- Used solutions and features of the method

- Why is it necessary to cement wells

- Description of the carburizing process

- How is the quality of cemented wells assessed?

- Well cementing methods

- CEMENTING TECHNOLOGY

- Annular space sealing methods

- Working solution for well sealing

- Well sealing technology

- Well sealing equipment

- WELL CEMENTING TECHNOLOGICAL PROCESS

- CEMENTING PROCESS

- DISCHARGE FEATURES

- TOOLS AND MATERIALS:

- 17.8. Isolation of absorption zones

- Well cementing - the main highlights of the process

- The main types of work carried out within the process

- The duration of hardening of the protective layer and checking its quality

- Drillers' advice

Used solutions and features of the method

Before carrying out a well cementing project, a whole range of calculations is carried out, which allows you to calculate the volume of the mixture used, its composition, and methods of supply. In the process of performing preliminary analyzes, it is worth considering the following factors:

- Depth of a hydraulic structure.

- The distance between the outer surface of the casing string and the walls of the well.

- Passage form. Violations and defects that were identified during drilling.

- Soil composition and characteristics.

If drilling has already been done in the area, many of the data can be obtained from the old project. At the same time, the well cementing process will be successful with a minimum consumption of materials only with proper calculation and availability of the project.

Depending on the composition of the soil, different grouting solutions can be used:

The traditional cement-sand slurry is suitable for cementing wells located in dense shale.

- If the water well is made in porous rock, then work is carried out using fillers for the mixture. For this, asbestos, paper and other fibrous materials are used. If you try to perform the work with a conventional cement-sand mortar, this can lead to an increased consumption of the mixture.

- Foaming compounds are sometimes used for plugging, which expand during the solidification process. Thanks to them, the quality of sealing water intake structures is significantly improved.

Sand and gravel are added to the cement mixture. But the consistency of the solution should remain liquid. The mixture is prepared quickly for easy pumping. The solution is fed through the filling pipe to a height of up to 3 m. For disinfection, bleach is added to it.

Why is it necessary to cement wells

- First, the overall strength of the structure is increased.

- Secondly, grouting protects the surface of the pipe, which is made of metal, from corrosion, which may occur due to subsoil moisture.

- Thirdly, if the well is built in such a way that connects different oil and gas spaces, then after cementing they will definitely be isolated from each other.

Description of the carburizing process

Not surprisingly, grouting technology has undergone major changes. It is completely different from the old one. Now they use computerized technological calculations for the correct ratio of water in cement mortars and use special additives for them.

Additives to cement mortars can be in the form of:

- Quartz sand - it allows you to reduce shrinkage and maximize strength

- Fibrous cellulose, which does not allow leakage of liquid cement anywhere, especially the most porous rocks

- Priming polymers - during solidification, they expand and compact the soil

- Pozzolanov. This is a special crumb - ultralight minerals, they are waterproof and are not afraid of aggressive chemicals. Oil wells during cementation require a special multi-stage quality control of the plug made.

How is the quality of cemented wells assessed?

Perform special procedures:

- Thermal - determine the level of maximum rise of cement

- Acoustic - detects possible internal empty spaces in the cement

- Radiological - it is a kind of x-ray during this procedure

Well cementing methods

At the moment, there are four main methods of cementing:

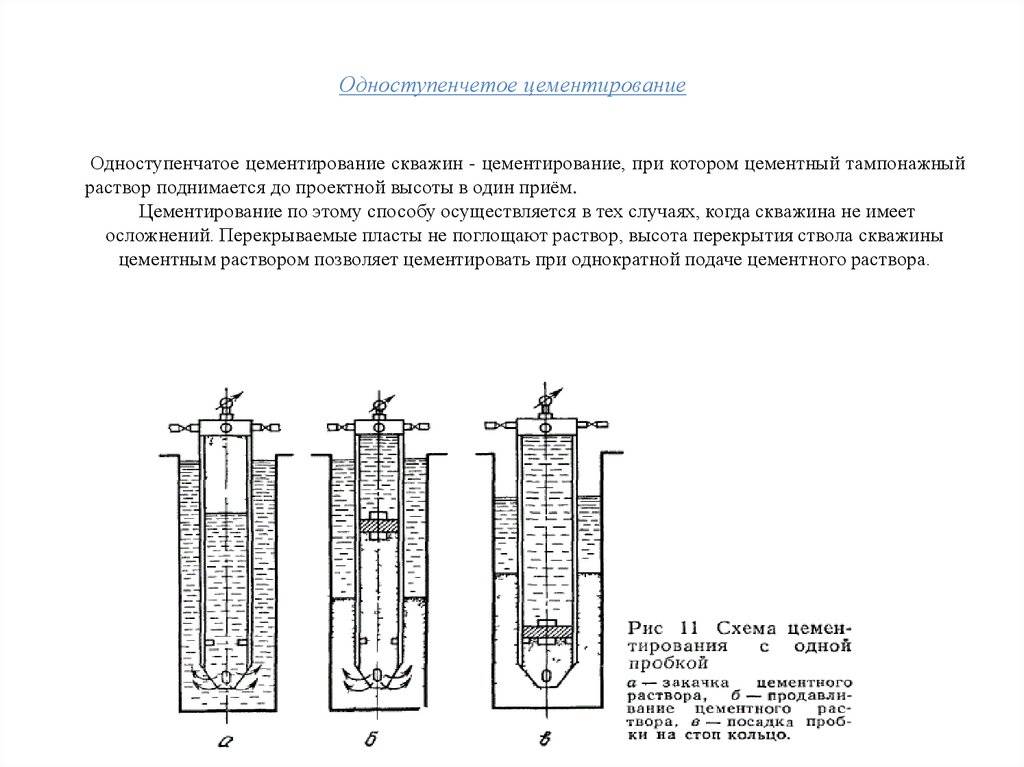

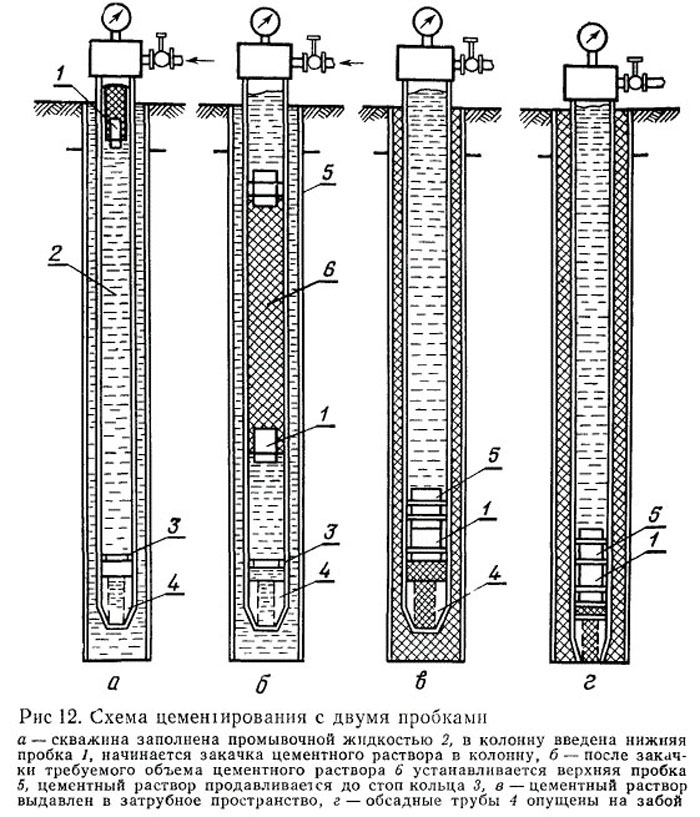

- Single step method. The cement mixture is poured into the casing string and plugged with a plug. Washing solution is applied to the plug. Such actions lead to the fact that the cement is displaced into the annulus

