- Design of a centrifugal fan

- Technical points

- The principles of the exhaust system in the house

- How to make a centrifugal fan

- A vacuum cleaner

- Radial

- Device and design

- Peculiarities

- Impellers, blades

- Kinds

- Natural and artificial ventilation system

- Centrifugal fan design

- Some application examples

- Ship ventilation devices

- Apartment ventilation

- Drying chamber ventilation

- household fan

- Fans by version

- Multi-zone fans

- Duct fans (straight-through)

- Radial Roof Fans (VKR)

- The device and principle of operation of centrifugal fans.

- Vents VK 125 – affordable price

- Design and principle of operation

- Housing materials

- Working wheel

- Electric motors

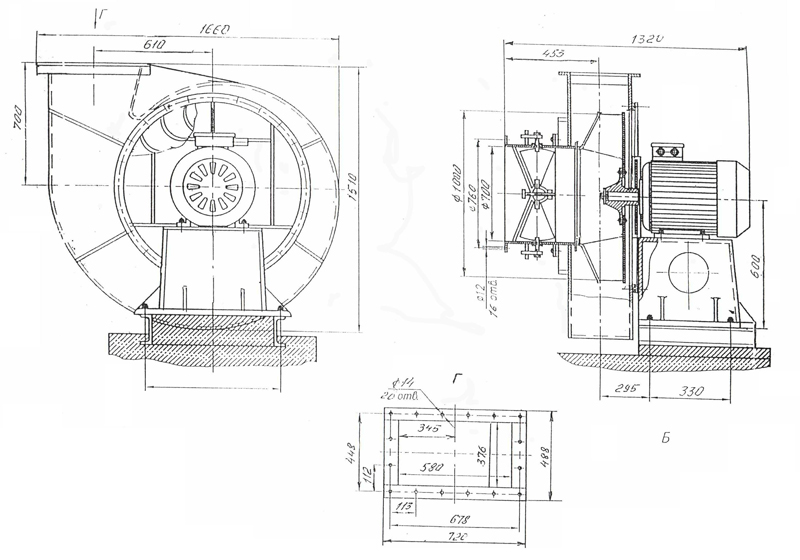

- Dimensions

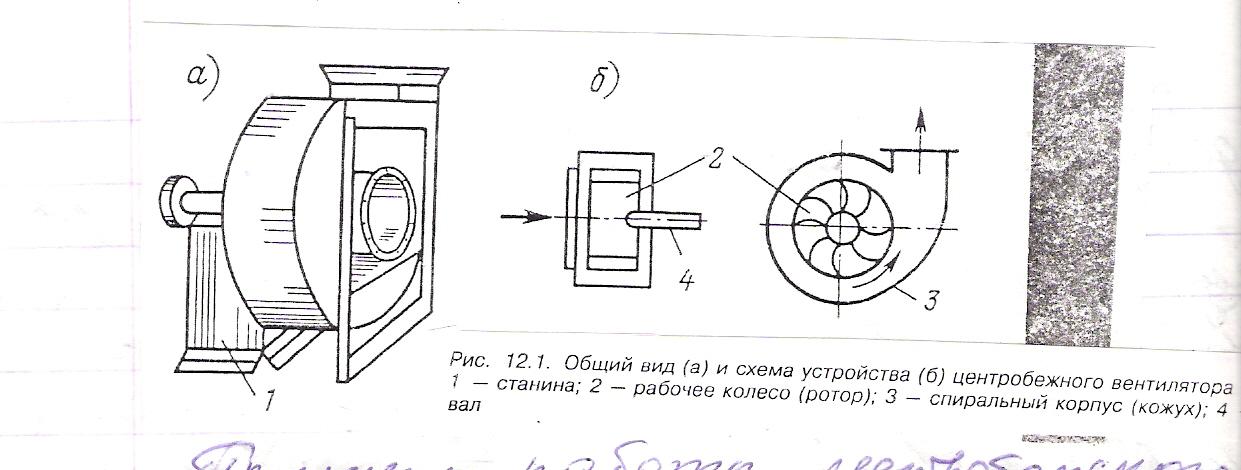

Design of a centrifugal fan

The design of a centrifugal fan is quite simple. A wheel with blades is located in the housing with inlet and outlet openings. An electric motor is used to operate the device.

The unit works according to the following principle: the blades rotate and thereby provide air movement. Air is sucked in through the inlet under the influence of centrifugal force, and pushed out through the outlet.

The direction of movement of the air masses at the exit is perpendicular to the incoming flow. Due to the fact that high pressure is created inside, such fans can move a large amount of air.

This feature allows the use of centrifugal devices in the main channels of complex design and long length. These fans are easy to use and with proper operation serve for quite a long time.

Rotating blades can be mounted perpendicular or parallel to the axis of the circle. With a parallel arrangement, the noise during operation of the device is reduced, while the efficiency is not reduced.

During production, centrifugal fans are equipped with additional functions to perform certain tasks. For example, for use in a room with high temperatures, the device must be equipped with a special thermal protection.

If you intend to use in conditions of high humidity, then the device must have increased resistance to corrosion. In some models, even explosion protection is provided.

These functions can be combined in one unit, but more often models have one of them.

When choosing a centrifugal model, it is necessary to be guided by two important parameters:

- the volume of air masses that pass through the outlet in a certain period of time;

- air pressure at the outlet of the fan.

Knowing these indicators will help you make the right choice.

Technical points

For the manufacture of the impeller, lightweight materials are used. She may be:

- plastic;

- duralumin;

- aluminum;

- for air transfer of aggressive media - from stainless steel.

