- Evaluation of indirect water heaters

- How to clean the heating element in the boiler from scale

- How often should boilers be flushed?

- How to clean the boiler with your own hands

- chemical method

- Cleaning water heaters inside with your own hands from the smell

- Expert advice

- Cleaning the boiler from scale

- Signs of limescale in the water heater

- How to choose an indirect heating boiler

- Calculation of the volume of the storage tank

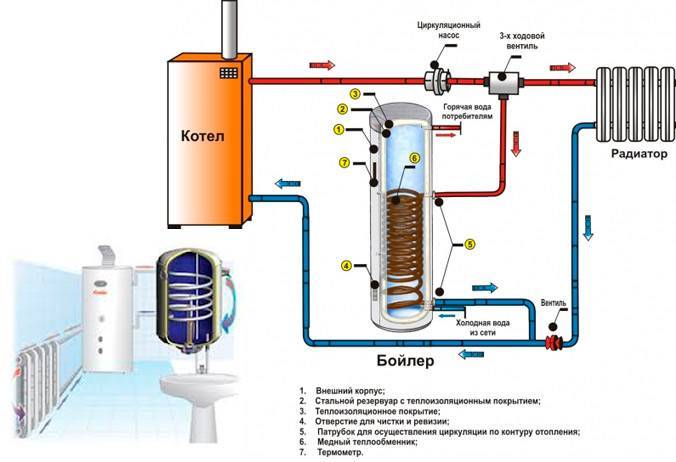

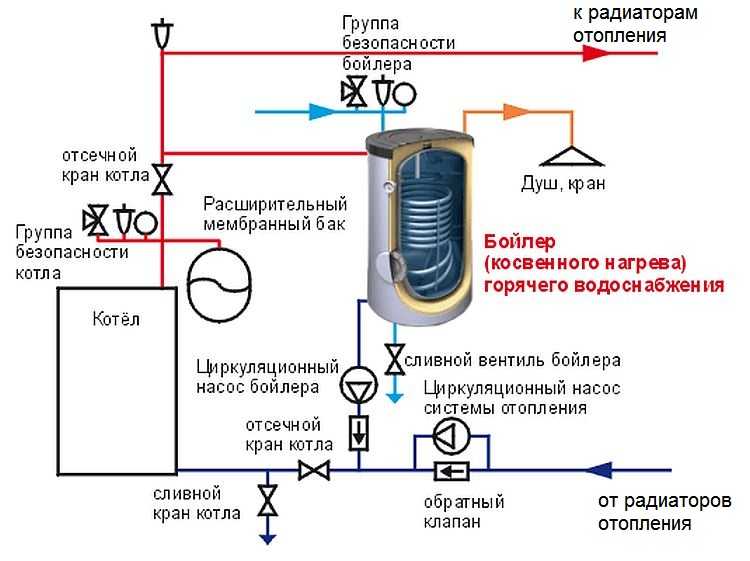

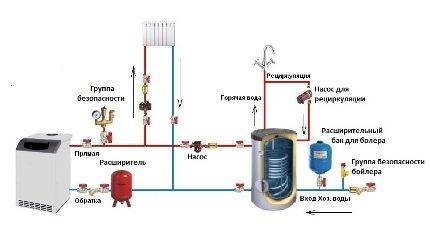

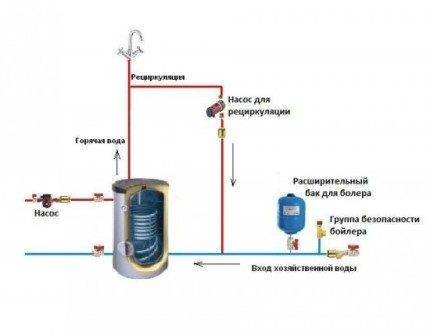

- Connection diagrams for the heating system

- Details

- Cleaning the heating element of the water heater from scale without disassembly