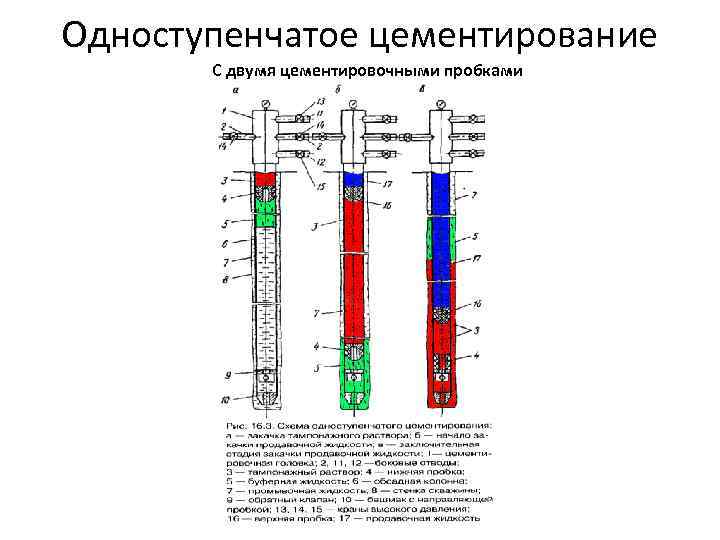

- Two-stage. According to technology, it is exactly the same as the single-stage one. The difference is that actions are performed first with the lower part, and then with the upper. A special ring is used to separate the two departments.

- Cuff.Cementing is used with a solid collar to cement only the top of the well.

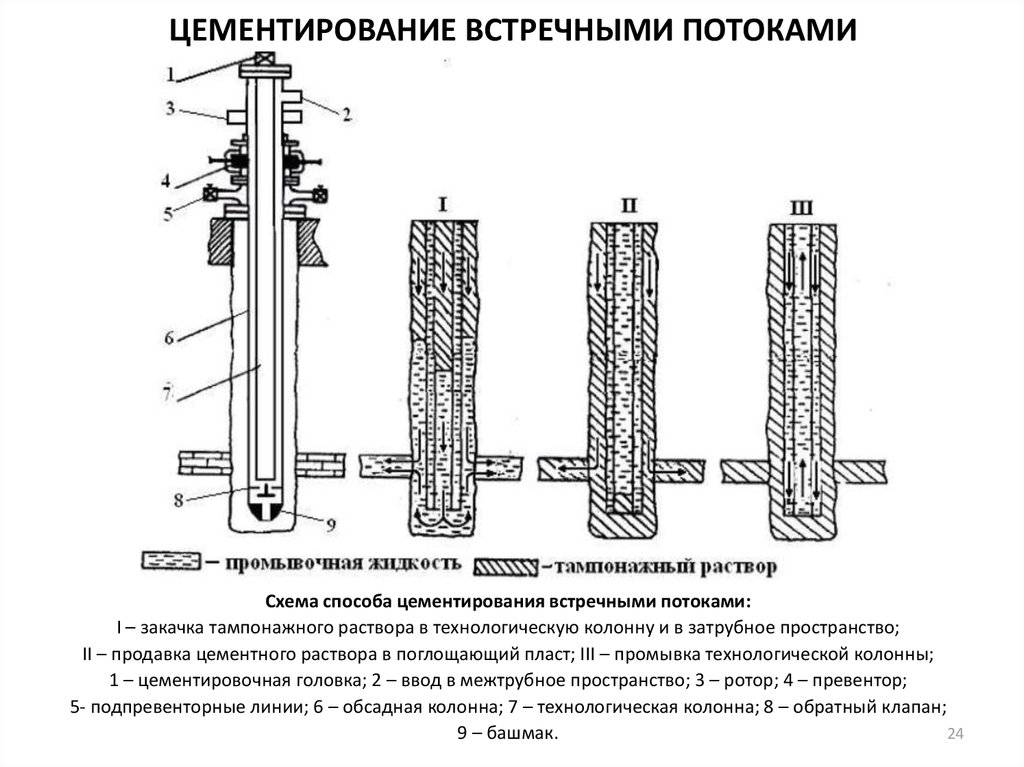

- Back. Cement slurry is poured immediately into the space behind the pipe, drilling and cleaning solutions are forced out into the cavity of the columns.

