- Safety measures for killing wells.

- Packing technologies

- Packing equipment

- One-stage plugging

- Two-stage or two-cycle cementing

- Well plugging during liquidation

- Description of the types of plugging

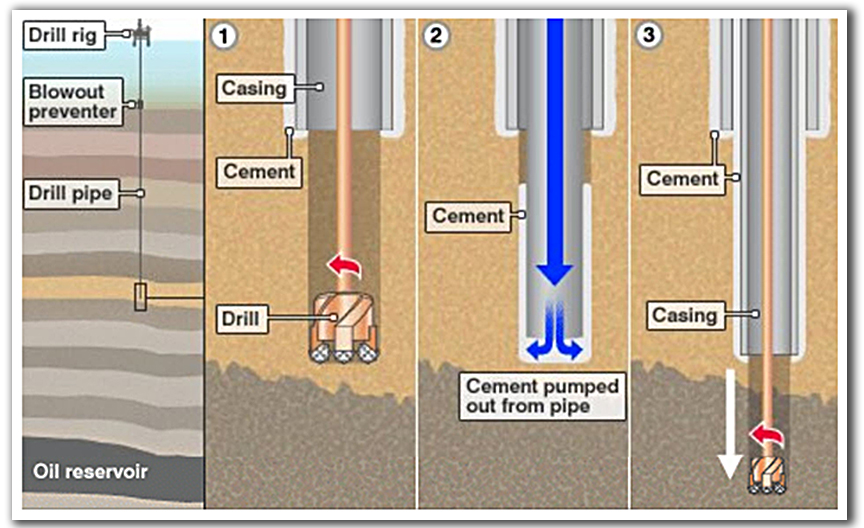

- How cement slurry enters the well

- WELL CEMENTING TECHNOLOGICAL PROCESS

- CEMENTING PROCESS

- DISCHARGE FEATURES

- TOOLS AND MATERIALS:

- The duration of hardening of the protective layer and checking its quality

- Well cementing methods;

- Proper preparation of the solution

- Conclusions and useful video on the topic

Safety measures for killing wells.

6.1. Well killing can be

started only after the execution of a bilateral act on the acceptance of the well for repair

(foreman of the KRS brigade and representative of PDNG, TsPPD).

6.2. well killing

produced on the instructions of the KRS master. Killing a well without a plan

PROHIBITED.

6.3. well killing

usually done during daylight hours. In special cases, jamming

can be carried out at night when the illumination of the well is not

less than 26 hatch.

6.4. Playground size

40x40 m, on which the units are installed, must be freed from

foreign objects, in winter from snow.

6.5. Before jamming

it is necessary to check: the serviceability of all gate valves and flange connections on

wellhead equipment; the presence of a duct

liquid along the flow line from the well to the metering unit and at its

stop working at the well until the causes are clarified and eliminated.

6.6. washing unit and

tank trucks should be located on the windward side at a distance of at least

10 m from the wellhead. At the same time, the cabin of the unit and tankers must be

facing away from the wellhead, the exhaust pipes of the unit

and tank trucks must be equipped with spark arresters, the distance between them

must be at least 1.5 m.

flushing unit, except

In addition, it must be equipped with safety and non-return valves.

6.7. In the process of silencing

well It is FORBIDDEN to fasten any units of the unit or the wellhead piping

wells and pipelines. There must be constant monitoring of:

readings of pressure gauges, behind the piping line, behind the location of people. Pressure gauges

must be installed on the pumping unit and the flow line of the well.

6.8. When killing wells

the pumping pressure of the killing fluid must not exceed the pressure of the pressure test

production string of this well.

6.9. Disassembly of the flushing

lines should only be started after the pressure in the discharge line has been reduced to

atmospheric. At the same time, the gate valve on the X-mas tree from the side of the well

should be closed.

6.10. After graduation

of well killing operations, valves must be closed, the area around

the well has been cleaned, the dead well must be awaiting repair

over 36 hours.

With a longer

downtime of the well in anticipation of repair, the well must be killed again before

start of repair work.

6.11. After the end of all

well killing operations, a “Well killing act” is drawn up.

In the act of silencing

wells should be indicated:

- date of well killing;

- specific gravity of the kill fluid;

- the volume of killing fluid by cycles;

- the time of the beginning and end of the jamming cycles;

- the initial and final pressure of pumping the killing fluid.

