- General characteristics of the Grundfos circulation pump

- A bit of history

- 1 Advantages and disadvantages of the UPS line

- 1.1 Range of equipment

- Application and purpose

- The lineup

- Design and application features

- Stages and rules of repair

- Service life of the heating pump

- We extend the service life - the secrets of specialists

- Summarizing

- Features and benefits of pumps

- Installation

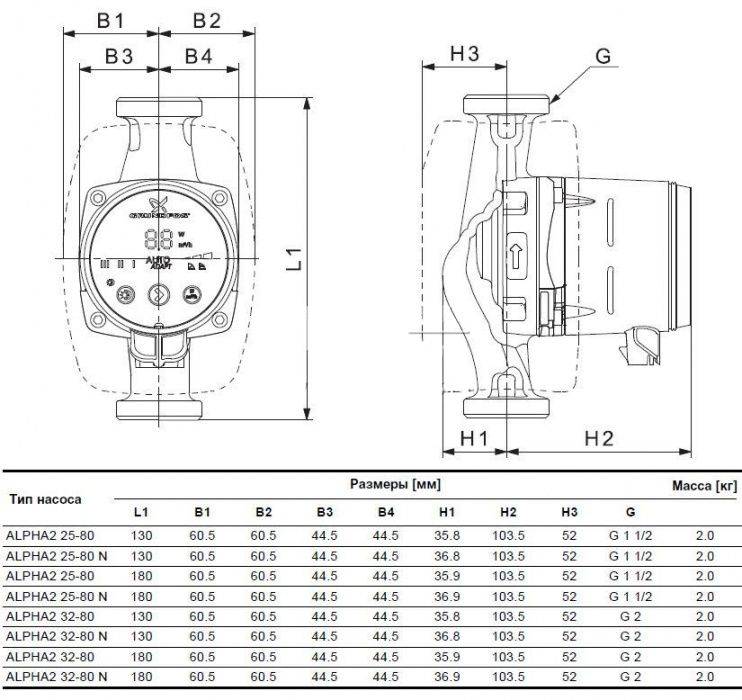

- 2 Model range

General characteristics of the Grundfos circulation pump

The company produces a wide range of units suitable for use in the heating system, hot water supply, hot water recirculation.

Grundfos brand products work with solid fuel boilers (they have the largest temperature differences), gas, electricity, and even in projects with innovative heat sources: solar energy or a heat pump.

The advantages of Grundfos products are reliability, reliability, and versatility.

The only downside is the relatively high price of the product. The cost of one unit depends on the power, configuration, performance and ranges from 5 to 70 thousand rubles

Therefore, it is important to choose the right system configuration. Given the service life and reliability of the design, investments in such equipment are fully justified /

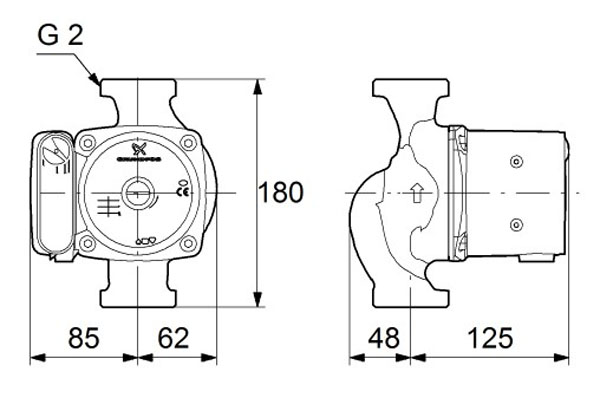

The company produces models with flange mounting and traditional screw: American. The compact design allows installation of pumps in a wide power range with a standard mounting dimension of 180 mm. And for particularly cramped conditions, pumps of the same performance can have a reduced landing distance of 130 mm.

Marking is standard and quite simple.

The letter index gives an idea of the specialization of the pump, followed by three groups of numbers, the first of which indicates the diameter of the connection, the second - the pressure in decimeters, the third - the installation length.

The main letter indices that are indicated on the devices:

- BP/BP stands for nut/nut fastening combination.

- BP/HP - nut/thread.

- UP - circulation.

- S - equipped with a rotor speed switch.

- D - duplex, paired.