The MosOblBureniye company performs well drilling with high quality. You will be satisfied with the cooperation with our specialists.

CEMENTING TECHNOLOGY

Turbulator

Lecture 14

Cementing is the process of filling a given interval of a well with a suspension of binders, capable of thickening at rest and turning into a solid, impermeable body.

Cementing O.K. - one of the most critical stages of well construction. High quality cementing of any wells includes: and cement stone behind the column.

The main goals of cementing are:

one). Isolation of permeable horizons from each other after they are opened by the well, and prevention of formation fluid overflows through the annulus;

2). Suspended casing string;

3). Protection of the casing string from the impact of aggressive formation fluids;

four). Elimination of defects in the lining of the well;

5). Creation of dividing screens that prevent watering of productive horizons;

6). Creation of high-strength bridges in the well, capable of absorbing sufficiently large axial loads;

7). Isolation of absorbing horizons;

eight). Strengthening of the walls of the well;

9). Wellhead sealing in case of well abandonment.

-implementation of the developed norms and rules of work in order to most completely fill the annular space of the well with cement slurry of a certain quality (instead of drilling slurry) in a given area, ensuring contact of the cement slurry - stone with the surface of OK. and well wall while maintaining the integrity of the layers.

The technological process of cementing is determined by geological and technological factors.

These factors are:

1. Setting time and thickening time of the cement slurry, its rheological characteristics, sedimentation stability, water loss and other properties.

2. Compatibility and relationship between drilling and cement slurries in the annulus.

3. Mode of movement of drilling and cement slurries in the annulus.

4. The volume of the injected cement material, the time of its contact with the well wall.

5. Quality and quantity of the buffer liquid.

7. Cementing the column.

There are several cementing methods:

– methods of primary cementing (single-stage, multi-stage, reverse, sleeve);

– methods of secondary (repair and correction) cementing;

— Methods for installing dividing cement bridges.

Single-stage cementing - the cement slurry is pumped in the volume necessary to fill the specified interval of the well annular space and the O.K. section. below the check valve, and the squeezing liquid - in the amount necessary to fill the internal cavity of the column above the check valve. The density of the cement slurry must be greater than the density of the drilling fluid.

Types of primary cementing:

The opposite is true when cement slurry is immediately pumped into the annulus.

Direct, when the cement slurry is pumped into the O.K., and only then it is pressed into the annulus. It is subdivided into:

A) One-stage (used most often).

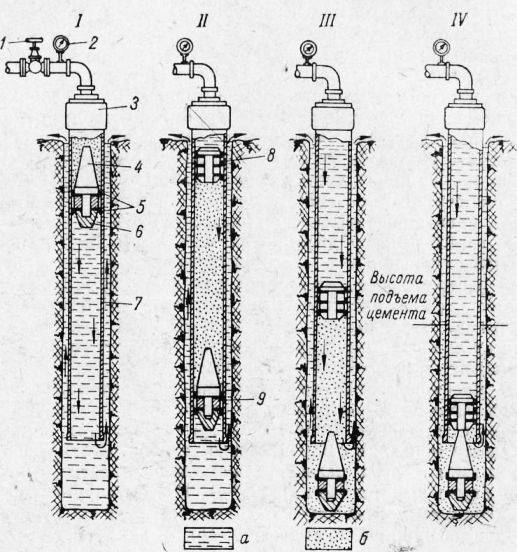

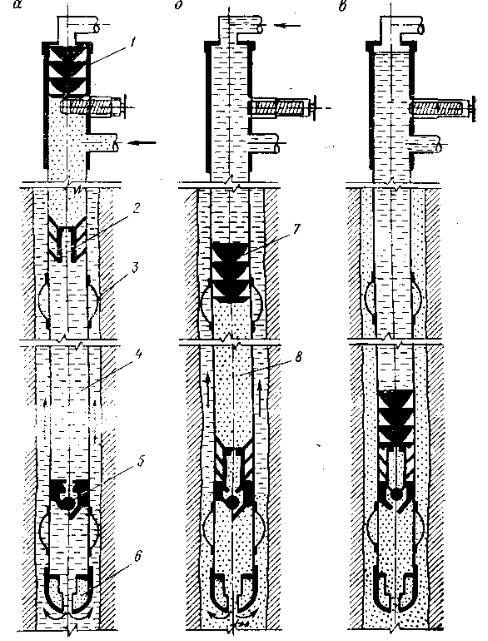

B) Two-stage (used on long intervals or with ANPD). It can be with a time gap and without a time gap.

