- Crack in the slate - is it worth sounding the alarm?

- How to fix a crack in slate?

- Pros and cons of a sealant

- Repair of asbestos-cement roof without dismantling

- Sealing cracks with silicone paste

- Use of polyurethane foam ↑

- Mastic to repair damage ↑

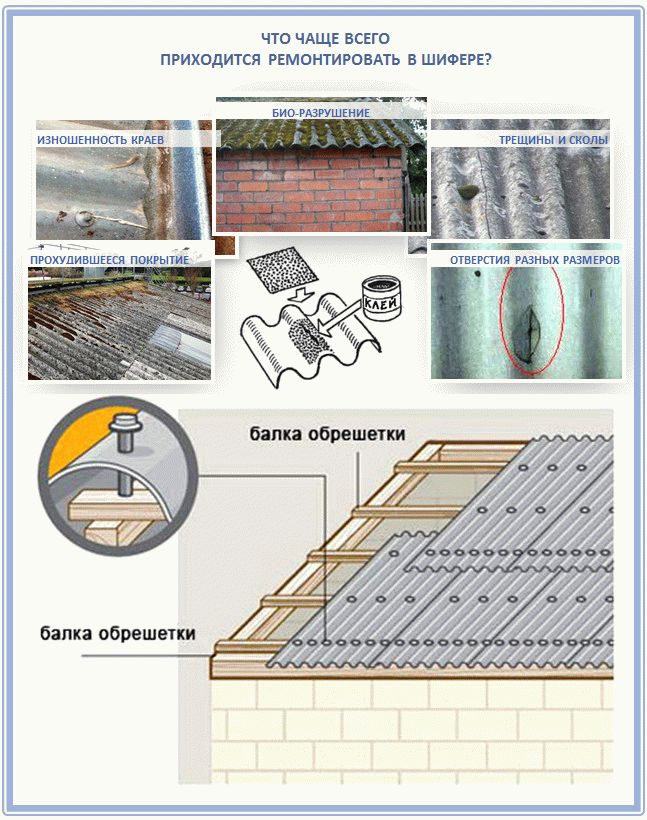

- Slate defects and their causes

- Slate roof defects

- Reasons for the destruction of slate

- Reasons for the destruction of slate sheets

- What are the reasons for the formation of cracks and holes in the slate

- Fixing leaks on the roof

- Slate sheet repair

- Repair option 1

- Repair option 2

- Repair option 3

- Repair option 4

- Repair option 5

- Repair option 6

- Repair option 7

- Repair option 8

- How to fix cracks

- Step-by-step instructions for using asbestos paste

- Preparation of the composition

- Application method

- Using foil ↑

Crack in the slate - is it worth sounding the alarm?

In order to avoid the need to completely replace the sheet, which is not an easy task, you can use various methods to correct the defect that has arisen. And, despite the requirement for certain skills, it is easier than replacing the entire sheet.

Most often, damage occurs due to the "aging" of the slate. But besides this, there are other reasons:

- the kit included a sheet created in violation of manufacturing technology;

- poor quality of processing the sheet itself at the final stage;

- low-quality asbestos material;

- error in choosing the angle of inclination when laying it;

- violation of the order of laying sheets, which caused additional stress;

- special nails were not used to fasten the slate;

- the crack appeared during the drilling of slate or its cutting;

- hard material on the roof as a result of gusts of wind or pranks of children.

Often roofing manufacturers do not comply with curing time requirements. It is determined by the standards in 28 days. But, as always, profit becomes a priority. Many reduce this period by sending unseasoned sheets for sale. This is the main reason for the increased fragility of slate. But the experience of roofing masters is the source of many recipes for repairing cracks and chips in slate.

Our advice and knowledge will help you choose the most suitable way

It is important to ensure that the problem is resolved as quickly as possible. Especially when weather conditions don't allow for long reflections.

How to fix a crack in slate?