The use of lightweight materials is due to the fact that a powerful engine is not required to rotate the blades. Even on industrial air blowers, motors with a power of more than 800 W are rarely used.

The main technical characteristics of the device depend on:

- axis rotation direction (left or right);

- the number of blades;

- forms of bladed blades (curved or flat);

- installed engine power;

- the size of the impeller in diameter;

- body shape (most often, the body has the shape of a cylinder);

- protective technique to reduce injuries: grille or blinds.

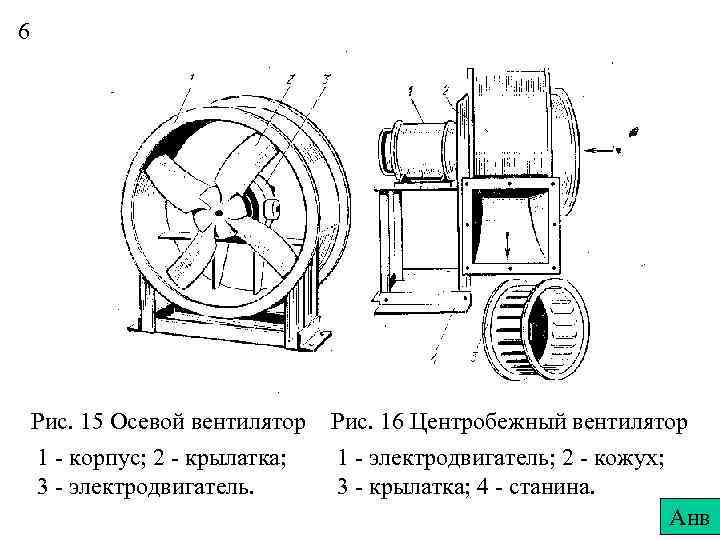

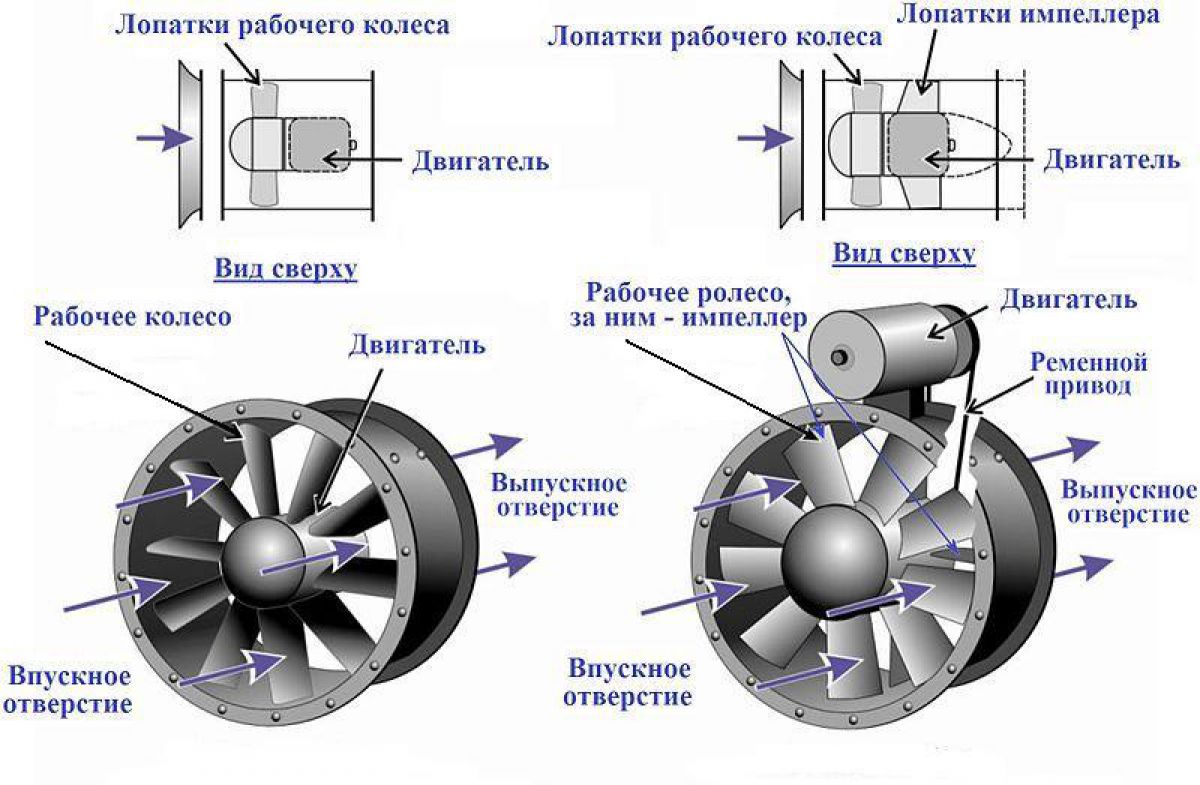

Sometimes they confuse centrifugal and axial fans, believing that they are one and the same, but the difference between these devices that enhance air flow is large. They differ in technical characteristics and in the principle of operation.

The principles of the exhaust system in the house

To understand exactly how exhaust ventilation is done at home with your own hands, you need to understand its device. Namely, for example, consider a ventilation system made by real professionals in their field.

- In the first place is the supply valve. Its feature lies in the ability to change the amount of air passed through the damper. It needs to be placed on the north side, since according to statistics, the wind blows from here most often. At the air inlet to the valve there is a fan that discharges the flow, forcing the incoming air into the channel. This channel may consist of branches that go to the desired rooms in the house. They are connected by a collector - a distribution compartment.