- F - flange connection. The absence of this letter in the marking indicates a threaded connection.

- N - the case is made of stainless steel (the absence of a letter indicates a cast-iron case, B - a bronze case).

- A - the body is equipped with an air release valve.

- K - a special design that allows the use of antifreeze as a coolant.

So, marking UPS 25–60 130 says that this is a circulation pump with a power (speed) switch, has a connection diameter of 25 mm, a head of 6 meters and a reduced landing dimension of 130 mm.

A bit of history

Grundfos is a company based in Denmark. Its main specialization is circulation pumps. The history of this manufacturer begins in 1945. Danish engineer Paul Du Jensen organized a small production called "Bjerringbro Pressestoberi og Maskinfabrik".The translation is as follows: injection molding and machining factory in Bjørringbro.

At the very beginning, the engineer developed exclusively pumping equipment. High quality and a non-standard approach to solving many problems regarding the design and dimensions of devices contributed to the fact that the products manufactured by the company began to be in great demand.

Production was constantly increasing, and the number of users who were interested in the company's products became more and more. Until the mid-1960s, the name of the company was constantly changing. And only in 1967 the name Grundfos was approved, which exists to this day.

World statistics show that Grundfos heating circulation pumps account for more than 50% of world consumption. First of all, this is due to the high quality of products. In addition, the company has become an international concern. Plants, workshops, factories - you can find them all over the world. Russia is no exception.

1 Advantages and disadvantages of the UPS line

The UPS 100 circulation equipment series includes wet rotor circulation pumps. The device of such pumps involves the placement of working units and the engine in one housing, while the rotation shaft and the impeller attached to it are isolated from the pumped working medium. Such a device allows the use of only two sealing glands, without a mechanical seal, which simplifies the design and makes it more reliable.

All pump models are equipped with durable ceramic bearings, which are lubricated by the pumped liquid during operation.In addition to heating systems, the UPS 100 series is suitable for use in the following areas:

- in industrial heating and water pumping systems;

- heat pump systems;

- underfloor heating systems;

- geothermal heating;

- heat recovery systems;

- air conditioning;

- refrigeration units.

Among the operational advantages of such units, we highlight the high efficiency, which can reach 80%, the reliability and maintainability of the design, and a long service life. Another important plus is the ability to operate the pumps in 3 speed modes, which allows you to configure them for any operating mode.

UPS series pump device

The advantages of the UPS 100 series pumps include:

- simple electrical connection;

- no need for additional electrical protection due to the use of current-resistant blocking motor windings;

- a hollow shaft structure, through the hole in which air is removed from the chamber;

- no need for maintenance.

The disadvantage of this type of equipment is the relatively high noise level during operation (this does not apply to several models of pumps with a dry rotor, also presented in the UPS line) and high cost. However, given the reliability of such equipment, it can be argued that it fulfills its price in full.

1.1 Range of equipment

The Danish company Grundfos in the UPS 100 line represents more than 25 models of circulation pumps, the cost of which varies between 6-40 thousand rubles. Consider the most popular equipment in different price categories:

- Grundfos UPS 25-40 (7 thousand);

- Grundfos UPS 40-50F (27 thousand);

- Grundfos UPS 20-60 130 (10 thousand);

- Grundfos UPS 32-100 (35 thousand).

The most affordable circulator is the Grunfdos UPS 25-40 pump. This is a small-sized pump, characterized by economical energy consumption and low noise during operation. UPS 25-40 is a "dry" type pump, in which the rotor and electric motor are isolated from the working environment.

Grunfdos UPS 25-40

The unit has 3 fixed circulation speeds, which can be switched using a lever located on the terminal box. Built-in automation allows you to configure any mode of operation - continuous, on a timer or based on the characteristics of the coolant.

Consider the technical characteristics of UPS 25-40:

- power - 25/38/45 W;

- working pressure - up to 10 bar;

- temperature of the pumped liquid -25+110 degrees;

- operating flow - 1.6 m3 / h;

- head - up to 4 m;

- threaded connection standard - G 1½".

