- Belamos device

- Design and types of circulation pumps

- Characteristics of the first five models of pumps for heat supply

- Types and characteristics

- Basic pump selection criteria

- Maximum head and flow

- Other Important Features

- Necessary calculations

- Nuances of choice

- pressure

- Heat pump manufacturers

- Circulation pumps for heating systems: technical specifications

- What to look for when choosing

- The best pumps in terms of value for money

- DAB EVOTRON 40/180

- JILEX Compasses 32-80

- Wilo Star-RS 25/4-180

- WCP 25-80G (180 mm)

- How to improve system reliability

- Conclusions and useful video on the topic

Belamos device

When answering the question of which circulation system is best to choose, it is important to consider the Belamos apparatus. This manufacturer is the leader in the Russian market, it supplies a large number of good equipment for home heating

The Belamos BR 25/4 G model is especially popular.

The cost of the device in Moscow reaches 2100 thousand rubles. The device can withstand liquid heating up to 110 degrees Celsius, the maximum pressure reaches 4.5 meters, and the throughput is 2.8 cubic meters of water.The main advantages of such a device include: the ability to mount in a vertical or horizontal position, acceptable cost for many users, quiet operation, high quality construction.

Originally posted 2018-07-04 08:13:41.

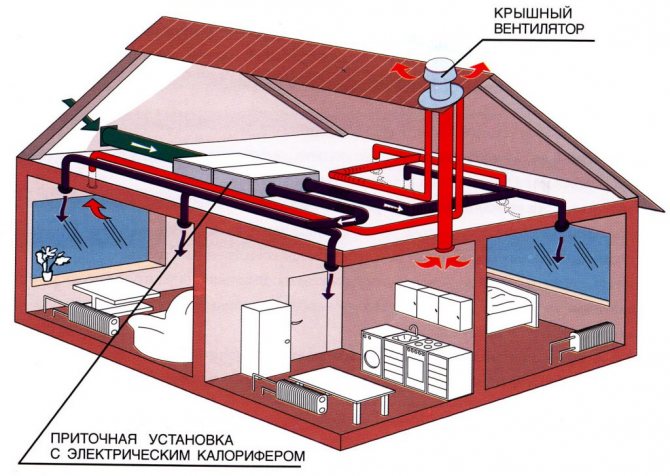

Design and types of circulation pumps

Most pumps have the following design:

- Casing with attached volute

- Contour pipes are screwed to the snail

- An electric motor with a control board and terminals for connecting wires to the mains is mounted in the housing.

- The rotating part of the engine - a rotor with a nozzle (impeller) - moves water, sucking it in on one side and pumping it into the circuit pipes, on the other side

As a result of the work, some vacuum is obtained at the inlet of the pump and the desired pressure (compression) is obtained at the outlet. All circulation pumps, depending on the design features, are classified into two types:

- "dry" type (with a dry rotor);

- "wet" type (with a wet rotor).

does not come into contact with the working fluid of the circuitneed periodic maintenance of separate boiler rooms

In "wet" type pumps, the rotating rotor itself is in contact with the pumped coolant liquid, and the stationary part of the pump motor, the stator, is isolated from it. By interacting with the liquid, the necessary lubrication of the rotor parts and the noiselessness of the operation of the entire pump as a whole are achieved.

Typically, pumps have a built-in step speed controller. Wet-type circulation pumps can operate for years, and sometimes decades, without requiring any maintenance. But they have low efficiency - only 50-65%.Pumps of this type are most widely used in private domestic heating systems precisely because of their small size and quiet operation. These aspects are one of a number of others when choosing a circulation pump for the heating circuit of your home. But there are other aspects to choosing a pump. We will consider them.

