- Technology of drilling an artesian well for water

- Pipes for artesian wells

- Well insulation

- Proper well construction - video

- Insulation materials

- Horizons and types of wells: accessible and not very

- Horizons have boundaries

- The whole range of wells

- Abyssinian well

- Well on the sand

- Artesian well

- Do-it-yourself thermal insulation stages

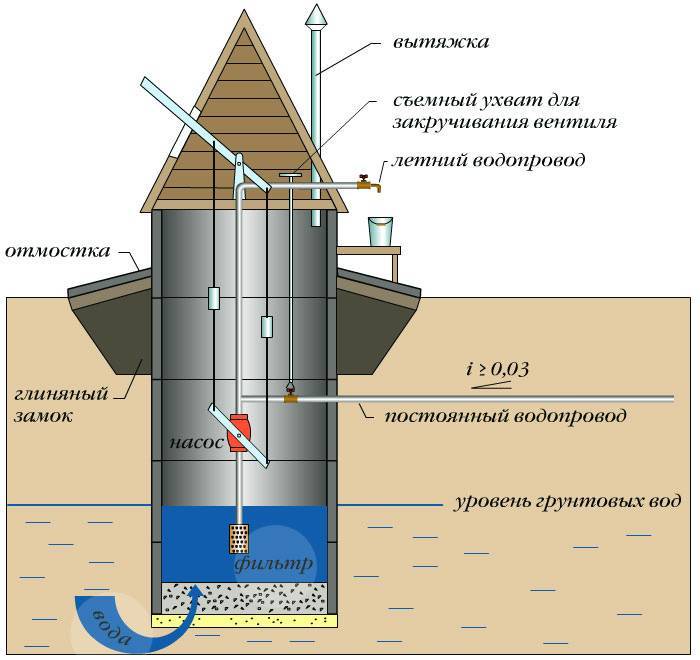

- Caisson

- Casing pipe and head

- street plumbing

- Lead to the house

- Briefly about the main

- Without caisson

- sand wells

- Advantages and disadvantages

- What sources underground

- Verkhovodka

- Primer

- Sources between layers

- Artesian

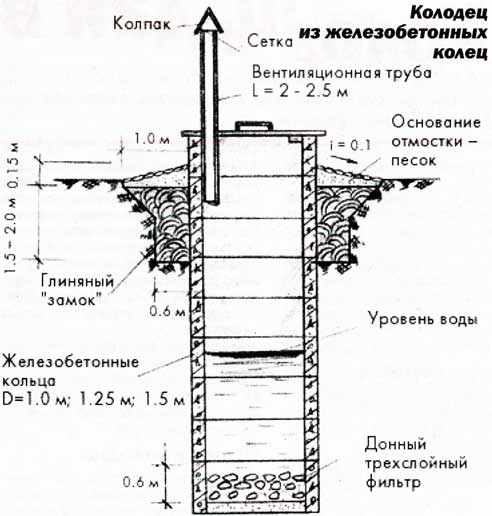

- The concept of a well

- How to remove a pipe from a well?

- What threatens the sand in the well?

