- Closed system health monitoring

- How to choose a hydraulic accumulator by volume?

- Device and principle of operation

- Features of starting a closed heating system with distilled water

- What is an expansion tank for?

- Expansion tank open

- Closed expansion mat

- Selection of pressure values in the system and expansion tank

- Conclusion

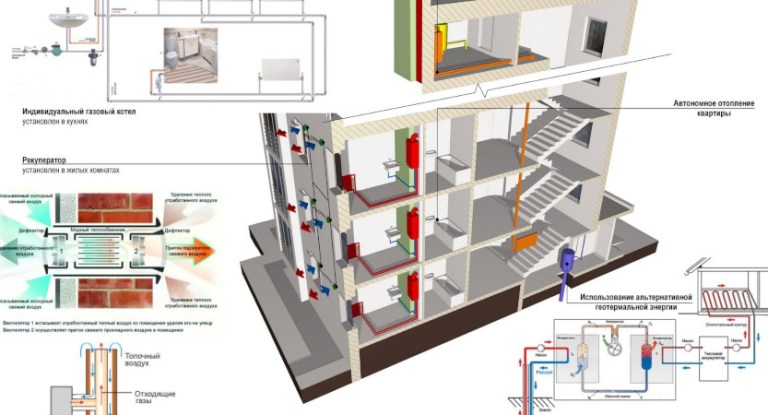

- Open and closed heating system

- Filling methods built-in mechanism and pumps

- Filling the heating with antifreeze

- Automatic filling system

- Pressure indicators in a private house and the reasons for its fall

- Kinds

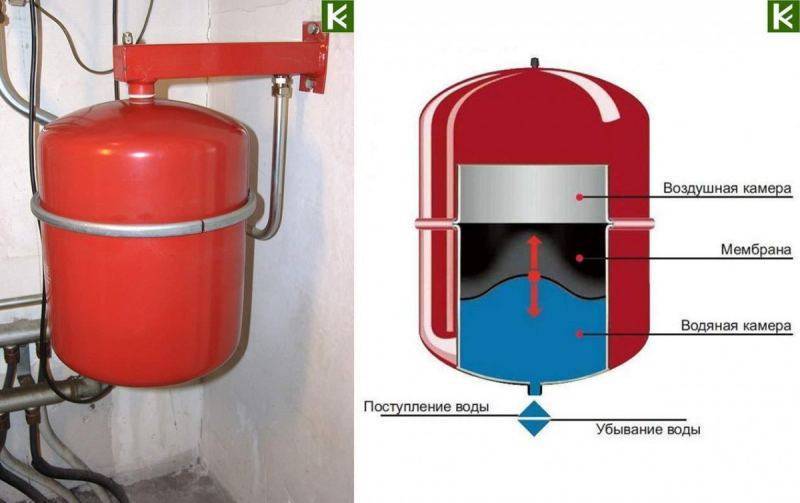

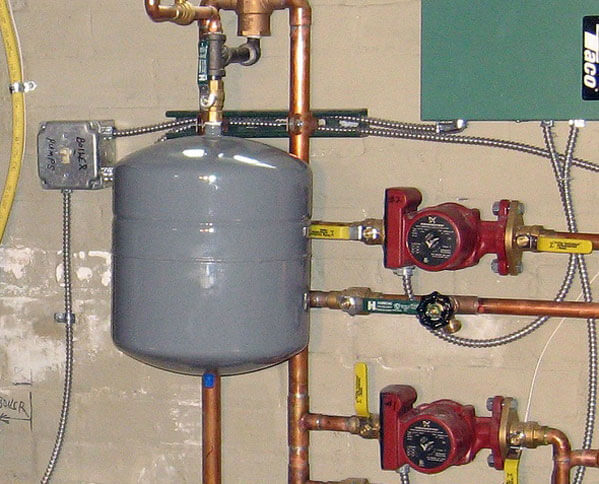

Closed system health monitoring

The main indicator of performance is pressure. It is controlled by manometers. For individual closed-type heating systems with forced circulation, the working pressure is 1.5-2 atm. Moreover, it is desirable to embed pressure gauges at key points through three-way valves, which make it possible to remove the device for repair / replacement, blow through or reset to zero.

In this system we see an expansion tank (red left) and menometers

If the system is large and powerful, then there are many control points (pressure gauges):

- on both sides of the boiler;

- before and after the circulation pump;

- when using heating regulators - before and after them;

- it is desirable to install before and after mud collectors and filters to control the degree of their clogging.

According to the readings of pressure gauges at these points, it is possible to control the performance of the entire system.

How to choose a hydraulic accumulator by volume?

