- How to make the right selection of a circulation pump for a heating system

- The device and principle of operation of the circulation pump

- Where to put

- forced circulation

- natural circulation

- Mounting Features

- About installing additional units

- The use of circulation pumps in home heating

- closed system

- Open heating system

- Underfloor heating system

- Price factor

- Video description

- Benefits of a separate pumping unit

- Conclusion

- Design features of a pump for heating a private house

- wet rotor

- Dry Rotor

- How to choose

- The need to install an additional circulation pump

- hydraulic separator

- Functionality

- Where to put the second device in the house

- How to install a pump with your own hands in a private house

- Correct installation scheme

- Types of circulation pumps

How to make the right selection of a circulation pump for a heating system

As we found out above, a wet rotor circulation pump is suitable for a private house or apartment. On what characteristics to choose it? When planning the purchase of a circulation pump for a heating system, it is necessary to study its following parameters:

Productivity - the amount of fluid pumped by the pump per unit of time, as well as the pressure it creates.This characteristic must be selected for each specific heating system.

Permissible coolant temperature. As a rule, it is +110 °C.

Passport value of the maximum pressure in the system (usually not more than 10 bar).

Pressure of the circulation pump of the heating system. This indicator is often written on the markings of models, in the passport - always. For example, a combination of numbers 25-40 means: 25 - the cross section of pipes in the heating system in millimeters (the parameter can be specified in inches: 1 ″ or 1¼ ”(1.25 ″ \u003d 32 mm)), 40 is the height of the liquid rise (maximum - 4 m, for pressure maximum - 0.4 atmospheres).

The pump must be adequately protected against external ingress of dust and water splashes. These parameters are placed in the protection class of the instrument case - IP. For a circulation pump, the acceptable class must be at least IP44. This value indicates that the device is protected from dust fragments up to 1 mm in size, and its electrical part is not afraid of water drops at any angle.

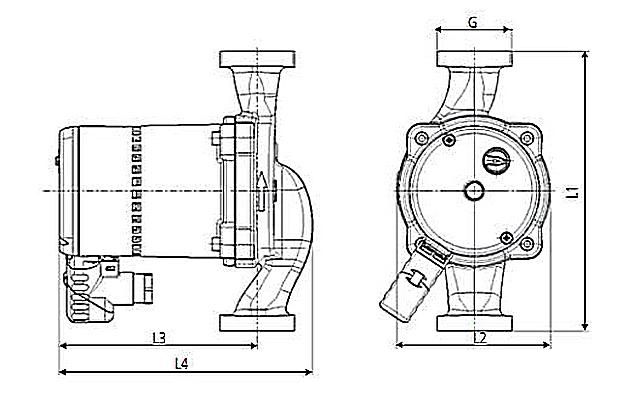

Mounting dimensions and features of the pump. The connection of the devices can be flanged or threaded. The pump must be completed with mating flanges or union nuts (“American”) of a suitable diameter. It is necessary to evaluate the nominal diameter of the pipe to which the circulation pump for heating systems will be attached. Diameter can be specified both in metric system (15–32 mm) and in inches

It is also important to know the installation length of the pump (in the diagram shown - L1), the value of which must be taken into account when replacing a broken device with a new one.

It is not uncommon for a circulation pump for a heating system to be installed in a small area. In such cases, in addition to the parameters described above, it is necessary to know other linear dimensions of the pump (indicated in the diagram - from L2 to L4). The main characteristics of the devices are indicated on the nameplates. The marking on circulation pumps for heating systems is as follows:

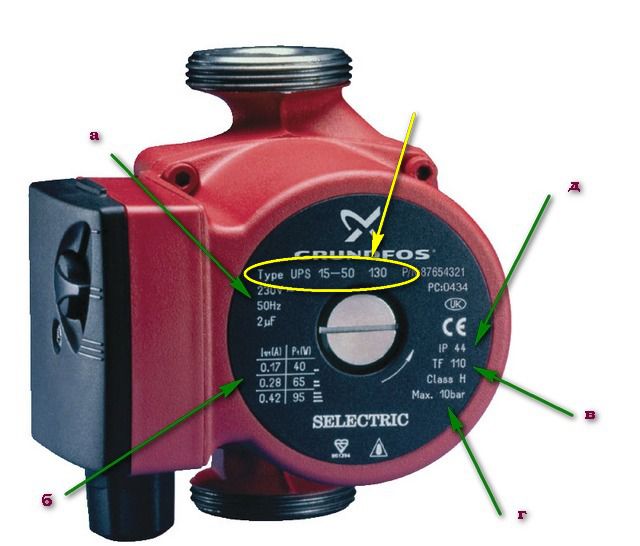

a - voltage and frequency of the power supply network;

b - current and power consumption in various operating modes;

c - maximum temperature of the pumped liquid;

g - the maximum allowable pressure in the heating system;

d – protection class of the instrument case.

The factory name of the model is circled in yellow oval, by which it is possible to determine the characteristics of circulation pumps for heating systems.

The figure shows a UPS 15-50 130 pump. What can be understood from these numbers?

-

UP - circulation pump;

-

S – number of operating modes: empty – one operating mode; S - with speed switching;

-

15 - conditional diameter of the pipe passage (mm);

-

50 - the maximum pressure created (in decimeters of the water column);

-

Insertion system: empty - threaded sleeve; F - connecting flanges. Case execution features: empty - gray cast iron; N - stainless steel; B - bronze; K - it is possible to pump liquids with negative temperatures; A - an automatic air vent is installed.

-

130 - installation length of the pump (mm).

Read the material on the topic: Do-it-yourself heating in a private house

The device and principle of operation of the circulation pump

The device is one of the modifications of the hydraulic centrifugal machine and consists of the following main components:

- Metal or polymer case;

- Rotor, which ensures the rotation of the impeller;

- Trumpets;

- Lip, disc and labyrinth seals;

- An electronic control unit that allows you to control the parameters of the electric motor and set the required mode.

The inlet and outlet pipes can have a different location, which allows you to choose a circulation pump that fits optimally into the scheme of the designed circuit. Due to its small overall dimensions, the pump is often installed in the heat generator housing, which greatly simplifies the installation of the pipeline.

The principle of operation of the circulation pump

The process of forced submission can be divided into several stages:

- Suction of the liquid heat carrier through the inlet pipe;

- The rotating turbine throws the liquid against the walls of the housing;

- Due to centrifugal force, the working pressure of the coolant increases and it moves through the outlet pipe into the main pipeline.

In the process of moving the working medium to the edge of the turbine, the vacuum in the inlet pipe increases, which ensures continuous fluid intake.

If the power of the device built into the heat generator is not enough to ensure efficient circulation, the required parameters can be achieved by installing an additional circulation blower in the system.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C.There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