- Types of materials

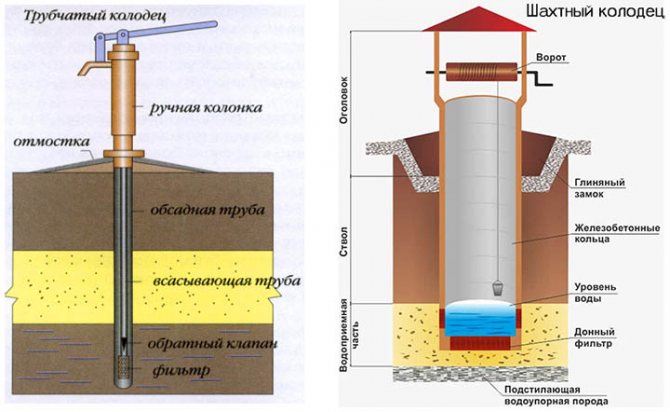

- Abyssinian well

- Advantages and disadvantages

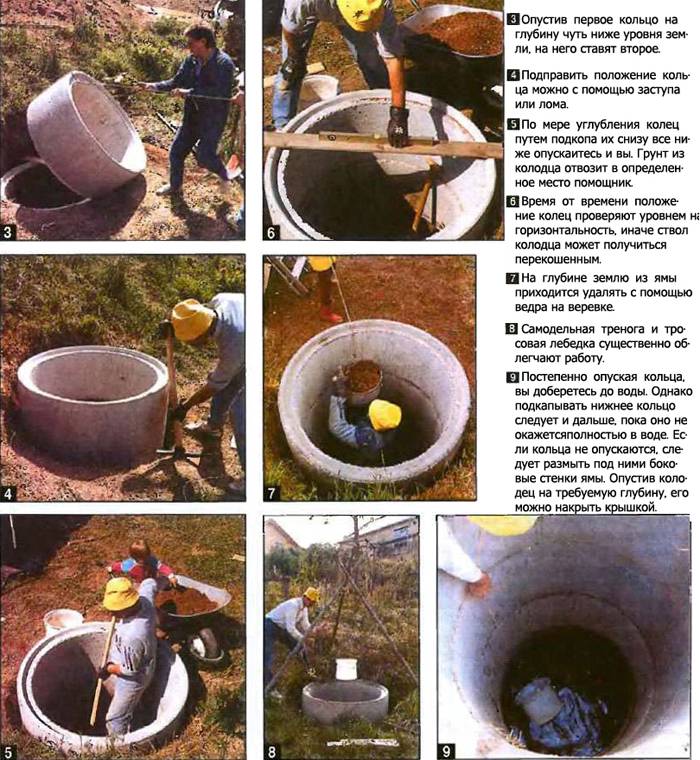

- How to make a well in the country

- Conclusions and useful video on the topic

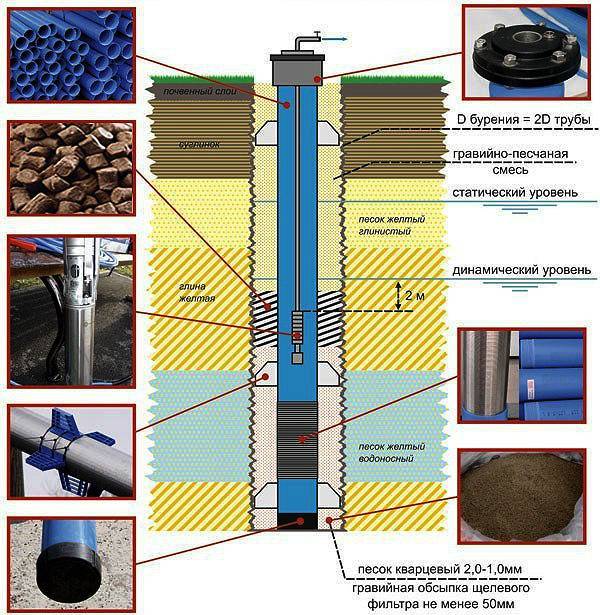

Technology of drilling an artesian well for water

When ordering the drilling of an artesian well, it is desirable to control the entire drilling process from start to finish in order to understand what the drillers are doing and whether they are cheating, simplifying their work. This article is intended to make it clear to the owner of the land the technology of drilling artesian wells for water (for limestone), in order to properly accept work from drillers and not waste money.

The technology of drilling an artesian well for water includes 3 stages:

- The destruction of the rock.

- Removal of rock from the well.

- Arrangement of the walls of the well with casing pipes.

For drilling wells, mobile drilling rigs based on MAZ, ZIL and KamAZ trucks are used (imported drilling rigs are also based on tracked vehicles for difficult terrain). The method of drilling is called rotary, because a rotor on a drilling rig is used to rotate the bits.

As a drilling tool, a cone bit of different diameters is used. Transportation of drilled rocks to the surface is carried out using a special solution that enters the well through the drill rod.

The upper rocks are drilled with a large bit (it is not known whether one, two or even three pipes will have to be used for artesian well casing, and to put them one inside the other, you need a larger drilling diameter, so first drill with a large bit).

In the process of removing soil rocks, the driller must record changes in the rock in the drill log.

When passing unstable rocks, a clay solution is used to flush the well. If drilling starts immediately with clay layers, then the solution itself will turn out to be clay. To make clay mortar artificially, bentonite clay is used (sometimes with a little cement added).

When the drill reaches solid limestone, drilling is stopped for a while and the well is equipped with a casing pipe of the largest diameter to protect the walls of the well from shedding and penetrating surface water from the overlying soil layers.

Depending on soil types, up to three casing pipes can be used to equip an artesian well (for example, if clay veins are present in hard limestone rock).The design of three casing pipes is called telescopic.

After the well is cased to limestone in the casing, the limestone is drilled with a smaller diameter bit (in this process, the limestone is flushed with clean water so that the dirty solution does not enter the clean aquifer after drilling is completed). Then, a production perforated pipe is lowered into the drilled hole. Pipes are washed until clean water appears.

A very important point when drilling an artesian well is the isolation of the lower clean layers of water from the upper ones. Compactonite material is used for high-quality insulation. These are granules of dry clay, which, when meeting with a moist environment, swell several times, preventing the penetration of moisture into the well. This method of isolation is reasonably more expensive than the others. Before ordering drilling, be sure to check what kind of insulation the drilling company uses.

Upon completion of all work on drilling an artesian well, drillers make all the necessary measurements and check the well. Then the owner is issued a passport, which indicates the depth of the well, the debit, the height of the water level and other characteristics.

Pipes for artesian wells

For artesian wells, as a rule, steel pipes are used as casing, but metal-plastic pipes are also becoming popular now. Welding was used to connect pipes, but it has proven to be a risky connection method. Therefore, pipes with threaded connections are now being produced. Pipes made of plastic and its types, as well as steel pipes, are used as operational pipes.

Well insulation

In order for the water in the well not to freeze, the concrete walls of the tank are insulated with polystyrene foam.Styrofoam is also used to insulate the well. After the concrete walls are insulated, you will be able to receive water from the well all year round.

