- Heaters for thermal insulation of a chimney

- Plaster

- Broken brick or slag

- stone wool

- Insulation for chimney pipes and its advantages

- Varieties of materials

- Refractory insulation

- Methods for insulating a metal chimney

- How to wrap stove or fireplace metal chimney pipes?

- How to isolate the metal pipes of the chimney of a gas boiler?

- Ways to fight

- Insulation of pipelines according to SNiP

- Basic norms and rules for thermal insulation

- The main tasks of thermal insulation, features of the choice of materials

- Types of heaters

- Types of gas exhaust chimneys

- Chimney pipes made of stainless steel

- Brick chimney device

- Chimney from asbestos-cement pipes

- Smoke channel from ceramic pipes

- Phased insulation technology

- Asbestos cement chimneys

- Steel chimneys

- brick chimney

- How to protect sewer pipes from freezing

- engineering method

- Thermal insulation method

- active way

Heaters for thermal insulation of a chimney

According to the regulations, only non-combustible materials can be used to insulate the chimney to ensure the fire safety of the structure. Among the popular means of thermal insulation of smoke channels, 3 categories are distinguished - plaster, slag and stone wool.

Plaster

When planning how to insulate a brick or stone chimney on the street, you can use a heat-resistant plaster mortar. To apply the finishing mixture, the surface must be reinforced with a metal mesh.

Broken brick or slag

If a brick channel or an iron chimney is to be insulated, a casing is constructed from improvised means, and the voids are filled with broken bricks or other non-combustible material.

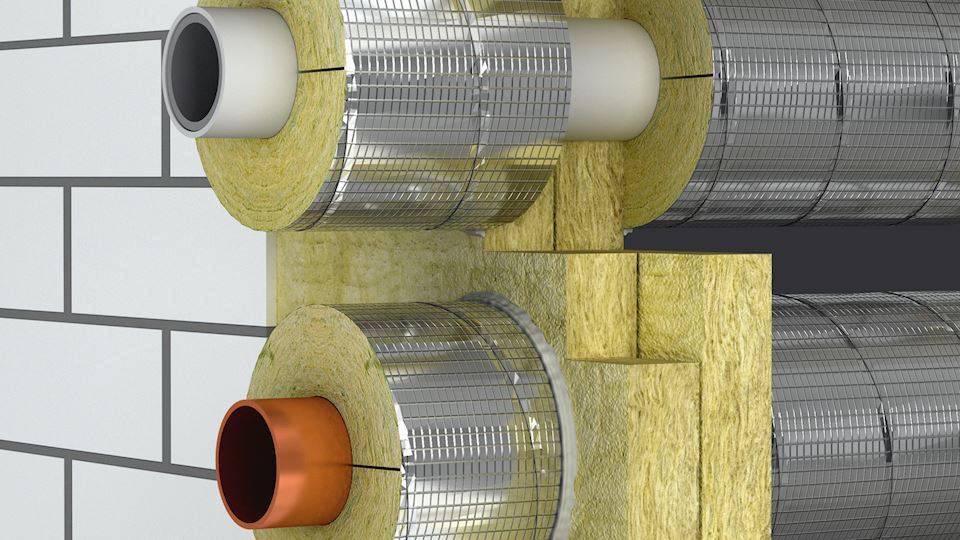

stone wool

When deciding how to insulate a metal smoke exhaust pipe with your own hands, most often they prefer basalt wool. Insulation options in the form of cylinders are of interest: the material is presented with a different internal section. You can also use basalt mats. Thermal protection made of stone wool is wrapped around an iron pipe and fixed with clamps or metal wire. Further, the design is equipped with a sealed steel casing.

Basalt wool

Basalt wool

Insulation for chimney pipes and its advantages

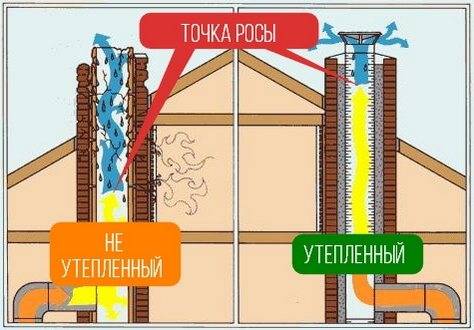

Dew point of insulated and non-insulated chimney

Many users are constantly wondering: is it necessary to insulate the chimney pipe from the outside? Of course, the insulated pipe has a number of positive properties. As already noted, timely thermal insulation of the chimney reduces the negative impact of many factors that adversely affect the material of manufacture.