There are a number of ways to restore the integrity of asbestos-cement sheets. It could be:

1) cover cracks in the slate with sealing material

2) patching

3) replacement sheets

Next, the most effective ways to seal a crack in a slate sheet will be considered:

1) Sealing cracks in the slate is carried out using a solution, which includes cement, water, fluffed asbestos and PVA glue. First, a mixture of cement and asbestos is made in a ratio of one to three.

And then a solution is made from water and PVA glue in a ratio of one to one. The two resulting solutions are mixed until a creamy consistency is obtained.

First you need to caulk the cracks, and then process it with the prepared mixture.

With the help of such repairs, it is possible to extend the life of the roof by five to ten years.

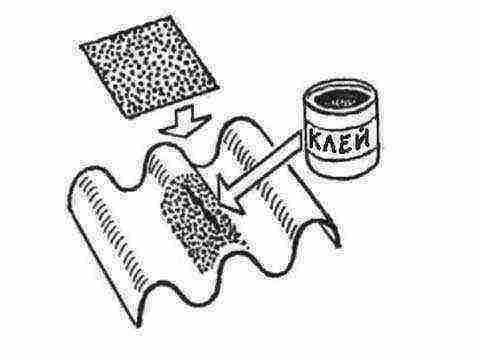

2) Making a patch from ordinary aluminum foil. To do this, apply universal glue to the back of the foil, which will hold the patch tightly.

To make a patch, follow these steps:

remove old fasteners from the slate sheet;

round the corners of the aluminum foil;

apply a patch of foil;

attach the slate sheet with screws or nails, making holes for them in new places;

if the slate is colored, then you can paint the patch to match the color of the roof;

3) If the slate sheet has split into several parts along, then its wavy joints can be fastened with epoxy glue. But first, you need to connect all the parts of the split sheet from below with adhesive tape, and then fill the gaps between the parts of the asbestos-cement sheet with epoxy glue.

4) Very often, cracks can be repaired on the roof without removing the damaged sheets. This can be done, for example, using silicone paste. But for this you must first clean and dry the surface. The surface is first cleaned with a wire brush and then treated with a paint thinner such as acetone.

You can also use another proven method, which consists in processing a crack in the slate in several layers. To do this, it is necessary to clean the surface and “blow out” the crack with foam.

We wait for the foam to dry, and then apply a sealing layer. After the last layer has dried, apply a layer of bituminous resin to the damaged area.

Chimney outlet through the roof

Advantages of flexible slate with other roofing materials

Advantages of aluminum slate

What are the advantages of PVC roofing membrane?

Pros and cons of a sealant

Home-made polymer sealant is practically not inferior to factory counterparts intended for roof repair in a private house. Advantages of the composition made of foam:

- The price of adhesive-sealant tends to zero. You buy gasoline, use a maximum of 0.5 liters, pour the rest into the car tank or use it in the household in another way. Styrofoam is suitable for any, even small waste.

- Roofing sealant is frost-resistant and suitable for all outdoor applications. You can close up roof leaks, cracks on the balcony of the apartment, cracks between the blind area and the wall of a private house.

- If the roof of the house has flowed in the middle of winter, the composition can be applied at sub-zero temperatures.

- High adhesion to various surfaces. The main thing is to remove the dust.

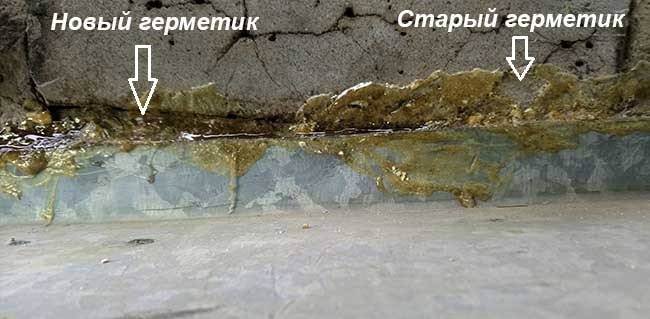

Adjacency of roofing iron to a brick wall. Shown on the right is last year's sealant, which holds pretty well.