Characteristics of the first five models of pumps for heat supply

| Manufacturer | Grundfos | Knight | Oasis | Grundfos | Grundfos |

|---|---|---|---|---|---|

| Model | UPS 25-40 180 | TsN-25-4 | CN 25/4 | UPS 25-60 180 | ALPHA2 25-60 180 |

| Pump type | circulation | circulation | circulation | circulation | circulation |

| Rotor type | wet | wet | wet | wet | wet |

| Performance | 2.93 cubic meters per hour | 3 cubic meters per hour | 3.6 cubic meters per hour | 4.35 cubic meters per hour | 2.8 cubic meters per hour |

| pressure | 4 m | 4 m | 4 m | 6 m | 6 m |

| Power | 45 W | 72 W | 72 W | 60 W | 34 W |

| Housing material | cast iron | cast iron | cast iron | cast iron | cast iron |

| Thread diameter | 1 1/2″ | 1 1/2″ | 1 1/4″ | 1 1/2″ | 1 1/2″ |

| Liquid temperature | from 2 to 110 deg. | from -10 to 110 degrees. | from -10 to 110 deg. | from 2 to 110 deg. | from 2 to 110 deg. |

| The weight | 2.6 kg | 3 kg | 2.68 kg | 2.6 kg | 2.1 kg |

Types and characteristics

A circulation pump is a centrifugal type device, the impeller of which draws in and ejects liquid in a given direction. Like all similar devices, it works on suction and discharge with the same efficiency. Given the specifics of use, these qualities are basic for him.

There are two main types of circulation pumps:

wet rotor

The impeller of these pumps is mounted directly on the motor shaft. The pump housing is sealed, and an oil seal is placed on the shaft to protect against leakage.For domestic systems, such designs are considered the most suitable, since they do not create noise during operation. In addition, wet rotor pumps are able to independently remove air plugs, and the liquid provides lubrication and cooling of the electric motor;

Dry Rotor

The pump and motor are two separate units connected by a coupling or flange. Such designs are designed to work in large heating systems, as they can pump large volumes of liquids. The main disadvantage of dry pumps is the high noise level during operation, which is unacceptable at home.

Pumps: 1-with a wet rotor 2-with a dry rotor

Pumps: 1-with a wet rotor 2-with a dry rotor

Main technical characteristics of circulation pumps:

- Performance. This is a value showing the amount of coolant pumped by the pump per unit time. Determines the ability of the installation to provide a given fluid velocity for the available volume of the system;

- Head. Often they are confused, but this is the wrong approach. The head indicates the height to which a given pump is capable of lifting a liquid column. For heating systems of houses with several floors, this indicator is very important, since the hydraulic resistance in the circuits is high and must be overcome;

- Engine power. This indicator is important because insufficient power will not allow the pump to perform its tasks, and excess power will make the pipes make a lot of noise;

- Maximum temperature. Since we are talking about a heating system, the coolant is hot. If the pump is not able to work in such conditions, it will seize, leaks and other problems will appear.It should be borne in mind that during rotation, the parts of the device heat up, and an additional temperature rise for them sometimes becomes an excessive load.

- Connecting dimensions. pump installation is simple, but it requires the appropriate elements. They should be selected immediately after the purchase of the pump, so as not to be in a difficult position during installation;

- Manufacturer. This factor does not significantly affect the operation of the system, but the products of well-known and reliable companies are much more durable and do not create such problems as products of little-known companies.

It is recommended that when buying, carefully study the technical characteristics of the pump and compare them with the operating conditions in the existing circuit. Devices capable of withstanding temperatures of 110°C should be selected.

Basic pump selection criteria

In order for the circulation pump to be used for heating a private house, you must first determine the necessary values of its main indicators. And only then choose the manufacturer and model according to such parameters as brand, quality and price.

