pumping will remove all particles of sand and silt from the aquifer. The minimum amount of time required for this process is 14 hours and depends on the type of soil.

Errors when cleaning a new well:

- incorrect location of the pumping unit;

- draining dirty water near the well;

- thin cord for the pump.

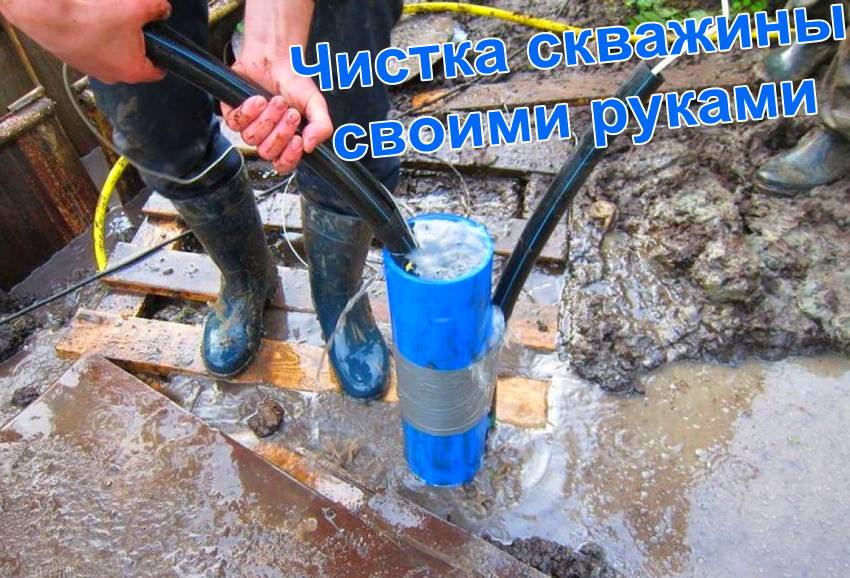

Common mistakes when flushing a well

Inexperienced well owners often make the mistake of ignoring well flushing after drilling is complete. As a result, the water in the working remains untreated, which makes its use limited. One of the most common mistakes when flushing a well with a pump is its incorrect hanging height.

The pump must not be allowed to touch the bottom, in which case the cleaning will not be effective: the pump will not be able to capture silt particles under its body. As a result, silt will remain at the bottom of the well, blocking access to the aquifer and deteriorating water quality.

In addition, a too low position of the pump can lead to the fact that the equipment "burrows" in the sludge and it will be problematic to get it out of there. It also happens that the pump gets stuck in the wellbore.This can be avoided if a thin but strong cable is used for immersion, and when pulling the pump back, do not make sudden movements, but gently swing the cable to lift the pump from the well.

Another mistake is improperly organized drainage. Contaminated water coming from the well should be diverted as far as possible from the mouth. Otherwise, there is a risk that it will again enter the source, which will lead to an increase in the flushing period, and hence additional financial costs. For the organization of drainage, it is best to use durable fire hoses.

It is important to flush the well before clean water comes out of it. Putting an uncleaned well into operation is prohibited! This will lead to damage to pumping equipment and problems in the operation of the well in the future.