A more functional modification of 25-40 is the UPS 20-60 model. This unit, in addition to heating, can be used in hot water, cooling and air conditioning systems. The model is designed for pipelines with a stable flow rate of the working medium, the pressure of which does not exceed 10 bar, and the hydrostatic head is 1.62 m. In the UPS 20-60 pump, the nominal flow rate is increased to 2.3 m/h.

The casing of the UPS 20-60 is made of cast iron, the impeller is made of a corrosion-resistant composite alloy. The installation length of the pump is 130 mm, the thread size is G 1½”. The model corresponds to energy efficiency class C.

Grundfos UPS 20-60 130

Grundfos UPS 20-60 130 is one of the few wet rotor models that meets IP 44 protection class.The cost (28 thousand) of this circulator is due to its high reliability - the pump is focused on operation in heating systems of increased responsibility.

Specifications UPS 20-60 130:

- maximum power - 115 W;

- throughput - 9.1 m3 / h;

- liquid temperature - from -25 to +110 degrees;

- pressure - up to 15 bar;

- maximum head - 5 m.

The UPS 20-60 130 has a cast iron casing with a reinforced polymer impeller, a stainless steel bearing plate, heat-resistant synthetic rubber seals, and an aluminum oxide shaft.

Application and purpose

Dzhileks Compasses are circulating devices designed for heating and cooling, air conditioning, ventilation systems. The purpose of the units is to circulate the working fluid in closed systems. When operating the apparatus, pipes of a smaller diameter are used than with natural circulation. Provide uniform distribution of temperatures in systems. A series of units is distinguished by a wet rotor and a three-speed motor. The engine is equipped with a block for manually adjusting the speed of the working fluid in a closed system.

Gileks Compass provides heating of the heated room and uniform distribution over all parts of the working fluid circuit.

Standard equipment of the pump Gileks Compasses

The presence of a wet rotor allows you to adjust the system. It features high performance, energy efficiency and low noise operation.

The lineup

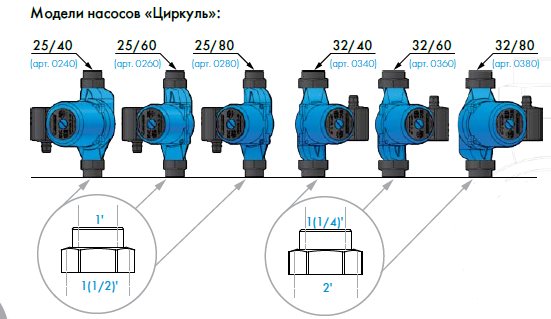

The Jilex Compass series consists of six models with different characteristics.

Description of compasses models:

- 25 40.Circulation pumps Dzhileks Compasses 25 40 operate with a temperature range from ten to one hundred and ten degrees Celsius. Creates a pressure of four meters. Throughput three cubic meters per hour. Has three speeds. It is operated at room temperatures up to fifty degrees. Weighs three kilograms;

- 25 60. The difference between the model and the previous one is in the generated pressure of six meters and throughput of 3.8 cubic meters per hour. Generates 65 dB noise;

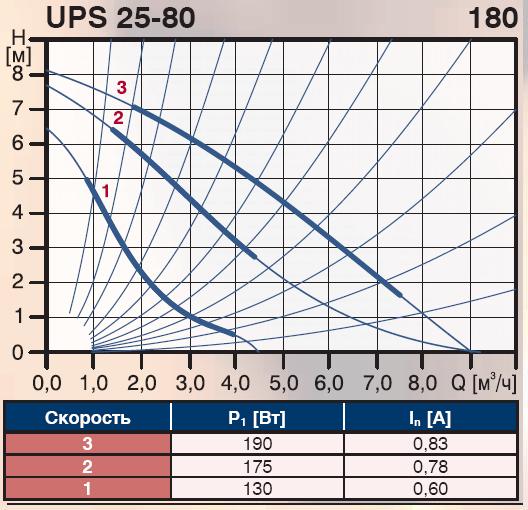

- 25 80. The model creates a maximum pressure of eight meters. Throughput of eight cubic meters per hour. Pumps Gileks Compasses 25 80 emit a noise of 45dB;

- 32 40. The model of circulation pumps Dzhileks Compasses 32 40 is made of cast iron. Works with liquid temperatures up to one hundred and ten degrees Celsius. Circulation pumps Compass 32 40 have a rated power of 32 W, a pressure of four meters, a weight of 3600 grams, a hole diameter of 1.25 inches;

- 32 60. The power of the model is 55 W, it creates a pressure of six meters, the throughput is 3.8 cubic meters per hour. Emits 45 dB noise;

- 32 80. Pump model 32 80 The compass weighs six kilograms. The rated power of the device is 135 watts. Circulation pumps Dzhileks Zirkul 32 80 operate at three speeds. The maximum head and throughput are eight meters.