- At the outlet is a mixer. This is a special camera that is placed in every room. It brings fresh air into the room.Here is a recuperator - a device that serves to heat the air to a comfortable temperature. Heating occurs without significant costs, since in fact there is a normal exchange of energy between the exhausted hot carbon dioxide from the room and the outdoor, cooled air. In the summer, it is recommended to install air conditioners to cool the hot stream coming from the street.

- As for the air used, it passes through the hood and enters the fan, passing through special holes in the form of gratings located in the upper part of the room or on the ceiling. The blades carry the air out into the pipe, which is placed at the same level as the roof ridge of your house.

Read also: T160 thyristor power regulator

As you can see, installation of such complexity requires the participation of professionals in the work. But there is a do-it-yourself supply and exhaust ventilation in the house, which is much easier.

How to make a centrifugal fan

From what has been said, the obvious way to carry out the plan is to remove the tangential fan from the hood, for example. Benefit: Silent operation is ensured. The manufacturer complies with the norms prescribed by the standards, so factory hood class devices are relatively quiet. We believe that for most readers this is not the best solution to the problem, let's continue our consideration.

A vacuum cleaner

Inside the vacuum cleaner there is a ready-made centrifugal fan. A big plus is that there is already a ready-made case, which must be mounted in the channel in place. Additional benefits include:

- The vacuum cleaner motor is designed for long-term operation. Spins the blade for days on end.The windings are often protected from overheating, in addition, air passes through the channels, cooling the stator.

- The motor of the vacuum cleaner is aimed at overcoming significant pneumoloads. When disassembling this housewife's assistant with your own hands, you will see a safety valve inside. Try to remove and blow with the force of the lungs. Does not work? And the engine does it jokingly! Clamp the inlet, or bend the hose in half. A click coming from the inside of the case indicates the operation. We believe that such a force is more than enough to ventilate the facility.

- Plus - suction power (in aerowatts) is indicated in the technical specifications, similar to the pressure generated. Thus, it is easy to calculate in advance by formulas whether the engine power is sufficient for the chosen task. Sometimes manufacturers are so kind that they indicate the flow rate, for example, 3 cubic meters per minute. Anyone can calculate: 180 cubic meters per hour. Due to the high power, the flow will be maintained despite the turns and bends of the duct.

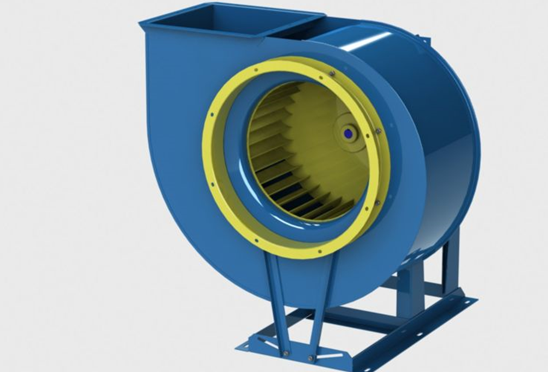

Radial

A radial or centrifugal device differs from other types in an unusual spiral casing design, in which an impeller is located, which compresses air masses during rotation, moving them in the direction from the center to the peripheral part. The flow enters the casing under the influence of centrifugal forces from the rotation of the wheel with blades.

The blades are welded to the hollow cylinder along its entire perimeter strictly parallel to the axis of rotation using steel disks, their ends are bent inward or outward, depending on the direct purpose of the device.Rotation can be performed in any direction - it depends on how the fan is arranged and what tasks are assigned to it (forcing or extracting).