Step cementing (with a break in time). It is used in cases:

1. If it is impossible to cement this interval at one time due to the danger of rock rupture;

2. If there is a danger of GNVP during the setting and hardening of the cement slurry;

3. If cementing the upper section of a long interval, a cement slurry must be used that cannot be exposed to the high temperatures typical of the lower section.

Sleeve cementing. It is used if the lower section of the casing string is made up of pipes with pre-milled holes. At the end of flushing, a ball is dropped into the well. With the flow of the pancreas, the ball goes down and sits on the saddle of the lower sleeve of the cementing sleeve. As the pump continues to pump the pancreas, the pressure in the string rises sharply, the sleeve cuts off the pins that hold it in the coupling body, goes down to the limiter and opens the windows for the fluid to exit into the annulus. From this point on, the process proceeds in the same way as with two-stage cementing.

93.79.221.197 Not the author of the materials posted. But it provides free access. Is there a copyright infringement? Write to us | Feedback.

Disable adBlock! and refresh the page (F5)very necessary

Annular space sealing methods

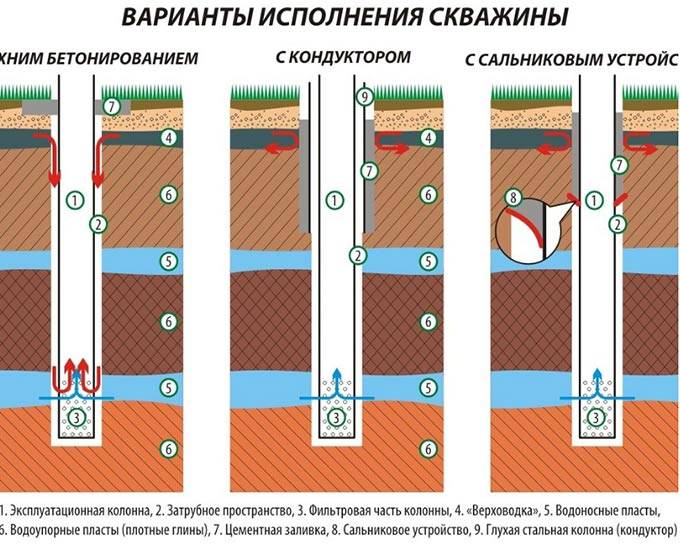

Well cementing additionally strengthens the casing string, reducing the risk of its deformation and the appearance of leaks at the joints due to shear and soil pressure. Before starting work on sealing, a number of mandatory procedures are performed:

Well analysis, during which the depth of the well and the size of the gap between the walls of the shaft and the casing are measured. The geometry of the entire structure is checked. Soil characteristics are clarified - rock types, porosity, fracturing and other geological and hydrogeological properties.

Considering that cementing the annular space is an irreversible process, mistakes cannot be made during sealing, since it will not be possible to correct the violations, which will lead to a change for the worse in the functionality of the water intake structure. This means that professional drillers should perform well cementing work, moreover, on the basis of well-developed design solutions.

Working solution for well sealing

Taking into account the geological features of the site, the type of mixture for grouting is determined. Cement-sand mortar is used to seal the annulus of a well drilled in clayey rocks. Porous soils require the use of mixtures with the addition of fibrous materials such as asbestos or bitumen. The use of a standard cement-sand mixture will cause the porous rocks to absorb a significant volume of the solution. This will lead to a significant overspending of building materials.