The service life of the sealing solution is limited. After 1–2 years, the polymer putty may crack and peel off at the edges. Factory sealants also suffer from a similar drawback, so a roof leak should be repaired thoroughly - change cracked slate, cover with galvanizing, and so on. Covering up is a temporary measure.

Other disadvantages of homemade adhesive-sealant:

- in the process of preparation and application, the solution emits a pungent smell of gasoline, respectively, it is not recommended to seal cracks inside the house;

- the composition cannot be prepared in advance, as it thickens;

- prolonged hardening, after which the crust becomes brittle;

- preparation of liquid polymer takes time (30…60 minutes);

- after sealing, the defect site looks ugly.

Long hardening of the sealant is not always a disadvantage. If the gap is “live”, for example, the junction of metal and brick with different coefficients of thermal expansion, then elasticity is only a plus. How the seams on the roof look a year after the repair is shown in the video:

Repair of asbestos-cement roof without dismantling

There are some ways to repair an asbestos-cement roof for which damaged sheets are not dismantled. These works are performed directly on the roof, so it is necessary to provide insurance.

There are some ways to repair an asbestos-cement roof for which damaged sheets are not dismantled. These works are performed directly on the roof, so it is necessary to provide insurance.

Sealing cracks with silicone paste

Cracks can be covered with silicone paste, which has good adhesion to the asbestos-cement coating. The damaged area is carefully cleaned of dust and small crumbs of asbestos with a metal brush. Then it must be degreased. To do this, you can use, say, acetone or a special solvent. Asbestos chips are poured into the crack gap in a uniform layer.

Cracks can be covered with silicone paste, which has good adhesion to the asbestos-cement coating. The damaged area is carefully cleaned of dust and small crumbs of asbestos with a metal brush. Then it must be degreased. To do this, you can use, say, acetone or a special solvent. Asbestos chips are poured into the crack gap in a uniform layer.

The next step is to pour the crumbs with silicone paste, let it grab and paint over the color of the roof. These works take a little time, and the result is quite reliable.

The repaired sections of the roof are painted over as soon as the silicone paste sets. This is necessary because of the porous structure of the asbestos-cement sheets, whereby the repaired surface quickly becomes dirty at the edges.

Use of polyurethane foam ↑

The damaged area is cleaned and degreased. Next, the crack is blown out with foam, but not completely. The repaired area is dried and the excess foam is cut off on the sides, after which a layer of sealant is applied.The work is completed by covering the restored surface with bitumen mastic. To keep the resin liquid, a little diesel fuel is added to it when heated. It turns out a kind of primer. The desired density of the mixture can be achieved by adding ordinary clean sand.

Mastic to repair damage ↑

Sheets with joints are treated with mastic with a reinforcing filler of a wavy structure. Small pieces of bitumen are melted in a separate container. In this case, foam and impurities are formed, which are removed in the process. Melting at 200–220°C is continued until the bitumen is completely dehydrated. Then filler is added to small portions of molten bitumen, which is preheated to 110°C. Hot mastic is applied to the joints with a spatula or other suitable tool. In the process of application, the material is smoothed. Thus, excess moisture is removed and the mastic is firmly tamped.

Sheets with joints are treated with mastic with a reinforcing filler of a wavy structure. Small pieces of bitumen are melted in a separate container. In this case, foam and impurities are formed, which are removed in the process. Melting at 200–220°C is continued until the bitumen is completely dehydrated. Then filler is added to small portions of molten bitumen, which is preheated to 110°C. Hot mastic is applied to the joints with a spatula or other suitable tool. In the process of application, the material is smoothed. Thus, excess moisture is removed and the mastic is firmly tamped.