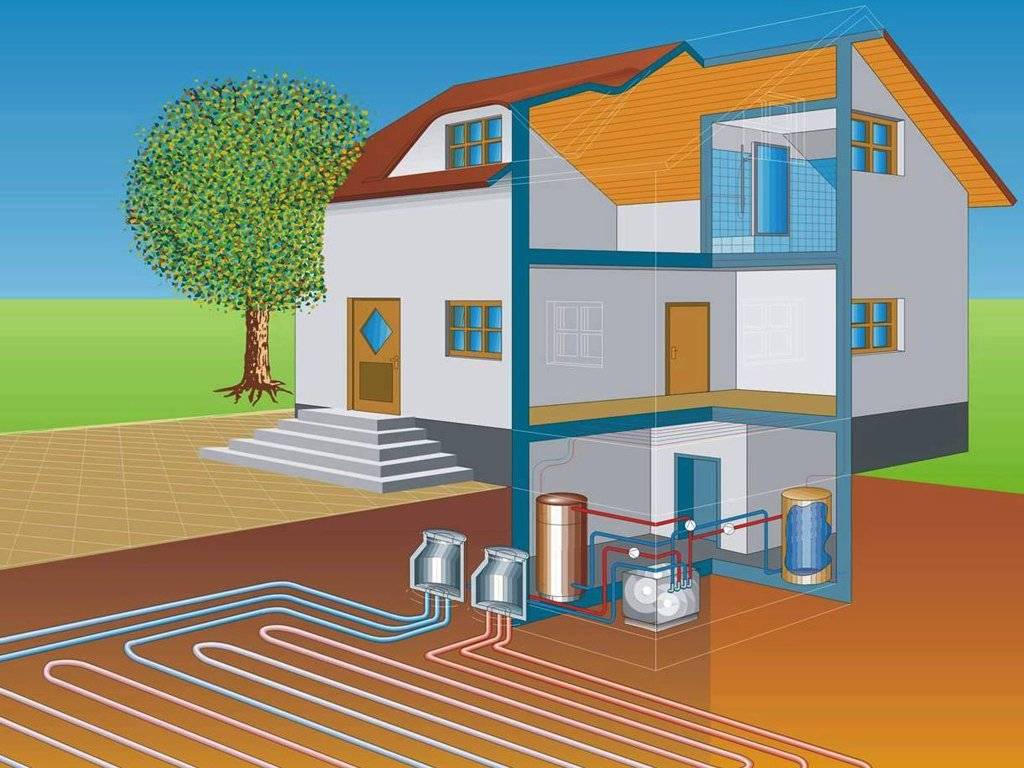

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer.However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

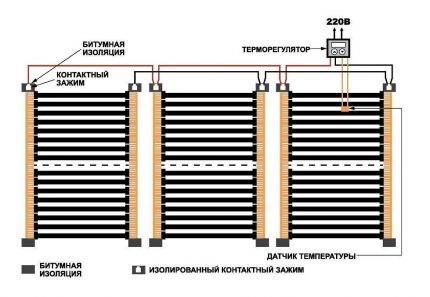

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

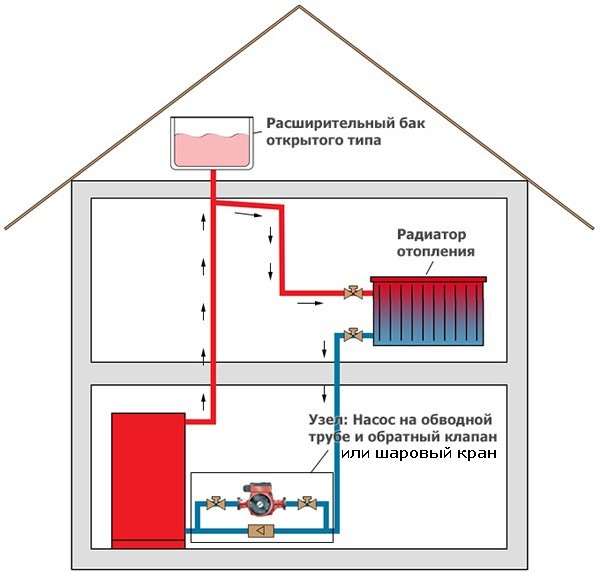

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running.One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

About installing additional units

As a rule, in a closed or open radiator heating system, where the heat source is a single boiler, it is enough to install one circulation pump. In more complex schemes, additional units are used for pumping water (there may be 2 or more). They are placed in such cases:

- when more than one boiler plant is used to heat a private house;

- if a buffer capacity is involved in the piping scheme;

- the heating system has several branches serving various consumers - batteries, underfloor heating and an indirect heating boiler;

- the same, using a hydraulic separator (hydraulic arrow);

- for organizing water circulation in the contours of underfloor heating.