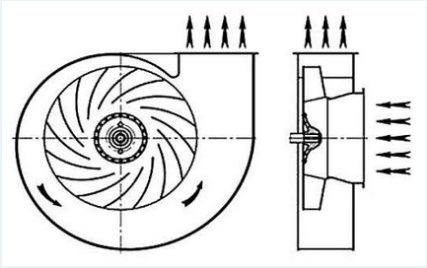

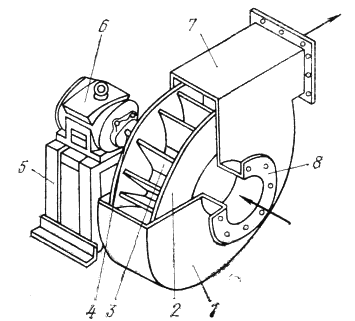

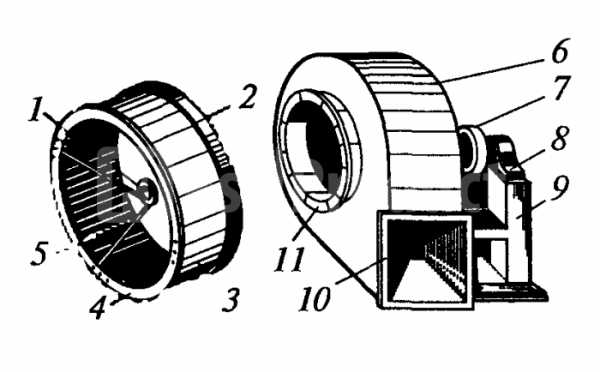

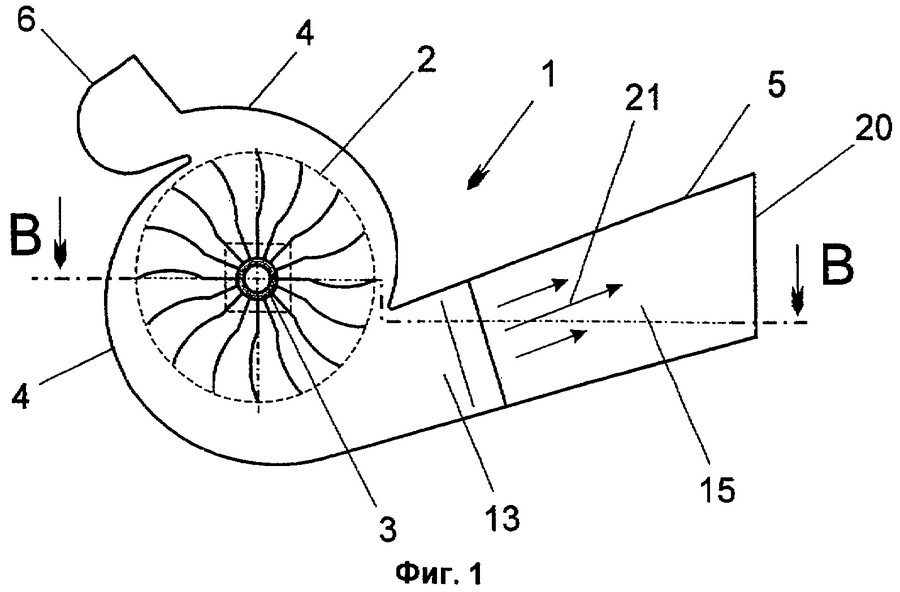

The main components of a radial fan are shown in the drawing below, where 1 is the housing; 2 - impeller; 3 - impeller blades; 4 - fan axis; 5 - bed; 6 - engine; 7 - exhaust pipe; 8 - suction pipe flange

Pros:

- withstands decent overload;

- energy savings up to 20%;

- small diameter of the impeller;

- low speed of rotation of the drive shaft.

Minuses:

- high vibrations and noise;

- exactingness to the quality of manufacturing of rotating parts.

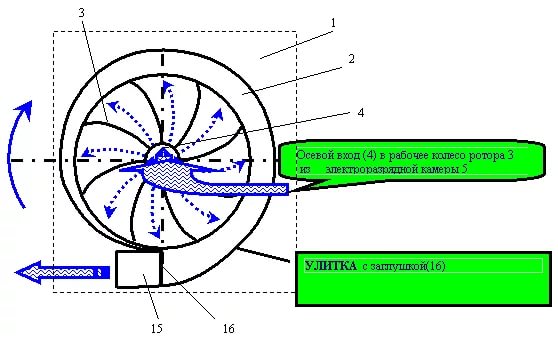

Device and design

The suction takes place in the direction of the axis of rotation, and the ejection occurs tangentially to it, perpendicular to the suction. When the blades rotate, they capture air particles and throw them out with force in a centrifugal direction. The fan housing does not allow the flow to dissipate, directing it to the outlet. In the region of the central part of the impeller, a vacuum is formed, which is immediately replenished by the inflow from the inlet located in the central part of the flat side of the housing.

Peculiarities

The specificity of the operation of centrifugal fans is the ability to reverse the air jet when the direction of rotation of the impeller changes. At the same time, there is practically no difference in pressure, there are only small differences in the parameters due to the use of the reverse sides of the blades.This allows you to install the fan in different parts of the duct system and provide certain modes of operation of the system.

The design of the snail fan is quite simple. An impeller is mounted on the drive shaft, which rotates inside the housing. There are design options where the impeller does not have its own shaft and is mounted directly on the motor shaft. This is typical for small fans. The value is determined by the fan number, which indicates the impeller diameter in dm. For example, radial fan No. 4 has an impeller with a diameter of 40 cm.

Impellers, blades

The impeller (impeller) consists of blades that act on certain sections of the air flow, and a carousel-type support structure.

There are two types:

- drum impeller. It looks like a squirrel wheel. It is used in fans carrying out the movement of a gas-air medium with the usual requirements - temperatures up to 80 °, the absence of aggressive, flammable, sticky or fibrous inclusions. Installed in most fans

- open impeller. It is used much less frequently, since a design of this type is less resistant to mechanical stress. Most manufacturers make such impellers only to order. It is used for work as dust devices, working with complex materials with fibrous inclusions.

Kinds

The scale of the premises, as well as the level of pollution and heating of the air in them, require the installation of exhaust systems of the appropriate size, power and configuration. Therefore, centrifugal fans are of various types.

Depending on the level of pressure created by air masses in the exhaust duct, they are classified into fans:

- Low pressure - up to 1 kPa. Most often, their design provides for wide sheet blades, which are bent forward to the suction pipe, with a maximum rotation speed of up to 50m/s. The scope of their application is mainly ventilation systems. They create a lower noise level, as a result of which they can be used in rooms where people are constantly present.

- Medium pressure. In this case, the load level created by the movement of air masses in the exhaust duct can be in the range from 1 to 3 kPa. Their blades can have a different angle and direction of inclination (both forward and backward), withstand a maximum speed of up to 80m/s. The scope of application is wider than low-pressure fans: they can also be installed in process plants.

- High pressure. This technique is mainly used for process plants. The total pressure in the exhaust duct is from 3 kPa. The power of the installation creates a circumferential velocity of the suction masses of more than 80 m/s. Turbine wheels are equipped exclusively with backward curved blades.