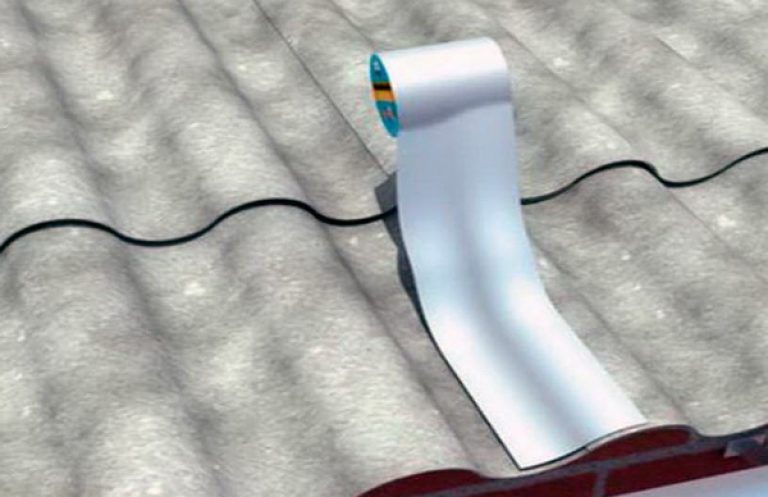

Another option for sealing cracks is to use self-adhesive butyl rubber tape. It has exceptional adhesion characteristics to any substrate. After gluing the crack, a high-quality overlay is formed, which excludes the ingress of water, is resistant to any weather conditions, ultraviolet radiation, and temperature extremes.

To increase the adhesion of repair materials, it is desirable to prime cracks or chips with PVA glue.

It is possible that during the inspection of the roof, a sheet split along the length will be found, it will be possible to glue it with epoxy. First, parts of the sheet are fastened from the inside with adhesive tape, and only after that the gap is filled with epoxy.

It is possible that during the inspection of the roof, a sheet split along the length will be found, it will be possible to glue it with epoxy. First, parts of the sheet are fastened from the inside with adhesive tape, and only after that the gap is filled with epoxy.

If the slate sheet turns out to be badly damaged, say, partially destroyed, or an impressive hole has formed on it, even several, its complete replacement is necessary. Partial repair of the old slate in this case is ineffective. Not only will it not provide the coating with the desired characteristics, but it will not stop further destruction and soaking.

2018

votes, average:

out of 5)

Slate is an asbestos-cement roofing material with a wide range of applications that has been in demand for many decades.

Slate is an asbestos-cement roofing material with a wide range of applications that has been in demand for many decades.

It has established itself as a very reliable, soundproofing material, often used in modern construction.

Even with the appearance of new analogues on the roofing market, slate remains the most popular among them.

Slate defects and their causes

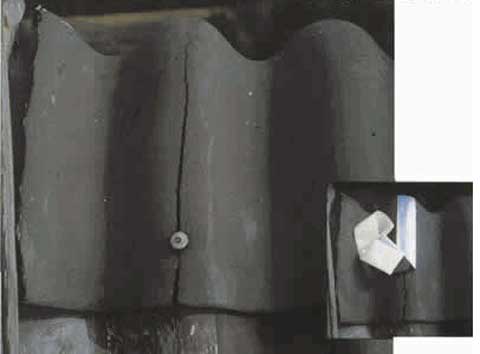

Old, kind, gray wavy slate, proven over the years. It would seem that he has no demolition. However, in reality, this is far from the case. Cracks, chips, holes - a familiar thing for him. Repair? Yes, it's possible. But you need to clearly understand that patches will not save you for a long time. If only for a short time, while funds for radical repairs are accumulated, but then the roof still needs to be changed. Alas, slate is not the most technologically advanced material. And you should start by determining the causes that contribute to the appearance of these same cracks. And there can be many such reasons.

- natural "aging" of the material or its operation beyond the prescribed period;

- non-compliance with the technological process of production; liberties can be very diverse: for example, the norm of cement embedded in the mortar is not observed, short ones are used instead of long asbestos fibers, the time for hardening the sheet is not met, etc.;

- the slate roof is based on the wrong angle of inclination of the slopes;

- violation of the manufacturer's requirements during the transportation of slate, errors in preparation for fixing work, during laying and installation;

- use for fastening not slate (with special rubber gaskets), but ordinary nails;

- mechanical impact on the slate.