It is very important to choose the correct thickness of the chimney insulation. So you will completely get rid of the problem with condensate, because

the dew point shifts to the section of the pipe that is above the roof level.

In addition, the chimney heater performs a number of important functions:

- Heat-insulating materials do not allow moisture to accumulate on the walls of pipes.Due to the same temperature regime of the chimney and combustion products, this does not allow condensation to appear and all harmful substances are removed to the outside.

- The value of the limiting temperature difference between the hot gases and the flue duct is reduced.

- Characterized by energy saving. During operation, the insulated chimney takes a small amount of energy that is generated during the combustion of fuel. This reduces the consumption of fuel and energy, which is spent on maintaining a constant temperature in the furnace.

- The design of smoke channels becomes more durable.

Read more about stainless steel pipes here.

Varieties of materials

Material for chimney pipe insulation the heating system of private houses is selected based on the type of chimney, its location, as well as the material of its manufacture:

- broken brick;

- plaster;

- mineral wool;

- wooden shields;

- concrete;

- metal cases.

When carrying out insulation, you must strictly follow the safety rules

It is very important that chimney insulation was non-combustible. This is due to the fact that during the operation of the heater, the temperature of the insulation will reach up to 100-150 ° C, and in the area where the pipe exits through the ceiling, it can be even higher

If the work on the insulation of the pipe will be carried out by one person, then it is better to give preference to a lighter and more solid material. Otherwise, in the process of warming, you will have to face a number of difficulties that will negatively affect the final result.

Now consider the most popular methods of insulation:

- Plaster is used to insulate chimneys made of brick and stone.A pre-prepared reinforced surface is covered with a solution.

- In order to insulate a brick chimney, broken brick is most often used. The material is poured into a casing, which is fixed around the chimney. The minimum distance from the chimney is 60 mm. There are times when slag is used instead of broken bricks.

- Chimney insulation with basalt wool above the roof. Such material is in great demand, it is produced in the form of mats / cylinders with different internal sections. The material is wrapped near the chimney and fastened to steel crimp clamps. The material is inexpensive, and in terms of quality and efficiency it occupies a leading position.

Refractory insulation

Currently, in private homes, the key link in the heating system is the factory boiler, the chimney in which is made of metal or asbestos cement.

Fire-resistant insulation for a chimney constructed from asbestos cement is carried out by coating the outer side of the pipe with materials with high thermal insulation performance. The area, which is located above the interfloor ceiling, must be well cleaned of dirt, and then lay mineral wool. After, the entire structure must be placed in a steel casing.

Using non-combustible refractory material to insulate the chimney, do not forget that the minimum distance between the outer wall of the pipe responsible for the removal of gases and the inner wall of the casing should be 60 mm.

Methods for insulating a metal chimney

Chimneys of different types and designs require different methods of insulation. There are types of insulation depending on the purpose of the chimney.

How to wrap stove or fireplace metal chimney pipes?

Steel chimneys can be used for decorative stoves and fireplaces that do not function as a permanent source of heating. It is enough to isolate such a chimney with a layer of plaster mortar. This method is mainly used for insulating brickwork chimneys, but a variation is also possible, calculated for metal pipes.

The mixture is prepared from a special mixture and water. It would be technologically correct to first pour water into the mixing container, and then add the dry mixture there. After beating with a construction mixer, a homogeneous dense mass should be obtained.

To insulate a fireplace pipe or a decorative stove, you can use special plaster

The solution is applied to the surface to be insulated with spots using a spatula. Lumps of mortar must be distributed evenly over the entire area of the pipe. These sections are needed to fix the reinforcing frame of the fiberglass mesh on them. Without a frame, a thick layer of plaster may soon crack and become unusable.

First, a rough layer of plaster is applied to the reinforcing frame, adjacent to the duct. After applying the main thickness of the plaster, a final finishing layer can be formed.

How to isolate the metal pipes of the chimney of a gas boiler?

Insulation of functional chimneys with your own hands can be done using a "sandwich" type design. This method is the most popular and effective in terms of protecting the structure from condensation and saving energy. The design of the sandwich chimney consists of two metal pipes and a layer of mineral wool between them.Moreover, a pipe with a large diameter in this case is a protective sleeve, while a smaller pipe will be a chimney.