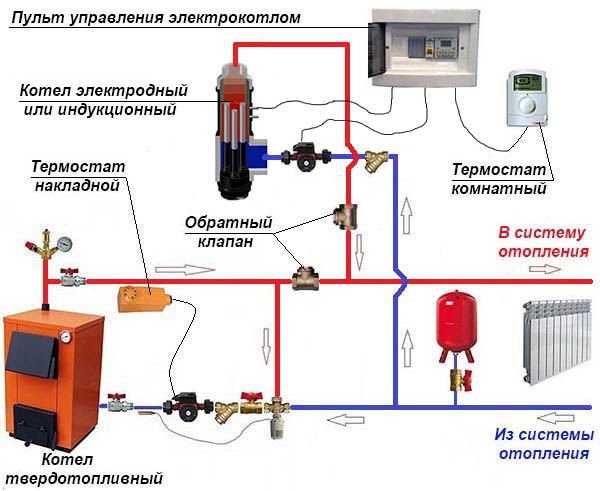

Proper piping of several boilers operating on different types of fuel requires that each of them has its own pumping unit, as shown in the diagram of the joint connection of an electric and TT boiler. How it works is described in our other article.

Piping of an electric and TT boiler with two pumping devices

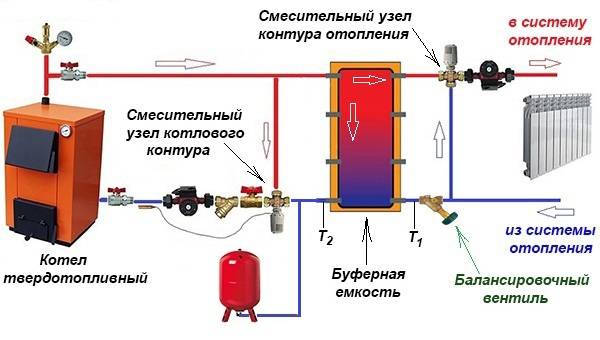

In the scheme with a buffer tank, it is necessary to install an additional pump, because at least 2 circulation circuits are involved in it - boiler and heating.

Buffer capacity divides the system into 2 circuits, although in practice there are more of them

A separate story is a complex heating scheme with several branches, implemented in large cottages on 2-4 floors. Here, from 3 to 8 pumping devices (sometimes more) can be used, supplying the coolant floor by floor and to different heating devices. An example of such a circuit is shown below.

Finally, the second circulation pump is installed when the house is heated with water-heated floors. Together with the mixing unit, it performs the task of preparing a coolant with a temperature of 35-45 °C. The principle of operation of the circuit below is described in this material.

This pumping unit makes the coolant circulate through the heating circuits of underfloor heating

Reminder. Sometimes pumping devices do not need to be installed for heating at all. The fact is that most electric and gas wall-mounted heat generators are equipped with their own pumping units built into the housing.

The use of circulation pumps in home heating

Since some features of the operation of circulation pumps for water in various heating schemes have already been mentioned above, the main features of their organization should be touched upon in more detail. It is worth noting that in any case, the supercharger is placed on the return pipe, if home heating involves raising the liquid to the second floor, another copy of the supercharger is installed there.

closed system

The most important feature of a closed heating system is sealing. Here:

- the coolant does not come into contact with the air in the room;

- inside the sealed piping system, the pressure is higher than atmospheric pressure;

- the expansion tank is built according to the hydraulic compensator scheme, with a membrane and an air area that creates back pressure and compensates for the expansion of the coolant when heated.

The advantages of a closed heating system are many. This is the ability to carry out desalination of the coolant for zero sediment and scale on the boiler heat exchanger, and filling in antifreeze to prevent freezing, and the ability to use a wide range of compounds and substances for heat transfer, from a water-alcohol solution to machine oil.

The scheme of a closed heating system with a single-pipe and two-pipe type pump is as follows:

When installing Mayevsky nuts on heating radiators, the circuit setting improves, a separate air exhaust system and fuses in front of the circulation pump are not needed.