- Boiler disassembly and heating element cleaning

- Assembly technology

- Water heater tank

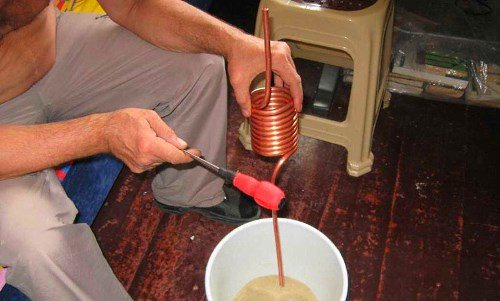

- Making a coil

- We insulate the structure

- final assembly

Evaluation of indirect water heaters

In today's world it is very difficult to do without hot water, so most people use boilers. In stores you can find different types of water heaters.

They are of the following types:

- electric boilers;

- boilers indirect water heaters;

- gas boilers;

- those that are heated by the heat of the sun.

In this video you will learn how to make a boiler with your own hands:

To heat water in an indirect water heater, you do not need to use gas, electricity or solid fuel. The basis for the manufacture of a water heater made by hand is the use of thermal energy, which is produced by third-party sources.Due to the transitional heat transfer fluids, heat transport is necessary. As such substances, you can take antifreeze or water. Using a boiler, you can save a lot of energy.

Unfortunately, the plumbing heater has a significant disadvantage: the inability to use it at the end of the heating season. The use of the boiler during the hottest periods of the year only to obtain hot water is considered an economically unprofitable action. In this case, it is rational to make a combined water heater with your own hands, which, in addition to the heat exchanger, will also be equipped with a powerful heating component.

How to clean the heating element in the boiler from scale

In order to clean the heating element, you can call professional craftsmen. Most companies that provide services of this kind offer a complete package: install, clean, repair.

Highly qualified specialists perform the work as accurately as possible and in the shortest possible time. The only negative is the high cost of services, so many are wondering how to clean the boiler from scale on their own.

Action algorithm:

- Disconnect the mains supply;

- Turn off the tap supplying cold water to the equipment;

- Drain the water.

To do this, take a hose and attach it to the safety valve of the device. Lead the hose into the toilet or bath and wait until the tank is completely empty.

Next, the following steps are performed:

- Removing the decorative protective cover;

- Detachment of heating element fasteners;

- Removing the heating element.

The front panel can be easily removed with a screwdriver. Then you should disconnect the wiring and unplug the power cable. It is required to unscrew the screws securing the conductors (phase, zero, ground).

Next, the temperature relay is removed, the sensor is removed and the heating element is removed. All actions must be carried out as carefully as possible. Beforehand, a large basin must be placed under the water heater, the remaining water and deposits will fall out.

The devices of most water heaters are typical, however, some manufacturers create original products, so before you clean the boiler from scale, you need to study the instructions that describe the design of the equipment.

Assembly is carried out in exactly the reverse order.

After removing the heating element, its condition should be assessed. In especially neglected situations, the heating element is so damaged by scale that its further use is impossible. In this case, a replacement is necessary.

The heating element is cleaned in two ways:

- Mechanical way;

- The use of chemicals.

Initially, the resulting upper wet layer is scraped off with a metal brush. Next, a solution of organic acid (citric or acetic) is created in a deep container at the rate of 1 cup of acetic essence (or 200 g of citric acid) per 1 liter of water.

The solution is heated and the heating element is lowered into it for a couple of hours.

Hard deposits will soften and be easily removed using a regular sponge or rag. Rinse and let dry.

Details on how to clean the boiler at home:

How often should boilers be flushed?

Manufacturers always leave instructions for use in the instruction manual. In particular, there is always a paragraph explaining all the nuances in carrying out cleaning procedures.The BKN must be cleaned on average once a year if there are no serious breakdowns that affect the correct operation of the equipment. It can be a stench that resembles the smell of rotten eggs when using warm and hot water. Also, a sign may be a decrease in temperature for heating water, the occurrence of rust. If you find any of these signs, then you need to urgently stop further operation of the equipment and carry out maintenance. The frequency of cleaning procedures is influenced by the following circumstances: Output quality.