A chimney pipe insulated in this way is not fire hazardous, since the winding layer is protected by stainless steel or galvanized iron.

Mineral wool can be used to insulate both the inside and outside of the chimney

The formation of the sandwich chimney structure occurs in several stages:

- holes are made in the roofing and the roof itself, the diameter of which will be 25 cm larger than the chimney pipe;

- a metal chimney should be insulated with a layer of basalt wool (a more practical variety of mineral wool) at least 5 cm thick. The winding is overlapped;

- the insulation is fixed with steel wire, which must be wrapped several times around the pipe;

- a casing is put on from a larger pipe. If the casing was made from a sheet of thin iron, it is fixed with adhesive tape and tie-down straps.

After making sure that the insulation was carried out correctly and there were no unfixed joints, you can put insulated pipes on the furnace nozzle through a hole in the roof. After completing the installation work on connecting the chimney to the heating source, it is necessary to fill the sheet of metal surrounding the riser with non-combustible material. For this, expanded clay, asbestos or clay is used.

Today, there are many options for how to insulate a chimney pipe. These works can be carried out independently, choosing a heater for chimney pipes is also quite simple. The main thing is that the design of the chimney system meets all the necessary requirements. Otherwise, thermal insulation can become an absolutely senseless waste of money.

Ways to fight

You can avoid emergencies and prevent freezing of sewer pipes in the ground using the following tips:

The laying of the pipeline for sewerage must be carried out to a certain depth. It is recommended to place it below the freezing level. The fact is that the temperature indicators at this level do not fall below 1-2 ° C. This indicator is optimal, and allows you to carry out work without the use of insulating materials. If the work is performed by non-professionals, then this rule is not respected. Pipes are laid above the freezing level, which can create an unusual situation during severe frosts and lead to a breakthrough. This method of deepening is needed when sewer insulation is carried out in a private house, and the owners do not live here permanently.

Special materials designed for thermal insulation should be used. Pipes are carefully covered with a material with high thermal insulation properties. It slows down the cooling process and the outflow of heat. Pipes are also heated with an electric cable specially designed for this purpose. If it is necessary to insulate a device that is subject to freezing, then the slope of the pipes is performed. It is at least 2 cm per meter. At the same time, an electric cable is laid outside the pipe, which performs the functions of a heater. In its absence, the pipes freeze through, and the frozen water in them forms ice jams.

As a result, the sewer system fails.

It is important to properly insulate the ventilation pipes. They are located outside, and are brought to the surface of the roof from the sewer riser.Some of them come from underground and serve to ventilate a septic tank or sewer tanks.

When the effluents evaporate, they settle on the inner sides of the pipes. Over time, they freeze and fill the entire system. Residents begin to smell the stench due to a failed ventilation system. The situation can be corrected by pouring a bucket of water into a frozen riser. Only after that it should be insulated. If an electric cable is used for insulation, then it must be packed in a corrugation. A plastic container will do as well. This will ensure the longevity of the ventilation system.

Some of them come from underground and serve to ventilate a septic tank or sewer tanks. When the effluents evaporate, they settle on the inner sides of the pipes. Over time, they freeze and fill the entire system. Residents begin to smell the stench due to a failed ventilation system. The situation can be corrected by pouring a bucket of water into a frozen riser. Only after that it should be insulated. If an electric cable is used for insulation, then it must be packed in a corrugation. A plastic container will do as well. This will ensure the longevity of the ventilation system.

Insulation of pipelines according to SNiP

When performing work on equipment and installation of pipelines, it is necessary to comply with the norms of SNiP.

What is SNiP? These are building norms and rules for the organization of construction production, for compliance with standards, specifications and regulatory departmental acts.

Basic norms and rules for thermal insulation

Heat networks are one of the main elements of district heating. It is necessary to strictly adhere to the norms and rules when drawing up a project for the thermal insulation of pipelines.

Subject to SNiP, thermal insulation of pipelines will be carried out qualitatively without violating standards.

Thermal insulation of pipelines SNiP is provided for linear sections of pipelines, heating networks, compensators and pipe supports.

Insulation of pipelines in residential buildings, industrial buildings requires strict compliance with design standards and a fire safety system.

The quality of materials must comply with SNiP, thermal insulation of pipelines must be aimed at reducing heat loss.

The main tasks of thermal insulation, features of the choice of materials

The main purpose of thermal insulation is to reduce heat loss in heating systems or pipelines with hot water supply. The main function of the insulation is to prevent condensation.