Before starting repairs, the slate should be cleaned with a broom and water.

To know how to repair slate, you need to determine what type of planned work belongs to.

- Radical (complete) repair, which involves the replacement of the entire roofing system, namely: rafters, roof coverings. It is used when the slate sheets and rafters are seriously damaged or the person just wanted to change the slate to a different roofing material, and it requires a completely different design of the rafters and battens.

- Partial renovation. It happens when you need to change the old slate, dotted with cracks, chips and large holes, for new sheets.

- Redecorating. In this case, small defects in the slate are repaired with patches, special compounds, etc.

Slate roof defects

The list of slate defects that may appear during the operation of the roof:

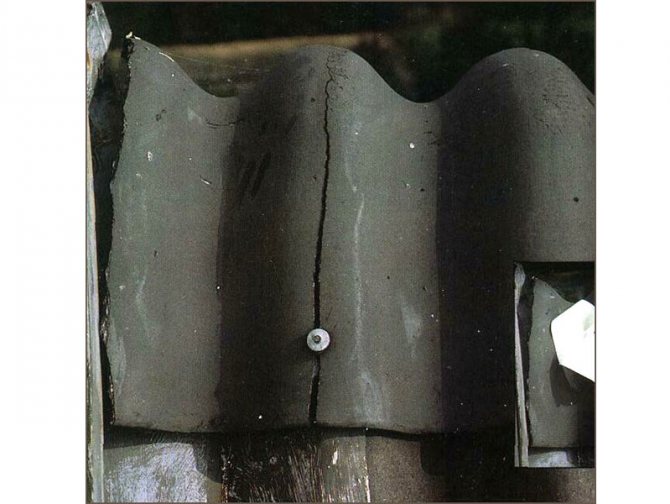

- the appearance of cracks in the slate;

- overgrowing of material with moss;

- mechanical damage;

- roofing defects remaining after installation;

- physical aging;

- other flaws.

When the owner decides to cover the roof with slate, he knows what lies ahead for him. Heavy transport of material to the workplace. Low aesthetics of the material, its fragility, additional work to improve it.But, the budget cost of the material overpowers, its versatility - it was these indicators that made it possible for slate to become popular.

Experts advise: in order to permanently protect the material from the appearance of lichen, moss, use special antiseptics. This design will increase the operating time.

Slate cannot be called the most technologically advanced material. But holes, chips, cracks, any flaws can be repaired. Naturally, simple patches will not save. We will have to allocate funds to eliminate deficiencies. While the roof is new, it is advisable to immediately provide for the rules for cleaning the material and caring for it.

Reasons for the destruction of slate

Most often provoke the destruction of the slate roof strong shock loads. If you make a point strike, then most types of slate will simply break through with the formation of a hole. This can happen when a tree or branch falls, large debris is carried by gusts of wind, or a stone hits. Other causes of damage to building material can be:

Growth of moss and lichens. Such organisms are easily distributed over the surface of the slate, penetrate into its structure and destroy it. They create obstacles for the flow of rainwater, which does not drain, but lingers, further damaging the slate.

Long service life. Over time, any building material inevitably loses some of its useful functions. Slate also wears out, ages and begins to crack, and in urban conditions this happens faster.

Laying technology violations

For fastening sheets, it is important to use special roofing, and not simple, nails. Drilling holes must be in strict accordance with the diameter of the fastener

The solution should be prepared exactly according to the recipe.There are quite a few such conditions, and if they are not observed, the roof will deteriorate an order of magnitude sooner.

The material can quickly crack if it is produced in an artisanal way, short asbestos fibers were added to the composition instead of long ones, and the period of full maturation of the sheets was artificially reduced.

Reasons for the destruction of slate sheets

Asbestos cement slate is a rather fragile material, and it is often damaged under impact loads.

damaged under impact loads.