How to clean the boiler with your own hands

You can descale the heater at home with your own hands or invite a service representative. The designs of different models of boilers are different, but the technology has one algorithm.

There are two common cleaning methods:

- Chemical, not requiring disassembly of the device, using an industrial liquid. Many craftsmen clean the boiler with their own hands, using homemade cleaning products with citric acid.

- mechanical way. Before you clean the Ariston boiler at home in this way, you will need to disassemble it. Clean the heater and the tank at the same time. This is a complex, labor-intensive method and is expedient for use if chemistry has not given the desired effect.

Before cleaning the boiler from scale, preparatory operations are performed:

Turn off the power to the boiler, and close the water supply tap.

Remove the panel and power terminals.

Disconnect the ground, electrical wire. Pre-take a photo of the electrical circuit in order to assemble it correctly in the future.

Before cleaning the Ariston water heater, the water is drained, having previously prepared the vessels and hoses for draining the water into the sewer, with the least spillage in the room.

After the cranes empty the storage tank, disconnect the fasteners and dismantle it.

If there is no drain cock, drain through the safety valve. Given its small passable cross section. The process will be lengthy.

Before cleaning the heater, unscrew the bolts and remove the flange with the heater

For wall-mounted models, the case is removed from the fasteners and carefully placed on a clean surface with the taps up.

Loosen the clamping bracket and take out the electric heater.

chemical method

This is the easiest way and can be done without disassembling the unit. Such preventive cleaning of the boiler prevents the deposition of hard-to-remove scale. The method is based on the use of a descaling agent, such as water vinegar or citric acid solution.

Cleaning water heaters inside with your own hands from the smell

Many owners of water heaters notice over time that the heated water began to stink terribly. This unbearable smell can have several reasons:

- Dirty water is supplied to the boiler. If there are many impurities in the water, especially hydrogen sulfide, it emits an unpleasant odor.

- Specific bacteria and fungi started up in the tank. Such living creatures are born in limescale on the walls of the container. As long as there are not many microorganisms, the smell of water does not change. But over time, their number increases, and the water begins to stink.

- Cheap or damaged plumbing. Poor-quality tubular plastic transfers its chemical odor to the water.And the old metal plumbing is ideal for the life of bacteria and fungi.

Water with hydrogen sulfide cannot be smelled

There is a way to determine which of these cases is the case:

- Run cold tap water for 5 minutes. Then substitute a clean bottle under the jet and close it after filling. After half an hour, you need to open the bottle and check the smell of water. If it smells bad, there is a problem with pipes or water.

- If the cold water from the bottle smells normal, the reason must be sought in the boiler itself. To do this, you again need to fill the plastic container, but only from the hot tap closest to the water heater. We wait 30 minutes and smell. If you can’t inhale from the bottle, then harmful microorganisms have wound up in the tank.

In order to eliminate the unpleasant odor due to bad water or rusty pipes, you can do the following:

- Install a filter that purifies the water from bad-smelling gases.

- Complain to the SES about the poor quality of tap water.

In the first case, you do not have to wait until someone comes and fixes the problem. Therefore, if there is no strength to endure smelly water, it is easier and faster to install a filter.

Problems with microorganisms in the boiler are solved differently:

- Tank sterilization. The water in the boiler is brought to a boil and remains in this state for a long time.

- Descaling the water heater (see above). This will destroy the favorable environment for the reproduction of microbes and bacteria.

So that smelly water does not go out of the boiler again, you must follow simple preventive measures:

Do not leave water in the switched off water heater when it is not in use for a long time. Periodically clean the tank from scale.It is recommended to install a filter

Pay attention to water quality. If necessary, contact the sanitary epidemiological station

Expert advice

Sometimes the cause of the smell can be a poor-quality heating element or anode. If the smell or taste in the water reappears after cleaning, the problem may be in them.

To avoid problems with scale, make the boiler prophylaxis once a year.

If you have dirty water coming from a water supply system, a well, or a well, put a filter in front of the boiler entrance and change or clean it periodically.

Do not heat water below +55 degrees. At a lower temperature, microorganisms will multiply in it, especially the dangerous legionella.