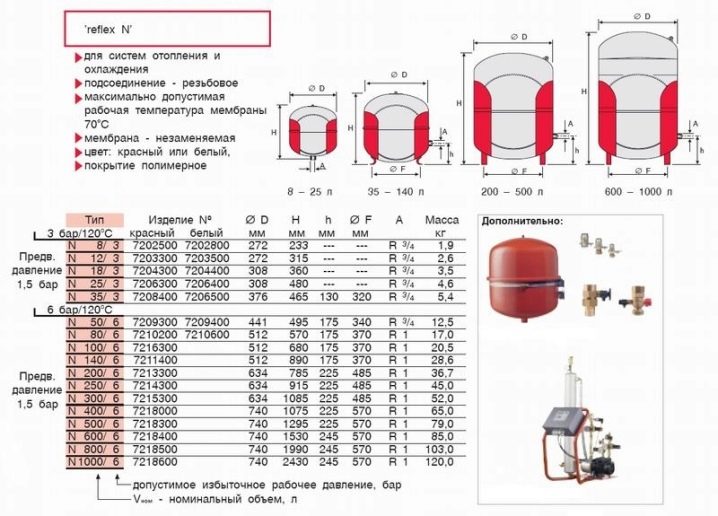

There are formulas for calculating the required tank capacity, taking into account the water supply. But for the water supply of a country house, it is enough to know a few parameters. The tanks are available in the following sizes:

- 4-35 liters. They are used with a pump capacity of 1.5-2 m³ / h and for 2-3 water consumption points. Such units are suitable for seasonal houses for 1-2 people.

- 50-100 liters. Hydraulic tanks are designed to work with a pump of 3.5-5 m³ / h and for 7-8 consumers. A good choice for a family that spends a lot of time in the country.

- 100-150 liters. Capacious tanks for pumps over 5 m³/h and 8-9 water consumption points. Such devices are chosen for permanent residence in a private house.

Do you need a reserve of volume hydraulic accumulator for water supply? This will not affect the longevity of the pump. Manufacturers provide a duty cycle of 20-30 inclusions per hour. If it turns on less often, then this will not extend the service life much. But if you need a supply of water in case of frequent shutdowns, then a capacious reservoir is indispensable.

It is important to strike a balance here. Too large water tank causes it to stagnate

Double stock (from the minimum required) will be enough.

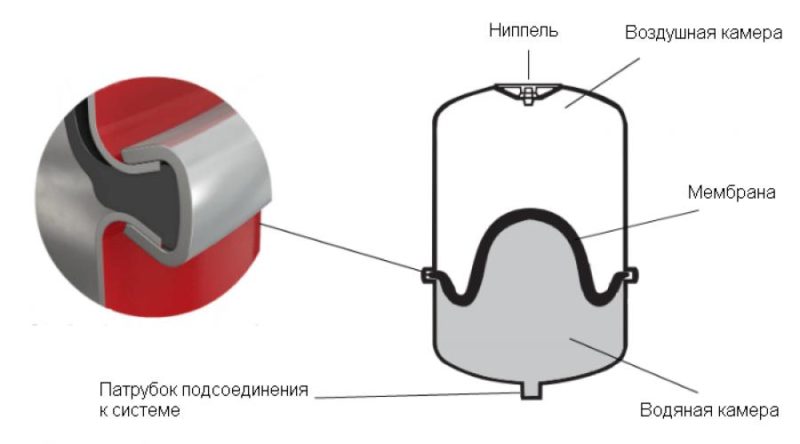

Device and principle of operation

The body of the tank has a round, oval or rectangular shape. Made from alloy or stainless steel. Painted red to prevent corrosion. Blue-painted cisterns are used for water supply.

Sectional tank

Important.Colored expanders are not interchangeable

Blue containers are used at pressures up to 10 bar and temperatures up to +70 degrees. Red tanks are designed for pressure up to 4 bar and temperatures up to +120 degrees.

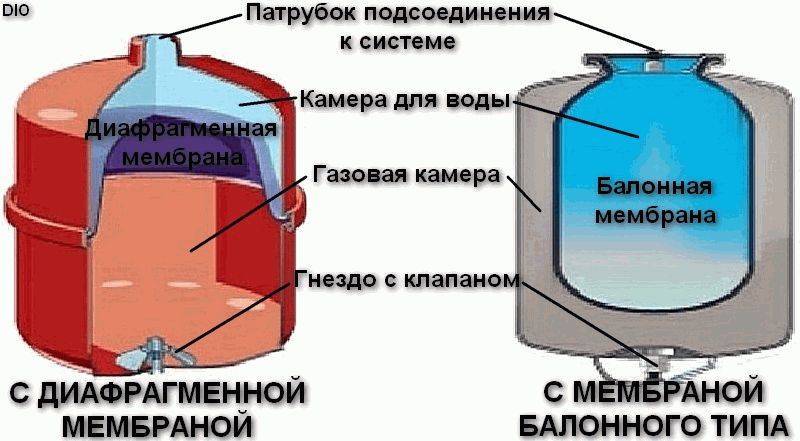

According to the design features, the tanks are produced:

- using a replaceable pear;

- with membrane;

- without separation of liquid and gas.