Pressure is not the only feature by which centrifugal fans are distinguished. Depending on the speed of air masses, which is provided by the impeller, they are divided into two classes:

- I class - indicates that frontally curved blades provide a speed of less than 30 m / s, and backward curved - no more than 50 m / s;

- Class II includes more powerful installations: they provide the speed of the driven air masses higher than class I fans.

In addition, the devices are manufactured with a different direction of rotation relative to the suction pipe:

- oriented to the right can be installed with the housing turned clockwise;

- to the left - counterclockwise.

The scope of snails largely depends on the electric motor: its power and method of attachment to the impeller:

- it can gain momentum directly on the motor shaft;

- its shaft is connected to the engine by means of a coupling and is fixed by one or two bearings;

- using a V-belt drive, provided that it is fixed with one or two bearings.

Natural and artificial ventilation system

Natural ventilation is created without the use of electrical equipment (fans, electric motors) and occurs due to natural factors - air temperature differences, pressure changes depending on altitude, wind pressure. The advantages of natural ventilation systems are low cost, ease of installation and reliability caused by the absence of electrical equipment and moving parts. Due to this, such systems are widely used in the construction of typical housing and are ventilation ducts located in the kitchen and bathrooms.

The reverse side of the cheapness of natural ventilation systems is the strong dependence of their effectiveness on external factors - air temperature, wind direction and speed, etc. In addition, such systems are in principle unregulated and with their help it is not possible to solve many problems in the field of ventilation.

Artificial or mechanical ventilation is used where there is not enough natural.Mechanical systems use equipment and devices (fans, filters, air heaters, etc.) to move, purify and heat air. Such systems can remove or supply air to ventilated rooms, regardless of environmental conditions. In practice, in apartments and offices it is necessary to use an artificial ventilation system, since only it can guarantee the creation of comfortable conditions.

Centrifugal fan design

The centrifugal design system is a pumping mechanism with a radial architecture that is capable of generating pressure of any range.

Designed for transportation of mono- and polyatomic gases, including chemically “aggressive” compounds.

The design is “clothed” with a metal / plastic case, which is called a protective casing. The shell protects the inner chamber from dust, moisture and other substances that may adversely affect the operation of the unit.

A high-quality ventilation product always has a certain protection class. The degree of protection of the shell (Ingress Protection) is a single international product quality standard that determines the level of equipment protection from environmental influences.

The radial fan develops significantly more pressure than the axial version. This is due to the message of a portion of the air that has entered the drum of energy, which is formed during the transition from the inlet to the outlet of the system.

The mechanism is driven by an electric motor or an internal combustion engine (typical for industrial fans).The most common method is an electric motor that rotates a shaft with an impeller.

There are several options for transmitting rotational motion from the motor to the impeller:

- elastic coupling;

- V-belt transmission;

- stepless transmission (hydraulic or inductive slip clutch).

Given the existence of a huge number of manufacturers that create unique systems with a variety of dynamic parameters, consumers have a fairly extensive range of fans at their disposal.

There are two main channels in the case: input and output. The gas mixture enters the first channel, moves to the chamber, is processed there, and then exits to another

As a result of the intensive work of developers, we have a wide range of applications for such machines, including:

- ventilation and heating systems in private and multi-storey buildings;

- supply and purification of air for non-residential buildings;

- filtration systems in agriculture;

- execution of technological processes in light and heavy industry of various directions.

There are also applications for blowers in fire extinguishing systems and ultra-rapid air exchange in confined spaces.

Such fans operate with high-temperature gas mixtures, which obliges manufacturers to include in the technical documentation information on the compliance of their equipment with international standards.

The proven and simple design of the centrifugal mechanism has a number of clear advantages:

- high reliability and unsurpassed performance;

- ease and availability of equipment maintenance;

- safety of integration and operation of units;

- minimum costs for energy resources and repairs in case of failure.

In addition, blowers have a fairly low noise threshold, which allows them to be used in domestic conditions. Centrifugal fans also have an extremely long service life due to the absence of direct contact between the working parts of the mechanism in the working chamber.

Some application examples

Ventilation is nowhere to be found. Here are a few examples when other devices cannot work without ventilation:

- on ships (marine and freshwater);

- in the apartment (especially in the kitchen and bathroom);

- in drying chambers of various types.

Ship ventilation devices

Three types of ship fans are installed on boats and ships:

- Injection. These ship blowers are used when it is necessary to force air into the room, often equipped with a diffuser. Without ship blowing devices, the full operation of the boiler room, the supply of fresh oxygen to the boiler and the cooling of overheated parts are impossible.

- Exhaust. Such axial ship instruments are capable of forcibly, by the method of backwater, to remove air from the instruments. With the help of exhaust ship axial models, it is possible to quickly clean the premises from smoke and harmful emissions.

- Forcing (windmills). Ship vans are designed for forced circulation of air masses without extracting and replacing them.

Apartment ventilation

In the apartment, full ventilation in the kitchen, bathroom and restroom is especially important.

- In the kitchen, the exhaust fan is always installed on the hood, installation at the outlet of the duct ventilation is additionally desirable, both fans for air boosting work almost silently.

- In the restroom, the exhaust device is mounted on the outlet of the duct ventilation and helps to remove odors.

- For a bathroom, the selection of a ventilation system is more difficult due to high humidity. It is not enough to simply install the hood on the duct ventilation, additional installation of condensers is required.

Drying chamber ventilation

Special drying chambers are used in everyday life and production. With the help of drying chambers you can:

- dry clothes;

- prepare dried fruits;

- reduce the moisture content of the wood.

Drying chambers are able to dry quickly, but for efficiency they need:

- the presence of capacitors;

- a fan that evenly distributes the supply air that has passed through the heating through the drying chamber.