If your water heater tank is made of stainless steel, paint over the welds with enamel. This is the weakest point of such boilers.

Install back pressure valve. It will bleed water if the pressure in the system is too strong, or a water hammer occurs. Thus, you protect yourself from surprises.

Cleaning the boiler from scale

The cleaning process does not provide much complexity. Despite the fact that boilers of various manufacturers have their own design features. For all devices of this type, there is the same algorithm for carrying out the cleaning procedure. To work, you will need a screwdriver, a wrench, a screwdriver and a special cleaning agent.

The whole process involves the following steps:

- Disconnecting the appliance from the mains.

- Shut off cold water supply.

- Removing the boiler cover, and then disconnecting the wires.

- Removing the thermostat.

- Draining.

removing the boiler cover

To drain water, a tube or thin hose of short length is used, which is installed at the collecting outlet, near the place where the safety valve is located. In order for air to enter the check valve, you need to slightly open any hot water tap. Through the tube, the water is drained into the sink or toilet. If the safety valve is damaged or does not function, then its subsequent replacement is required. In this case, first shut off the cold water supply and disconnect the supply hose. After that, connect the tube to the ball valve. Then drain the water from the boiler. To unscrew the nuts holding the flange plate, you must first substitute a basin so that the remaining water does not spill onto the floor. Then push the flange up. Then it is turned over and taken out. It is necessary to remember the original location of the flange so that when reassembling it, you do not put it upside down and mix up the location of the terminals.

removal of the heating element

removal of the heating element

For cleaning, you can use vinegar and special cleaning fluids. By the way, you can even clean the washing machine with citric acid and vinegar - a kind of universal remedy, not a food additive. In this case, you must act carefully so as not to scratch the surface of the heater. Scale should not be chipped from the walls of the tank with a knife, scissors or other sharp objects, as the protective layer may be damaged.

After the heating element is disconnected, you need to clean the inner surface of the tank from accumulated dirt with a rag. If it is covered with enamel, then there may be little scale on the walls. Scale from the bottom of the tank is best removed by hand (you can wear rubber gloves).After removing the dirt, the tank is washed with a jet of water and wiped dry.

The whole process of disassembly and cleaning is presented below in a video:

Signs of limescale in the water heater

- There is noise during the operation of the boiler. Usually this electrical equipment works almost silently, but scale can lead to unusual sounds, hum during water heating;

- The process of heating the water to the set temperature begins to take more time. Electricity is consumed, but the heating elements, due to a layer of solid deposits, cannot heat the water normally;

- The boiler starts turning off more often to prevent overheating.

Boiler cleaning steps:

- First of all, the electrical device is disconnected from the network. The safest thing is not just to unplug the socket, but also turn off the machine, disconnect the wires from the thermostat.

- It is advisable to wait until the water in the tank cools down a bit, so it will be safer to work.

- The water supply tap to the boiler must be turned off so that the boiler does not fill up.

- Water from the tank must be drained, following the instructions for the boiler or the scheme for supplying water through the boiler.

- So, the boiler is empty, the water is dumped. Now you should get to the heating element. To do this, first of all, the decorative tank cover is removed, it is usually fastened with several screws. A screwdriver is required. To clarify: for most standard vertical models of water heaters, you can remove the heating element directly on the wall without removing the boiler itself from the mounts. However, for example, if you have a flat model mounted horizontally, it will be inconvenient to work. In this case, after draining the water, it is advisable to remove the tank and move it to where it will be comfortable for you to work with it;

- For some models, the thermostat is removed along with the heating element, for others it is pulled out of the case;

- There are models in which the entire stand with a heating element is held by just one nut, so it will not be difficult to remove. Other models have more nuts - five or six, but in any case they should be unscrewed to get to the heating element.