Proper well construction - video

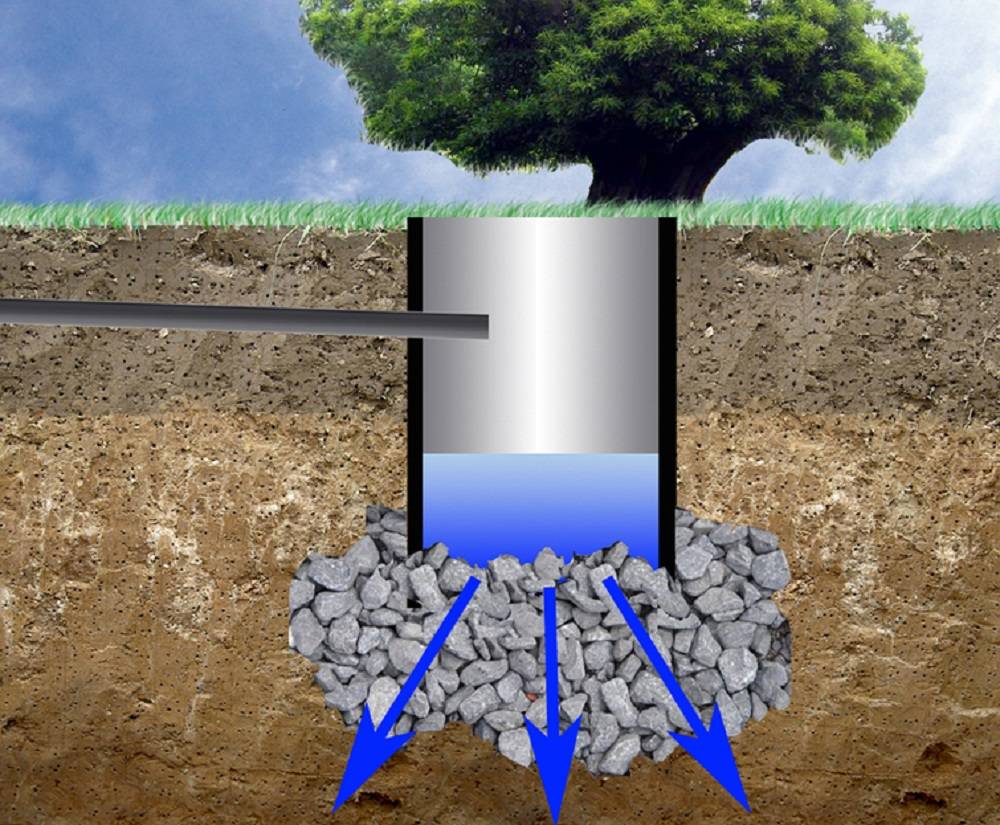

Immediately after the drilling rig has finished working, several more actions are performed, which in no case can be postponed for several days.

First, casing pipes for the well with a filter must be installed immediately. And the second work that does not suffer any delays is the gravel filling of the well.

All this is done to strengthen the walls and fix the casing pipes, as well as for the normal functioning of the well. One filter located on the last section of pipes does not guarantee the supply of pure water. Filling the space between the walls of the well and the outer surface of the filter with a sand-gravel mixture enhances its effect.

An additional filter layer traps large soil particles that come with water to the holes in the filter.

It must be taken into account that the casing pipes for the well are located in a dense water-resistant layer, and the filter itself in a sandy aquifer. Therefore, backfilling of the lower part of the well should be carried out with a sand-gravel mixture of a coarse fraction, not less than 4 times the fraction of the natural layer.

It is possible to use crushed stone of 2-4 mm fraction, but this material is much more expensive than sand mixture. It is necessary to ensure that there are no particularly large particles in the sanding, due to which voids can form in the space to be filled.

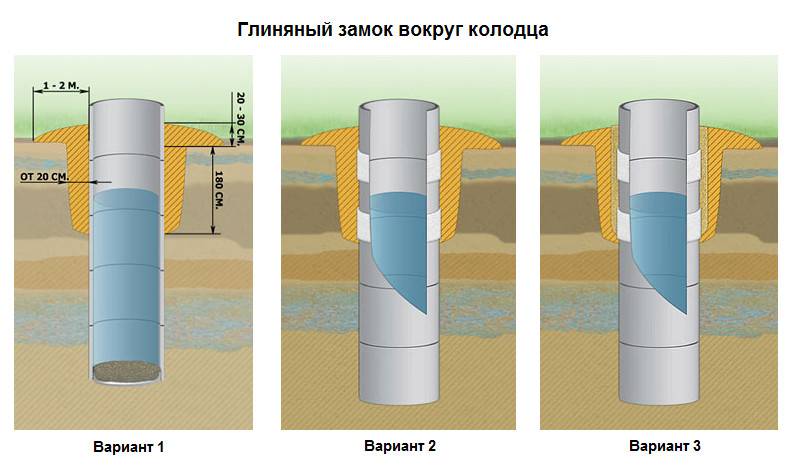

Sprinkling is carried out to the entire height of the filter and about a meter above, in order to increase the filter layer. After that, a clay castle is installed, also no less than a meter thick.

Read also Natural tiles photo of roofs

After that, the wellhead can be filled with ASG of a finer fraction. This is where the urgent work ends and the piping (or arrangement) of the well can be done in a few days.

Hello! We drilled a well, and now the question arose of how to fill it up, since there were gaps of 4-5 cm on each side between the casing pipe and the soil (bore diameter - 200 mm, and pipes - 125 mm).

Insulation materials

To insulate a do-it-yourself water pipe in a country house, several options for special materials are used. The first variety, which is called "pipe shell", is a shell in the form of a pipe.

