- What to consider when choosing the right location

- Where is it better to install: supply or return

- What is a circulation pump and why is it needed

- The principle of operation of the pump

- Direct installation

- Place for tie-in

- Improving Efficiency

- Structural scheme

- Sequence of work

- Carrying out work

- Where to put

- forced circulation

- natural circulation

- Mounting Features

- Do I need a pump in the home heating circuit Does gas consumption decrease when using an athunder pump

- Purpose and types

- Dry Rotor

- wet rotor

- 1 Circulation pump installations device and principle of operation

- 3 Installation of the circulation motor

- Carrying out work

- Conclusions and useful video on the topic

What to consider when choosing the right location

When installing the device in the circuit, the following is taken into account:

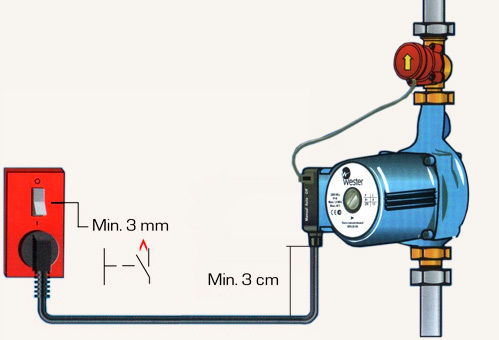

- correct orientation (indicated in the instructions, horizontally or vertically);

- correct piping (correctly selected set of additional devices);

- if there are two or more branches, then the best option is to install a separate pump for each (in this case, it is possible to immediately achieve an equal temperature in the rooms for each branch and use fuel more economically).

Where is it better to install: supply or return

Professionals recommend placing the pump in front of the first branch of the circuit. The device is designed for the temperature of the pumped liquid up to 115°C, so the choice of supply or return pipe is not critical.

This is significant when installed in a system with a steam boiler, since the coolant at the outlet has a temperature above 100 ° C, which is unacceptable. The temperature on the return pipe is set within the normal range.

The return is the only option for solid fuel boilers, except for systems with automated control.

Important! Boilers without automation often overheat the coolant to a boil, so steam enters the pump installed in the supply. This leads to an almost complete cessation of fluid movement along the circuit and an emergency, even an explosion. The return pump can also be filled with steam, but in this case, the time of operation of the safety valve is increased, which solves the problem and avoids misfortune

The return pump may also be filled with steam, but in this case, the response time of the safety valve is increased, which solves the problem and avoids misfortune.

What is a circulation pump and why is it needed

A circulation pump is a device that changes the speed of movement of a liquid medium without changing the pressure. In heating systems, it is placed for more efficient heating. In systems with forced circulation, it is an indispensable element, in gravitational systems it can be set if it is necessary to increase the thermal power.Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the temperature outside, thus maintaining a stable temperature in the room.

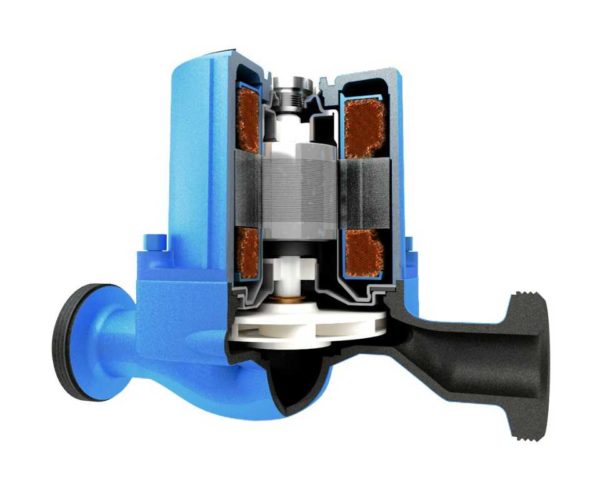

Sectional view of a wet rotor circulation pump

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but they are very noisy and require regular maintenance. Wet rotor units operate almost silently, with normal coolant quality, they can pump water without failures for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than enough to heat any private house.

The principle of operation of the pump

Circulation devices for heating houses are needed to ensure the movement of heat in the water circuit. After mounting the device, the natural process of fluid circulation in the system no longer occurs, in this case the pumps begin their work in a constant mode. That is why many specialists look at circulating devices more carefully and set many requirements for them. These include:

- high level of reliability;

- isolation from unnecessary sounds;

- high performance;

- long equipment life.