- For convenience of work, the heating element pulled out of the water tank should be unscrewed from the cover on which it is installed. First of all, we wash the heating element under cold water to wash off the top layer of scale, possibly rust;

- The remaining plaque will have to be removed differently. The easiest chemical method is to soak the heating element in water with dissolved citric acid. Remember that it is citric acid that is recommended as a folk remedy for preventing the appearance of scale in the washing machine. She handles flying very well. Dilute citric acid to clean the heating element with water in the proportion of 10 grams (one sachet) per liter of water. In this solution, the heating element is simply soaked for a while, periodically check its condition. To increase the effect, the citric acid solution should be heated;

- It is not recommended to clean off hard, petrified plaque with a heating element with a knife - there is a risk of damaging the top layer if you are too zealous. If you decide to use a mechanical method, you can take sandpaper, but you should also be careful;

- Instead of citric acid or vinegar, as folk remedies, heating elements can be cleaned with special anti-scale chemicals;

- The tank itself should also be washed. If you removed it from the wall, you will have to fill in the water and then pour it out manually.If it still hangs in its place and it is convenient for you to work, then just turn on the water supply, but do not close the hole from where you pulled out the heating elements so that the dirt immediately pours out. Walk along the walls of the tank with a rag to remove plaque. The walls of the boiler are enameled inside, there is no scale on them, but dirt may remain;

- Abrasive substances should not be used when cleaning the tank, so as not to damage the walls;

- After cleaning the heating element and the tank, the boiler should be assembled - everything happens in the reverse order. The main thing is to securely fasten the connecting screws and nuts, install a thermostat, use a winding for pipes, connect wires;

- Then we start the water, fill the boiler and connect it to the network to check how it will work now. If you have any questions on this topic, ask them to specialists and readers of our project here.