Often problems arise precisely because of improper fasteners, so it is very important to follow the installation technique during installation. Do not pierce the sheets with nails, and before installation, you need to drill it in the attachment points

When the lathing is done correctly - there is no sagging and the step of the lathing is observed, then the roof will serve for many years.

During operation, slate is constantly exposed to negative environmental factors, which affects the condition of the roof not in the best way.

NOTE!

The main reasons for the destruction of slate during operation are sagging from heavy snow masses. Also, a negative factor is stagnant rainwater, branches falling on the roof. As a result, microcracks appear, which further lead to the destruction of the coating.

Also, slate can be spoiled by lichen mosses growing on it, they release acid-containing substances that destroy it.

As a result, microcracks appear, which further lead to the destruction of the coating. Also, slate can be spoiled by mosses growing on it, lichens, they release acid-containing substances that destroy it.

What are the reasons for the formation of cracks and holes in the slate

For the correct selection of the method by which repair work will be carried out, it is first necessary to find out what caused the damage. Thanks to this, it will be possible to seal holes in the roofing material in such a way that after a short time period this defect does not reappear.

Due to the rather high fragility of slate, its damage occurs for a number of the following numerous reasons:

Impact loads. The reason is inaccurate walking on the roof.

Technological marriage. During the production of the material, the hydration of the cement base is carried out in conditions of insufficient moisture, which is why the slate does not acquire the optimal level of strength. As a result, such sheets are easily covered with cracks even under the influence of minor loads, and repair work in such situations is pointless.

Long period of operation. Basically, the service life of the roofing material is relatively short and reaches only 10-12 years, after which cracks and other damage begin to appear on its surface.

Careless transportation and storage. Because of this, defects cannot always be identified initially, but they become clearly visible when walking on the laid sheets of slate on the roof

In order to avoid the formation of damage to the slate, care should be taken not only during installation, but also throughout the entire process accompanying this process (during transportation and storage before installation work).

Wrong coverage. In such a situation, problems can arise if the sheet waves are partially on the roof without being supported by the rail.

As a result, with this method of installation, the formation of a crack can occur when walking carelessly on the roofing material or when a heavy tool and branches of nearby trees fall on its surface.

Use of unsuitable fasteners. Among the fairly common mistakes is the use of ordinary nails to fix the roofing material without the presence of rubber gaskets. In addition, damage appears in cases where slate is laid without first drilling holes in dry sheets for hammered fasteners. If they are not done before driving in nails, very oblong and dangerous cracks, as well as small holes, can occur in the coating.

Note! To avoid possible damage to the slate during the seasonal expansion of the metal, the holes in it must be made slightly larger than the fasteners used. They should not be greatly increased so that water does not leak during precipitation, additional protection from which rubber gaskets provide.

- Inappropriate roof pitch. As a result of laying slate on such a roof, water stagnation can be observed.

- Rough material surface. For this reason, snow regularly accumulates on slate in the winter. Under the influence of warm sunlight in the spring, the snow cover begins to melt, and as a result, the water flows down. Above the eaves, the roof is always colder, the snow does not melt very quickly and the flowing liquid re-turns into ice, under the influence of which the slate is slowly destroyed.

- Sudden temperature changes. Because of them, the material begins to acquire microcracks.

- Cutting sheets with insufficient knowledge and experience. The most difficult thing is to cut slate in situations where it is necessary to carry out work close to the edge or extreme wave, as well as when making a hole for the pipe. In this case, it is possible to close holes in the roofing material from the last factor only during the installation of a double patch.

Note! With extremely careful handling of slate, you can significantly reduce the likelihood of cracks and holes, to eliminate which you will need to carry out repairs or even replace the sheets.

In addition, quite often cracks in slate appear due to non-compliance with the production technology of the material at different stages:

- During the preparation of the mortar, a smaller amount of cement is added than required.