Models assembled according to the first variant have a body, inside of which there is a rubber pear. Its mouth is fixed on the body with the help of a coupling and bolts. If necessary, the pear can be changed. The coupling is equipped with a threaded connection, this allows you to install the tank on the pipeline fitting. Between the pear and the body, air is pumped under low pressure. At the opposite end of the tank there is a bypass valve with a nipple, through which gas can be pumped in or, if necessary, released.

This device works as follows. After installing all the necessary fittings, water is pumped into the pipeline. The filling valve is installed on the return pipe at its lowest point. This is done so that the air in the system can freely rise and exit through the outlet valve, which, on the contrary, is installed at the highest point of the supply pipe.

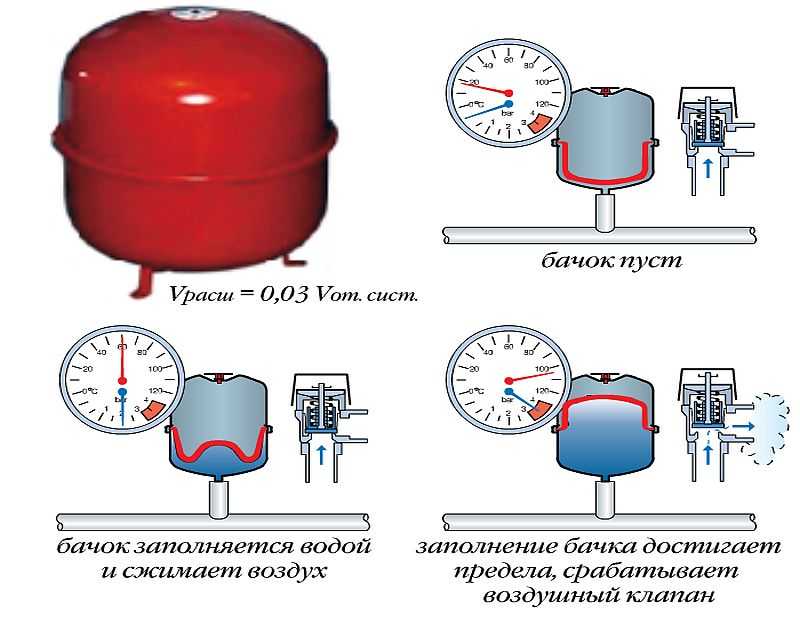

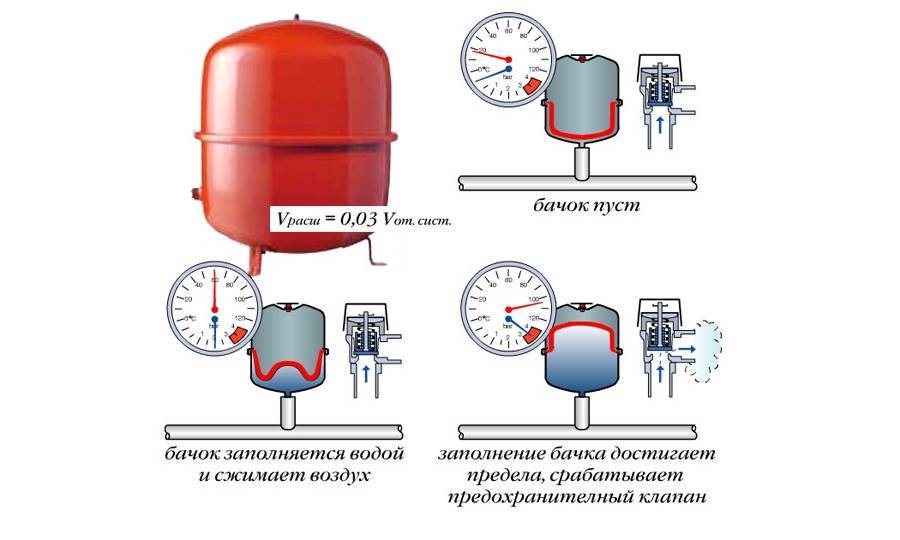

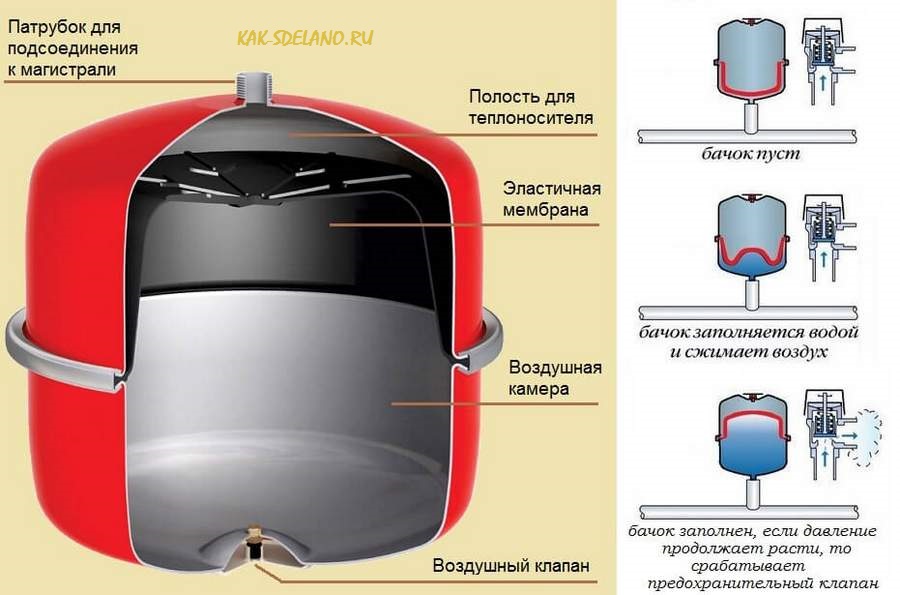

In the expander, the bulb under air pressure is in a compressed state. As water enters, it fills, straightens and compresses the air in the housing. The tank is filled until the pressure water is not equal to air pressure. If the pumping of the system continues, the pressure will exceed the maximum, and the emergency valve will operate.

After the boiler starts to work, the water heats up and begins to expand. The pressure in the system increases, the liquid begins to flow into the expander pear, compressing the air even more. After the pressure of water and air in the tank comes into equilibrium, the flow of fluid will stop.

When the boiler stops working, the water begins to cool, its volume decreases, and the pressure also decreases. The gas in the tank pushes the excess water back into the system, squeezing the bulb until the pressure equalizes again. If the pressure in the system exceeds the maximum allowable, an emergency valve on the tank will open and release excess water, due to which the pressure will decrease.