Design and application features

Compass devices have a number of features that distinguish them from other models and manufacturers.

Model range of pumps Dzhileks Compasses

Device features:

- devices are characterized by high performance;

- are applied to household systems of hot water supply and heating;

- not to be used in potable water systems;

- wet rotor for all models;

- three-speed manual control motor;

- works with water and liquids with ethylene glycol;

- cast iron body, not subject to corrosion;

- mounted horizontally and vertically;

- lowering the rotation speed reduces the energy consumption and the volume of the device;

- in the package there are nuts for mounting;

- low vibration.

Stages and rules of repair

Repair of the Sololift pump, as well as repair of the Grundfos pumping station for any purpose, can be done independently, having previously identified the source of the problem.

Equipment diagnostics involves several stages:

- start the pumping station, evaluate the level of noise and vibration;

- check the pressure indicators;

- make sure that the motor does not overheat during operation;

- check the presence and quality of lubrication of nodal connections;

- make sure the integrity of the structure and the absence of leaks;

- inspect the box for secure fastening of the terminals.

If you are sure that the malfunctions are not caused by lime deposits and pollution, overloads or operation at maximum capacities, the pump can be disassembled. When planning to repair the Grundfos pump with your own hands, make sure that water is drained from the pipelines and turn off the system. Disassembly begins with the junction box and a visual assessment of the components. As a rule, such an inspection makes it possible to immediately detect a burnt or worn part. If not, we will continue to disassemble the installation.

The engine must be in a vertical position during disassembly. This will prevent the risk of oil leakage. To diagnose the trigger mechanism, an ohmmeter must be connected to the engine.This tool, when the handle is rotated, generates a voltage in the range of 200-300 V, sufficient to take readings on the resistance determination device. Too high diagnostic data, reaching infinity, indicate a break in the working phase, too low - an interturn circuit. Self-adjustment of operating parameters with such deviations is not possible.

Service life of the heating pump

Boiler house repair

The event is complex and responsible. The main thing is to choose a high-quality pump with which the heating system in the house will function. Among the huge variety of pumps offered by various manufacturers, it is difficult for an ordinary person to make the right choice in favor of a particular model. The main problem is that a person cannot determine the characteristics of the product and independently calculate the required power of the unit for the heating system. ToHouse heating was the most effective, you need to independently make calculations and find out how much heat is required to heat all rooms. Experts recommend installing pumps with an automatic adjustment system (ask at the store). This type of equipment is able to function taking into account all the requirements of the system, and at the same time, consuming very little electricity. If the user is concerned about such a question asheating pump life , the minimum is 10 years. The time frame is impressive. But these figures will be true only if the product is chosen correctly.Service life of the heating pump will largely depend on the correct operation of the product. Timely maintenance will help to avoid unforeseen breakdowns and malfunctions.

We extend the service life - the secrets of specialists

Service life of the heating pump

So that the heating season does not turn into a nightmare, you need to follow a few simple rules that will help extend the life of the pump:

- By producing boiler room repair , it is necessary to install the unit in accordance with all the technical requirements of the manufacturer (the relevant documentation is attached to the product). The main rule is as follows: the rotor (more precisely, its axis) must be located strictly horizontally. Even a slight tilt can lead to improper operation of the unit and, subsequently, to its breakdown;

- Monitor the formation of air congestion - it is because of them that most of the malfunctions occur. Timely deflated air from the heating system will avoid unforeseen breakdowns;

- Periodically monitor compliance with the temperature regime of the product and observe the pumped liquid (water must be clean, without various litter). All norms are indicated in the technical data sheet of the product;

- House heating should only be done with treated water.