Maximum head and flow

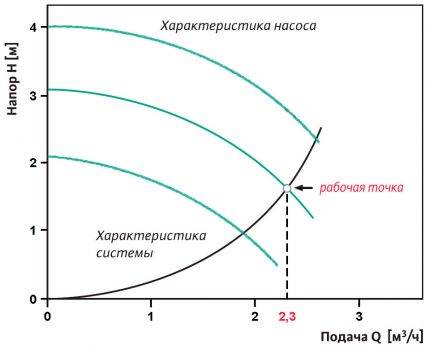

Each pump has two main characteristics:

- maximum head - how many meters the unit can raise a column of water;

- maximum flow - how many cubic meters per hour the pump will pass under the condition of a completely horizontal circuit without resistance.

These two values are “ideal”, unattainable in real conditions. They serve as extreme points in the head versus flow curve. This function in graphical form for different modes of operation of the pump is in the user manual.

For the circuit through which the coolant flows, using complex formulas, a curve is drawn up of the relationship between water flow and pressure loss due to the hydraulic resistance of the network elements.

The point where these two curves intersect is called the “pump duty point”. It will show the flow rate of the coolant that this device will provide for a particular hydraulic system.

Knowing this value and the cross section of the heating pipes, it is possible to calculate the speed of water movement through them. The optimal value is in the range from 0.3 to 0.7 m/s.

The calculated coolant flow rate when the pump is operating in the second mode will be 2.3 m3/h. With a pipe diameter of 1.5 inches, the flow rate through them will be 0.56 m / s. The model in question is suitable for this heating system (+)

The calculated coolant flow rate when the pump is operating in the second mode will be 2.3 m3/h. With a pipe diameter of 1.5 inches, the flow rate through them will be 0.56 m / s. The model in question is suitable for this heating system (+)

It is desirable that, according to the calculations, the operation of the pump at the second (medium) speed would be sufficient.

This is due to the following reasons:

- Error in calculations. The actual values of the resistance of the heating circuit may differ from the calculated ones. In this case, to achieve normal speed, it may be necessary to switch the mode to a more or less powerful one.

- Probability of adding new elements such as heatsinks, controls, etc. In this case, the resistance will increase, which will lead to a decrease in the flow rate. To solve this problem, it may be necessary to switch to the third speed.

- Increased equipment wear at maximum load. Operation at medium power significantly extends the period of trouble-free operation of mechanical devices. This rule also applies to pumps.

Now modern devices for forced circulation are equipped with automated systems for maintaining optimal operating parameters.With their use, it has become much easier to achieve the desired temperature in the rooms.

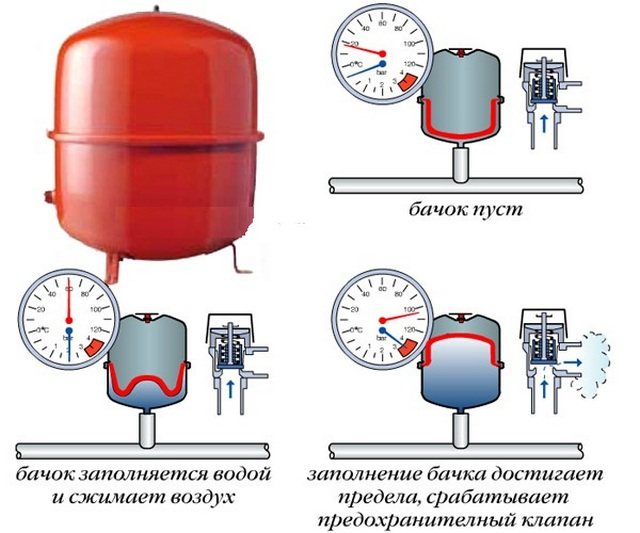

Other Important Features

The pump must be selected taking into account the “thread diameter” parameter. It must correspond to the internal size of the heating pipes.

To connect the pump to the pipes of the heating circuit, special union nuts are used, which usually come with the equipment

Another important parameter is the noise from the operation of the device. Since the task is often to choose a quiet circulation pump for a residential heating system, almost all manufacturers indicate this indicator along with technical data.