With full ventilation and even distribution of heated supply air, the drying chamber will work efficiently with minimal energy consumption.

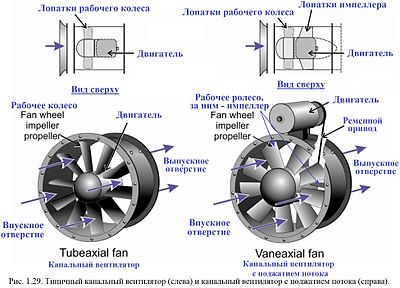

A short overview of the various axial fan options allows you to determine which device in terms of size, power consumption and technical characteristics is the best choice depending on the intended application.

household fan

The fan is designed to create a flow of air in the room, providing a comfortable stay in the summer.

Household fans are classified by size, performance, number of blades, design and functionality.

By execution there are: floor, table and ceiling.

The number of blades can be from three to six.

Fans can have the functions of speed control and "auto-rotation".

"Auto rotate" moves axis of rotation of the rotor in the horizontal plane and is designed to expand the airflow space in the horizontal plane.

Fan blades are usually made of plastic, sometimes wood or metal. The plastic fan is lighter, and therefore safer, but fragile.

To protect against moving blades, the fans are equipped with a grille. They can also be equipped with a timer, backlight, etc.

Fan manufacturers: VENTS Elenberg, Scarlett, Vitek, Systemair, Polaris, ROVEN, etc.

Fans by version

Also, fans are divided according to the method of execution:

- multizone

- centrifugal (radial)

- canal

- rooftop

- ceiling

- axial

- window

Multi-zone fans

Multi-zone centrifugal exhaust fans have a special housing that allows you to connect several suction ducts that draw air from different zones. A zone can be a separate ventilation duct, a room, or even part of a large room. Such fans can be indispensable at facilities where an exhaust hood should be made. from several places, and there is only one air outlet. Multi-zone exhaust fans allow you to optimize the network of air ducts, reduce the number of expensive fittings, while using the same type of flexible air ducts.

|

|

|

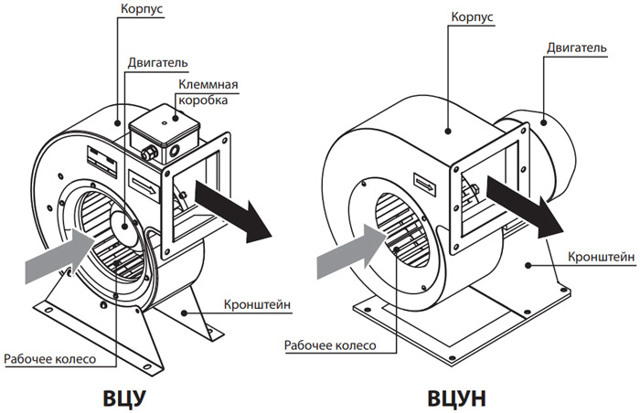

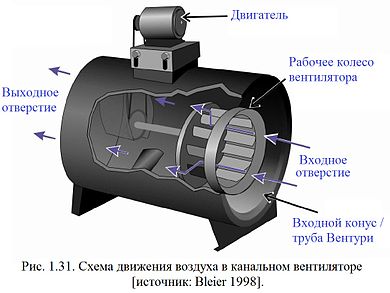

Duct fans (straight-through)

Are intended for installation in the ventilating channel of round or rectangular section. Fans of this type are installed on the same shaft with an electric motor in a single housing using vibration isolating pads.

The fan can be axial, multi-blade or radial, with blades curved both forward and backward, single or double suction.

The case of duct fans can be made of special plastic, galvanized steel and even be mixed. Due to their small overall dimensions, duct fans can be installed directly in the air duct network, built into duct ventilation and air conditioning systems and hidden behind a false ceiling or in special vertical cabinets. Any (horizontal, vertical or inclined) position of the fan is possible when installing it. The main advantages of the duct fan are related to its compactness with significant air flow.

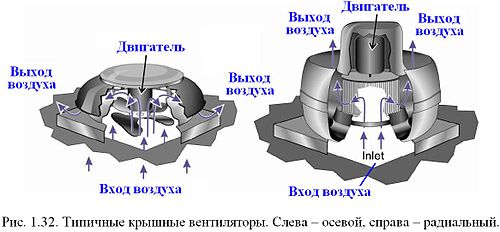

Radial Roof Fans (VKR)

The figure shows typical roof fans. Left - axial, right - radial

The figure shows typical roof fans. Left - axial, right - radial

large fans are mounted directly on the roof of the building, usually with a special frame for durability and weather resistance. Due to the fact that they are almost the entire service life on the street, they are subject to special requirements for moisture and dust resistance. Usually they are made of high quality steel with an epoxy corrosion-resistant coating, or galvanized. There are roof fans for both general ventilation systems and special heat-resistant fans for high-temperature systems, such as smoke extraction systems in case of fire, organizing an exhaust for a fireplace or a gas boiler.