- Production in artisanal conditions without the use of high-quality equipment and a number of other nuances.

- Use of short asbestos fibers.

- Poorly executed processing of finished slate sheets.

In order to avoid the purchase of low-grade roofing material, it is best to give preference to products from manufacturers that have proven themselves in the market.

Fixing leaks on the roof

The technology for applying sealant is simple to disgrace:

- We scoop up glue, transfer it to a spatula and cover the gap.

- Layer thickness - from 1 mm. If you apply more than 3 mm of liquid polystyrene, nothing bad will happen, only the hardening period will increase.

- In hard-to-reach places on the roof - a gap around the pipe, in valleys, where the roof adjoins a vertical wall - the composition can be applied with your fingers (it is advisable to wear gloves).

When it is required to seal a gap near a chimney or a crack in a slate roof, it is better to apply a reinforcing plaster. The technology is as follows: we smear the area around the defect with sealant, lay a piece of fiberglass mesh, and on top - another layer of glue. Instead of fiberglass mesh, gauze, tulle and similar mesh fabrics will do.

Applying adhesive-sealant to the joint of the roof adjacent to the wall of the house

Homemade sealant does not harden immediately, hardening can take from several days to a month, depending on the thickness of the layer. The described property is not a problem - after sticking to surfaces, the polymer will no longer let water through.

Slate sheet repair

It is worth knowing that any repair manipulations with slate should be carried out only after it has been cleaned of debris and moss, thoroughly washed and dried. In addition, a crack or hole should be degreased with cotton wool soaked in solvent or acetone.

Repair option 1

If you don’t know how to close holes in slate, then the simplest and most ancient method with which you can close a hole is to use bituminous mastic. Previously, it was only used to cover up any holes in the walls of a house or a fence / roof. It is prepared simply in a bucket on a fire, melting to a viscous state. If repair work is carried out in cold weather (with minuses), then about 10% of mining should be added to the mass of bitumen so that the mastic is plastic. The crack is gradually filled with the finished mixture, leveling its level with the sheet.

Repair option 2

Or you can use a cement-sand mixture if you don’t know how and how to patch holes in the slate.To prepare the mixture, you need to mix the named components in a ratio of 1: 2. Dilute the mass with water to the consistency of thick sour cream. Holes and cracks are covered with the resulting solution and left to dry in the shade. The finished repaired sheet can be painted in the desired color.

Repair option 3

Also, for sealing slate roofs, you can use a ready-made putty solution and not be tormented by special inventions. The mixture can be bought at a specialized store. Before applying it, the surface of the crack or hole must be well primed. Then putty is applied to the hole and after six hours it is covered with a piece of fiberglass. Another layer of putty is applied on top, and thus the use of a sealing combination saves the slate.

Repair option 4

And here, in order to cover the slate roof, you can use a mixture of cement, asbestos and PVA glue. Such a mass is very plastic and fits well into all joints and gaps of slate.

So, we prepare the mixture:

- First, mix equal parts water and PVA glue. Mix everything well until smooth.

- Now mix cement and asbestos in a 2:3 ratio in a separate container.

- We mix all the components to a state of very thick sour cream.

- In a separate container, we prepare another PVA solution from three parts of water and one part of glue.

- We cover the finished, fat-free and dried surface of the crack with the resulting mixture of glue, cement and asbestos. From above we lubricate with an additional solution of glue. And again we apply two more layers of asbestos cement on top.

Repair option 5

And in this way, you can close up holes from nails that have crumbled over time and now let water through.In this case, you need to take a piece of aluminum foil and cut a patch out of it according to the desired hole size. The foil is smeared with universal glue and the patch is put on the hole.

Repair option 6

Here, in order to repair a large break or a hole from a nail, you can use tin for a patch. A piece is cut out of it, rolled into a tube and, crushing, pushed into the hole. It is necessary to tamp the tin so that it fills the hole as much as possible. Now a hole for a self-tapping screw is drilled in a tin cork and the slate is fixed on the roof using a high-quality rubber gasket. In this case, water will not flow under the roof.