The second variety is a variety of insulating materials made in rolls of various widths and lengths.

"Pipe shells" are made from polystyrene foam, extruded polystyrene foam and polyurethane foam. It is a product in the form of a semi-rigid cylinder, which consists of two halves. It is put on the pipe, and fastened with overlaps, special glue, clamps and foil tapes.

Typically, the length of such a "shell" is one meter, but can reach two meters. Such products can be produced with additional coatings of foil, fiberglass or galvanized. This type of insulation material is quickly and easily mounted, as well as removed and replaced during repairs. "Shell", covered with fiberglass, can be used for all types of water pipes or pipelines that are placed in the ground, outdoors and indoors.

It will be useful to read:

Ways to drill a well for water Water has always been and is one of the necessary elements of life.And even the very first settlements tried to create on ...

Styrofoam is called foamed plastic in the form of small white balls (known to absolutely everyone), which, in the manufacture of the “shell”, are pressed into the shape of a pipe and then steamed. Interestingly, this material is almost 97-98 percent air. The advantages of polystyrene are lightness, practicality and low cost. And the disadvantages include fragility and fragility.

Styrofoam

Extruded polystyrene foam is a type of polystyrene foam that uses pressure and heat to produce it. The result is a stronger material than foam. This material is liked for its resistance to environmental influences (does not rot). It does not absorb moisture, has a long service life, low weight and is easy to install.

Polyurethane foam is a plastic foam material consisting of numerous gas-filled cells.

It attracts attention with the best sound insulation characteristics, good mechanical strength, ease of use and low weight.

polyurethane foam

From insulating materials that produced in the form of rolls, it is worth mentioning stone wool, polyethylene foam and glass wool.

Glass wool is a material for insulation, consisting of glass fibers.

It attracts attention with its noise and heat insulation characteristics, durability and price. The disadvantages include the fact that when working with glass wool, it is imperative to observe safety precautions, since this material is prickly

During isolation work, the respiratory organs and skin are protected by protective equipment (special work suits, gloves and masks).

glass wool

Stone or basalt wool

Fibers of stone or basalt wool are produced from molten rocks of volcanic origin, slag and silicate materials

This insulating material attracts attention with its high resistance to various loads and impacts, incombustibility, as well as the fact that products of various shapes and densities are made from it.

Foamed polyethylene is obtained by processing ordinary high-pressure polyethylene using propane and butane. It is an elastic porous material consisting of a large number of cells. Foamed polyethylene stands out among other insulating materials with its highest resistance to water, and it is also not affected by fungi and bacteria. It tolerates well the effects of petroleum products, alkalis and acids.

Horizons and types of wells: accessible and not very

Before you start preparing for such a large-scale work, you need to find out where to drill, but without conducting geological exploration, you will not be able to find the exact answer.

Horizons have boundaries

Water is located on different horizons, these sources do not communicate with each other. This is provided by layers of impermeable rocks - clay, limestone, dense loam.

- The shallowest source is perched water, which is provided by precipitation and reservoirs. It can start at a depth of 0.4 m and end at 20 m from the surface. This is the dirtiest type of water, it always has a lot of harmful impurities.

- Having drilled a well up to 30 m deep, you can “stumble” on cleaner groundwater, which is also fed by precipitation.The upper boundary of this horizon can be located at a distance of 5 to 8 m from the surface. This liquid is also recommended to be filtered.

- The underground water source, located in the sandy layer, is already filtered with high quality, therefore it is optimal for water supply. It is this horizon that must be reached by those who want to drill their own well.

- Depth from 80 to 100 m is an unattainable ideal with crystal clear water. Artisanal drilling methods do not allow you to get so deep.

Since the occurrence of horizons is influenced by relief and other factors, the boundaries of perched water and groundwater are conditional.

The whole range of wells

Drilling water wells manually depends on the type of future well. The types of structures cannot be called numerous, because there are only three of them:

- Abyssinian;

- on the sand;

- artesian.

Abyssinian well

This option is optimal when the water in the area is 10-15 m away from the surface. It does not require a lot of free space. Another advantage is the relative simplicity of work, which allows even a beginner who is just learning the science of drilling to cope with the task. This is a well-needle, which is a column constructed from thick-walled pipes. A special filter is arranged at the bottom of it, drilling holes at the end of the pipe. The Abyssinian well does not require drilling as such, since the chisel is simply hammered into the ground. But the most common way to make such a well is still called impact drilling.

Well on the sand

If the aquifer lies at a depth of 30 to 40 m, then it is possible to build a sand well, with the help of which water is extracted from sands saturated with water.Even a 50-meter distance from the surface does not guarantee the purity of drinking water, so it must be given for laboratory analysis. Since in this case there will be no insurmountable obstacles on the way - hard rocks (semi-rocky, rocky), manual drilling of water wells does not imply any special difficulties.

Artesian well

This aquifer can be located at a depth of 40 to 200 m, and water has to be extracted from cracks in rocks and semi-rocks, so it is inaccessible to mere mortals. Without knowledge and serious equipment for drilling, the task of building a well for limestone is an impossible mission. However, it can serve several sites at once, so drilling services ordered together promise significant savings.