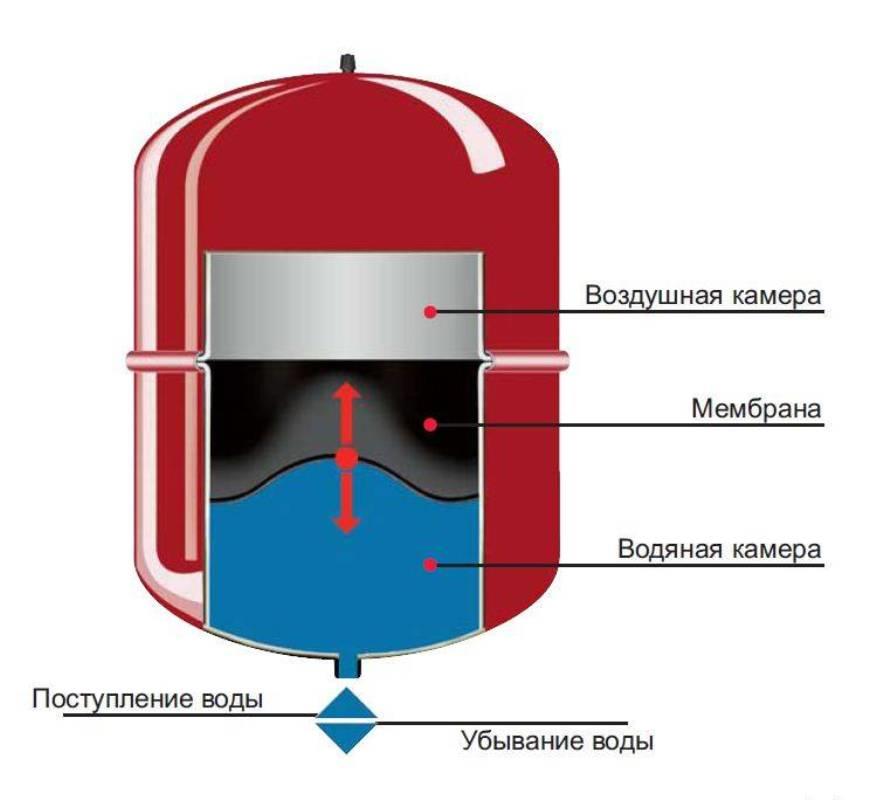

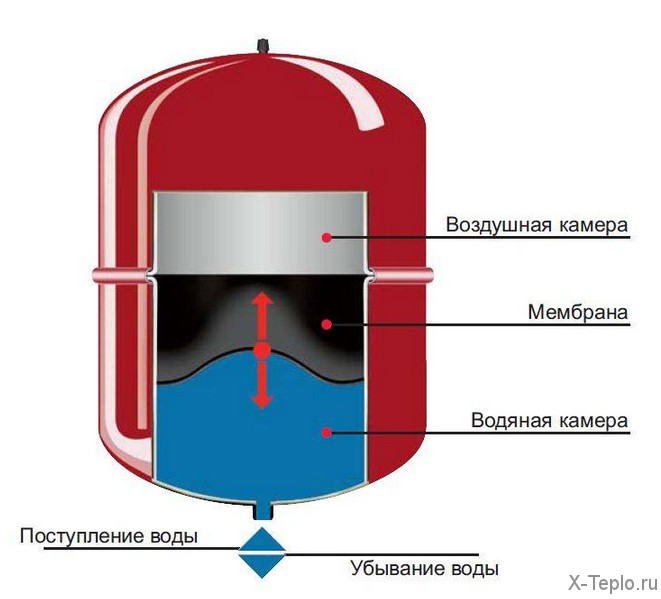

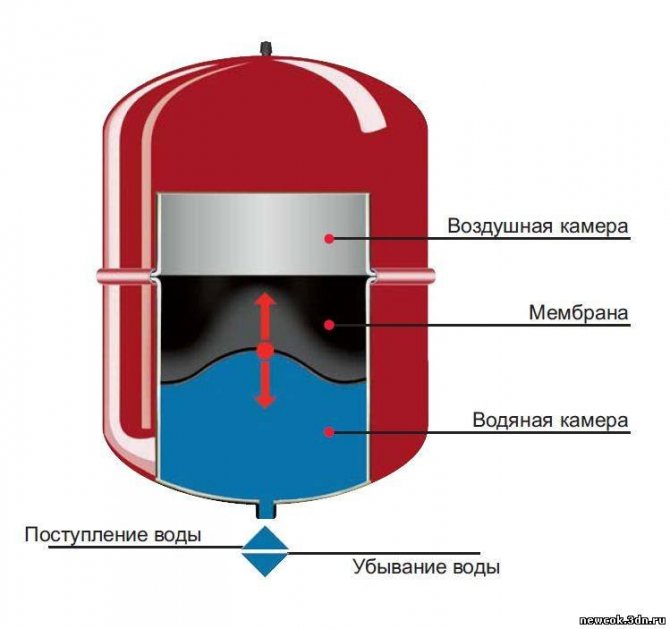

In the second version, the membrane divides the container into two halves, air is pumped in on one side, and water is supplied on the other. Works in the same way as the first option. The case is non-separable, the membrane cannot be changed.

Pressure equalization

In the third variant, there is no separation between gas and liquid, so air is partially mixed with water. During operation, gas is periodically pumped up. This design is more reliable, since there are no rubber parts that break through over time.

Features of starting a closed heating system with distilled water

Filling a closed heating system with water has the following features:

It will be much easier to provide the heating circuit with the necessary pressure if the dwelling has access to the central water supply. In this situation, to pressure test the heating system, it is enough to fill it with water through a jumper that separates the water supply, while carefully monitoring the increase in pressure on the pressure gauge.After completing such an event, unnecessary water can be removed using any of the valves or through an air vent.