Condensation can form both on the surface of the pipe and in the insulating layer.

In addition, according to safety standards, the insulation of pipelines must provide a certain temperature on the surface of the insulation, and in case of stagnant water, protect it from freezing and icing in the winter.

Insulation of pipelines also increases the life of pipes.

According to the norms of SNiP, thermal insulation of pipelines is used both for centralized heating and reduces heat losses from in-house heating networks. What to consider when choosing thermal insulation:

- Pipe diameter. It depends on what type of insulator will be used. Pipes can be cylindrical, semi-cylinders or soft mats in rolls. Insulation of pipes of small diameter is mainly carried out using cylinders and half-cylinders.

- Heat carrier temperature.

- The conditions under which the pipes will be operated.

Types of heaters

Consider the most popular and commonly used materials for thermal insulation:

- Fiberglass. Glass fiber materials are often used for above ground pipelines because they have a long service life. Fiberglass has a low application temperature and is characterized by low density. High-quality fiberglass has high vibration, chemical and biological resistance.

- Mineral wool. Thermal insulation of pipelines with mineral wool is a very effective heat insulator. This insulating material will be used in different conditions. Unlike fiberglass, which has a low application temperature (up to 180ºC), mineral wool can withstand temperatures up to 650ºC. At the same time, its heat-insulating and mechanical properties are preserved. Mineral wool does not lose its shape, has a high resistance to chemical attack, acid. This material is non-toxic and has a low degree of moisture absorption.

In turn, mineral wool comes in two forms: stone and glass.

Insulation of pipelines with mineral wool is mainly used in residential buildings, public and domestic premises, as well as to protect surfaces that are heated.

- Polyurethane foam has a wide range of applications, but is a rather expensive material. According to the norms of SNiP, thermal insulation of pipelines is environmentally friendly and does not affect human health. Polyurethane foam is resistant to external factors, non-toxic and quite durable.

- Styrofoam.In some areas of industry, foam is an indispensable material, as it has low thermal conductivity and moisture absorption and a long service life. Expanded polystyrene is difficult to ignite, and is an excellent sound insulator.

- In addition to the above materials, the insulation of pipelines can also be carried out using other less well-known, but no less practical heaters, such as foam glass and penoizol. These materials are strong, safe and are close relatives of Styrofoam.

Corrosion protection and high thermal insulation of pipes can also be provided by heat-insulating paint.

This is a relatively new material, the main advantage of which is that it penetrates into hard-to-reach places and is able to withstand high temperature differences.

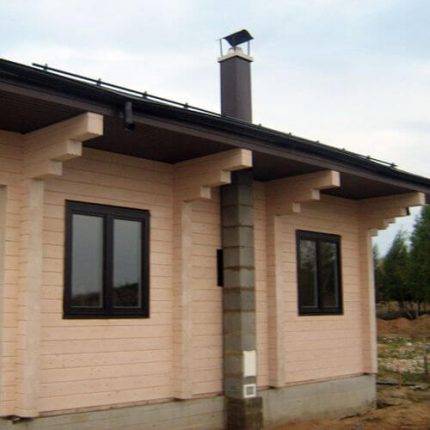

Types of gas exhaust chimneys

Depending on the material used, gas chimneys are divided into several types, while brickwork is practically not used for venting gases.

However, brick is often used for tying the exhaust pipeline. This is not a simple facing brick - it has a square shape, and its inner part is a round section.

Chimney pipes made of stainless steel

Metal chimneys are the most popular. The most commonly used stainless steel, which is characterized by high corrosion resistance.

Chimney pipes made of stainless steel are easy to install and highly resistant to corrosion in any aggressive environment.

Chimney pipes made of stainless steel are easy to install and highly resistant to corrosion in any aggressive environment.

The main advantages of stainless steel structures:

- Resistance to condensed moisture;

- Resistance to precipitation;

- Chemical resistance to soot from gas combustion;

- Resistant to high temperatures;

- The smooth inner surface reduces the coefficient of friction, ensuring the unhindered passage of gases with minimal soot deposits;

- Light weight allows the use of standard fasteners;

- Simple installation eliminates the complexity of work with significant destruction of the walls;

- Pretty democratic value.

It is not recommended to use ordinary stainless steel pipes. This is due to the fact that it is the chimney pipes that are made of special grades of stainless steel, which, thanks to the introduction of alloying elements, are highly resistant to acids resulting from the formation of condensate.