As many users note, if you place the station in any system with natural coolant operation, the heating rate of the house will increase and heat will be evenly distributed around the entire perimeter of the water circuit.

As many users note, if you place the station in any system with natural coolant operation, the heating rate of the house will increase and heat will be evenly distributed around the entire perimeter of the water circuit.

The main disadvantage of such a device will be a certain dependence of the functioning of the pumping device on electricity, but the difficulty is most often solved by connecting a special uninterruptible power supply.Experts recommend installing the pump in the heating of the house, both when creating a new design, and for pumping an existing one.

Direct installation

The process of installing a pump for heating requires the prior purchase of equipment with a split thread. In the absence of it, installation will be difficult due to the need for self-selection of transition elements. For long-term operation, you will also need a deep filter and check valves that provide pressure operation.

Installation is carried out using a set of wrenches of appropriate sizes, valves and bypasses equal to the diameter of the riser.

Place for tie-in

When connecting the pump, take into account its periodic maintenance and place it within direct reach. The priority installation site is also determined by other nuances. In the past, wet pumps were often mounted in return circuits. Cooled water, which washed the working part of the equipment, extended the life of seals, rotors and bearings.

The details of modern circulation devices are made of durable metal, protected from the effects of hot water, and therefore can be freely attached to the supply pipeline.

Improving Efficiency

A properly installed pump unit can increase the pressure in the suction area and thus increase the heating efficiency. The connection diagram implies the installation of the device on the supply pipeline near the expansion tank. This creates a high temperature zone in a given section of the heating circuit.

Before inserting the bypass with the pump, you will need to make sure that the device can withstand the onslaught of hot water.If a private house is equipped with underfloor heating, the device must be installed on the coolant supply line - this will protect the system from air pockets.

A similar method is suitable for membrane tanks - bypasses are mounted on the return line in the minimum proximity to the expander. This can make it difficult to access the unit. The problem will be corrected by installation on the supply circuit with a tie-in vertical check valve.