Despite the simplest design of the pump, its function in the heating system of the house is one of the most important - to ensure uninterrupted circulation of hot water. Only compliance with the above rules will help extend the life of the unit and get rid of unforeseen problems and malfunctions in the system.

Summarizing

The circulation pump is an excellent solution for a country (private) house or cottage. By purchasing the unit, a person becomes completely independent of the citywide heating system, which allows significant savings.A properly selected product will consume little electricity, which allows us to conclude that the purchase fully justifies the money invested in it.

Features and benefits of pumps

The main advantages of Grundfos pumps are:

- The optimum ratio of price and quality,

- high energy efficiency of equipment,

- Huge selection to suit every need.

- long enough service life

- good technical support.

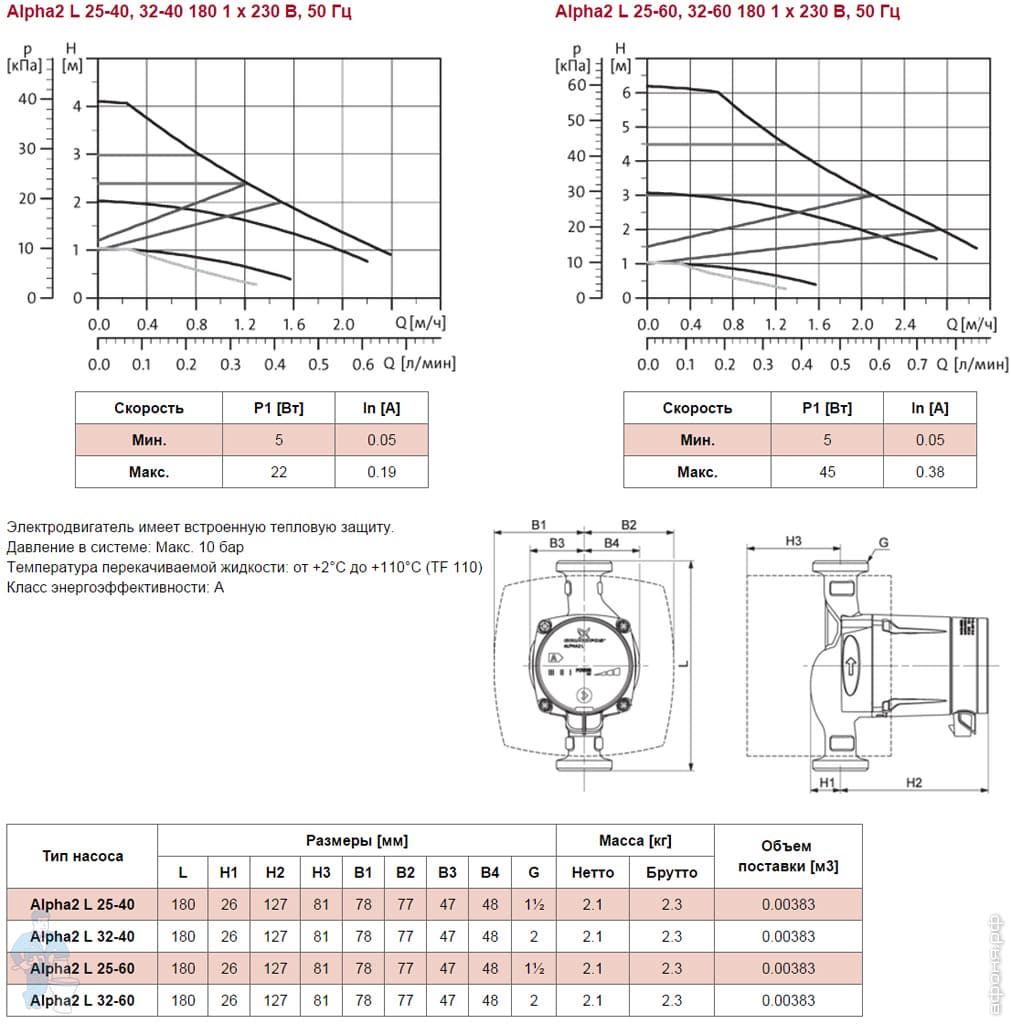

When choosing pumping equipment, the following technical parameters must be taken into account:

First you need to decide what type is needed. In total, three large groups are distinguished: for wells, for heating, for water disposal or sewerage. At Grundfos, the designers have thought through almost all the possible problems that may arise in a particular area of operation. Therefore, choosing the equipment of this manufacturer, you get a unit that takes into account many years of experience.