6.12. “Act to kill the well” signed (with

indicating the specific gravity and volume of the killing fluid), the person who produced

well killing, by the foreman of the workover team and the machinist of the unit.

Responsibility for Compliance instructions.

7.1. For preparation

the territory of the pad and the well to kill the well is the responsibility of the foreman of the TsDNG, TsPPD.

7.2. For authenticity

data on the current reservoir pressure, at the time of killing the well, corresponds to

geological service TsDNG, TsPPD.

7.3. For compliance

the specific gravity of the killing fluid to the calculated value - specified in the task plan

to kill the well, perform the entire range of work to prepare the well for

killing, compliance with well killing technology and safety measures when

killing the well is the responsibility of the workover team foreman.

Attachment 1

R A S X O D

materials

necessary for cooking one cubic meter of killing fluid relevant

density.

Solution liquid

– Cenomanian water with a density of 1.01 g/cm3.

| Density | Amount of NaCl, kg | Density | Amount of NaCl, kg |

| 1.02 1.03 1.04 1.05 1.06 1.07 1.08 1.09 1.10 | 19 38 56 75 94 113 132 151 170 | 1.11 1.12 1.13 1.14 1.15 1.16 1.17 1.18 | 188 207 226 245 264 283 302 321 |

| Killing liquid density, g/cm3 | The amount of CaCl2, kg | ||

| Fresh | Cenomanian | Commercial | |

| 1.19 1.20 1.21 1.22 1.23 1.24 1.25 1.26 1.27 1.28 |

Appendix 2

VOLUME

ring

space depending

from the diameter of production strings

and

Tubing lowered into the well.

| Volume | |||

| Descent depth Pump (tubing), m | NKT-60 | NKT-73 | NKT-89 |

| At | |||

| 800 1 000 1 200 1 400 | 8.68 10.85 13.02 15.19 | 7.50 9.38 11.26 13.13 | 5.86 7.32 8.78 10.25 |

| At | |||

| 800 1 000 1 200 1 400 | 12.25 15.31 18.37 21.43 | 11.06 13.83 16.60 19.36 | 9.42 11.73 14.11 16.49 |

| At | |||

| 800 1 000 1 200 1 400 | 4.27 5.34 6.41 7.48 | — — — — | — — — — |

Packing technologies

Well cementing methods that are currently used have differences in the supply of cementing (plugging) mixtures to the space behind the casing string and in the process equipment used.

There are the following schemes for pumping finished mixtures:

Direct scheme. In the course of injection according to this scheme, the mixture is fed directly into the casing string, which descends to the "shoe", goes into the annulus and fills it from bottom to top of the well.

Reverse scheme. The cement is fed directly into the annulus and is filled from top to bottom.

During large-scale drilling, the direct scheme is most often used, and the procedure itself is performed in one cycle, during which all the required amount of cement mixture is supplied.

Packing equipment

Well cementing equipment should be as follows:

- cementing unit, which ensures the mixing of solutions and their supply into wells under pressure;

- a mixing unit of the same purpose as the cementing unit;

- cementing head, with the help of which the wellbore is washed and its walls are plugged;

- pouring plugs, which are used as stops in the case of a two-stage carburizing process;

- other equipment such as mixing distributors, metal hoses, high pressure valves.