Do-it-yourself thermal insulation stages

The further fate of the entire water supply system will depend on how well the thermal insulation will be carried out. Therefore, it is better to entrust it to professional companies with extensive experience. Nevertheless, every private homeowner has the right to know how to insulate a well and water supply for the winter on the surface - a well for his own home for the entire period of turnkey cold weather with his own hands.

Visually about the insulation of the well, see this video:

In the standard case, the procedure consists of sequential thermal insulation of the following main elements:

Caisson

Stages of work:

- The required amount of foam or other heat insulator is prepared.

- Further, the material is cut into the necessary fragments, based on the shape and size of the caisson.

- The outer part of the caisson is waterproofed with bitumen, except when it is made of plastic or iron.

- The prepared fragments are applied to the outer walls and fastened with wire, stops, mesh or tape.

- The joints between the sheets are filled with mounting foam - for sealing.

- Upon completion of the fastening, the structure is covered with a layer of expanded clay.

Casing pipe and head

Subsequence:

- From pieces of chipboard, boards, plywood, sheets of metal or rigid insulation, a box is made for external closing of the casing and head.

- The box is installed over the casing pipe and the head.

- Its internal space is filled with parts of mineral wool, glass wool or natural components (hay, straw, paper).

Alternatively, instead of a box, a cylinder is formed from a chain-link mesh with a diameter exceeding the head by 0.3 m.

Do-it-yourself well insulation

street plumbing

Sequence of work:

- At the outlet of the pressure pipe of the well, at the point of connection to the domestic water supply, a piece of heating cable is wound or a special tee with a gland is installed.

- Next, the water pipe is placed in a PPS shell or in a sewer pipe of a larger diameter, which creates an air gap.

- The structure is laid in a previously dug trench and then filled with expanded clay, then with a layer of sand and previously removed soil.

Lead to the house

In view of the fact that the wellhead is already heated by a heating cable, and the supply water supply is insulated with shells, it is not necessary to make special heating of the liner. As a standard, it is thermally insulated along with the supply pipe.

See in this video how to mount the heating wire inside the pipe

Briefly about the main

Depending on the frequency of operation, there are the following ways to insulate a well on the street:

- Seasonal, when the well is not in operation, but simply drained and turned off for the winter.

- Periodic, when water is taken on weekends or every few days. To maintain efficiency, heat-insulating materials and heaters are used.

- Constant, when the well is practically not idle, so the flow never stops for a long time. However, in cold weather, icing can begin. Therefore, professional insulation is required.

At the same time, 4 technologies are used for thermal insulation - by means of a heater, with a coffered structure, without it, and with the installation of a heating cable. In most cases, combined methods are used. The heat-insulating materials are polystyrene foam, foam plastic, foamed polyethylene, mineral or glass wool, as well as penoizol, foamed polyurethane foam and expanded clay. You can do the thermal insulation yourself, but it is better to entrust the matter to a professional team.

Without caisson

Water supply equipment, filters and related electronics are located in the house or a separate room - this does not mean that the shaft does not need to be isolated. There are several ways to insulate a source without a caisson:

- Thermal protection of the mine shaft with wood chips or sawdust. The pipe is dug around the entire circumference to a depth of 2 - 2.5 meters. The width of the trench is 30 - 40 centimeters. Then a mesh with a large mesh is wound to provide an air gap between the wall and the insulation. Then the material (sawdust or peat) is gradually poured. You can not ram the insulation, it is better to let it stand for a while, and after shrinkage, add more. A strong cover made of a wooden shield or metal is put on top.

- Thermal insulation with mineral wool.In the same way, they dig a trench and stretch the mesh. Then several layers of glass wool or mineral wool are wound around the pipe. It is better to use a 5 cm thick mat. The final insulation layer is 35 cm.

- Insulation with liquid polyurethane foam is a little easier. No need to wind the net. A special device is simply lowered into the pit and polyurethane foam is sprayed layer by layer on the surface of the pipe.

- Heating with electric cable. The principle is to use a special heating cable, which is tightly wound to the borehole pipe. A non-combustible film must be wrapped over the heating element and provide additional waterproofing.