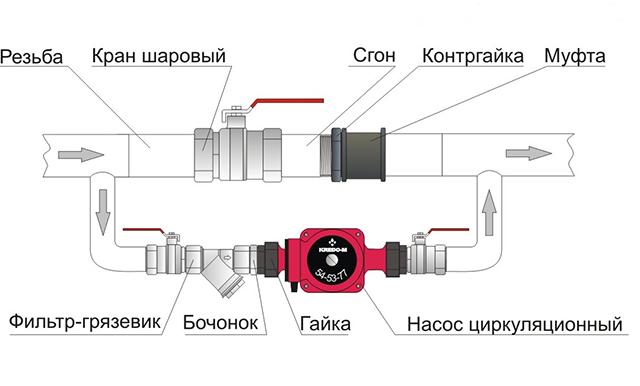

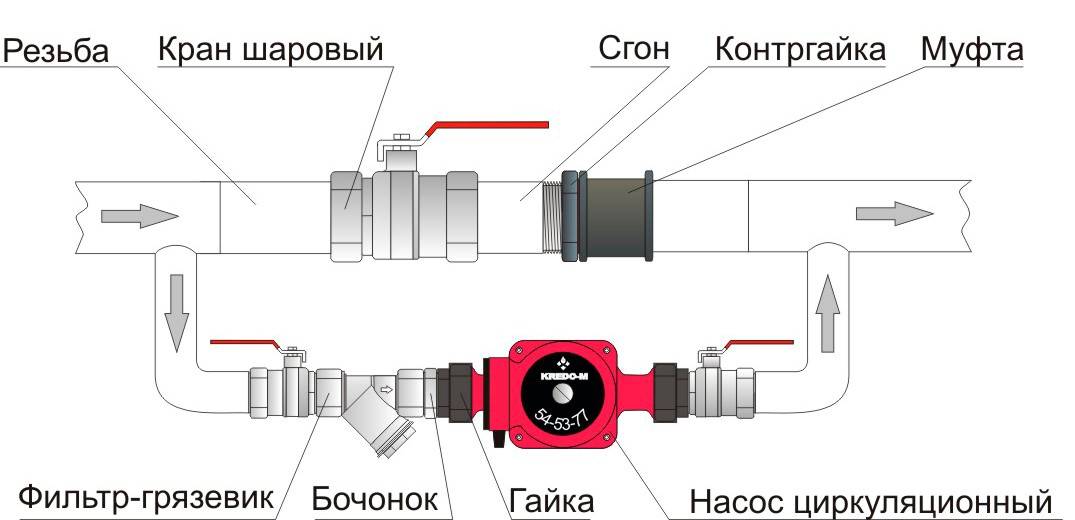

Structural scheme

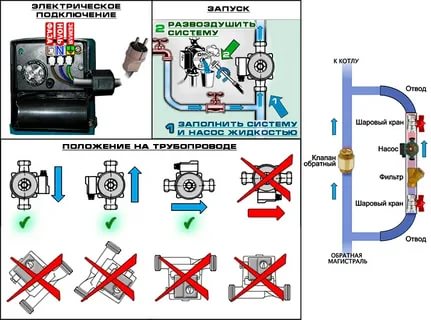

The installation of circulation equipment requires compliance with the rules regarding the sequence of fastening elements:

- ball valves mounted on the sides of the pump provide the possibility of removing it for inspection or replacement;

- a filter embedded in front of them protects the system from impurities clogging the pipes. Sand, scale and small abrasive particles quickly destroy the impeller and bearings;

- The upper parts of the bypasses are equipped with air bleed valves. They can be opened manually or operate automatically;

- the scheme for the correct installation of a "wet" pump implies its horizontal mounting. The arrow on the body must coincide with the direction of water movement;

- protection of threaded connections is ensured by the use of sealant, and all mating parts are reinforced with gaskets.

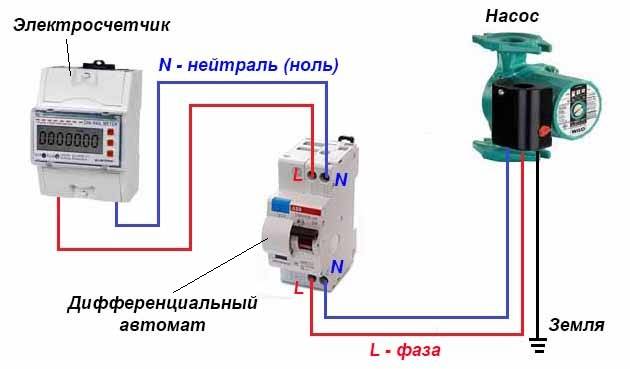

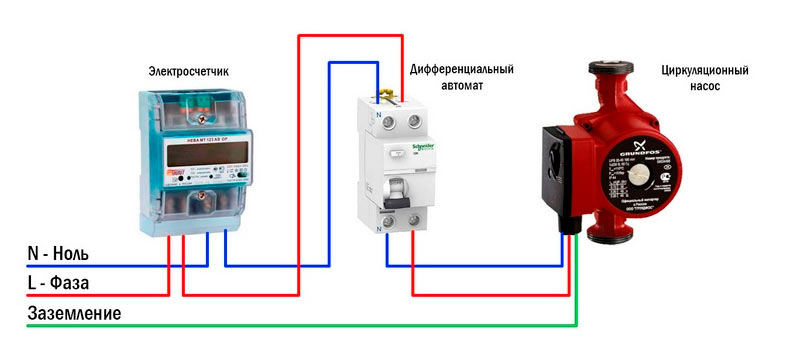

For safety reasons, pumping equipment can only be connected to a grounded outlet. If grounding has not yet been carried out, it must be provided before the machine is put into operation.

The dependence of the pump on the availability of electricity is not an obstacle to normal functioning. When developing a project, it is necessary to include the possibility of natural circulation in it.

Sequence of work

When connected to an existing heating network, you will need to drain the coolant from it and blow the system. If the pipeline has been actively used for many years, it must be flushed several times to remove scale residues from the pipes.

The functional chain of the circulation pump and its fittings is mounted in a pre-selected location in accordance with the connection rules. When the installation cycle is completed and all additional devices are attached, the pipes are again filled with coolant.

To remove residual air, you need to open the central screw on the cover of the device. A signal of successful bleeding will be water flowing from the holes. If the pump has manual control, the gases will need to be removed before each start. To save equipment and reduce interference in the heating process, you can install an automatic pump with a work control system.

Carrying out work

Proper installation of the pump in the heating system of a private house requires performing work, observing certain installation rules. One of them is a tie-in on both sides of the ball valve circulation unit. They may be needed later when dismantling the pump and servicing the system.

Be sure to install a filter - for additional protection of the device.

Usually the quality of the water leaves much to be desired, and particles that come across can damage the components of the unit.