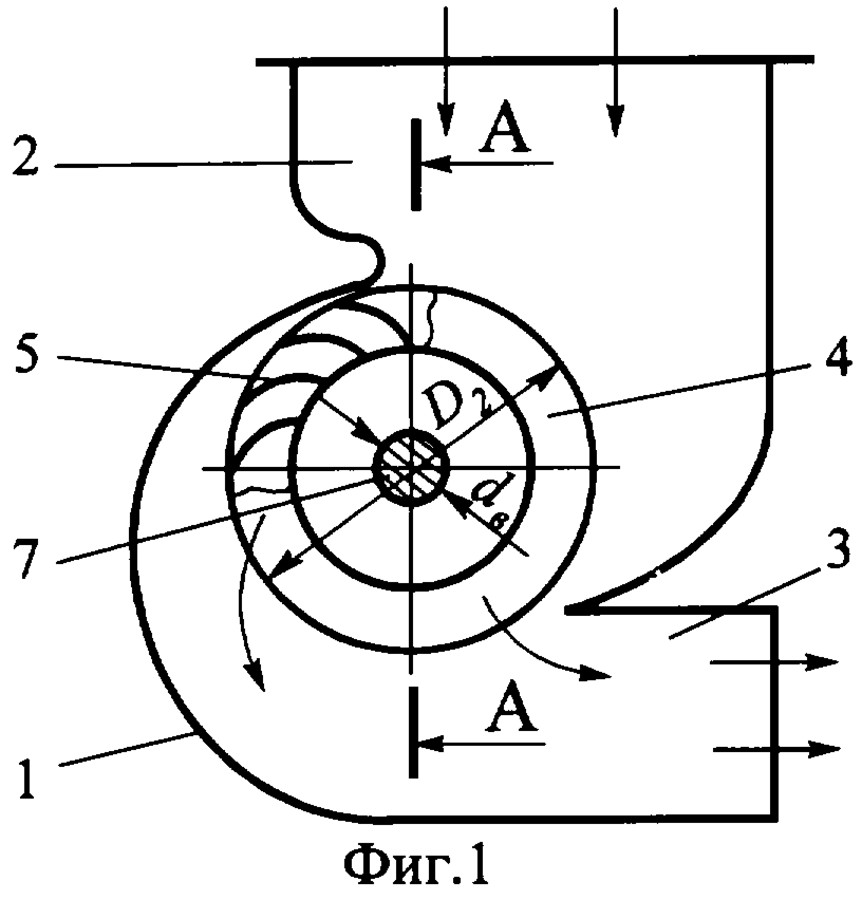

The device and principle of operation of centrifugal fans.

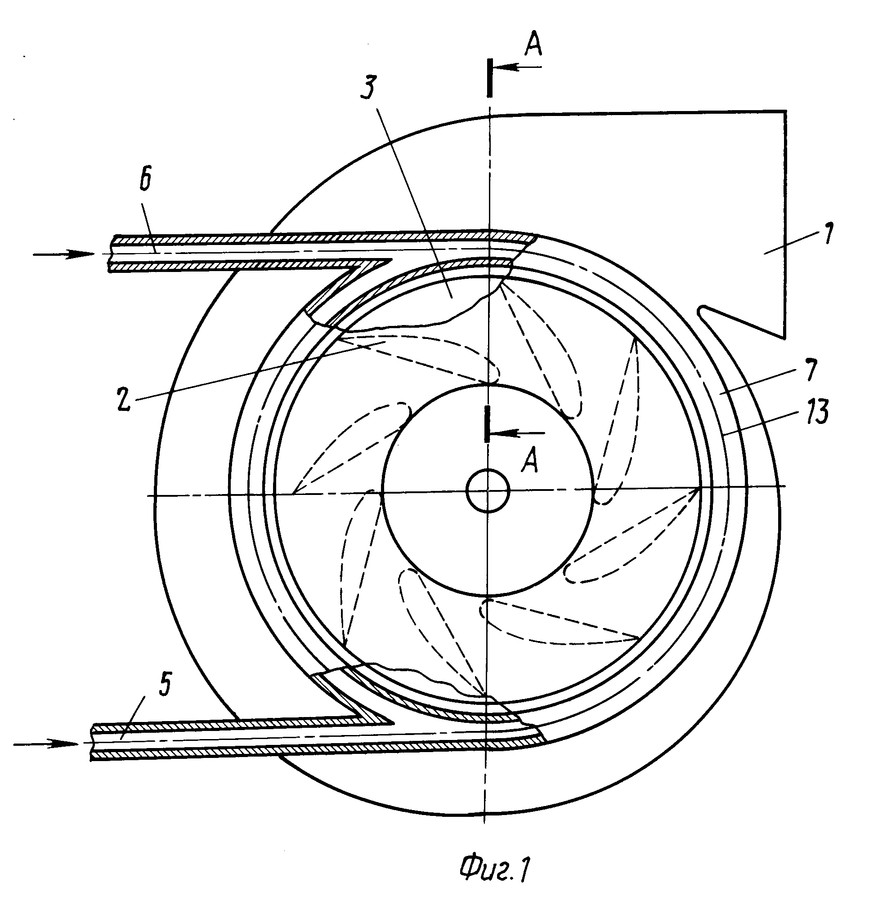

The design of the fan is determined

its aerodynamic scheme, under which

understand the schematic drawing of it

flow part indicating the main

dimensions in fractions of the outer diameter

wheels D2. Fans

different sizes, made one by one

aerodynamic design, refer to

the same type and are geometrically

similar.

Main elementsare:

impeller with blades, inlet

branch pipe (collector), spiral body,

hub, shaft

By design impellershave

a number of modifications:

-

drum impellers are performed

with shoulder blades curved forward. Width

wheels = 0.5 diameter. Peripheral speed

allowed up to 30-40 m/s. -

annular impellers have a smaller

width. Circumferential speed - 50-60 m / s. -

impellers with conical front

discs are very durable

and rigidity. Peripheral speed up to 85

m/s. -

three-disc wheels are used on

double inlet fans. -

single-disk are used for dust

fans.