Many are wondering whether special water treatment for the heating system should be carried out or whether it can be limited to water from the nearest reservoir. At the same time, some argue that distilled water in the heating system will have a beneficial effect on the life of the equipment and will prevent it from failing ahead of time. But it is much more important to figure out how to prepare water for heating if a special non-freezing liquid like ethylene glycol is added to it and how to subsequently fill the heating circuit with such a coolant.

For these purposes, it is customary to use a special pump that serves to fill the system with water, and it can be controlled both automatically and manually. The connection of this pump is carried out using a valve, and after providing the necessary pressure, the valve is closed. There are situations when such equipment is not at hand. As an option, it is allowed to connect a standard garden hose to the discharge valve, the second end of which should be raised to a height of 15 meters and filled with water using a funnel. This method will be especially relevant if there are tall trees near the building to be equipped.

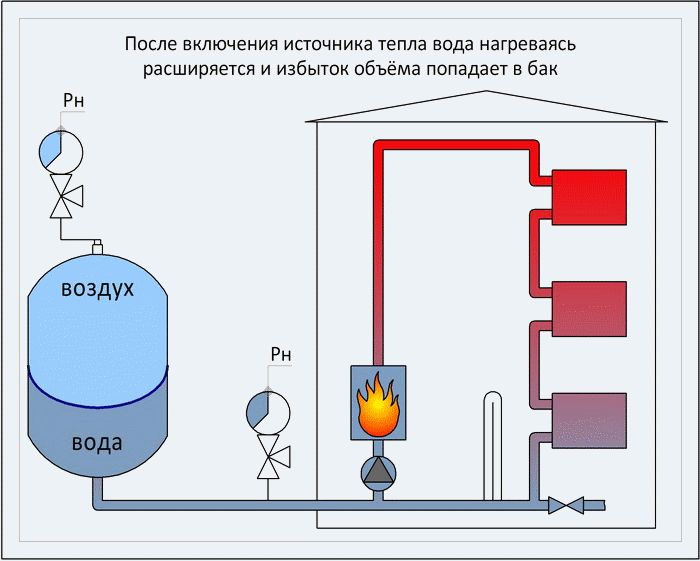

Another option for filling the heating system is to use an expansion tank, which performs the function of accommodating excess coolant caused by its expansion during the heating process.