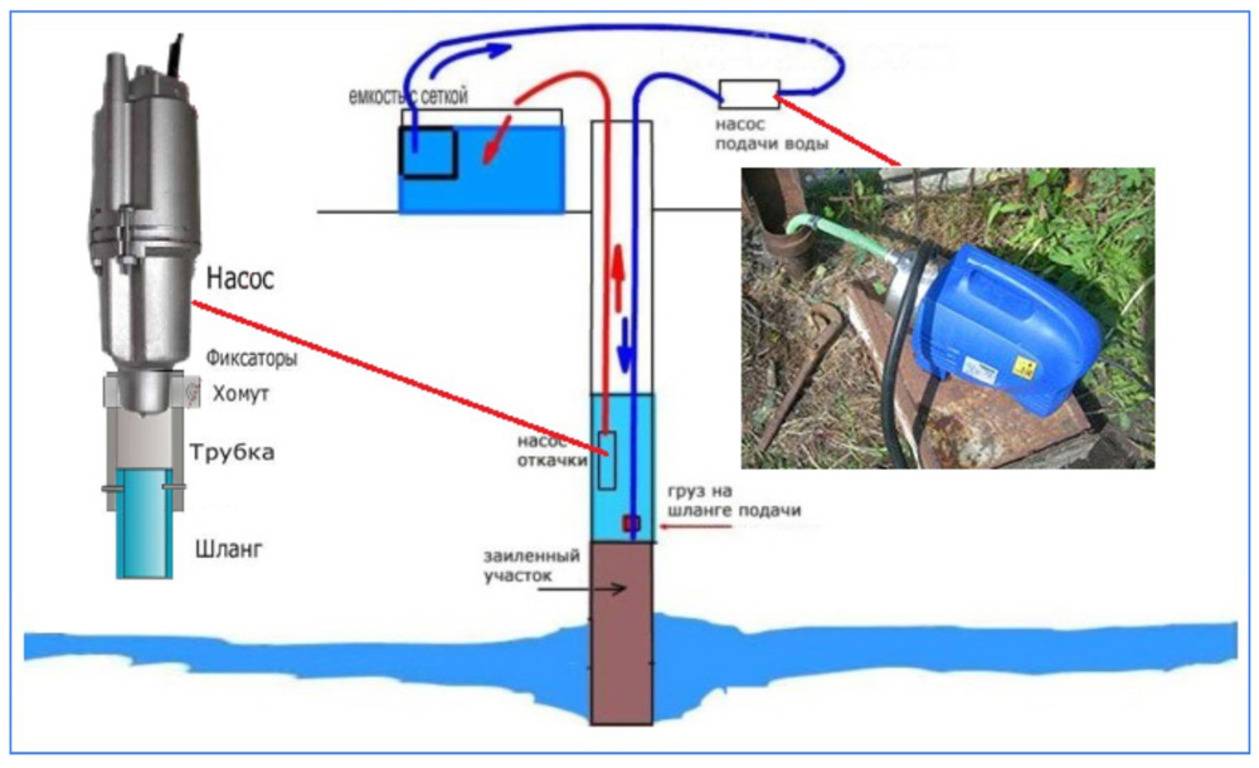

Method 5 using an airlift

How to clean a well in the country from sand and silt using an airlift? The method consists in using the law of Archimedes. What exactly is a well? This is a container of water. A water-lifting pipe is placed in it, into the lower part of which compressed air is supplied by means of an air compressor. A mixture of air and foam is formed in the pipe. The water column presses from below on the riser pipe - the process begins, it must be controlled so that the water in the well being cleaned does not run out.

Since the bottom of the pipe is located almost on the sand, sand with water rises and is absorbed by the riser pipe. The task of the person involved in cleaning is to monitor the water level in the well.

Cleaning with an airlift pump is also an effective way. Compressed air is supplied under pressure, at the bottom of the pipe, silt, water, small stones rise, are absorbed by the pipe and are pushed to the surface

As a rule, the wells in the areas are shallow, and a standard vibratory pump or bailer is suitable for cleaning. If the depth of the well is significant, you can try the mechanized cleaning method. When using a fire truck hose, cleaning the well will be very fast, but it is expensive. Unfortunately, this method often leads to damage, and this entails additional costs. If the main source of water in your country house is a well, choose a cleaning method that is convenient for you and periodically clean it so that there are no interruptions in the water supply, because water in the country is the main condition for a comfortable stay.

Do it yourself

Do-it-yourself well cleaning is not the most reliable method, but most of the above progressive methods are too expensive. In addition, this requires machines with special equipment. Fortunately, you can make cleaning equipment with your own hands, but they will only get rid of silt and sand.

Do-it-yourself bailer for cleaning the well with your own hands is the easiest to make. To do this, you need a metal pipe 60 cm long and 50 mm in diameter, a metal ball (40 mm in diameter). The bottom of the pipe should be very thick with a funnel-like appearance inside, and the seat should match the circumference of the ball.