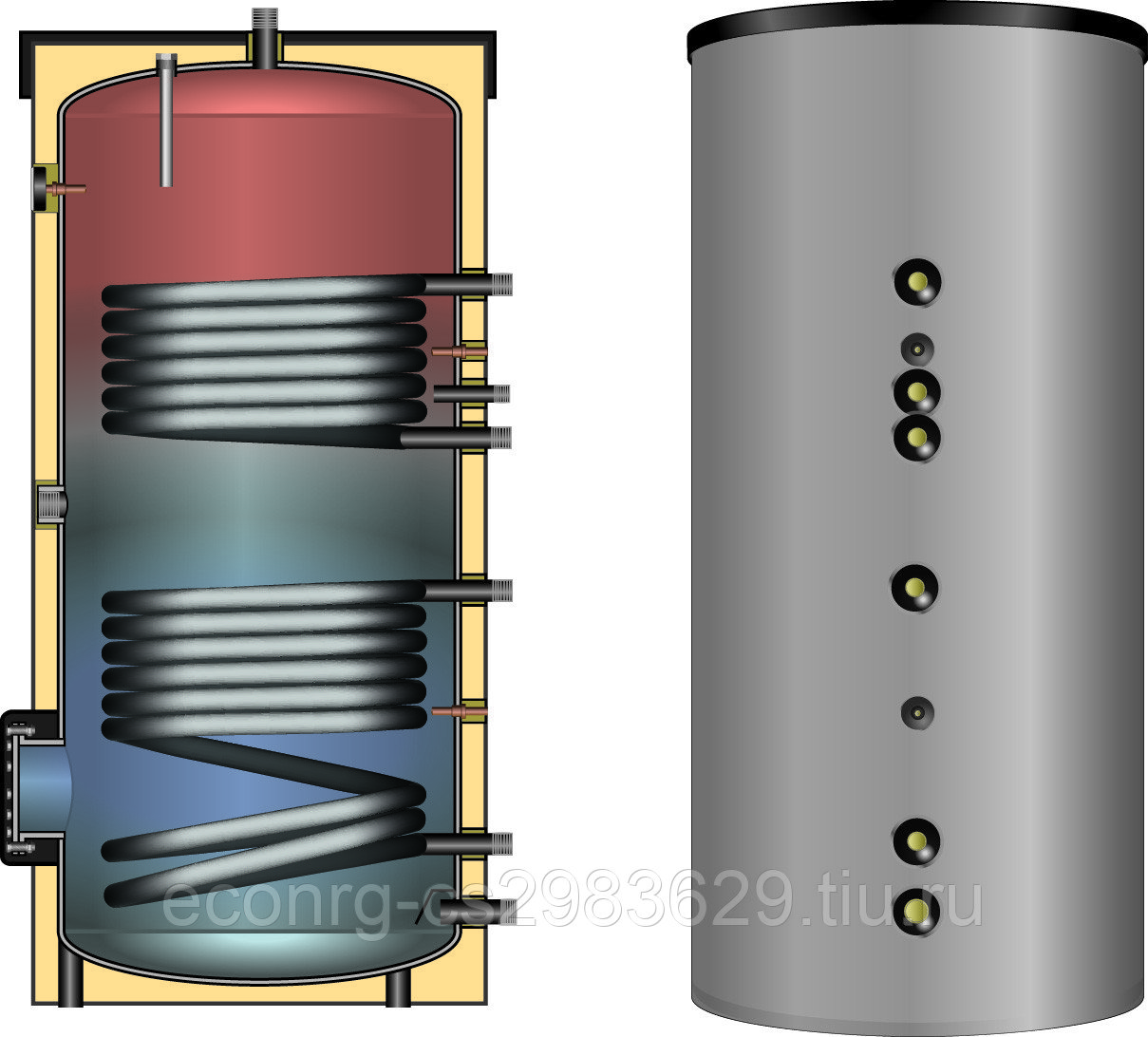

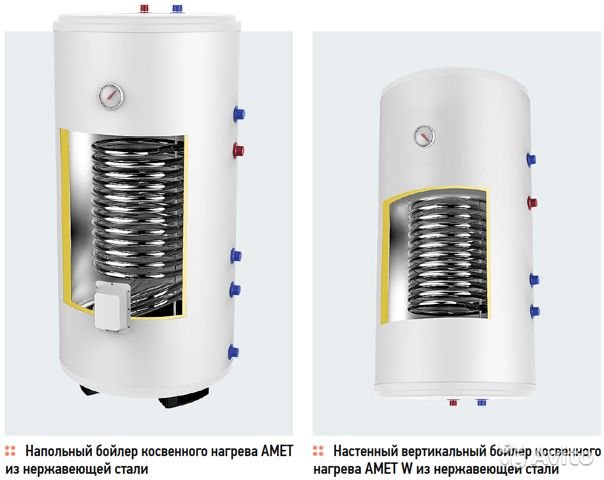

How to choose an indirect heating boiler

Making the right choice of a suitable indirect heating boiler model is a difficult task for a beginner. However, there is nothing overwhelming here, you just need to take into account a few important nuances:

When choosing a water heater with indirect heating for an apartment or a private house, the first step is to determine the optimal volume of the storage tank. In order for all family members to have enough hot water, they calculate taking into account the approximate consumption of 100 liters per day by one person.

Cost-effective indirect water heating boiler for a family of four or more people

With this number of people, the approximate consumption of hot water is 1.5 l / min.