Such a tank has the form of a reservoir, which is divided in half by a special elastic rubber membrane.One part of the container is for water, and the other for air. The design of any expansion tank also includes a nipple, with which it becomes possible to set the desired pressure inside the unit by removing excess air. If the pressure is insufficient, then this parameter can be compensated by pumping air into the system using a usually bicycle pump.

The whole process is not particularly difficult:

to begin with, air is eliminated from the expansion tank, for which you need to unscrew the nipple. Ready tanks go on sale with a slightly overpressure, which is equal to 1.5 atmospheres;

then the heating circuit is filled with water. In this case, the expansion tank must be mounted so that it is located with the thread up

It is important to remember that it is absolutely not worth filling the tank with water completely. It would be more correct if the total volume of air in this apparatus is approximately one tenth of the total volume of water, otherwise the tank will not be able to cope with its main function and will not be able to accommodate excess heated coolant;

after that, air is pumped into the system through the nipple, which, as mentioned above, can be done using a conventional bicycle pump. The pressure must be controlled with a manometer.

The pressure must be controlled with a manometer.

All these actions will allow you to accurately fill the heating system with water and ensure stable and high-quality functioning of the entire circuit. If necessary, you can always seek help from specialists who always have various photos of the devices necessary for such work that can help in connection.

Filling the heating system with water in the video:

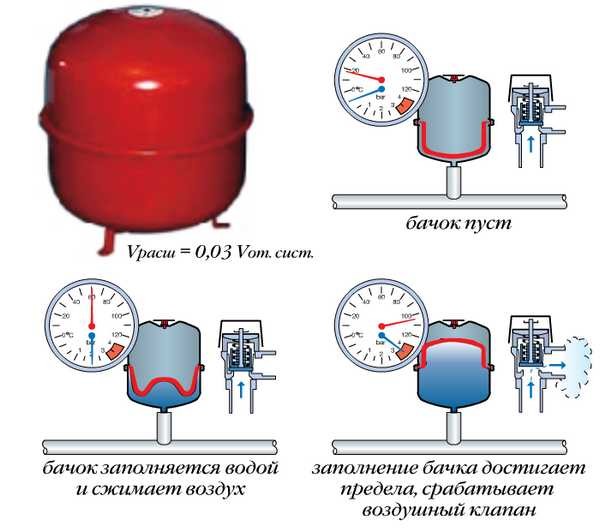

What is an expansion tank for?

In the process of heating, water tends to expand - as the temperature rises, the volume of the liquid increases. Pressure begins to rise in the heating system circuit, which can have a devastating effect on gas equipment and pipe integrity.

The expansion tank (expansomat) performs the function of an additional reservoir into which it squeezes out the excess water formed as a result of heating. When the liquid cools and the pressure stabilizes, it returns through the pipes back to the system.

The expansion tank performs the function of a protective buffer, it dampens the water hammer that is constantly formed in the heating system due to the frequent turning on and off of the pump, and also eliminates the possibility of air locks.

To reduce the likelihood of air locks and prevent damage to the gas boiler by water hammer, the expansion tank should be mounted in front of the heat generator, on the return

To reduce the likelihood of air locks and prevent damage to the gas boiler by water hammer, the expansion tank should be mounted in front of the heat generator, on the return

There are two different versions of damper tanks: open and closed types. They differ not only in design, but also in the way, as well as in the place of installation. Consider the features of each of these types in more detail.

Expansion tank open

An open tank is mounted at the top of the heating system. The containers are made of steel. Most often they have a rectangular or cylindrical shape.

Usually such expansion tanks are installed in the attic or attic. Can be installed under the roof

Be sure to pay attention to the thermal insulation of the structure

In the structure of the open-type tank there are several outlets: for water inlet, cooled liquid outlet, control pipe inlet, as well as an outlet pipe for coolant outlet to the sewer. We wrote more about the device and types of an open tank in our other article.

Functions of an open type tank:

- controls the level of the coolant in the heating circuit;

- if the temperature in the system has decreased, it compensates for the volume of the coolant;

- when the pressure in the system changes, the tank acts as a buffer zone;

- excess coolant is removed from the system into the sewer;

- removes air from the circuit.

Despite the functionality of open expansion tanks, they are practically not used anymore. Since they have many disadvantages, for example, a large container size, a tendency to corrosion. They are installed in heating systems that operate only with natural water circulation.