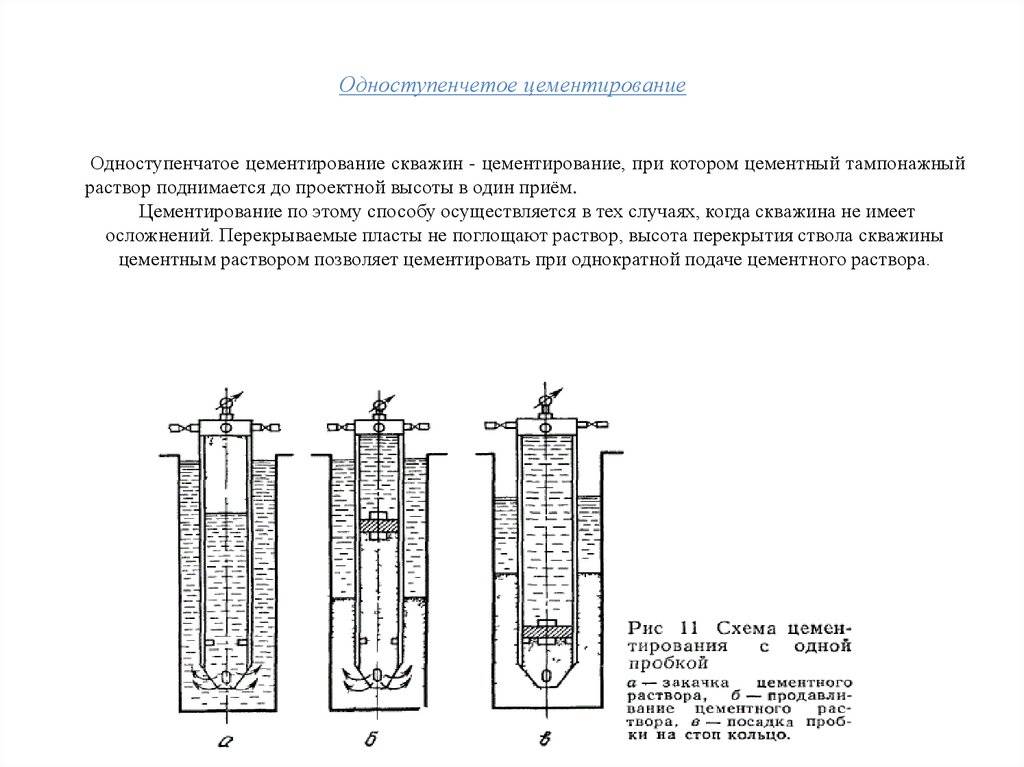

One-stage plugging

Single-stage cementing of wells has become widespread in the cementing of domestic water wells. At the same time, the overpressure cement mixture is supplied into the annulus by units installed on a truck chassis or a stationary platform located at a close distance. The cement mixture moves down the string, reaches the bottom and then fills the entire annulus.

There is a certain well cementing technology. Before cementing, they are flushed, and the bottom plug is fixed into the casing string as a stopper. Then, with the help of a concrete pump, the mixture is supplied. Descending along the barrel, the mixture presses on the plug, advancing it to the "shoe" of the column. After that, the upper plug is placed in the column and the process of compacting the mixture with the help of a vibropress begins with simultaneous pumping of an additional amount of the mixture into the well.

At the moment the top plug touches the bottom plug, it is considered that the process of sealing the solution is completed and that all the supplied solution has filled the space behind the casing string. Upon completion of the cementing process, the mortar is allowed up to 48 hours to completely solidify. Single-stage plugging is used for shallow wells with a simple hole geometry. The main disadvantage of this method is that it is impossible to determine the time the solution reaches the “shoe” of the column.