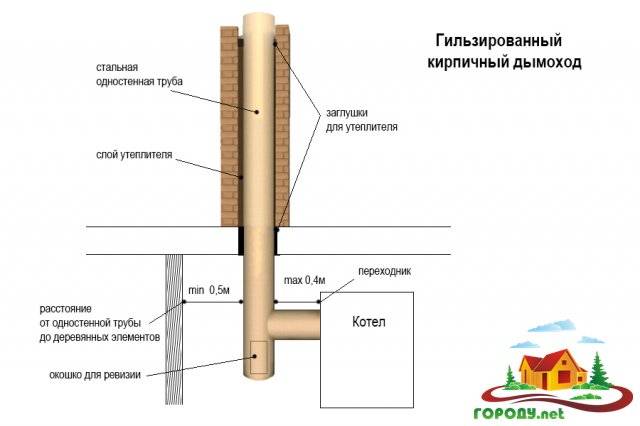

Brick chimney device

Currently, a brick chimney is used much less frequently, because. is being built mainly for brick ovens, and they are being actively replaced by gas models. In addition, its device takes a lot of time.

Along with this, the brick chimney has the following disadvantages:

- Rough inner surface, contributing to the accumulation of soot and reduced traction;

- Not resistant to acid attack. Due to the hygroscopicity of the material, condensate is absorbed and quickly destroyed;

- Difficulty of construction. Masonry from piece building materials takes much more time than the assembly of metal or ceramic modules.

You can eliminate the negative qualities of a brick chimney by inserting a sleeve in the form of an asbestos or stainless steel pipe.

Chimney from asbestos-cement pipes

Previously, asbestos-cement pipes were very widely used in the construction of chimneys for gas boilers.Despite the porosity of the material, the roughness of the inner walls and the far from ideal cross section, the popularity of asbestos-cement pipes is due to their low cost.

The chimney made of asbestos-cement pipes is characterized by a low price, but for reliable operation it requires a strictly vertical arrangement

The chimney made of asbestos-cement pipes is characterized by a low price, but for reliable operation it requires a strictly vertical arrangement

To avoid these shortcomings, the chimney made of asbestos-cement pipes should be as straight as possible with sealed joints. A simple cement mortar is not enough here, dried joints must be treated with a sealant or special sealed clamps should be used.

In general, the work is easy. With proper sealing of the joints, a chimney made of asbestos-cement pipes is in no way inferior to its stainless steel counterpart. However, during active operation, it will serve no more than 3-5 years, after which it requires mandatory replacement.

Smoke channel from ceramic pipes

Chimneys made of ceramic pipes are distinguished by reliability, durability, high corrosion resistance to aggressive substances and temperature extremes.

When constructing a high chimney from a ceramic pipe, a reliable foundation is required, since they are built according to the “radical chimney” scheme

When constructing a high chimney from a ceramic pipe, a reliable foundation is required, since they are built according to the “radical chimney” scheme

However, along with this, they have their drawbacks - a lot of weight, the mandatory construction of a separate foundation and high cost. But all these shortcomings of ceramic chimneys are covered by decades of reliable and stable operation.

Phased insulation technology

Due to the fact that chimneys come in different types and designs, we will describe how to properly insulate a chimney pipe made of brick, asbestos cement and steel.

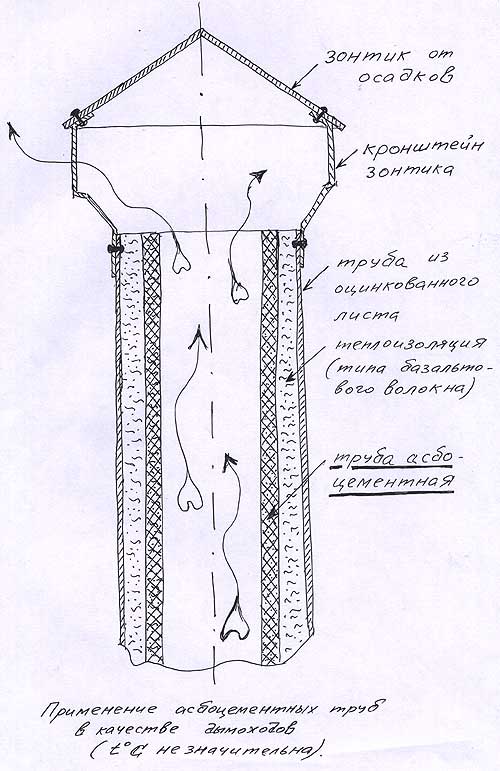

Asbestos cement chimneys

Asbestos-cement pipe

To understand how to insulate a chimney from an asbestos pipe, we will analyze the entire procedure in stages, following the recommendations of professional builders:

First you need to thoroughly clean the place of work from dust and dirt;

The next step is to make a special folding casing for the insulation (made of galvanized iron)

When determining its parameters, it should be taken into account that at least 6 cm must remain between the pipe and the iron for insulation;

Pay attention to the fact that a casing assembled from several parts is put on the asbestos pipe, and each of them should not exceed 1.5 m;

First of all, fix the lower part of the casing and carefully fill it with a sealant. Then, the second part is put on and the procedure is repeated. This design must run along the entire length of the asbestos pipe.

This design must run along the entire length of the asbestos pipe.

Thermal insulation scheme from a home master

This is what an asbestos chimney with a casing looks like

Often, many of the owners of cottages do without a casing. The pipe is simply wrapped with a roll of mineral wool and pulled together with staples. In order for this method of insulation to become truly reliable, several layers should be wound.

Steel chimneys

So, we sort of figured out the asbestos pipes, now let's see how to insulate the metal chimney pipe. In general, many manufacturers of building materials produce ready-made chimneys made of stainless steel. The design is quite simple and consists of only two pipes of different diameters.

How to insulate a metal chimney? To do this, take a pipe of a smaller diameter and insert it into a pipe of a larger diameter. Then, the remaining space between the pipes is filled with any of the above types of insulation. If you are interested in modern materials, then you can recommend basalt chimney insulation, which in its structure resembles mineral wool, but is much more practical and durable.

Thermal insulation of a steel chimney

In principle, it is much easier to insulate an iron pipe than the same asbestos one, so there should not be any problems here.

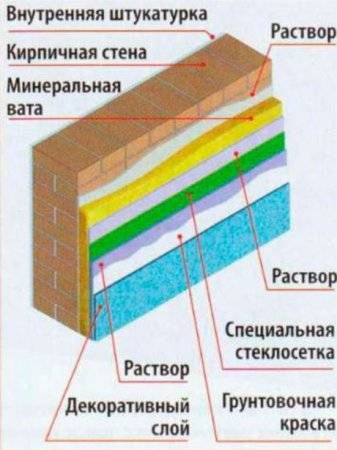

brick chimney

Brick chimney

Insulation of a brick chimney is perhaps the most difficult type of all presented in this article. Now we will give several options, of which everyone will choose for himself how to insulate a brick chimney:

Plastering method. To do this, you will need to fix a reinforced mesh on the chimney. Then prepare a solution of lime, slag and a small portion of cement. Spread the resulting solution over the entire surface of the chimney and level it (all work is done in one layer, which must be at least 3 cm).

When the solution dries, it will be possible to add a few more layers, and immediately cover up the cracks that have formed. To give an attractive appearance, in the future the pipe can be whitewashed or painted.

Scheme of thermal insulation of a brick chimney

Mineral wool insulation. To do this, you will need to take a roll of basalt wool and cut it into pieces that correspond to the size of the chimney area. Then, the insulation is glued to the pipe with adhesive tape. The last step of the work is to lay the insulation (for example, Rocklight) with a second layer of bricks or asbestos-cement slabs.

The process of thermal insulation of the chimney with mineral wool

Good luck!

How to protect sewer pipes from freezing

- engineering;

- with the help of a heater;

- active.

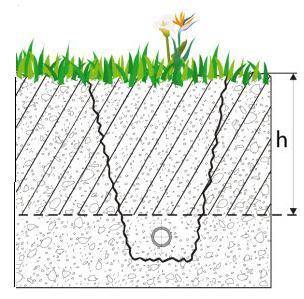

engineering method

The engineering method is the simplest solution to the question of how to insulate sewer pipes on the street. It consists in the following - the pipes are simply laid below the level of soil freezing. As practice shows, for this they sometimes have to be laid to a depth of 2 m or more. For each region, depending on the climate, the depth of the bookmark will be different. Implement this method as follows:

- At a given depth, they dig a trench under the drain pipeline with a slope of 1 cm per meter of its length. The depth can be found in a special table for each region.

- At the bottom of the dug trench, a sand cushion or a cushion of fine gravel (grain size no more than 20 mm) is made, at least 10 cm thick.