Before ordering the equipment, it is necessary to decide what type of voltage will be used: single-phase or three-phase. For domestic pumps, single-phase is mainly used, in industry three-phase is used more.

The main characteristic when choosing a pump is the graph of the dependence of pressure on flow. Such a graph shows how much water the pump will pump, depending on the required pressure. The higher the pressure that needs to be maintained, the less water the pump can pump. When selecting equipment, the required operating point must be under its curve. It is also necessary to give a margin of 20% for filing.

Power is also an important parameter. It depends on the strength of the current and the magnitude of the voltage.This parameter is taken into account when selecting pump protection, as well as when calculating the required cross-section of power supply cables. The higher the power, the greater the performance.

When choosing pumps, geometrical parameters and connection dimensions must also be taken into account.

Before placing an order, you must make sure that the selected equipment is suitable both in terms of weight and dimensions.

Depending on the operating conditions, the minimum and maximum permissible temperatures of the pumped medium must be observed. There are times when the wrong choice of range led to equipment failure.

Also, when choosing from equivalent pumps, it is necessary to choose the one with a higher efficiency indicator.

In the long term, such equipment will provide significant energy savings.

In order for the unit to work for a long time and without interruptions, it is necessary to install it correctly. Installation of any equipment must be carried out strictly according to the attached installation instructions. Also, do not forget about the installation of automated control systems for pumps.

Such a system will protect your unit from power surges, from engine overheating, from the possibility of working without water, from water ingress, etc., and will also allow you to control the process automatically, without human intervention.

Another condition for longevity is proper maintenance. It's also listed in the instructions.

It is important to understand that if a pumping unit protection system is installed, then when it is triggered, you need to be alert. It is best to conduct a full cycle of equipment inspection.

Installation

Detailed tips and installation rules are in the accompanying documentation.It is included as standard on original equipment. In practice, instructions are addressed at the last moment. Usually, when something has already broken or stopped working. Installation of a circulation pump with dry rotors in the heating system is carried out on the return line, usually immediately after the expansion tank. Glandless circulation pumps can be installed in supply pipes.

Although the installers claim that in this matter it is better to take into account the features of a particular heating system. The general rules imply that the carrier temperature is lower on the return, so the pump will operate in a gentle mode. And also the efficiency of the device installed on the return line is the best. From a hydraulic point of view, the location of the pump in a closed circuit does not matter. Do not start the installed pump with the system unfilled with liquid. During installation, the correct position of the unit must be taken into account.

Only with a vertical arrangement, the coolant will completely lubricate the rubbing parts. If the connection is incorrect, the unit will fail faster, it will need repair. This happens when the device is installed horizontally, since the internal volume of the case is not completely filled with coolant. With frequent power outages, pumps are recommended to be supplemented with uninterruptible power supplies. They will contribute to a better safety of the unit from breakdowns.

During installation, the following order of work should be taken into account:

- First you need to mount the water circuit. The unit must be installed with a threaded connection with the same diameter in the pipes and in the pump. The correct direction of installation of the device can be determined by the arrows that are equipped with the device case;

- using the couplings offered in the kit, you need to connect the pump;

- you need to fill the heating system;

- bleed any air that may have remained inside the pump. To do this, unscrew the bolt on the top cover that closes the engine.

You need to select the operating speed. Experts advise setting the minimum speed. In this mode, bearings and other rubbing mechanisms wear out less. As a rule, at minimum speed, the load is not particularly strong. During further operation, it is worth choosing the mode in which the entire heating system will warm up more evenly. If a model with an electronic unit is purchased, then these units will independently select the desired circulation rate for the connected system.

The water filter will help increase the life of the pump. The filter must be installed before the unit is installed. Neglecting the filter will shorten the life of the unit, since litter will enter the device case along with the coolant. In order for the installed device to be repairable, it is necessary to install stopcocks that can block the access of liquid. Connections between taps must be tight.