Open heating system

The external characteristics of an open system are similar to a closed one: the same pipelines, heating radiators, expansion tank. But there are fundamental differences in the mechanics of work.

- The main driving force of the coolant is gravitational.Heated water rises up the accelerating pipe; to increase circulation, it is recommended to make it as long as possible.

- The supply and return pipes are placed at an angle.

- Expansion tank - open type. In it, the coolant is in contact with air.

- The pressure inside an open heating system is equal to atmospheric pressure.

- The circulation pump installed on the feed return acts as a circulation amplifier. Its task is also to compensate for the shortcomings of the pipeline system: excessive hydraulic resistance due to excessive joints and turns, violation of tilt angles, and so on.

An open heating system requires maintenance, in particular, a constant topping up of coolant to compensate for evaporation from an open tank. Also, corrosion processes are constantly taking place in the network of pipelines and radiators, due to which the water is saturated with abrasive particles, and it is recommended to install a circulation pump with a dry rotor.

The scheme of an open heating system is as follows:

An open heating system with the correct angles of inclination and a sufficient height of the accelerating pipe can also be operated when the power supply is turned off (the circulation pump stops working). To do this, a bypass is made in the pipeline structure. The heating scheme looks like this:

In the event of a power outage, it is enough to open the valve on the bypass bypass loop so that the system continues to work on the gravitational circulation circuit. This unit also makes the initial start-up of the heating easier.

Underfloor heating system

In the underfloor heating system, the correct calculation of the circulation pump and the choice of a reliable model are a guarantee of stable operation of the system.Without forced water injection, such a structure simply cannot work. The pump installation principle is as follows:

- hot water from the boiler is supplied to the inlet pipe, which is mixed through the mixer block with the return flow of the underfloor heating;

- the supply manifold for underfloor heating is connected to the pump outlet.

The distribution and control unit of the underfloor heating is as follows:

The system works according to the following principle.

- At the pump inlet, a main temperature controller is installed that controls the mixing unit. It can receive data from an external source, such as remote sensors in the room.

- Hot water of the set temperature enters the supply manifold and diverges through the floor heating network.

- The incoming return has a lower temperature than the supply from the boiler.

- The thermostat with the help of the mixer unit changes the proportions of the hot flow of the boiler and the cooled return.

- Water of the set temperature is supplied through the pump to the inlet distribution manifold of the underfloor heating.

Price factor

When choosing a circulation pump, the cost of the device itself and its efficiency during operation are important. As a rule, the operation of the pump is justified by saving on fuel consumption, and the cost of the model itself is determined by its performance. In Moscow, the range of prices for pumps is very large. Conventionally, they can be divided into 3 categories:

For 3.5-7 thousand rubles, you can buy basic functions, with a minimum period of work and most often one-time use;

Comparison of characteristics of economy segment pumps

- Devices for 7.5-20 thousand are “workhorses” that accurately provide the declared characteristics, with a service life not less than that specified by the manufacturer and with several degrees of protection and an optimal margin of safety;

- VIP systems with full automation, a set of additional functions, a high margin of safety and the ability to provide heat to a large volume will already cost from 20 to 45 thousand rubles.

Video description

And some more thoughts about circulation pumps in the following video:

Benefits of a separate pumping unit

The use of pumping equipment is justified in terms of fuel economy and increase in boiler efficiency, so many companies build pumping units into boilers. But a separate installation of the unit has its advantages: quick replacement without removing the boiler, the ability to control the process in case of emergency situations (for example, using a bypass). In addition, the pump can be installed in a system not provided for by the project at the initial stage.

Conclusion

Despite the apparent simplicity of the choice, the pump parameters must be technically justified, for which mathematical calculations are carried out taking into account the laws of heat engineering, the characteristics of the individual system, so the exact choice should be made by a specialist who takes into account all factors based not only on theoretical knowledge, but also on practical experience.