Well sealing technology

The main methods of cementing:

- One of the simplest methods is direct injection of the mixture into the annulus, when the solution fills the free gap by gravity due to gravitational forces. The disadvantage of the technique can be considered the possible formation of voids when the mixture does not completely fill the space between the casing and the shaft wall.

- Reverse sealing is a more acceptable option. The technology involves the supply of the solution directly into the casing, and the mixture fills the annulus from the bottom up. A special diaphragm is used to cut off the aquifer.

For deep wells, a staged grouting scheme has been developed. Requirements for the resulting cement layer:

- lack of voids;

- mechanical strength;

- adhesion with surfaces;

- the ability to withstand the pressure of groundwater, possibly containing aggressive solutions of chemicals.

Well sealing equipment

To perform the annular space cementation procedure, various units are used, including:

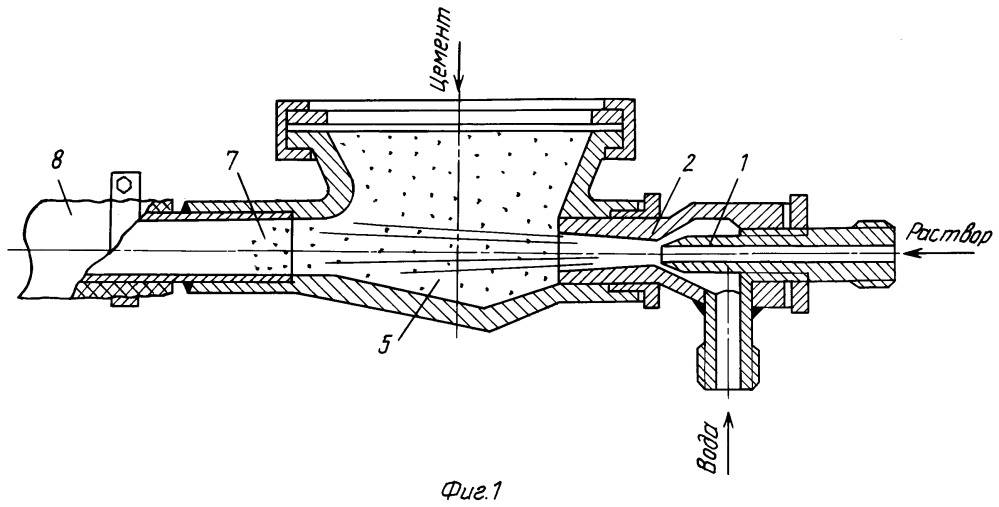

- cement-mixing equipment for mixture preparation;

- units for supplying solution under the required pressure;

- equipment for flushing the well from traces of drilling fluid, which reduces the adhesive properties of the cementing mixture.

At all stages of the procedure for cementing the annulus and sealing the well, it is necessary to strictly follow the technology of operations in order to ensure a high-quality result.

WELL CEMENTING TECHNOLOGICAL PROCESS

The final stage of drilling operations is accompanied by a process that involves well cementing. The viability of the entire structure depends on how well these works are carried out.The main goal pursued in the process of carrying out this procedure is to replace the drilling fluid with cement, which has another name - cement slurry. Cementing wells involves the introduction of a composition that must harden, turning into stone. To date, there are several ways to carry out the process of cementing wells, the most commonly used of them is more than 100 years old. This is a single-stage casing cementing, introduced to the world in 1905 and used today with only a few modifications.

CEMENTING PROCESS

Well cementing technology involves 5 main types of work: the first is mixing the cement slurry, the second is pumping the composition into the well, the third is feeding the mixture into the annulus by the selected method, the fourth is the cement mixture hardening, the fifth is checking the quality of the work performed.

Before starting work, a cementing scheme should be drawn up, which is based on technical calculations of the process.