When connecting the device, it is worth considering the order in which the pipes are filled with coolant. Experts recommend running the liquid first into the lower pipes, then gradually fill the entire system. Such a process will facilitate the release of accumulated air into the expansion tank. If air remains inside the pipes, it will lead to system inefficiency. Mayevsky cranes or special automation will contribute to better removal of air from the system.

2 Model range

Grandfos devices have a wide range of models.

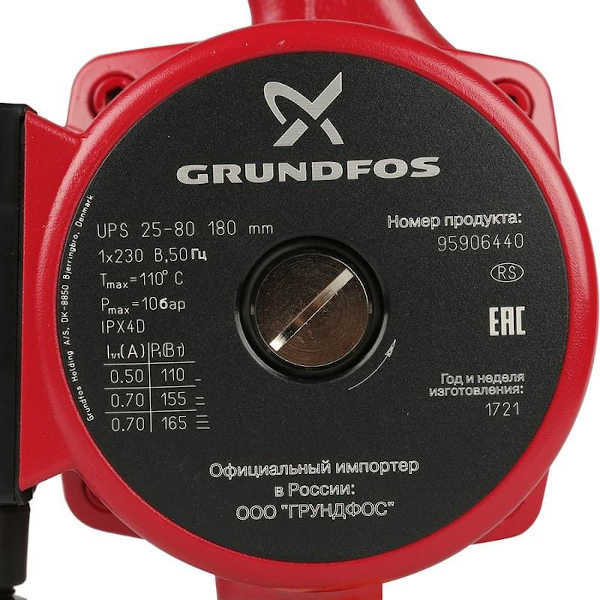

Grundfos circulation pump UPS 25-40 130

Fixed Speed Series

- Grundfos UPS 1560 with a capacity of 3300 liters per hour, a power of 105 W and a pressure of 5.8 meters;

- Grundfos UPS 1560 130 has a capacity of 1.59 cubic meters per hour, head 60 meters, power 50 W, weight 2.3 kg;

- Grundfos UPS 25 40 is equipped with motor protection against power surges. The productivity of the device is 2900 liters per hour, the pressure is 3.8 meters, the temperature regime of the liquid is from 2 to 110 degrees Celsius. Single design type with 3-speed operation. It is popular in dwellings with intermittent voltage work. The analog of the model grundfosups 25 40 130 and 180 has the same characteristics, differs only in the installation length;

- Grundfos UPS 25 60 180 is versatile and is used for hot water and heating systems. Productivity of the device is 4300 liters per hour at a pressure of 6.5 meters. It has a three-speed mode of operation, a working chamber made of cast iron and an aluminum body. The installation length is 180 millimeters. A variation of the model is Grundfos UPS 25 60/130, characterized by an installation length of 130 millimeters;

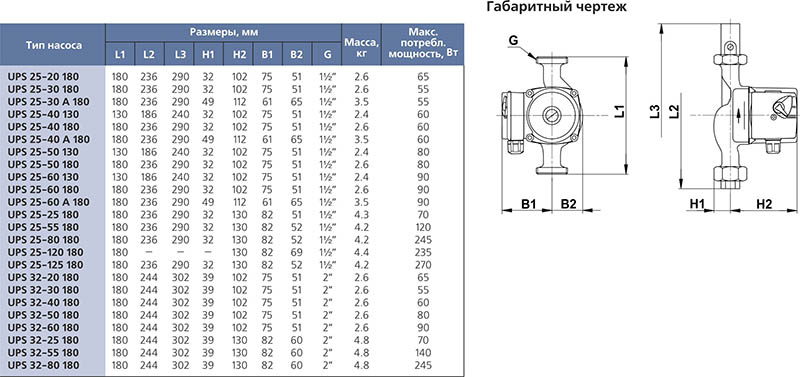

- Grundfos UPS 25 80 creates a maximum head of 8 meters. The throughput of the device is 8 cubic meters per hour. Rotor type - wet. The number of speeds is three. The device is used in a traction heating system. Operates at a maximum pressure of 10 bar;