Install a valve on top of the bypass - it does not matter if it is manual or automatic. It is needed to bleed air pockets periodically formed in the system. Terminals should be directed straight up

The device itself, if it belongs to the wet type, must be mounted horizontally.If this is not done, only part of it will be washed with water, as a result, the working surface will be damaged. In this case, the presence of a pump in the heating circuit is useless.

Terminals should be directed straight up. The device itself, if it belongs to the wet type, must be mounted horizontally. If this is not done, only part of it will be washed with water, as a result, the working surface will be damaged. In this case, the presence of a pump in the heating circuit is useless.

The circulation unit and fasteners must be placed in the heating circuit naturally, in the correct sequence.

Before starting work, drain the coolant from the system. If it has not been cleaned for a long time, clean it by washing it several times.

On the side of the main pipe, in accordance with the diagram, mount a bypass - a U-shaped pipe section with a pump built into its middle and ball valves on the sides. In this case, it is necessary to take into account the direction of water movement (it is marked with an arrow on the body of the circulation device).

Each fastening and connection must be treated with sealant - to prevent leakage and make the whole structure more efficient.

After fixing the bypass, fill the heating circuit with water and check its ability to function normally. If errors in operation or malfunctions are found, they must be eliminated immediately.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C.There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

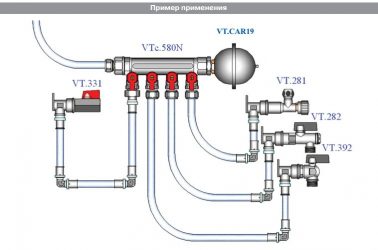

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer.However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

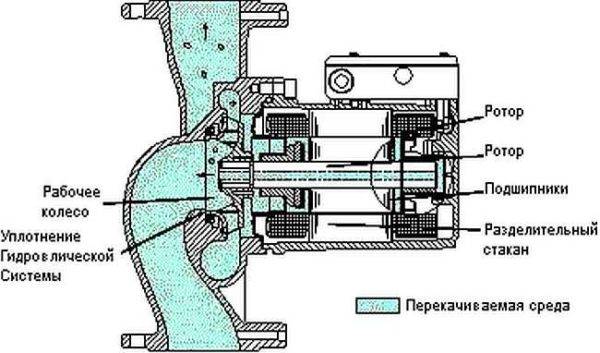

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

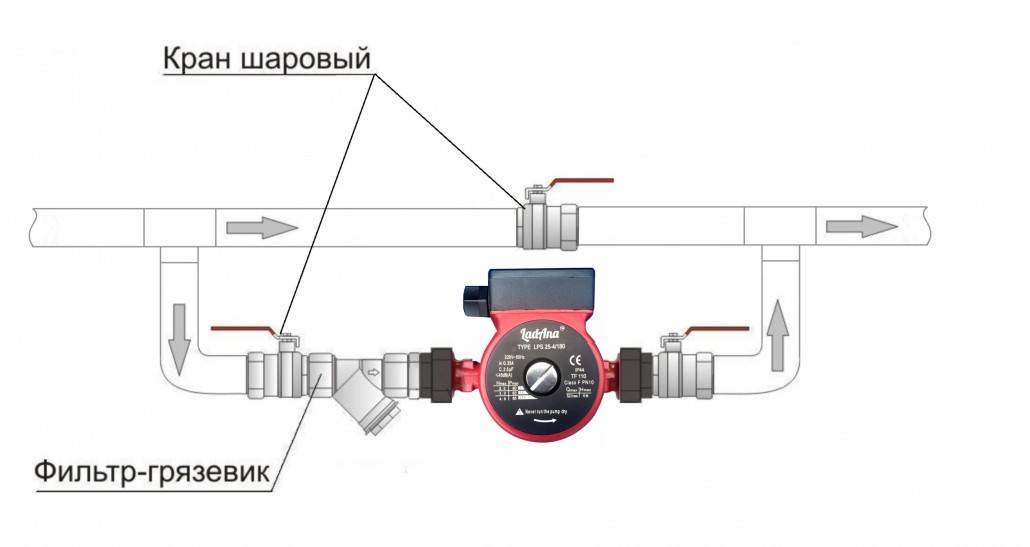

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running.One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Do I need a pump in the home heating circuit Does gas consumption decrease when using an athunder pump

In the Kuban, I encountered the fact that people are convinced without exception that it is necessary to put a pump in the circuit of the home heating system in order to reduce gas consumption (of course, when using a gas boiler for heating a house). Yesterday, gas workers from RostovGorGaz also mentioned this during preventive measures. In this regard, I would like to raise the question of whether the pump is really needed in the home heating circuit.