Way of connecting blades with disks

has a significant impact on

structural rigidity. Apply

connections: solid forged, on

spiked, riveted, welded, glued. AT

one-piece forged blades and front

the disk is stamped from one sheet. Most

riveted joints are often used. Welded

connection is used for wheels of large

diameter, especially for blades curved

back. In any case, the impellers

must be balanced.

Shoulder blades. The advantage of sheet

blades is the simplicity of design.

The disadvantage is high rigidity. Profiled

shell and shell-frame have

high rigidity and work at

circumferential speed up to 130 m/s.

input manifold.

Input devices are axial and

knee-shaped. Axial represent

a cylindrical or conical

pipe connecting inlet

wheels with atmosphere or suction

pipeline. knee-shaped

is a suction chamber

with a rectangular inlet.

The flow in such a chamber makes a turn

90. Section of the knee-shaped

boxes are usually larger than the section of the entrance to

wheel 2-2.5 times.Frame. Performed

in the form of a special case with parallel

side walls. At the exit from the body

conical can be installed

diffuser with opening angle up to 25.

Spiral chambers perform either

welded or riveted. Frame

is made removable. Most

fan cantilever designs

the body is suspended from the bracket

drive part. Such a design

allows you to get different schemes

assembly by rotating the body

relative to the axis. Only for large

double suction designs

the body is mounted on a frame or on

feet .Blower fan housing

due to strength and stiffness conditions

has a frame made of profiled steel and

sheathing from a thin sheet with a thickness of 4-6

mm. For dusty gases

body is made of sheet metal

thicker steel. Most

wear sheets are protected by overlays

steel or white cast iron. For chemically

active media body is made of

alloyed steel Kh18N9T.

Vents VK 125 – affordable price

Inexpensive among analogues, supply and exhaust unit for air exchange in residential, utility and industrial buildings. Refers to the channel centrifugal type. Made of durable, water and dust resistant plastic. Rolling ball bearings are used.

Built-in protection against overheating - by means of thermal fuses and automatic switching on after a forced stop. The dynamic balancing of the reverse rotor contributes to the reduction of vibration and noise. Blades with reverse bend (back) are installed.

Pros:

- Low cost, simple design.

- High-quality materials, resistant to moisture and dust.

- Possibility to adjust the speed.

Minuses:

During installation, please read the instructions carefully. The device itself is very delicate and fragile.

Design and principle of operation

There are several types of fan devices used to move various mixtures of gases and air. The most popular is the centrifugal radial unit "snail".

It has a rotating wheel in the assembly and blades fixed on it. Different models of fans contain a different number of blades.

The principle of operation of the "snail" hood is as follows:

- Air is sucked into the rotor through the inlet;

- The air mass receives rotational motion;

- Further, by means of centrifugal force, which is created by rotating blades, air under pressure is injected to the outlet. It is located in a spiral casing.

Due to the similarity of the casing with a snail, the fan got its name.

Housing materials

An industrial “snail” may include different materials, depending on the aggressiveness of the application environment. Sheathing of a general purpose unit operated in non-aggressive gas mixtures with a particle content of less than 0.1 g / cu. m, made of galvanized or carbon steel sheets of different thicknesses.If the environment contains aggressive gas mixtures, characterized by the presence of active gases and the evaporation of acids, corrosion-resistant steels are used. The "snail" fan in this design operates at temperatures up to 200 degrees Celsius.

An industrial “snail” may include different materials, depending on the aggressiveness of the application environment. Sheathing of a general purpose unit operated in non-aggressive gas mixtures with a particle content of less than 0.1 g / cu. m, made of galvanized or carbon steel sheets of different thicknesses.If the environment contains aggressive gas mixtures, characterized by the presence of active gases and the evaporation of acids, corrosion-resistant steels are used. The "snail" fan in this design operates at temperatures up to 200 degrees Celsius.

There is an explosion-proof version of the hood housing. It is assembled from ductile metals: copper or aluminum alloys. Here, during the operation of the hood, sparking, which is the main cause of explosions, is excluded.

Working wheel

Material requirements for impeller with blades - plasticity and protection against corrosion. Then the wheel will withstand vibration loads and chemical effects of the environment.

For the design of the shape and number of blades, aerodynamic loads and rotational speed are taken into account. High rotation speed of a large number of slightly curved or straight blades, forms a stable air flow

This creates less noise.

Centrifugal extractor should be classified as equipment with increased vibration. The cause of the vibration is the low level of balance of the spinning wheel. Vibration carries such negative factors: the destruction of the base at the installation site of the equipment and a high noise level. The installation of shock-absorbing springs minimizes vibration. The springs are mounted under the base of the housing. In addition, rubber pads are used instead of springs for some models.

Electric motors

Equipment for ventilation of the "snail" type is supplied with electric motors with explosion-proof covers and housings. A special protective composition is used for painting engine cases. For the most part, these are asynchronous mechanisms with a fixed speed.They are connected to a single-phase or three-phase network, depending on the design. In special cases, variable speed motors are used.

Dimensions

The sizes of extracts "snail" can be various. The diameter of the unit varies from 250 to 1500 mm. "Snails" can represent a single whole or be divided into several parts. In the case of small fans with a solid volute, the angle of rotation can be neglected. It is enough to unscrew the bolts and turn it into the desired position. Larger models are mostly collapsible. For them, the angle of rotation is an important parameter to consider.

The figure shows typical duct fans.

The figure shows typical duct fans.  The figure shows a radial straight-through fan.

The figure shows a radial straight-through fan.