Design features of a pump for heating a private house

In principle, a circulation pump for heating is no different from other types of water pumps.

It has two main elements: an impeller on a shaft and an electric motor that rotates this shaft. Everything is enclosed in a sealed case.

But there are two varieties of this equipment, which differ from each other in the location of the rotor. More precisely, whether the rotating part is in contact with the coolant or not. Hence the names of the models: with a wet rotor and dry. In this case, we mean the rotor of the electric motor.

wet rotor

Structurally, this type of water pump has an electric motor in which the rotor and stator (with windings) are separated by a sealed glass. The stator is located in a dry compartment, where water never penetrates, the rotor is located in the coolant. The latter cools the rotating parts of the device: the rotor, impeller and bearings. Water in this case acts for bearings, and as a lubricant.

This design makes the pumps quiet, because the coolant absorbs the vibration of the rotating parts. A serious drawback: low efficiency, not exceeding 50% of the nominal value. Therefore, pumping equipment with a wet rotor is installed on heating networks of small length. For a small private house, even 2-3 floors, this would be a good choice.

The advantages of wet rotor pumps, in addition to silent operation, include:

- small overall dimensions and weight;

- economical consumption of electric current;

- long and uninterrupted work;

- Easy to adjust rotation speed.

Photo 1. Scheme of the device of a circulation pump with a dry rotor. Arrows indicate parts of the structure.

The disadvantage is the impossibility of repair. If any part is out of order, then the old pump is dismantled, installing a new one. There is no model range in terms of design possibilities for pumps with a wet rotor.All of them are produced of the same type: vertical execution, when the electric motor is located with the shaft down. The outlet and inlet pipes are on the same horizontal axis, so the device is installed only on a horizontal section of the pipeline.

Important! When filling the heating system, the air pushed out by water penetrates into all voids, including the rotor compartment. To bleed the air plug, you must use a special bleed hole located at the top of the motor and closed with a sealed rotating cover. To bleed the air plug, you must use a special bleed hole located in the upper part of the electric motor and closed with a sealed rotating cover

To bleed the air plug, you must use a special bleed hole located at the top of the motor and closed with a sealed rotating cover.

Preventive measures for "wet" circulation pumps are not required. There are no rubbing parts in the design, cuffs and gaskets are installed only on fixed joints. They fail due to the fact that the material has simply grown old. The main requirement for their operation is not to leave the structure dry.

Dry Rotor

Pumps of this type do not have a separation of the rotor and stator. This is a normal standard electric motor. In the design of the pump itself, sealing rings are installed that block the access of the coolant to the compartment where the elements of the engine are located. It turns out that the impeller is mounted on the rotor shaft, but is in the compartment with water. And the entire electric motor is located in another part, separated from the first by seals.

Photo 2. A circulation pump with a dry rotor. There is a fan at the back to cool the device.

These design features have made dry rotor pumps powerful. The efficiency reaches 80%, which is quite a serious indicator for equipment of this type. Disadvantage: the noise emitted by the rotating parts of the device.

Circulation pumps are represented by two models:

- Vertical design, as in the case of a wet rotor device.

- Cantilever - this is a horizontal version of the structure, where the device rests on the paws. That is, the pump itself does not press on the pipeline with its weight, and the latter is not a support for it. Therefore, a strong and even slab (metal, concrete) must be laid under this type.

Attention! O-rings often fail, becoming thin, which creates conditions for the penetration of the coolant into the compartment where the electrical part of the electric motor is located. Therefore, once every two or three years, they carry out preventive maintenance of the device, inspecting, first of all, the seals

How to choose

Parameters that you need to pay attention to when purchasing the device:

- Power. This indicator is influenced by: the degree of pressure of the liquid, the performance of the boiler, its throughput, the temperature of the coolant, the diameter of the pipeline.

- Flow rate of the circulation pump. It is determined by the formula: Q=N/t2-t1, where N is the power parameter, t2 is the temperature leaving the heat source, and t1 is present in the return pipeline.