I have an old one-story house. In the heating system, natural circulation, i.e.The water heats up and moves on its own through pipes and radiators. The heating system works fine, since the relatives ate the dog in the design and installation of heat supply systems, heating, as well as setting up houses, from cottages to high-rise buildings. Including they often have to correct the mistakes of unfortunate specialists.

In a one-story house, forced circulation (using a pump) allows you to warm up the house faster. All this is due to the fact that warm water flows faster into cold rooms. But if you permanently live in the house, then there may not be much advantage in this at all.

If there is a decrease in gas consumption when using the pump, then it is insignificant. In this case, the pump consumes electricity. Let this be a maximum of 20-50 W, but with round-the-clock operation, electricity costs should not be neglected.

The pump in the heating system is really needed if natural circulation does not work. But even in a multi-storey building, it may be optional.

In one-story houses, with the exception of rare cases, there is a banal divorce for money, and not at all a concern for reducing gas consumption.

Update (26.01.2016 21:58) A correction has been made after the designer's comment: It is also not necessary to use a pump in high-rise buildings (approx. it is logical if the pressure in the line is already high).

What helps save gas:

high-quality calculation of hydraulics,

proper selection of pipes and radiators,

well-tuned radiator fittings,

home insulation,

weather automatic,

temperature controllers on each appliance or in each room,

high efficiency boiler.

The post is about ONLY pump installation hardly will not lead to gas savings.

Purpose and types

As already mentioned, the main task of the circulation pump is to ensure the required speed of the coolant through the pipes. For systems with forced circulation, only under such conditions will the design capacity be reached. During the operation of the circulator, the pressure in the system increases slightly, but this is not his task. It's more of a side effect. To increase the pressure in the system, there are special booster pumps.

Glandless water circulation pumps are more popular

There are two types of circulation pumps: dry and wet rotor. They differ in design, but perform the same tasks. To choose the type of circulation pump you want to install, you need to know their advantages and disadvantages.

Dry Rotor

It got its name due to the design features. Only the impeller is immersed in the coolant, the rotor is in a sealed housing, it is separated from the liquid by several sealing rings.

The device of the circulation pump with a dry rotor - only the impeller in the water

These devices have the following properties:

- They have a high efficiency - about 80%. And this is their main advantage.

- Require regular maintenance. During operation, solid particles contained in the coolant enter the sealing rings, violating the tightness. To prevent depressurization and maintenance is required.

- The service life is about 3 years.

- During operation, they emit a high level of noise.

Such a set of characteristics is not very suitable for installation in heating systems of private houses. Their main advantage is high efficiency, which means less energy consumption. Therefore, in large networks, circulation pumps with a dry rotor are more economical, and they are mainly used there.

wet rotor

As the name implies, in this type of equipment, both the impeller and the rotor are in the liquid. The electrical part, including the starter, is enclosed in a metal sealed glass.

Glandless pump design - dry electrical part only

This type of equipment has the following properties:

- The efficiency is about 50%. Not the best indicator, but for small private heating systems this is not critical.

- Maintenance is not required.

- Service life - 5-10 years, depending on the brand, mode of operation and condition of the coolant.

- During operation, they are almost inaudible.

Based on the above properties, it is not difficult to choose a circulation pump by type: most stop on devices with a wet rotor, as they are more suitable for working in an apartment or a private house.

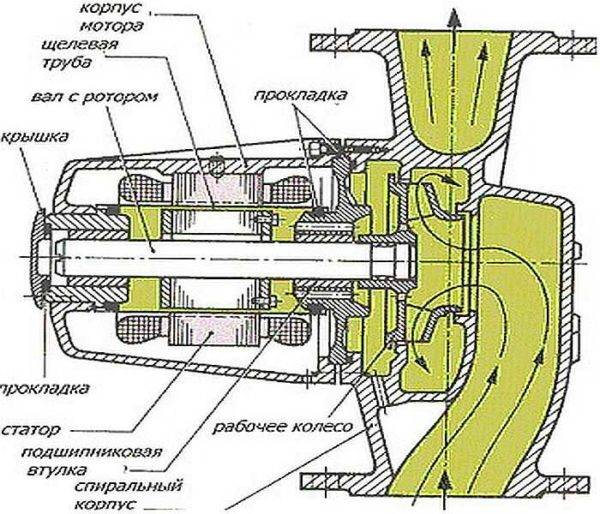

1 Circulation pump installations device and principle of operation

In closed heating systems, forced circulation of hot water is required. This function is performed by circulation pumps, which consist of a metal motor or a rotor attached to a housing, most often made of stainless steel. The ejection of the coolant is provided by the impeller. It is located on the rotor shaft. The entire system is driven by an electric motor.