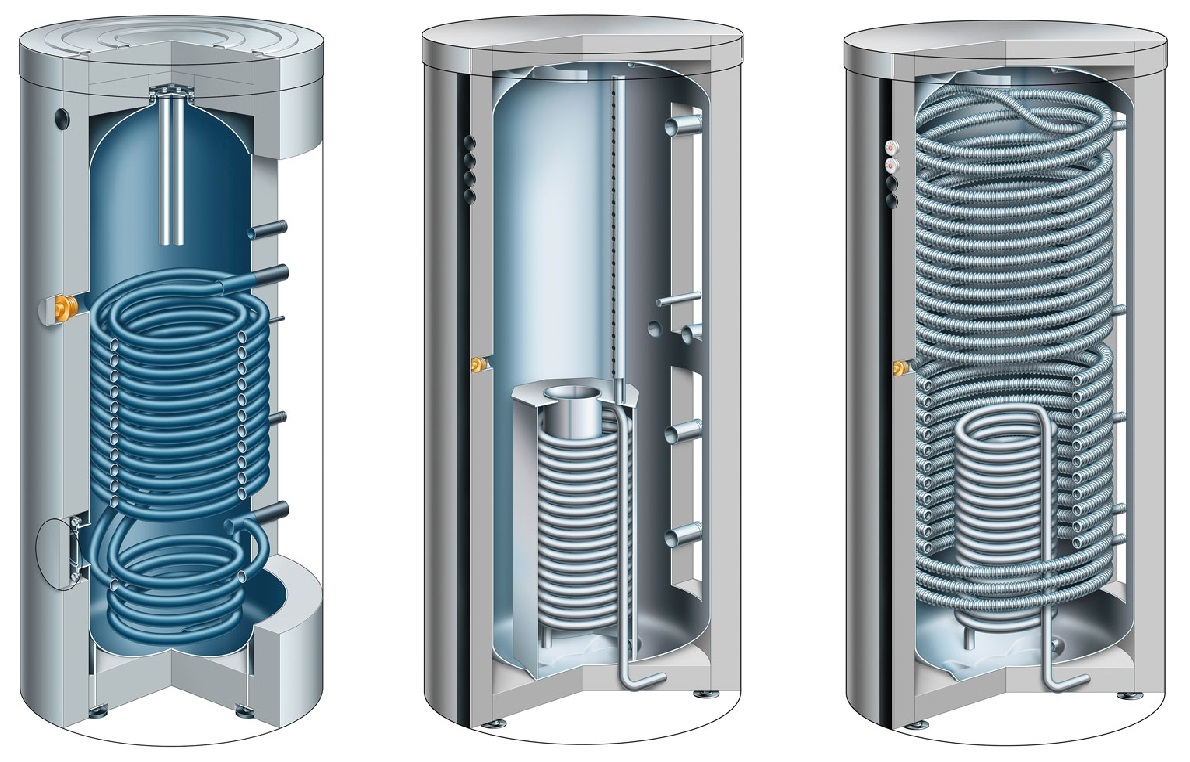

Paying attention to the volume of the tank, take into account the heating time. Large capacity will take longer to heat up.It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system.

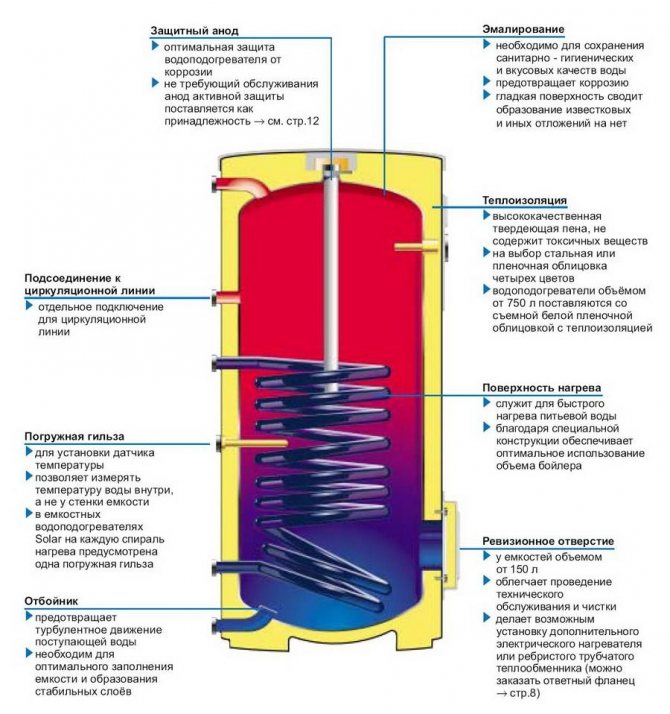

The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off.

Cheap water heaters come with foam. Porous material poorly retains heat and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam.

To make the right choice, you need to compare the power of the indirect water heater and the heating boiler. If the latter is characterized by weak parameters, the boiler will become an unbearable load.

When buying any model, be sure to pay attention to the presence of a thermostat, valve and other security elements.

It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system.