In order not to be mistaken in the purpose of the pump, it is necessary to pay attention to the range of permissible temperatures that is defined for the pumped liquid. The upper limit must be at least 110°C, since water boils in a closed system at approximately this temperature.

If the lower value is less than 0°C, then it is permissible to turn on the pump at a negative temperature of the antifreeze circulating in the system. With frozen water, even in the case of a circuit that has retained its integrity, it is impossible to start the device. First you will need to unfreeze the system.

Necessary calculations

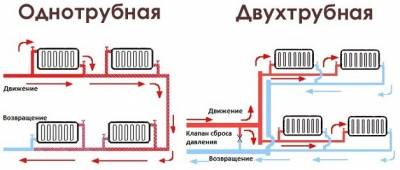

For example, it is necessary to make a calculation of a circulation pump for heating a square house with an area of 100 sq.m - for a single-pipe heating system.

Throttles or thermostats are installed directly on the heaters, and the break of the main ring is excluded.

The length of each wall is 10 m. The total length of the pipes in the circuit will be 10 x 4 = 40 m. Substituting the values in the above formula, you can find the desired pressure: 0.015 x 40 x 1.3 = 0.78.It should also be taken into account that the selected pump must have a head margin of at least 10%.

Nuances of choice

Having calculated the required values (the combination of these parameters is called the operating point), select the desired model. In principle, any of them is suitable, the technical characteristics of which will be no worse than those calculated

However, before choosing circulation pumps for heating systems, the following nuances must be taken into account:

- usually, when calculating the capacity, the largest loads that can occur at the lowest temperature in the season are taken into account. However, the heating system rarely operates in this mode - only a few days throughout the year. Therefore, if it seems that the pump power is greater than necessary, it is better to choose a model in which the parameter in question is slightly less;

- try to find the position of the calculated operating point on the flow-pressure curve for each of the proposed pumps. Choose a device where the operating point is closest to the graph;

- you should carefully approach the choice of such equipment, because a model with insufficient power will not be able to provide the required pressure, as a result, the radiators will not heat up to the required temperature;

- however, excess power is also not needed, since the consumption of electricity will increase, and an increase in noise level is also possible;

- it is undesirable that the diameter of the pump nozzles be smaller than the diameter of the pipes - otherwise it will not be able to maintain the required pressure.

Having calculated the power, you can choose the model that is most optimal for economical heating of the house.

pressure

According to the opinion of professionals, when organizing the conditions for the efficient operation of the central heating in the heating system, one should take into account the ratio of the maximum pressure of a particular model and the length of the OS circulation ring. Without going into technical details, we will announce a completely workable average indicator: choose a pump based on 0.6 meters of the declared pressure per 10 meters of the length of the heating circuit. That is, passport 6 meters of pressure (the Russian model "Compass 32-60") is enough to organize a stable circulation of the coolant, provided that the length of the heating circuit ring is not more than 100 m.

Heat pump manufacturers

Professionals choose heating components based on which company they were produced by. The reputation of the manufacturer helps determine the degree of quality of the product. This rule applies to pumps. Manufacturers whose products are presented in the rating:

- Stiebel Eltron is an international company founded in 1924 in Germany. The company produces a large number of electrical appliances, water heating and heating equipment. The manufacturing procedure takes place in high-tech production, which allows you to make complex, high-quality components.

- Daikin is a Japanese manufacturer that has been in business since 1924. The brand's products have spread to most countries of the world. The company manufactures advanced heating/heating equipment in large volumes. In its assortment there are many effective models of pumps.

- Cooper & Hunter is a company created as a result of the merger of three small manufacturers of air conditioning equipment in 1916.At the moment, the products of the American brand are recognized all over the world: the devices are used to equip thermal systems in domestic, office, industrial premises.

- Gree Electric is the largest manufacturer of air conditioners and heating equipment in China. Produces goods of all types, from household to industrial. Known for the production of multifunctional devices that provide efficient and economical heating.