Also in the design of the described installations there are the following elements:

- shut-off and check valves;

- the flow part (usually it is made of a bronze alloy);

- thermostat (it protects the pump from overheating and ensures the economical operation of the device);

- work timer;

- connector (male).

The pump, when installed in a heating system, draws in water, and then supplies it to the pipeline due to centrifugal force. The specified force is generated when the impeller produces rotational movements. The circulation pump will work efficiently only if the pressure it creates can easily cope with the resistance (hydraulic) of the various components of the heating system (radiator, pipeline itself).

3 Installation of the circulation motor

But there are exceptions. When an open-type expansion tank or a membrane expansion tank is installed on the coolant supply pipe, the pump can be mounted on any section of the "return" pipe.

This data should not be accepted as a rule at all. The position on the return pipe is recommended. It is believed that the equipment will last longer when working with chilled water than at the exit with hot water.

On the other hand, modern high-temperature pumps (up to 110 degrees) can also be installed on the supply pipe, but the parameters of the entire system must be precisely balanced and adjusted. This is due to the peculiarities of the design itself. If the motor is installed behind the boiler, then in severe frosts at maximum power the coolant may boil, since such equipment dilutes the liquid. The occurrence of such a situation can lead to a breakdown of the system as a whole.

In this regard, if the pump is mounted on the supply pipe, then it must be done away from the boiler, but before the first branching of the radiator.

Large heating systems sometimes have two groups of supply pipes that diverge in the opposite direction.In this case, it is better to install two circulation pumps in each direction before branching to the first radiator.

Thus, there are no certain general recommendations for installing the motor. You need to approach each case individually.

It is easy to choose and connect a circulation motor for heating a private house or apartment

The main thing is to pay attention to key factors such as manufacturer, pump type, power, performance and other data.

It is not difficult to connect it to the heating system, the circuit is quite simple. If the equipment breaks, changing the motor will not be a difficult task either.

Carrying out work

Proper installation of the pump in the heating system of a private house requires performing work, observing certain installation rules. One of them is a tie-in on both sides of the ball valve circulation unit. They may be needed later when dismantling the pump and servicing the system.

Be sure to install a filter - for additional protection of the device.

Usually the quality of the water leaves much to be desired, and particles that come across can damage the components of the unit.

Install a valve on top of the bypass - it does not matter if it is manual or automatic. It is needed to bleed air pockets periodically formed in the system.

Terminals should be directed straight up. The device itself, if it belongs to the wet type, must be mounted horizontally. If this is not done, only part of it will be washed with water, as a result, the working surface will be damaged. In this case, the presence of a pump in the heating circuit is useless.

The circulation unit and fasteners must be placed in the heating circuit naturally, in the correct sequence.

Before starting work, drain the coolant from the system. If it has not been cleaned for a long time, clean it by washing it several times.

On the side of the main pipe, in accordance with the diagram, mount a bypass - a U-shaped pipe section with a pump built into its middle and ball valves on the sides. In this case, it is necessary to take into account the direction of water movement (it is marked with an arrow on the body of the circulation device).

Each fastening and connection must be treated with sealant - to prevent leakage and make the whole structure more efficient.

After fixing the bypass, fill the heating circuit with water and check its ability to function normally. If errors in operation or malfunctions are found, they must be eliminated immediately.

Conclusions and useful video on the topic

Rules for installing heating equipment in the video:

The video explains the features of a two-pipe heating system and demonstrates different installation schemes for devices:

Features of connecting the heat accumulator to the heating system in the video:

p> If you know all the connection rules, there will be no difficulties with the installation of the circulation pump, as well as when connecting it to the power supply at home.

The most difficult task is to insert a pumping device into a steel pipeline. However, using a set of lerok for creating threads on pipes, you can independently arrange the arrangement of the pumping unit.

Do you want to supplement the information presented in the article with recommendations from personal experience? Or maybe you saw inaccuracies or errors in the reviewed material? Please write to us about it in the comments block.

Or have you successfully installed the pump and want to share your success with other users? Tell us about it, add a photo of your pump - your experience will be useful to many readers.