It will be important to take into account the mining and geological conditions; the length of the interval that needs strengthening; characteristics of the design of the wellbore, as well as its condition. Should be used in the process of carrying out calculations and experience in the implementation of such work in a particular area

DISCHARGE FEATURES

Cementing can be done by different methods of supplying the mixture into the annulus, moreover, various devices can be used in the process of work.Cementing wells may involve the direct supply of the mixture, such a scheme involves the flow of cement into the internal space of the casing string, followed by its passage directly to the shoe and further entry into the annulus, while the flow of the solution is made from the bottom up. With the reverse scheme, the injection is performed in the reverse order, from top to bottom.

In this case, well cementing can be carried out in one approach, during which the required volume for plugging the mixture is forced through at a time.

Two-stage cementing is used when the well has a significant depth. The technological process is divided into sequential filling of individual intervals through the use of equipment. Collar cementing, in contrast to the above methods, involves protecting a part of the wellbore from the passage of the cement mixture. The cuff allows you to isolate the area located along the length of the reservoir. The well may have hidden columns and sections, their cementing can be classified as a separate group.

The implementation of well cementing, regardless of the chosen method of work, pursues the goal of expelling the solution formed by drilling from the annulus, which is possible by placing a cement slurry there.Cementing ensures complete filling of the wellbore interval with cement mixture; elimination of the drilling fluid by penetration of the cement mixture within the interval intended for cementing; protection of the cement mixture from the penetration of flushing fluid; the formation of cement stone, which is characterized by significant resistance to various kinds of influences in the form of deep loads; excellent adhesion of cement stone to the walls of the well and to the surface of the casing.

TOOLS AND MATERIALS:

- cementing units designed for mixing the mixture and its subsequent punching under significant pressure;

- cement-mixing equipment;

- cementing head for flushing the wellbore and further cementing its walls;

- filling plugs for two-stage cementing;

- high pressure taps;

- steel flexible hoses;

- devices designed to carry out the distribution of the solution.

17.8. Isolation of absorption zones

Most

common way to isolate zones

absorptions is the cementing of the interval

absorption by fast-hardening compositions.

There are several varieties

cementation of absorbing zones.

To the first group

include cementing methods without

preliminary separation of the zone

absorption from other intervals. In that

case, a string is lowered into the well

drill pipes, lower open end

which I set a little higher

the roof of the absorbing horizon and in

the well is pumped with a portion of cement

solution in a volume sufficient for

filling a section of the trunk with a little length

above the absorption zone, as well as for

filling channels in the absorbing formation.

The cement slurry is forced out of

pipes with displacement fluid. Its volume

is chosen from the condition that at the moment,

when the upper boundary of the grouting

solution will be above the roof of the absorbing

interval, the pressure on the formation became equal to

reservoir in this zone. After download

drilling fluid

lifted from the well. expedient

inject squeezing fluid

in portions with the rise of drill pipes.

To the second group

types of cementing

with preliminary separation of the zone

losses from other permeable rocks

using various packers and spacers

traffic jams. According to the caliper chart find a site

trunk with a normal diameter near

the roof of the absorbing layer. Down the well

a column is lowered to this section

drill pipes, at the lower end of which

drillable packer is suspended. Produce

unpacking. Upload a specific

volume of cement slurry. Disconnected

from the packer and the pipe is lifted. Packer

prevents fluid flow from

upper pressure horizons into the zone

absorption.

In case when

absorption intensity is high in

the area under consideration is washed

coarse bridging material

and thus achieve a reduction

absorption intensity.

If available

several intervals of their absorption

can be isolated in series

from bottom to top, separating the next from

previous drilled packer: at

it is possible to cement the subsequent

proceed after completion of cementing

previous without waiting for hardening

solution. After hardening the packer and

cement stone is drilled. Quality

insulation is evaluated by crimping

the corresponding zone. If apart

cemented several areas,

press them separately from top to bottom,

after drilling out the packer and stone against

the corresponding zone, but before drilling

downstream packer.

For crimping in

drill pipes are lowered into the well

hydraulic-mechanical packer, which

set over the area under study

It is expedient to pressurize

clay solution with low water loss

creating the greatest

the pressure that may occur when

subsequent operations. Insulation quality

can be considered satisfactory if

the volume of liquid that

pump into pipes to maintain

constant pressing pressure

during crimping, does not exceed

significant losses due to

water loss.