- Pump head. In accordance with the standards for 1 sq. m. area of the room requires a power value of 100 watts.

- Connecting the device. The diameter of the pipe for fixing it is important - 2.5 or 3.2 cm.

- Pressure. The length of all pipes is multiplied by 100 Pa.

- Performance.

The need to install an additional circulation pump

The idea of installing a second device arises with uneven heating of the coolant. This is due to insufficient boiler power.

To detect a problem, measure the temperature of the water in the boiler and pipelines. If the difference is 20°C or more, the system should be purged of air pockets.

In the event of a further malfunction, an additional circulation pump is installed. The latter is also necessary if a second heating circuit is being installed, especially in situations where the strapping length is 80 meters or more.

Reference! Invite experts to clarify the calculations. If they are incorrect, installing an additional device will result in poor performance. In rare cases, nothing will change, but the costs of buying and hosting will go to waste.

A second pump is also not needed if the heating system is balanced with special valves. Purge the pipes of air, replenish the amount of water and carry out a test run. If the devices interact normally, then it is not necessary to mount new equipment.

hydraulic separator

Used when an additional pump is required. The device is also called an anuloid.

Photo 1. Hydraulic separator model SHE156-OC, power 156 kW, manufacturer - GTM, Poland.

Such devices are used in heating, if water is heated when using long-burning boilers. The devices in question support several modes of operation of the heater, from ignition to fuel attenuation.In each of them, it is desirable to maintain the required level, which is what the hydraulic gun does.

Installing a hydraulic separator in the piping creates a balance during the operation of the coolant. Anuloid is a tube with 4 outgoing elements. Its main tasks:

- independent removal of air from heating;

- catching part of the sludge to protect pipes;

- filtration of dirt entering the harness.

Attention! Characteristics must be carefully selected. Choosing a quality device will help protect the system from problems. Because of this, the installation of a pump becomes mandatory.

Because of this, the installation of a pump becomes mandatory.

Functionality

Piping with a circulation pump performs many tasks. They must be allowed regardless of the flow of working water and possible pressure surges in the pipes. Efficiency is difficult to achieve because the fluid is taken in from a common source.

Thus, the coolant leaving the boiler will unbalance the system.

Because of this, a hydraulic separator is placed: its main goal is to create a decoupling that will solve the problem described above.

The following features are also important:

- contour matching, if several are used;

- support of the calculated flow rate in the primary piping, regardless of the secondary ones;

- continuous provision of circulation pumps;

- facilitating the operation of branched systems;

- cleaning pipes from air;

- sludge recovery;

- ease of installation when using modules.

Where to put the second device in the house

In autonomous heating, it is recommended to install a device with a wet rotor, which is self-lubricated by the working fluid. Therefore, consider the following points:

- the shaft is placed horizontally, parallel to the floor;

- the flow of water is directed in one direction with the arrow installed on the device;

- the box is placed on any side except the bottom, which protects the terminal from water ingress.

The device is mounted on the return line, where the coolant temperature is minimal.

This increases the duration of operation, although some experts disagree with this phrase. The latter is related to the rules of operation: the device must withstand heating of the working fluid up to 100-110 ° C.

Important! Placement is possible not only on the reverse, but also on the straight pipe. The main thing is to install between the boiler and the radiators, since the opposite is prohibited. It also makes maintenance of the device easier.

This also makes the device easier to maintain.

How to install a pump with your own hands in a private house

One of the most important points is the direction of the rotor. If the installation is vertical, the system will almost certainly have to be redone. And also take into account the flow of fluid through the pipes. There is an arrow on the device for this.

The principle of installation does not matter. Read the instructions for the possibility of using in certain schemes. When choosing, take into account the power drop when the pump is not installed horizontally.

Correct installation scheme

It is often used to install the pump on a bypass. It allows the system to operate during a power outage. This also applies to the occurrence of malfunctions with the circulator, allowing the replacement of parts without draining the water.