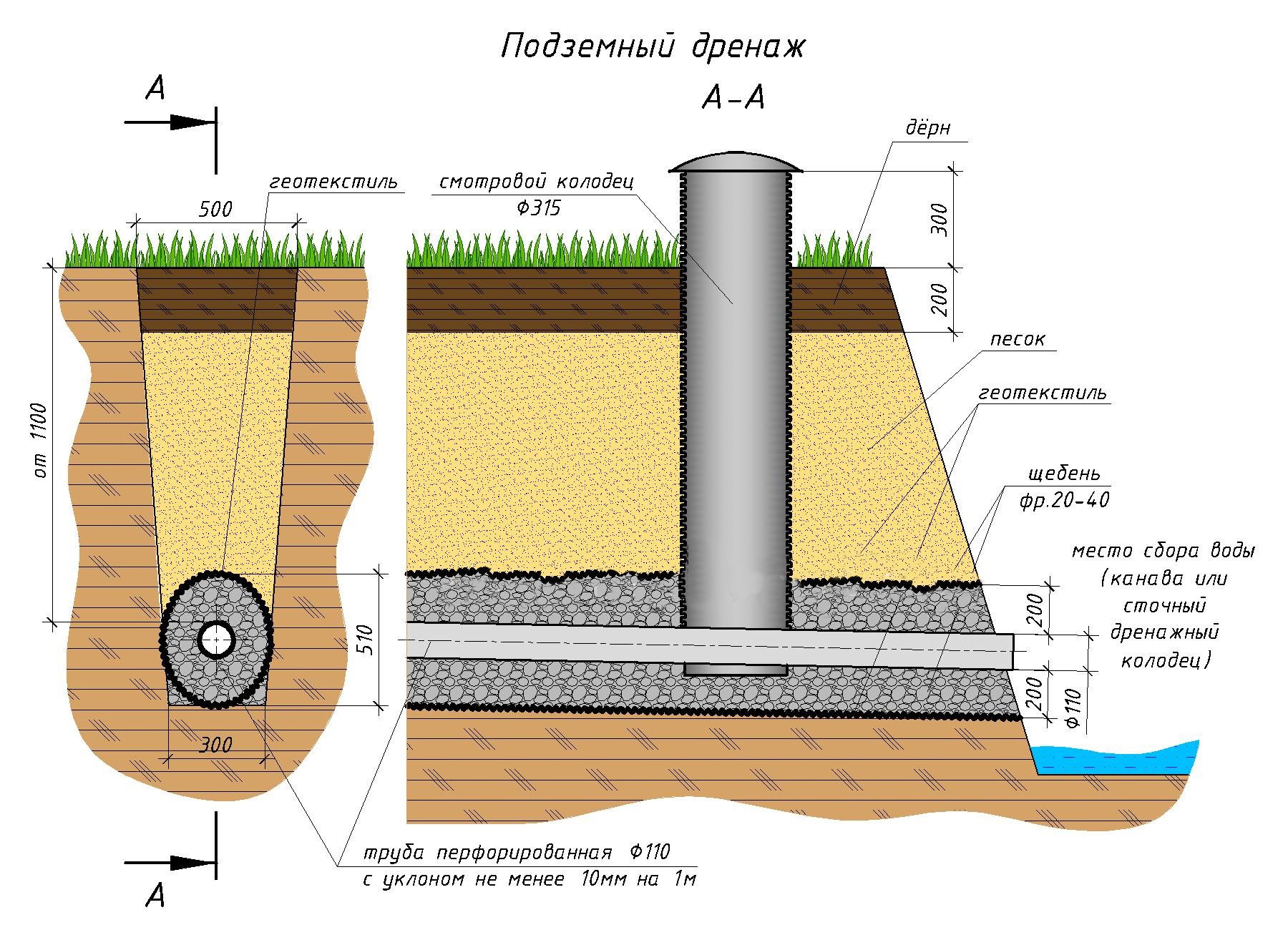

sand wells

Schematic of a sand well.

They are drilled using a screw method - penetration is carried out in soft rocks: loam, sand and pebbles. Excavation diameter ≥100 mm.

There are 2 types of sand wells by depth:

- up to 40 m - on the upper layer with a flow rate of 1 m³;

- 40-90 m - deep trunks with a water flow rate 2 times greater.

A casing string made of metal or plastic pipes with a filter in the bottomhole part of the well is lowered into the drilled working. The water is lifted by a submersible pump.

Advantages and disadvantages

The main advantage is the auger drilling method, which allows you to build a well in 1-2 days without much effort. The mechanization of all operations is ensured by the design of the drilling rig on a self-propelled or mobile chassis.

Other advantages:

- water purity;

- a permit for the construction of a water intake is not required;

- service life - up to 30 years.

Disadvantages are noted in wells of shallow depth: the dependence of the flow rate on precipitation, the sensitivity of the water composition to surface contamination at the location of the mine. Another minus has already been identified - the tendency to silting of the water intake.

What sources underground

Geological sections for land plots are not the same, but there are patterns in aquifers. With a deepening from the surface into the subsoil, underground water becomes cleaner. Water intake from the upper levels is cheaper, it is used by owners of private housing.

Verkhovodka

A water resource located in the ground near the surface above a water-resistant layer of rocks is called a perch. Waterproof soils are not available in all areas; it is not always possible to find a suitable site for organizing a shallow water intake. There is no filtration layer above such lenses, harmful substances, organic and mechanical impurities penetrate the soil with rain and snow and mix with the underground reservoir.

Verkhovodka is characterized by such indicators:

- Depth. On average 3-9 m depending on the region. For the middle lane - up to 25 m.

- The reservoir area is limited. Manifestations are not found in every locality.

- Replenishment of reserves is carried out due to precipitation. There is no water inflow from the underlying horizons. During dry periods, the water level in wells and boreholes drops.

- Use - for technical needs. If there are no harmful chemical contaminants in the composition, the water is improved to drinking water by the filtration system.

Verkhovodka is well suited for watering the garden. When drilling shallow wells, you can save money: sinking is available for self-execution.Option - the device of the well with the strengthening of its walls with concrete rings. It is not recommended to take water from the upper deposits, if fertilizers are used near the land plot, an industrial zone is located.

Primer

Verkhovodka is a disappearing resource, unlike the primer, which is the first permanent underground reservoir. The extraction of perched water from the bowels is carried out mainly by means of wells; wells are drilled to take the primer. These types of groundwater have similar characteristics in terms of depth −

Ground features include:

- The filter layer of rocks. Its thickness is 7-20 m, it extends directly to the layer located on the impervious platform of the rocky ground.