- Lay pipes.

- Cover them with a layer of sand or fine gravel. The layer should be located above the pipe at a height of at least 20 cm and be carefully compacted.

- Fill the trench with previously excavated soil.

Scheme of laying a sewer pipe below the freezing level

Thermal insulation method

What insulation to use - indicated above. The choice of material depends on many factors, among which, first of all, one should highlight the cost and thermal insulation properties.

So, let's consider how to properly insulate a sewer pipe. Installation of an external drain system using heat-insulating material must be carried out in the following sequence:

- The place where the trench will pass is marked.

- A trench is being dug, while its width should be at least 60 cm, and the depth should correspond to the project data with a margin of 5-10 cm.The trench is equipped with a mandatory slope (1 cm per 1 running meter) to ensure gravity flow.

- At the bottom of the trench, sand or gravel with a thickness of at least 10 cm is poured and rammed.

- The pipeline is assembled on the surface next to the trench.

- The seal and the edge of the pipe must be lubricated with sealant.

- The insulation is put on the pipe and fixed (usually with adhesive tape) so that it does not move.

- The pipe is lowered into a trench, covered with a layer of sand or gravel, after which it is rammed.

- Next, the trench is finally covered with soil, while making sure that it does not contain stones, broken glass or hard soil.

Internal sewerage, as a rule, is not insulated. Only the exit of the riser to the roof of the house is subject to thermal insulation, since with a sharp temperature drop it can simply burst. The material for insulation of the riser can also be either mineral wool or expanded polystyrene.

Heat-insulating shell for external sewage pipes

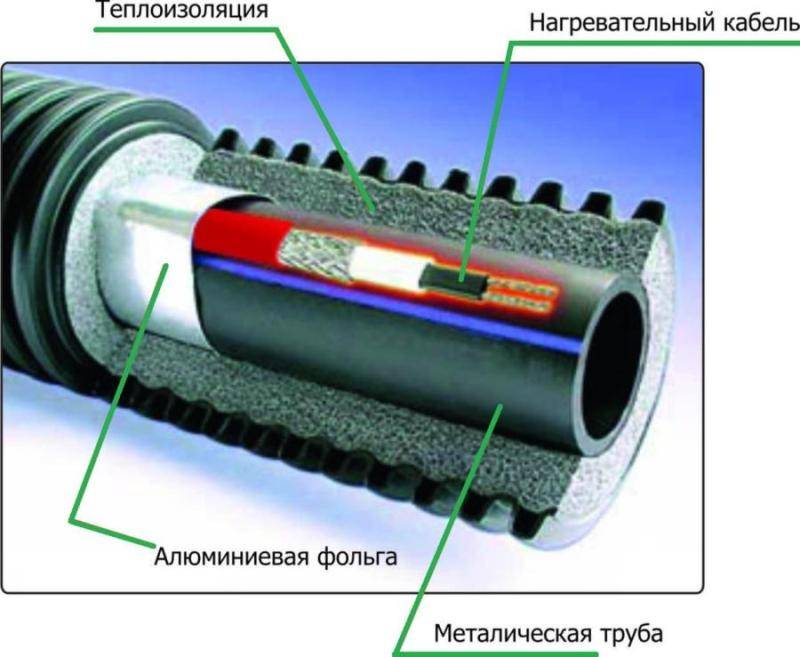

active way

The most costly way of thermal insulation is the so-called active insulation. It consists in laying electric heating cables along pipes. These cables, when heated, give off heat to the pipeline and prevent it from freezing. The heating system is controlled by a temperature sensor with automation connected to it. As soon as the temperature around the external sewer system approaches zero, the sensor is triggered and the cable heats up the pipeline. When the ground temperature rises, the system automatically turns off.

Applying active insulation in practice, you will also need to arrange an insulation system, because. the heating cable will heat the ground, not the pipes.This method is quite costly both during implementation and during operation, and not everyone can afford it.

How to insulate a drain pipe facing the street? The simplest and cheapest method is a foam shell, which will insulate it well. In everyday life, glass wool is more often used, which is simply wrapped around the drain pipe and tied with tape.

Scheme of heating a sewer pipe with a heating cable

Insulated outdoor sewer pipes will last longer if one of the thermal insulation methods described above is introduced. In addition, when laying the system, it is recommended to use smooth pipes made of polyvinyl chloride and polypropylene with an orange surface.