- Mitsubishi is a Japanese conglomerate with more than a century and a half history. It includes several companies at once that produce high-tech solutions for various areas of life, it is known for the production of cars. But besides them, a huge variety of other equipment is also being manufactured.

- Fairland is a company founded in 1999. She very quickly managed to gain worldwide fame thanks to the production of heating, air conditioning, swimming pool equipment with the introduction of innovative technical and structural solutions.

- Kitano is a relatively young manufacturer whose products appeared on the Russian market only in 2013. Manufactures air-to-water heat pumps designed for continuous use. The devices are able to maintain a comfortable temperature even in the coldest conditions.

- Hitachi is a company that manufactures many technological models of heating and air conditioning equipment. It manufactures universal devices that can work effectively in any type of premises.

- Panasonic is a large Japanese engineering corporation that has been operating since 1918. It is considered one of the largest manufacturers of household appliances with electronic appliances for the home.Among the various products you can find high quality heating equipment.

Circulation pumps for heating systems: technical specifications

The vast majority of existing schemes include one or another modification of the circulation supercharger. The main technical characteristics by which the necessary device is selected are:

Unit performance. The amount of coolant pumped per unit of time depends on the pump performance. The value of this parameter depends on the length of the pipelines, the number of turns, the presence of vertical sections, etc.;

Pressure characteristics show to what maximum height this device can raise the entire column of coolant;

Mains operating voltage. Various models can be connected to both single-phase and three-phase networks;

Rated pump power. If it is possible to work in several modes, the power and current indicators for each speed mode are indicated in the product passport. Most existing devices are rated at 55 - 75 watts.

Permissible medium temperature. When choosing equipment, it is advisable to focus on a model that can withstand a coolant temperature of 110 C;

Mounting dimensions of the device include the thread diameter of the inlet and outlet pipe (for home use, this is most often 1 or 1.25 inches) and installation dimensions (for the most common models, it can be 130 or 180 mm);

Level of protection of electrical equipment (engine). Household systems are equipped with circulation pumps with IP44 protection class.The designation indicates that the ingress of abrasive particles larger than 1 mm into the housing cavity is completely excluded, and the electrical equipment is reliably protected from splashes and condensate;

The limiting pressure of the liquid in the outlet pipe, for household modifications, this value rarely exceeds 10 bar.

What to look for when choosing

Choosing a circulation pump will become much easier if you pay attention to the following parameters:

Performance. Different heating systems need a pump with an optimal level of performance. Therefore, the owner of the house should know the capacity of the installed boiler. For example, if a 40 kW device is operating in the circuit, then the pump should have a capacity of 2.4 m³ / h.

lifting height

Another important characteristic that you should definitely pay attention to. Experts advise using this simple formula: for 10 meters of pipeline - a head of 0.6 meters

Thus, it will not be difficult to calculate that a heating main of 100 meters will need a pump with a lift height of 6 meters.

Streaming speed control. A rather useful option, due to which it can independently change the speed of water movement. Some models are equipped with a 2-3 position switch, more modern ones have electronic regulators that automatically change speed. Main: the indicator should not exceed 1.6 m / s.

Power level. Each pump has its own electric motor with a certain power level. The thinner the pipe in the heating system, the more power should be then. Some models have a power of 100 watts, more complex models - 150 watts.

Materials.Pay attention to what materials the parts and assemblies are made of, because this is what affects the life of the device. Ideally, the body should be cast iron, the impeller and impeller should be plastic.

The best pumps in terms of value for money

For efficient heating of houses on 1-2 floors with an average area, it is recommended to use equipment from the middle segment, which is the best in terms of cost, performance and quality.

DAB EVOTRON 40/180

It is made of a high-quality heat-insulating case, the current consumption is minimal, only 27 watts. Jet pressure up to 4 meters with a capacity of 4 cubic meters. m/h This will be sufficient for small areas. The model is reliable and of high quality with convenient operation, but the cost is too high.