- Application as drinking water. Unlike top water, for which a multi-stage cleaning system is used, the removal of mechanical impurities from the primer is done by a downhole filter.

Groundwater recharge is stable in forested and temperate regions. In dry areas, moisture can disappear in summer.

Sources between layers

Groundwater scheme.

The name of the second permanent source of water is the interstratal aquifer. Sand wells are drilled at this level.

Signs of lenses interspersed with rocks:

- pressure water, because it takes on the pressure of the surrounding rocks;

- there are several productive water carriers, they are dispersed in depth in loose soils from the upper waterproof layer to the lower underlying cushion;

- Stocks of individual lenses are limited.

The quality of water in such deposits is better than in the upper levels. The depth of distribution is from 25 to 80 m.From some layers, springs make their way to the earth's surface. Groundwater exposed at great depth due to the stressed state of the liquid rises along the wellbore to its usual proximity to the surface. This allows for water intake by a centrifugal pump installed at the mouth of the mine.

The interstratal variety of groundwater is popular in the arrangement of water intakes for country houses. The flow rate of a sand well is 0.8-1.2 m³/hour.

Artesian

Other features of artesian horizons are:

- High water yield - 3-10 m³ / hour. This amount is enough to provide several country houses.

- Purity of water: penetrating into the bowels through multi-meter layers of soil, it is completely freed from mechanical and harmful organic impurities. The enclosing rocks determined the second name of water intake workings - wells for limestone. The statement refers to porous varieties of stone.

On an industrial scale, the extraction of artesian moisture is carried out for commercial purposes - for the sale of drinking water. In areas located in lowlands, it is possible to find a pressure deposit at a depth of 20 m.

The concept of a well

A well is a mine working in the earth's crust, which has a small diameter compared to its length. The base of the well (on the surface) is the mouth, the bottom of the well is the bottom. Wells fall into two categories:

— exploration (drilled to calculate oil reserves at a new field);

- operational (for extracting oil from the reservoir).

An oil well is a capital structure, which is being built according to a pre-compiled technical specification. project. The basis of the project is the design of the well.

Well design refers to the number of casing strings that must be lowered into the well for successful drilling and subsequent long-term operation. The concept of well design also includes the optimal lifting height of the cement slurry in the annulus. The diameter of the well should be minimal, but at the same time sufficient to ensure the descent of casing strings to the designed depth, as well as to ensure reliable isolation of productive formations from aquifers and from the mutual influence of formations from each other. The drilling speed and the cost of well construction depend on the chosen well design.

Well design is selected based on factors:

— geological;

— technical and technological;

- economic.

How to remove a pipe from a well?

If the decision to pull out the pipe is nevertheless made, one of several possible methods can be used to do this.

- Contact professional drillers. They use special equipment (pipe cutters, overshots, taps, etc.), saving the owners of the site a headache and some money.

- Fix the end of the pipe, for example, with a loop or a crimp collar, fasten it to the short arm of the large lever and gradually remove the pipe.

Alternatively, you can get the pipe out of the well using a large railway jack.

Such a homemade device

Another way to remove the pipe is to make a special tool.

To do this, you need channel No. 10, from which two racks are made in the form of an inverted letter "T". The height of the structure should be one meter, and the width - 0.6 m.From above, a bearing is welded to each rack, the inner diameter is 40 mm.

Now you need to make an axis on which the handles and the drum are fixed. The edges of the axis are inserted into the bearings and the device can be considered ready. For lifting, the pipe is fixed with a steel cable, which is wound on a drum. To insure long structures, it is recommended to use a special chock to hold the pipe when intercepting the cable. To pull out the plastic pipe and not damage it, you will need a crimp clamp.

What threatens the sand in the well?

Water pollution is an emergency, since it is impossible to drink such water, it is quite problematic to filter it well, and it is not suitable for any other needs. However, the list of undesirable consequences does not end with inconvenience.

- Really significant decrease in well productivity. Filling the casing with sand is inevitable. In this case, due to a clogged sump, access to water is severely limited.

- Sand particles are an abrasive, therefore, passing through the pump, they will harm - abrade the material of the impeller. The inevitable consequences are the imminent failure of expensive equipment.

- Sand in the well contributes to the rapid occurrence of blockages in fine water purification systems. Filters in them are clogged much faster. The result is frequent replacement, which means additional expenses.

- Pipeline blockage. Sufficiently heavy particles of sand will be regularly added to the “deposits” that have already appeared, so sooner or later there will be problems with the throughput of the pipes. Another unpleasant moment is the increasing weight of the most critical nodes and sections of the pipeline.

- Inevitable contamination of faucets and siphons of plumbing equipment.He is threatened not only with problems during operation, but also with failure. This also includes clogging of elements of household appliances, expansion tanks and automation. The consequences of serious well sanding are similar for them.

The most serious result of the "subversion" of the sand is the reduction of the life of the well. If the installation of the casing pipe was carried out in accordance with all the rules, and the filters were selected correctly, then the first clogging can be expected only after 3-5 years. Some equipment is capable of operating without flushing and problems for a record period of up to 40 years.

Types of materials

There is a trouble-free way to insulate and improve a well in a country house without the use of additional heating equipment - this is to overlay all its components and protective structures with heat-insulating material. For professional installation, the following 4 varieties of it are used:

- Expanded polystyrene and foam.