Closed expansion mat

In closed circuit heating systems, a membrane-type expansion tank is usually mounted; it is optimally suited for any type of gas boiler and has many advantages.

Expanzomat is a hermetic container, which is divided in the middle by an elastic membrane. The first half will contain excess water, and the second half will contain ordinary air or nitrogen.

Closed expansion heating tanksare usually colored red. Inside the tank is a membrane, it is made of rubber. A necessary element to maintain pressure in the expansion tank

Closed expansion heating tanksare usually colored red. Inside the tank is a membrane, it is made of rubber. A necessary element to maintain pressure in the expansion tank

Compensation tanks with a membrane can be produced in the form of a hemisphere or in the form of a cylinder.Which is quite suitable for use in a heating system with a gas boiler. We recommend that you familiarize yourself with the features of the installation of closed-type tanks in more detail.

Advantages of membrane types of tanks:

- ease of self-installation;

- resistance to corrosion;

- work without regular topping up of the coolant;

- lack of contact of water with air;

- performance under high load conditions;

- tightness.

Gas attachments are usually equipped with an expansion tank. But not always the additional tank from the factory is set up correctly and can immediately start heating.

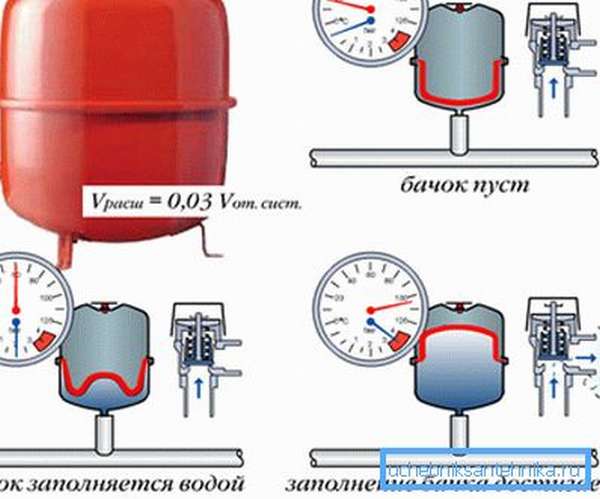

Selection of pressure values in the system and expansion tank

The higher the operating pressure of the coolant, the less likely it is that air will enter the system. It is necessary to remember about limiting the operating pressure to the maximum permissible value for the heating boiler. If, when filling the system, a static pressure of 1.5 atm (15 m of water column) was reached, then the circulation pump with a head of 6 m of water. Art. will create a pressure of 15 + 6 = 21 m of water column at the entrance to the boiler.

Some types of boilers have an operating pressure of about 2 atm = 20 m of water column. Be careful not to overload the boiler heat exchanger with unacceptably high coolant pressure!

The diaphragm expansion vessel is supplied with a factory set pressure of inert gas (nitrogen) in the gas cavity. Its common value is 1.5 atm (or bar, which is almost the same). This level can be raised by pumping air into the gas cavity with a hand pump.

Initially, the internal volume of the tank is completely occupied by nitrogen, the membrane is pressed by gas to the body. That is why it is customary to fill closed systems to a pressure level not higher than 1.5 atm (maximum 1.6 atm).Then, by installing the expansion tank on the "return" in front of the circulation pump, we will not get a change in its internal volume - the membrane will remain motionless. Heating the coolant will lead to an increase in its pressure, the membrane will move away from the tank body and compress the nitrogen. The gas pressure will increase, balancing the coolant pressure at a new static level.

Expansion tank pressure levels.

Filling the system to a pressure of 2 atm will allow the cold coolant to immediately compress the membrane, which will also compress nitrogen to a pressure of 2 atm. Heating water from 0 °C to 100 °C increases its volume by 4.33%. The additional volume of liquid must flow into the expansion tank. A large volume of coolant in the system gives a large increment during heating. Too much initial pressure of the cold coolant will immediately use up the capacity of the expansion tank, it will not be enough to receive excess heated water (antifreeze)

Therefore, it is important to fill the system to a correctly defined coolant pressure level. When filling the system with antifreeze, you need to remember about its higher coefficient of thermal expansion than that of water, which requires the installation of a larger expansion tank

Conclusion

Filling closed heating systems is not just a standard final operation before commissioning. Performing this step correctly or incorrectly can seriously affect the performance of the system, in the worst case, even disable it. Compliance with filling technology is the key to obtaining stable heating.