Well cementing - the main highlights of the process

In the event that the well drilling contractor in your area has concluded that the source lacks additional hardening, the recommendation should not be ignored, as your water intake may collapse in a couple of years. Well cementing is a fairly complex technological process that allows you to strengthen the source column and make it virtually indestructible.

The essence of the process is contained in the filling of the near-pipe cavity with a special cement mortar, which is also called grouting. At the end of its solidification and a set of strength features, a material is obtained that, in terms of hardness, is actually not inferior to stone.

The main types of work carried out within the process

We note right away that doing the work with your own hands without special equipment is virtually unrealistic, a high level of quality of work is achieved only with strict observance of all stages of the technological process. The price of this service is high, but these costs are fully justified.

The whole workflow can be divided into a couple of main stages, we will consider any of them in more detail:

- Preparation of a special solution to fill the cavity. Since the highest requirements are imposed on the composition, it is better to use a special cement Portland cement in it, which provides the solution with the highest strength indicators.

- The finished cement composition must be delivered to the well, since it solidifies rather quickly, the easiest way is to use special equipment on a truck platform, in which case all the necessary operations will be carried out right on the spot.

- Then the annular space is pumped with a cement composition. This operation can be performed by two methods, either of which we will discuss below.

- Then you need to allow the solution to harden and gain certain strength characteristics. The right time depends on several factors: the grade of the solution, the depth of the well and the highlights of the work.

- In addition, it is necessary to check the quality of work and identify all factors: layer thickness, uniformity of filling and other factors.

The duration of hardening of the protective layer and checking its quality

The formation of cement stone begins immediately after the completion of the pouring of the mixture. The process of complete hardening depends on the ambient temperature, the composition and moisture content of the soil, the material of the casing elements, as well as the characteristics and list of components of the solution itself.If it is not possible to determine when the protective layer has fully formed, wait at least 48 hours before taking any action.

After two days, it is recommended to check the obtained protective layer. More accurate results can only be obtained using special professional equipment. There are three ways to check the integrity of a solution:

- Acoustic. The technique is based on tapping casing pipes along the entire length of the shaft and processing the results obtained through a computer program.

- Radiological. The measurement is carried out by special radio devices.

- Thermal. The temperature is measured during the solidification of the layer.

If it is not possible to invite specialists to evaluate the work performed, you can check the readiness of the cement layer using a simplified thermal method. To do this, during the period of solidification of the mixture, the temperature at the walls of the casing is measured. It should first be equal to the ambient temperature, and then become 1-1.5 degrees lower.

The final step is to clean the barrel from the remnants of the mixture. When doing work with your own hands, cleaning can be done with a bailer. Before putting the source into operation, the shaft is checked for tightness. To do this, water is pumped into the barrel under pressure for 20-30 minutes. If during this time the water pressure decreased by no more than 0.5 MPa, the work was done with high quality.

Drillers' advice

The entire composition of the mixture is individually selected depending on many reasons. These may be reasons mainly related to the layers of the earth and its types.An increase in volume and density during cementing can be achieved by using a special solution that increases in volume. With a rock of the earth, which has a very high absorption and its percentage, it is impossible to use an ordinary solution. Such a mixture will simply crawl out in different directions, inefficiently filling the annulus. It is for this purpose that only cement slurry is used. It is also practiced to add special fibrous fillers to it.

Before starting work, it is imperative to check not only the readiness of the solution, but also all the equipment and the necessary pressure to complete the work. Before this, it is recommended to clean and flush the entire annular space with water, because the remnants of earth and rock will further interfere with the entire work of filling the solution or even break the structure of the well.

It is worth remembering the fact that such work is recommended to be performed only by those persons who have the appropriate skills and considerable experience in this industry. Wrong actions can only aggravate the entire process of work and lead to bad consequences. That is why, you should try to listen as much as possible to the opinion of experienced drillers and cementing masters. Or, alternatively, take advantage of their help in practice.

Tags on the page:

Our phones +7(937)532-77-37, +7(8442)50-18-61