Repair option 7

Ordinary polyurethane foam will also help repair holes in the slate. Craftsmen use it to fill cracks and crevices in slate roofing. This is a good answer to the question of how to repair and seal a slate sheet. The mixture is applied to a clean and degreased repairable area, and thus close up the hole. Then, after drying, the crack is treated with a sealant and everything is lubricated with epoxy.

Repair option 8

Often craftsmen seal cracks in ACL with butyl rubber tape. By the way, it is good for painting, which will allow your roof not to look like a patch. The tape is laid on cracks in the slate after they have been cleaned and degreased. They are well pressed, and after drying they are painted in any color.

- Slate defects and their causes

- Preparatory work and methods for sealing cracks

- A few more easy ways

How to fix a crack in the slate on the roof? Such a question can often be heard from summer residents who have a leaking roof of a house covered with slate for more than a decade. And to change, for various reasons, there is no possibility.

The appearance of cracks in the slate can be associated with both mechanical damage and improper installation and operation.

How to fix cracks

When the slate leaks, it means there are cracks in the coating. There are several fairly simple ways that really help restore its functionality. All of them are available for self-fulfillment, you just need to know how to glue the slate. Usually this is patching the damaged area or using a sealant. Let's see what needs to be done when the roof leaks, what is the fastest way to patch a slate roof than to glue

This is especially important in bad weather conditions.

Consider the most common technologies for restoring damaged sheets. So, burst, flowing, slate. How to close up, glue it? The simplest option is asbestos paste.

Step-by-step instructions for using asbestos paste

Repair work is recommended to be carried out on the product removed from the roof.

Preparation of the composition

The mixture is a composition that includes asbestos and cement, you can prepare it yourself. Powder components are mixed in a separate container (asbestos is taken three times more) and water and dispersion polyvinyl acetate glue taken equal in volume are added until a homogeneous creamy mass is obtained. Stir the mixture very carefully so that lumps do not form. Work with asbestos mixture is carried out in a respirator.

If the composition is not used for a long time, it loses its qualities. Therefore, it is advisable to knead it in small portions.

Application method

Before sticking the slate, prepare the damaged area:

- remove garbage;

- wash the place of damage and degrease, for example, with gasoline;

- in the case of an ordinary crack, a fiberglass tape (sickle) is fixed along its entire length, which is at least 5 cm longer than the crack.

- significant damage or holes are first filled, for example, with raw rubber or caulked, for a greater effect, the fibrous material is pre-treated with hydrophobic compounds.

The asbestos-cement composition is applied to the damaged area gradually, in successive layers as evenly as possible. The total layer thickness must reach at least 2 mm. When the patch dries, the resulting seam is treated with sandpaper. It is desirable that the mixture significantly covers the damage zone. Such repairs will protect the under-roof space from moisture penetration for 8-10 years.

Using foil ↑

The patch on the roof can be aluminum foil, even from an ordinary chocolate bar. Universal glue is applied to it and applied to the damaged area from the wrong side. So that the corners of the patch do not bend, they are rounded. The connection of the foil and the roof is strong and will reliably protect the roof from water access.

The patch on the roof can be aluminum foil, even from an ordinary chocolate bar. Universal glue is applied to it and applied to the damaged area from the wrong side. So that the corners of the patch do not bend, they are rounded. The connection of the foil and the roof is strong and will reliably protect the roof from water access.

If the crack passes through the place of the fastener, then first it is sealed with foil and a hole is drilled for the fastener in another part of the sheet. After the work has been done, the dismantled sheet is returned to its place. We must not forget that rubber gaskets for nails are a mandatory requirement. When the work is completed, the patch is masked to match the tone of the roofing. The paint is applied in dry weather, it is advisable to use a roller or brush.The best effect can be achieved if the repaired area is treated in two approaches with a break to dry the first layer.

These methods are much more convenient if you perform them on a removed sheet.