Instructions for making the device exist in a million copies, in which case you can view the manual on the video. A washer should be welded to the bottom of the pipe, and a grate should be attached at the inlet so that the ball does not fly out. It is also necessary to weld handles to the body from the outside, to which the cables for lowering will be tied.It will not be superfluous if a kind of fangs are welded to the bottom of the bailer, thanks to which it will be more efficient to knock down silt and sand at the bottom.

Before you clean the well with your own hands using such a home-made apparatus, you need to securely attach the cable to the winch, and fix it to the ground

You need to lower the device into your well very carefully and drop it sharply only 40 cm from the bottom. This action is repeated 4 times, and then all the accumulated dirt rises to the surface. If it still remains in the well, you need to make 2 more approaches.

If it still remains in the well, you need to make 2 more approaches.

Purification of water from a well in a country house can be carried out using a vibration pump that can only pull the liquid out. The method is laborious, lengthy, but quite simple and affordable. The principle of operation is that the water at the bottom of the well needs to be stirred up. To do this, it is necessary to attach an iron pin to the cable with a nut screwed to it. This design will serve as a baking powder.

To start the process of cleaning water from a well with your own hands, you should throw a pin and stir up bottom deposits. Then the pump instantly lowers, after which it is necessary to pump out the liquid until it comes out clean. The throw-in process must be repeated several times.

Possible causes of clogging

It is worth mentioning the types of clogging of wells, this will help identify the causes of problems and determine how to properly clean the well with your own hands:

No. 1 - sand penetration into the casing

"Sanding" is a problem encountered in shallow sand wells where the aquifer is located in a sand and gravel layer.

In a well-arranged well, sand penetrates into the casing in a small amount. If the performance of the source decreases, and grains of sand appear in the water, one of the following occurs:

- Sand penetrates from the surface - the cap, the caisson is leaky.

- The filter is irrationally selected, the cells are too large.

- The integrity of the filter has been violated.

- The tightness between the casing sections is broken. The thread is not fully tightened, the welding is poor-quality, corrosion has "eaten" a hole in the steel casing, mechanical damage to the plastic one.

It is not possible to eliminate leaks that appear inside the well. Fine sand constantly breaks through the filter, but it is also easier to remove it, it is partially washed out when the water rises.

Worse, if coarse sand penetrates into the well, over time the source may "swim"

That is why special attention should be paid to the quality of installation of casing elements and the selection of a filter.

The installation of a sand separator in the casing pipe significantly reduces the sanding of the filter and extends the service life of the well on the sand

No. 2 - siltation of a non-operating well

Over time, the smallest particles of clay, rust, calcium deposits, sedimentary rocks accumulate in the thickness of the soil in the filter zone.

When their number becomes too large, the pores in the aquifer and the cells of the mesh (perforated, slotted) filter become clogged, it becomes more difficult for water to penetrate through the mine shaft.

The flow rate of the well falls, it “silts up” up to the complete disappearance of water. In a source that is used regularly, the process is slow, stretching over decades. Without regular pumping, a well can become silted up in a year or two.

If the well is cleaned of silt in a timely manner, without waiting until it dries up completely, it is likely to give the source a “second life”. Water will be supplied in sufficient volume to supply a private house.

Water entering the well through the filter carries with it small particles of silt. So there is silting of the soil near the filter. Calcium salts also accumulate in the suction zone if the water hardness is high.

Conclusions and useful video on the topic

In conclusion, a useful video that shows step by step the available technique for flushing a clogged well:

Note that cleaning a well from sand and silt can be a very difficult task. And it’s not a fact that it will be possible to do it on our own at all.

And carelessly wielding mechanical projectiles, you can generally cause significant damage to the water source

At the same time, there is a special technique that very effectively and to a large extent restores the characteristics of wells.

Do you have personal experience in well cleaning on site? Want to share actionable methods or ask questions about a topic? Please leave a feedback form below.