How to implement alternative heating for private at home

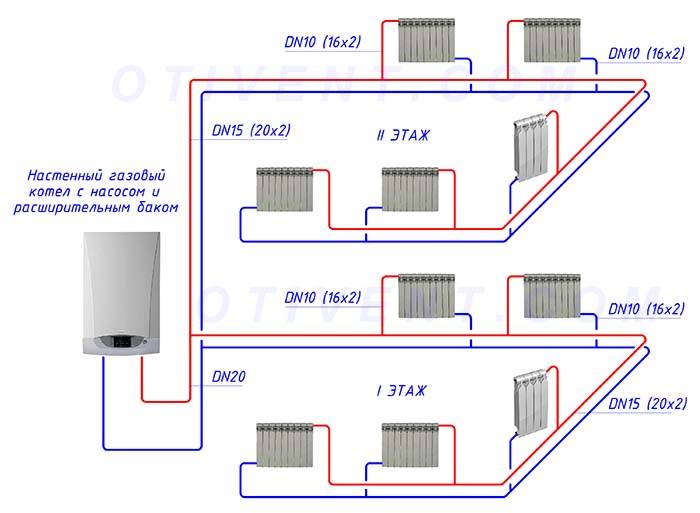

Two-pipe heating system of a private house - classification, varieties and practical design skills

One-pipe and two-pipe heating distribution in a private house

Open and closed heating system

If an open type expansion tank is installed, then the system is called open. In the simplest version, it is some kind of container (pan, small plastic barrel, etc.) to which the following elements are connected:

- connecting pipe of small diameter;

- a level control device (float), which opens / closes the make-up tap when the amount of coolant drops below a critical level (in the figure below, it works on the principle of a toilet flush tank);

- air release device (if the tank is without a lid, it is not necessary);

-

drain hose or circuit for removing excess coolant if its level exceeds the maximum.

Today, open systems are being made less and less, and all because a large amount of oxygen is constantly present in it, which is an active oxidizing agent and accelerates corrosion processes. When using this type, heat exchangers fail many times faster, pipes, pumps and other elements are destroyed. In addition, due to evaporation, it is necessary to constantly monitor the level of the coolant and periodically add it. Another drawback is that it is not recommended to use antifreezes in open systems - due to the fact that they evaporate, that is, they harm the environment, and also change their composition (concentration increases). Therefore, closed systems are becoming more and more popular - they exclude the supply of oxygen, and the oxidation of elements occurs many times slower, because it is believed that they are better.

The membrane type tank is installed in closed heating systems

In closed systems, membrane-type tanks are installed. In them, the sealed container is divided into two parts by an elastic membrane. At the bottom is the coolant, and the upper part is filled with gas - ordinary air or nitrogen. When the pressure is low, the tank is either empty or contains a small amount of liquid. With increasing pressure, an increasing amount of coolant is forced into it, which compresses the gas contained in the upper part. So that when the threshold value is exceeded, the device does not break, an air valve is installed in the upper part of the tank, which operates at a certain pressure, releasing part of the gas, and equalizes the pressure.

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed.This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature. Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite

This will greatly reduce the chance of leaks.

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all automatic filling devices water heating systems are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

Pressure indicators in a private house and the reasons for its fall

In closed heating systems of country houses and cottages, it is customary to withstand the following pressure values:

- immediately after filling the heating network with water and venting air, the pressure gauge should show 1 Bar;

- after warming up to operating temperature, the minimum pressure in the pipes is 1.5 Bar;

- during operation in different modes, the indicators can vary within 1.5–2 Bar.

Watch this video on YouTube

How to properly remove air from the heating lines and create the required pressure is described in a separate instruction. Here we list the reasons why, after a successful commissioning, the pressure indicators may decrease, up to the automatic shutdown of the wall-mounted boiler:

- Remaining air comes out of the pipeline network, underfloor heating and heating equipment channels. Its place is occupied by water, which fixes the pressure gauge by a drop to 1-1.3 bar.

- The air chamber of the expansion tank has emptied due to a leak in the spool. The membrane is pulled in the opposite direction and the container is filled with water. After heating, the pressure in the system jumps to critical, which is why the coolant is discharged through the safety valve and the pressure again drops to a minimum.

- The same, only after a breakthrough of the membrane of the expansion tank.

- Small leaks at the joints of pipe fittings, fittings or the pipes themselves as a result of damage. An example is the heating circuits of underfloor heating, where a leak can remain invisible for a long time.

- The coil of the indirect heating boiler or buffer tank is leaky.Then there are pressure surges depending on the operation of the water supply: the taps are open - the pressure gauge readings fall, closed - they rise (the water pipeline presses through the heat exchanger crack).

The master will tell you more about the causes of pressure drops and how to eliminate them in his video:

Watch this video on YouTube

Kinds

Pressure is of several types:

- static (a parameter depending on the height of the liquid column at rest, its pressure on the elements of the heating structure, when calculating, it must be taken into account that 10 m give a result of 1 atmosphere);

- dynamic (created by circulation pumps, but depends not only on their characteristics, occurs due to the movement of an energy carrier inside the pipeline, acts from the inside on structural elements);

- working (composed of the values of the first and second types, this is the level of normal and trouble-free operation of all structural elements).