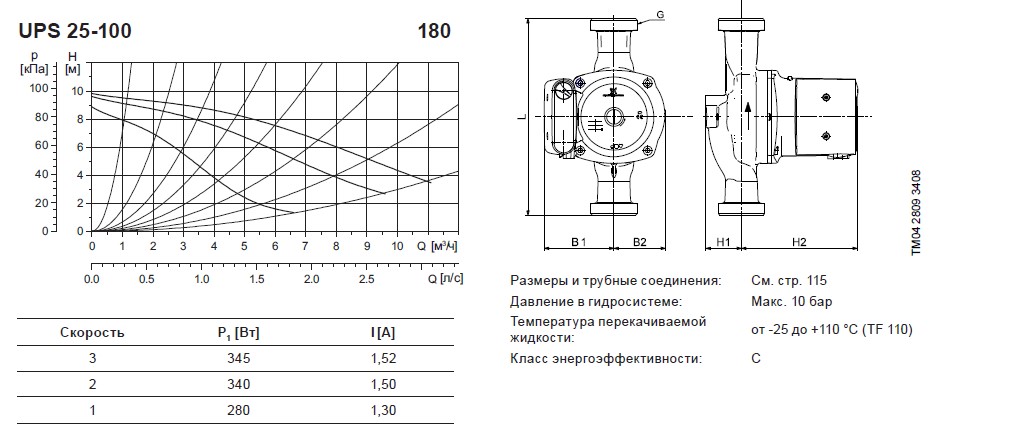

- Grundfos UPS 25 100 creates a pressure of 10 meters, power consumption is 280 W, productivity is 11 cubic meters per hour;

- Grundfos UPS 25 120/180 has the highest pressure in the 12 meters range and a capacity of 3.6 cubic meters per hour. Power 120 W;

- UPS 32/40 forms a head of 4 meters, is mounted in a vertical and horizontal position. Throughput 12 cubic meters per hour. Power 60 W;

- Grundfos UPS 3260 circulation pumps have a capacity of 4.6 cubic meters per hour, a head of 6 meters and a power of 90 watts. Operates at water temperatures up to 95 degrees Celsius. They weigh 2.6 kilograms. Ups 3060 180 grundfos with an installation length of 18 centimeters;

- Grundfos UPS 32 80 circulation pumps operate at pressures up to 10 bar and liquid temperatures from minus 25 to 110 degrees Celsius.

- Grundfos UPS 32 100 operates at a pressure of 10 bar, the flow rate of the device is 14 cubic meters per hour. Grundfos UPS 32 100 creates a pressure of 10 meters. The Grundfos UPS 32 100 model is designed for heating, plumbing, cooling and air conditioning systems;

- Grundfos UPS 32 120 f are operated at liquid temperatures from minus 10 to 120 degrees Celsius. Mounting length 22 cm. Features ceramic radial bearings, graphite axial bearing, aluminum stator housing, cast iron housing. Weight 17 kilograms;

- Grundfos UPS 40 120 f. The device creates a pressure of 120 dm. Has flange connection and 3 speeds;

- UPS 65 120 f Grundfos with 3 speeds and ceramic radial bearings and flange connection. Creates a pressure of 120 dm.

The UP series is applied to hot water supply in private dwellings (for recirculation). Quickly delivers water to the water intake point.

Series without fixed speeds UP:

- Grundfos UP 15 14 bpm pumps are used for hot water systems. The created pressure is 1.2 meters, the flow rate is 0.5 cubic meters per hour, the installation length is 8 centimeters.An analogue of the model are the circulation pumps grundfos up 15 14 but, characterized by the presence of a timer and thermostat;

- Grundfos UP 15 40 bt with a power of 25 W, a thermostat, a pressure of 1.2 meters, a throughput of 0.7 cubic meters per hour. Overheating protection extends the life of the device;

- Grundfos UP 2015 n is a single speed pump with a stainless steel housing;

- Grundfos UP 15 14 b circulation pumps are characterized by low energy consumption and low noise levels. The Grundfos UP 15 14 bapm model has a permanent magnet motor rotor;

- Grundfos UP 20 14 bxa pm is equipped with two temperature sensors. Recirculation, which is carried out by the machine once a week, is necessary to kill bacteria and flush the system. The analogue of the device is grundfos UP 2014bx pm;

- Grundfos UP 15 14b a pm is used for DHW recycling. Wet type of rotor protects the motor from overheating.