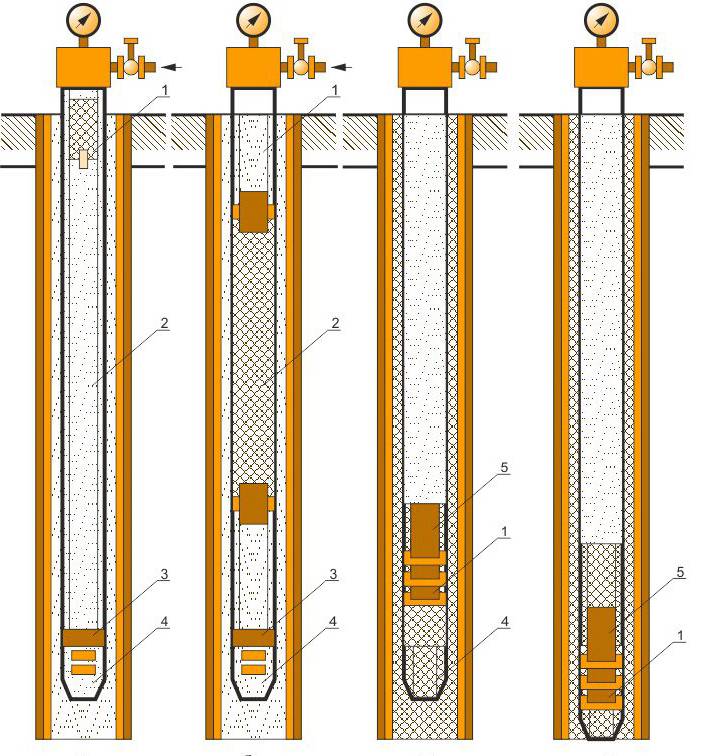

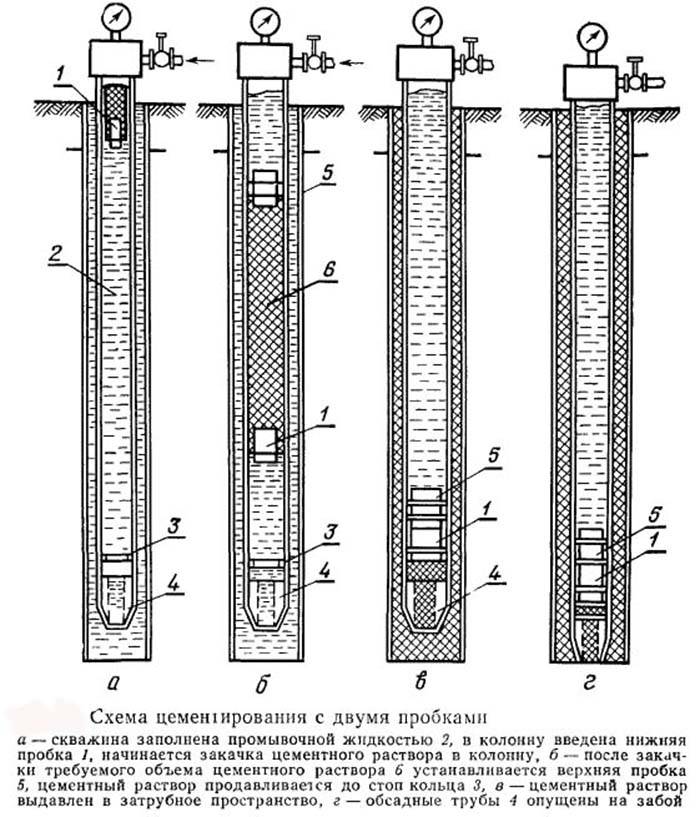

Two-stage or two-cycle cementing

Two-stage well cementing was specially designed for plugging oil-bearing sources. Requiring high capacity processing equipment, this plugging method is rarely used.

Basically, the method is used under the following conditions:

- when the cement mixture hardens in such a short time that it is impossible to fill the space behind the casing at one time;

- it is necessary to divide the space behind the casing string into several sections;

- large depth, which does not allow plugging due to the very high pressure required to supply the mixture.

The two-stage plugging method consists in the fact that the plugging mixture is supplied in two cycles. During the first cycle, an amount of mixture is pumped that fills only a certain part of the annulus. After the mixture has solidified, after at least 13 hours, the remaining required amount of the mixture is supplied to completely fill the annulus.

Well plugging during liquidation

Inside the fresh, first of all, it is necessary to carry out disinfection, the fact is that bacteria form in the wellbore, which must be cleaned up after themselves. To do this, for example, bleach is pumped into the well in a certain volume and exactly the same volume is pumped back. After decontamination of the well, it is necessary to start restoring the geological environment around it. It resembles a layer cake, if you simplify it very much, then you can reduce all layers to two main types:

-

the first is the type that contains and conducts water. This type is called aquifer;

- the horizon is the second type, which does not contain or conduct water. It's called waterproof.

In the intervals where the aquifers are located, sand and gravel are filled up, and it is filled up not just like that, but in such a ratio as to restore the filtration parameters of each aquifer, and those intervals where the water-resistant layers are located are concreted.

Description of the types of plugging

If we consider geological reasons in more detail, we can say that in this case, water intake may simply cease to fulfill its role, which quite often becomes a consequence of geological processes. Technical reasons - this is the case when the water intake was not maintained for a long time.

As an alternative, there may be a violation of technical standards during drilling. The work may have been carried out using inappropriate materials, repairs have not been carried out for a long time, and maintenance has not been carried out. Well plugging is also carried out in the case when the water intake was built for temporary use.