Pros:

- Silent operation.

- Availability of electronics for automatic speed correction.

- Minimum current consumption.

Among the minuses are the cost of the goods.

JILEX Compasses 32-80

It comes with a mount, inside there is a switch for 3 speeds of operation to optimize energy costs. Reviews are only positive, the model with the best value for money.

Pros:

- High degree of reliability.

- Quiet operation.

- Saves electricity and heat in the house.

- Quality build.

- Excellent technical specifications.

There are no downsides to this device.

Wilo Star-RS 25/4-180

A popular model among owners of country houses. The average market value is about 4800 rubles. It is recommended to buy equipment for small areas and heating mains.The motor consumes 48 W, while it allows you to make a pressure of 4 meters with a capacity of up to 3 cubic meters / hour.

The device is in a cast iron case, visually very reliable, inside there is a stainless shaft, which is characterized by durability. The pump is very quiet, and the user can switch speeds on their own. German-made model with excellent quality and reliability, but the performance is not the best, and installation can only be carried out in a horizontal plane.

Pros:

- Long service life.

- High quality and reliability.

- Quiet operation.

- Small current consumption.

- Optimal cost.

Of the minuses, weak performance is distinguished.

WCP 25-80G (180 mm)

The excellent choice for installation in the one-pipe or two-pipe heating main. The average market value is 4600 rubles. The total engine power is 245 W, while the productivity will be up to 8.5 cubic meters / hour, and the pressure will be up to 8 meters.

The device is made with high quality, the main components are installed in a cast-iron case, the motor is made of aluminum, it is characterized by a long service life. There is a speed controller in 3 modes, which will optimize the cost and heating of the house. The equipment is small in size and weight, so installation problems do not appear. The main disadvantage is loud work at peak load and plastic parts are not of the highest quality.

Pros:

- Small size and weight.

- Existence of 3 modes for regulation of work.

- Optimal cost.

Of the shortcomings, the noise of the equipment is distinguished.

How to improve system reliability

As a rule, the circulation pump does not require high performance, like drainage pumps, nor the need to lift liquid to a great height, like, say, downhole equipment. But they must work for a long time - throughout the entire heating season, and, of course, the heating should in no case fail during this period. Therefore, it is not worth saving, and to ensure absolute reliability, it is better to install a pair of pumps - the main and additional ones - on the bypass branch of the pipeline through which the coolant is pumped.

If the main pump suddenly fails, the homeowner can very quickly switch the heating medium supply to the bypass branch, and the heating process will not be interrupted. It is curious that with the current level of automation, this switching can also be done remotely, for which pumps and ball valves must be connected to the Internet. The cost of such automation (the price of a set of ball valves and a remote-controlled socket) is approximately 5–6 thousand rubles.

ShutterStock

Installing a pump in a hot water system with underfloor heating.

Grundfos

circulation pumps. Model ALPHA3 with data transfer function and support for mobile applications.

Grundfos

ALPHA1 L pumps are used for the circulation of water or glycol-containing liquids in controlled heating systems and in heating systems with variable flow. The pumps can also be used in DHW systems.

Leroy Merlin

Oasis circulation pumps, three power switching modes, cast iron housing, model 25/2 180 mm (2,270 rubles).

Conclusions and useful video on the topic

Calculation of the required characteristics of the pump depending on the parameters of the heating circuit:

Detailed video instructions for assembling a bypass from polypropylene pipes:

For any hydraulic circuit, you can choose a pump that helps to achieve the desired pressure

First of all, you need to pay attention to the pressure-flow characteristics of the device, and then to other technical data: efficiency, noise, reliability and connection method

Share with readers your experience of using a circulation pump. Tell us what the choice of the unit was based on, and whether you are satisfied with the purchase. Please post to the article, ask questions and participate in discussions. The contact form is located below.