Photo 1. Scheme of the heating system. The number nine indicates the installation location of the circulation pump.

For installation you will need:

- pump;

- union nuts or flange connections (included);

- filter;

- shut-off valves;

- bypass and valve for it.

Some space is required for installation.Depending on the characteristics of the building, a project may need to be developed.

When creating a piping with forced water circulation, it is recommended to install a special pipe section designed for the pump. They are not often found, but greatly facilitate the work. For the same reason, you should look for an assembled device. Otherwise, you will have to invite a specialist or do the process yourself. The assembly principle depends on the fasteners and material. The latter divides devices into two types: metal, requiring complex welding, and plastic.

Installation rarely takes more than an hour. This does not apply to steel pipes, which require the creation of complex connections. When installing, do not make a mistake with the calculations of lengths. The works are as follows:

- Preparation: selection of components and their purchase.

- Choice of tools: you will need keys, sealant, possibly a welding machine.

- First, three knots are packed on tow: two for the pump and one for the tap. The first are distinguished by the presence of a filter. The latter is placed in the lower part, combining the branch pipe and the drive. It is applied, outlining the installation site. And also think through the points of intersection.

- Then the loop is assembled without fully tightening the nuts. At this stage, measurements are taken, determining the characteristics of the node.

- The cut parts of the pipeline are placed along a common axis at arbitrary stops. The loop is tightened, then the structure is welded. Before the next step, it is recommended to remove the pump so as not to damage it.

- Fasten the bottom, docking the squeegee. Having packed the last, the pump is returned to its place. The rotor is aligned along the horizontal axis. The nuts are tightened, fixing the position of the structure.The joints are coated with sealant and proceed to the electrical part of the process, if required.

After completing the installation, you can not immediately check. First, the piping is filled with coolant. To prevent air from collecting in the loop at this time, open the tap. This step is optional if there is a gas outlet. When water flows out of the hole, it is blocked. Having completely filled the pipes, they repeat the procedure. Then everything is again tight, lubricated with sealant and begin to operate.

Types of circulation pumps

The design of a typical circulation pump consists of a housing made of stainless metal, a ceramic rotor and a shaft equipped with a wheel with blades. The rotor is driven by an electric motor. This design provides water intake from one side of the device and its injection into the pipelines from the outlet side. The movement of water through the system occurs due to centrifugal force. Thus, the resistance that occurs in individual sections of the heating pipes is overcome.

All such devices are divided into two types - dry and wet. In the first case, there is no contact between the rotor and the pumped water. Its entire working surface is separated from the electric motor by special protective rings, carefully polished and fitted together. The operation of dry-type pumps is considered more efficient, however, quite a lot of noise occurs during operation. In this regard, separate isolated rooms are equipped for their installation.

When choosing such models, one should take into account the presence of air turbulences formed during operation.Under their influence, dust rises into the air, which can easily get inside the device and break the tightness of the sealing rings. This will lead to the failure of the entire system. Therefore, as a protection between the rings, there is a very thin water film. It provides lubrication, preventing premature wear of the rings.

Wet type circulation pumps have a distinctive feature in the form of a rotor that is constantly in the pumped liquid. The location of the electric motor is securely separated by a sealed metal cup. These devices are usually used in small heating systems. They are much less noisy during operation and do not require additional maintenance measures. Typically, such pumps are periodically repaired and adjusted to the desired parameters.

A significant disadvantage of these pumps is considered to be low efficiency due to insufficient tightness of the sleeve separating the stator and coolant.

When choosing the right model, you should pay attention to the fact that the pump has not only a wet rotor, but also a protected stator

The latest generations of circulation pumps are almost completely automated. Smart automation ensures timely switching of the winding level and significantly increases the performance of the device. Such models are most often used with a stable or slightly changing water flow. Thanks to the stepwise adjustment, it became possible to select the most optimal operating modes and significant energy savings.