How cement slurry enters the well

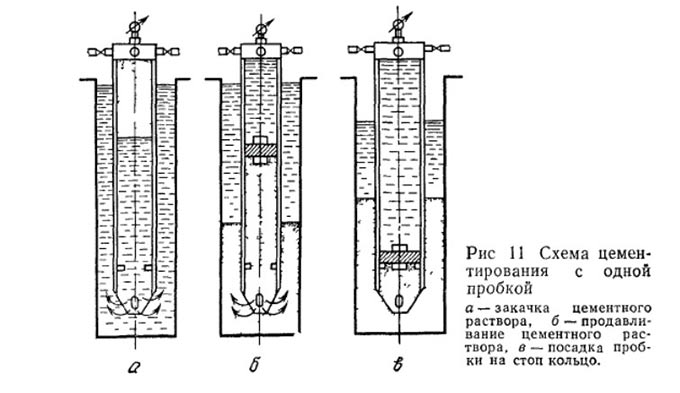

There are several main ways to supply the solution to the annulus. If the cement slurry is fed directly into the casing, this method is called direct. Then there is a slow filling of the lower part of the well, which goes into the annulus, filling it. This is the type of delivery that is most commonly used. To check the amount of cement slurry mass, two special plugs are used.The essence of the operation of these plugs is that when a solution is supplied, an additional liquid is pumped under a certain pressure, pressing on the upper plug. After that, it presses on the solution and the lower part of the well. There is an easier way using just one cork. To measure the pressure of a liquid, a manometer is usually used. There is also a reverse flow of the solution, in which it enters the annulus, but then descends through the casing.

There is also such a type of cementing as cementing in one stage. When using it, almost the entire portion of the solution passes in one go. In this form, one or two plugs with direct feed elements are also used.

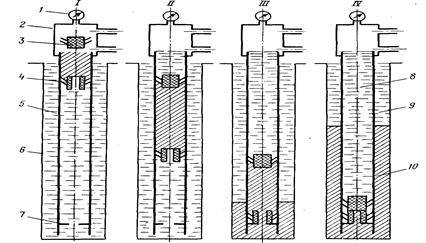

When cementing in two stages, a little more experience and coordination is needed. This option is a little more complicated and is partially used for greater depths. At such depths, resistance increases, so it is very difficult to do everything in one go, as in the methods described above. In order to somehow compensate for such a depth, the collar cementing method is used. These cuffs form some kind of rings that gradually limit the progress of the solution. This method allows gradual cementing of individual sections of the well.

WELL CEMENTING TECHNOLOGICAL PROCESS

The final stage of drilling operations is accompanied by a process that involves well cementing. The viability of the entire structure depends on how well these works are carried out.The main goal pursued in the process of carrying out this procedure is to replace the drilling fluid with cement, which has another name - cement slurry. Cementing wells involves the introduction of a composition that must harden, turning into stone. To date, there are several ways to carry out the process of cementing wells, the most commonly used of them is more than 100 years old. This is a single-stage casing cementing, introduced to the world in 1905 and used today with only a few modifications.

CEMENTING PROCESS

Implementation Technology well cementing involves 5 main types of work: the first - mixing the cement slurry, the second - pumping the composition into the well, the third - feeding the mixture into the annulus by the selected method, the fourth - hardening the cement mixture, the fifth - checking the quality of the work performed.

Before starting work, a cementing scheme should be drawn up, which is based on technical calculations of the process.

It will be important to take into account the mining and geological conditions; the length of the interval that needs strengthening; characteristics of the design of the wellbore, as well as its condition. Should be used in the process of carrying out calculations and experience in the implementation of such work in a particular area

DISCHARGE FEATURES

Cementing can be done by different methods of supplying the mixture into the annulus, moreover, various devices can be used in the process of work.Cementing wells may involve the direct supply of the mixture, such a scheme involves the flow of cement into the internal space of the casing string, followed by its passage directly to the shoe and further entry into the annulus, while the flow of the solution is made from the bottom up. With the reverse scheme, the injection is performed in the reverse order, from top to bottom.

In this case, well cementing can be carried out in one approach, during which the required volume for plugging the mixture is forced through at a time.

Two-stage cementing is used when the well has a significant depth. The technological process is divided into sequential filling of individual intervals through the use of equipment. Collar cementing, in contrast to the above methods, involves protecting a part of the wellbore from the passage of the cement mixture. The cuff allows you to isolate the area located along the length of the reservoir. The well may have hidden columns and sections, their cementing can be classified as a separate group.