- Differs in low heat conductivity, durability and moisture resistance. Suitable for lining both inside and outside the caisson, as well as external and underground pipes.

- Foamed polyethylene.

- It is characterized by good thermal insulation and low resistance to stress. Therefore, it is used for lining the internal walls of rooms and external pipelines.

External well insulation with foamed heat insulator

- Mineral or glass wool: the main feature is a large moisture absorption capacity. In view of this, it is used only in the inactive stage of water intake - for the period of winter conservation.

- Penoizol or foamed polyurethane foam: applied in liquid form through a special sprayer.The main disadvantages are the need to use equipment, low density and unevenness of the surface formed.

- Expanded clay: quite loose moisture resistant material. It is used for backfilling water trenches and caissons below the ground level.

Abyssinian well

Abyssinian well for water.

The tubular well got its name from the territory in Africa, where the technology of extracting groundwater from the bowels of the earth was first used without the use of special equipment.

Self-drilling of wells is performed in this old way. Water intake is carried out from a depth of 8-13 m.

Sequence of work:

- A drill string is assembled from 1-2 m pieces of pipes Ø2 ″, it will also serve as a casing. The drill filter is made by flattening the downhole end of the first pipe or a nozzle on the cone rod for better penetration into the ground. Holes of 6-8 mm are drilled in the walls of the drill, so that water enters them, they are wrapped with a metal filter mesh.

- A shock headstock is made from a guide pipe Ø100 mm 1 m long, weighted with metal weighing 10 kg, handles are welded on both sides.

- The drill filter is driven entirely into the ground, after which the next section of the column is attached to it by welding or threaded connection. Having hammered the pipe after the drill, the operation is repeated until the filter penetrates into the aquifer.

- A manual or electric vacuum pump is connected.

Pumping of a tubular well is carried out until clean water appears. The quality of the liquid is checked in the laboratory of the sanitary and epidemiological station.

Advantages and disadvantages

The advantage of the Abyssinian water intake is the ability to build it yourself with minimal investment.The well-needle is completely isolated from the perched inflow. A tubular well can be hammered into the ground from the basement of your house.

There are few disadvantages:

- the impossibility of using a submersible pump due to the small diameter of the column;

- the need to clean the well from sand and silt;

- restrictions on soil properties: the method is used on soft rocks and coarse sands.

Service life of water intake ≥30 years. A prerequisite for longevity is the periodic extraction of silt and sand from the casing string. This is done with the help of a bailer - a cylindrical vessel with a valve lock.

How to make a well in the country

Almost every owner of a country house, and even a villager, wants to have a well on his site. Such a source of water from which it would be possible to constantly obtain high-quality water.

It is worth noting that if the water is at a depth of up to ten meters, then such a well can be drilled independently. This is not such a laborious process as it might seem at first glance. We need a standard pump. It will pump out water and at the same time, in a sense, drill a well.

Video-how to drill a well in the country

Let's move on to the drilling process itself. It should be noted that the pipe that we will lower into the well must be located vertically. Water will be pumped into this pipe using a pump. The teeth should be located at the bottom end of the pipe. Such teeth can be made by hand. Water, which is under pressure from the lower end, erodes the soil. Since the pipe is heavy, it sinks lower and lower, and soon reaches the aquifer.

Video-how to drill a well under water

In order to really get drilling, we need only a steel pipe. The radius of such a pipe must be at least 60 mm (preferably more). Such a pipe will serve as a casing pipe. The length of such a steel pipe must not be less than the depth of groundwater. The end of the pipe, which we close at the top with a flange and a special fitting.

To do this, we use a pass-through fitting. Through this element, water will pump through the hose. We also need to use a welding machine. With it, we will weld four "ears" with special holes. These holes should fit the M10 bolts.

As a water tank, we will take a barrel with a volume of 200 liters. In order for us to somewhat speed up the drilling process, we need to shake the pipe and turn it a little either clockwise or counterclockwise. Thus, we will wash out a large amount of soil. For the convenience of pipe rotation, we can use a gate. To do this, take two metal tubes and attach them to the pipe. For these purposes, we can use special clamps.

For drilling, several people are needed (two are possible). In the place allotted for the well, a hole is dug. The depth of such a pit must be at least 100 cm. A pipe is lowered into this pit. And the jagged end down. Next, using the collar, deepen the pipe. It is worth noting that the pipe must be in a vertical position. Next, we turn on the pump. The hole will fill with water. We scoop it out. Then it can be spilled through a sieve and poured back into the barrel. It is quite possible to drill six meters in a few hours.

Here you can read:

how to drill a well for water, how to drill a well for water video, how to drill a well, how to make a well for water, how to make a well for water on the site video

Conclusions and useful video on the topic

Video #1 Elementary insulation of the walls and the cover of the caisson with foam plastic from the inside:

Video #2 Arrangement of a well with the help of a caisson, with the disclosure of the topic of insulation:

Freezing of a well and a water supply system is fraught not only with a cessation of water supply, but also with damage to equipment and elements of the system, the repair of which will require money and considerable effort. It is better to perform high-quality insulation work once and get constant access to water for many years.

Please write your comments in the box below. We are waiting for your stories about your own experience in insulating an autonomous water source. Perhaps you have questions or have interesting information that you are ready to share with us and site visitors.