The implementation of well cementing, regardless of the chosen method of work, pursues the goal of expelling the solution formed by drilling from the annulus, which is possible by placing a cement slurry there.Cementing ensures complete filling of the wellbore interval with cement mixture; elimination of the drilling fluid by penetration of the cement mixture within the interval intended for cementing; protection of the cement mixture from the penetration of flushing fluid; the formation of cement stone, which is characterized by significant resistance to various kinds of influences in the form of deep loads; excellent adhesion of cement stone to the walls of the well and to the surface of the casing.

TOOLS AND MATERIALS:

- cementing units designed for mixing the mixture and its subsequent punching under significant pressure;

- cement-mixing equipment;

- cementing head for flushing the wellbore and further cementing its walls;

- filling plugs for two-stage cementing;

- high pressure taps;

- steel flexible hoses;

- devices designed to carry out the distribution of the solution.

The duration of hardening of the protective layer and checking its quality

The formation of cement stone begins immediately after the completion of the pouring of the mixture. The process of complete hardening depends on the ambient temperature, the composition and moisture content of the soil, the material of the casing elements, as well as the characteristics and list of components of the solution itself. If it is not possible to determine when the protective layer has fully formed, wait at least 48 hours before taking any action.

After two days, it is recommended to check the obtained protective layer. More accurate results can only be obtained using special professional equipment.There are three ways to check the integrity of a solution:

- Acoustic. The technique is based on tapping casing pipes along the entire length of the shaft and processing the results obtained through a computer program.

- Radiological. The measurement is carried out by special radio devices.

- Thermal. The temperature is measured during the solidification of the layer.

If it is not possible to invite specialists to evaluate the work performed, you can check the readiness of the cement layer using a simplified thermal method. To do this, during the period of solidification of the mixture, the temperature at the walls of the casing is measured. It should first be equal to the ambient temperature, and then become 1-1.5 degrees lower.

The final step is to clean the barrel from the remnants of the mixture. When doing work with your own hands, cleaning can be done with a bailer. Before putting the source into operation, the shaft is checked for tightness. To do this, water is pumped into the barrel under pressure for 20-30 minutes. If during this time the water pressure decreased by no more than 0.5 MPa, the work was done with high quality.

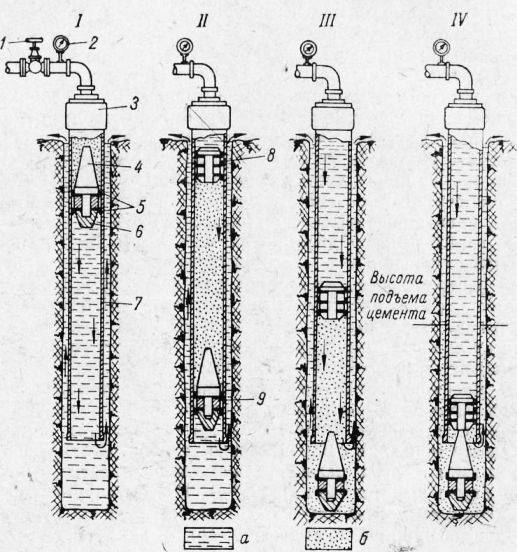

Well cementing methods;

The method of cementing is selected depending on the conditions of occurrence, lithological composition, permeability and degree of saturation of productive formations. There are several ways to cement wells:

Single-stage cementing is the most common and is as follows (Figure 73). After the casing is lowered into the well, a cementing head is installed on the wellhead and flushing is started until the density of the drilling fluid is completely equalized (the density of the drilling fluid at the inlet to the well should be equal to the density at the outlet).

Before starting cementing, all manifold lines from the cementing units to the cementing head must be pressurized to 1.5 times the working pressure for 3 minutes.

Before pumping a cement slurry into the well, it is desirable to pump a buffer liquid (an aqueous solution of NaCl, CaCl2 and others or alkali NaOH) to thin the drilling fluid and reduce viscosity and static shear stress.

Then, using cementing units and cement mixers, the cement slurry is mixed, which is pumped into the casing string through the cementing head. In order to squeeze out the calculated volume of cement slurry into the annulus, it is necessary to release the cementing separation plug, which is held inside the cementing head with a locking screw. Displacement fluid is pumped into the casing string from above the cementing separation plug.

Figure 73—Scheme of one-stage cementing

The last 0.5-1 m 3 of the displacement fluid is pumped by one cementing unit. As a result, the plug "sits" on the stop ring and at this moment the pressure on the cementing head increases sharply. This serves as the end of the cementing process.

Two-stage cementing is used in cases where there are difficulties in lifting the cement slurry to a predetermined height, or high bottomhole temperature, which limits the time for single-stage cementing, or non-continuous cementing is required.

To do this, a separating cementing sleeve is included in the casing string equipment, which is installed at the boundary of the cementing intervals. Cementing of the lower interval occurs in the same way as the one-stage.

Before pumping the second portion of the cement slurry with a volume equal to the volume of the upper part of the annulus, a ball is dropped into the well. Having reached the cementing sleeve, the ball moves down the movable sleeve under the action of pressure and side holes open, through which the second portion of the cement slurry enters the annulus.

Proper preparation of the solution

Cementing slurry for well cementing must meet a number of requirements and have:

- high adhesive properties with surfaces of any type;

- high strength after hardening, resistance to mechanical stress;

- plasticity and good fluidity to fill all cracks and voids;

- chemical neutrality in relation to plugged soil layers;

- resistance to erosion by groundwater;

- no shrinkage during hardening.

Also, the solution must have such a consistency that it can be easily delivered to the well and injected. The solution must be well washed off the equipment, not be chemically aggressive towards it, and have a minimum loss coefficient during transportation to the well.

The grouting slurry used must have a sufficiently liquid structure for pumping by injection equipment and at the same time have high strength characteristics.

The process of preparing a cement slurry for plugging consists in uniform mixing of the components that make up its composition, followed by pouring water into it, with special additives previously dissolved in it.

The simplest solutions that you can prepare yourself are:

- Portland cement + quartz sand (1:1) + special additives and water until the desired consistency is obtained. Such a solution has a low density, and its preparation is difficult, because. the sand that is part of the composition often precipitates and the use of the solution becomes impossible.

- Portland cement + barite (1.1:1) + special additives and water. The disadvantage of this solution is low strength.

- Portland cement + filler. Asbestos is used as a filler (on sandy soils), fibrous materials.

For the preparation of a cementing mixture, it is best to use Portland cement, which is a type of cement based on silicates.

Such cement, of course, is more expensive than ordinary Portland cement, but its strength characteristics are much higher than those of ordinary cement. Barite is a heavy mineral that increases the density of a solution. You can buy barite at a hardware store that sells bulk building materials.

Under the special additives that are part of cementing mortars, we understand various substances that give the mortar special properties. These include:

- cement setting accelerators (calcium chloride, soda ash, potash), used if cementing occurs at temperatures below +5 degrees;

- setting retarders used to prevent rapid hardening (these are calcium or sodium chlorides, sodium nitrite, etc.);

- plasticizers to obtain optimal viscosity (polymer modifiers);

- frost-resistant additives (organosilicon compounds coupled with plasticizers);

- moisture-absorbing additives (substances derived from compounds belonging to the groups of sugar, citric, tartaric and tetrahydroxyadipic acids), etc.

Special additives are mixed in water, which is subsequently used to prepare the cement slurry. Mix the solution with the help of special machines - mixers. Sometimes manual kneading is allowed, but it requires some skill and a lot of labor.

Cement stone, formed during the hardening of Portland cement, has high strength properties, withstands loads, mechanical and physical impact

Conclusions and useful video on the topic

In the videos below, we are talking about wells in the oil and gas industry, but the principle of work technology is the same as for aquifers.

One-stage well cementing procedure:

Specifics of sleeve cementing production:

Technological features of two-stage cementing:

Cementing is a complex process that requires the use of specialized equipment. However, this does not mean that it is impossible to carry it out on your own. Having chosen and properly prepared the cement slurry, using a minimum set of units, it is quite possible to cope with the work on your own.

In any case, the operation of a well without strengthening the wellbore with cement will not be long, and the cost of drilling a new water source will be no less.

If after studying the material you still have questions about how to properly cement a well after drilling, or you have valuable knowledge on this issue, please leave your comments in the block below.