The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off. Cheap water heaters come with foam. Porous material poorly retains heat and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam.

To make the right choice, you need to compare the power of the indirect water heater and the heating boiler

If the latter is characterized by weak parameters, the boiler will become an unbearable load.

When buying any model, be sure to pay attention to the presence of a thermostat, valve and other security elements.

When with all the important nuances of the question solved, you can pay attention to the shape, design, manufacturer and other details

Calculation of the volume of the storage tank

To make an approximate calculation of the volume of the storage tank, you can use a simple reading of the water meter.When the same number of people constantly arrive at the house, the daily consumption will have the same data.

A more accurate calculation of the volume is based on counting the water points, taking into account their purpose and the number of living family members. In order not to go into complex formulas, the hot water consumption is taken from the table.

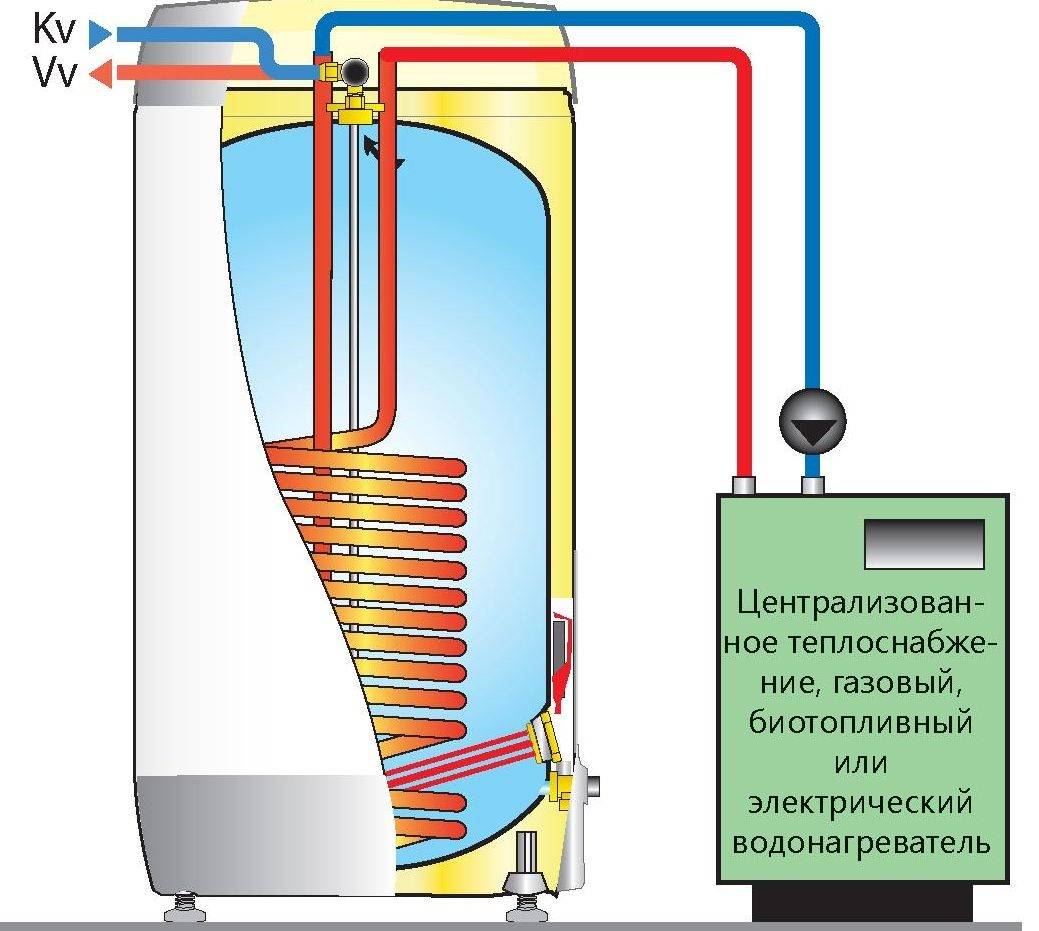

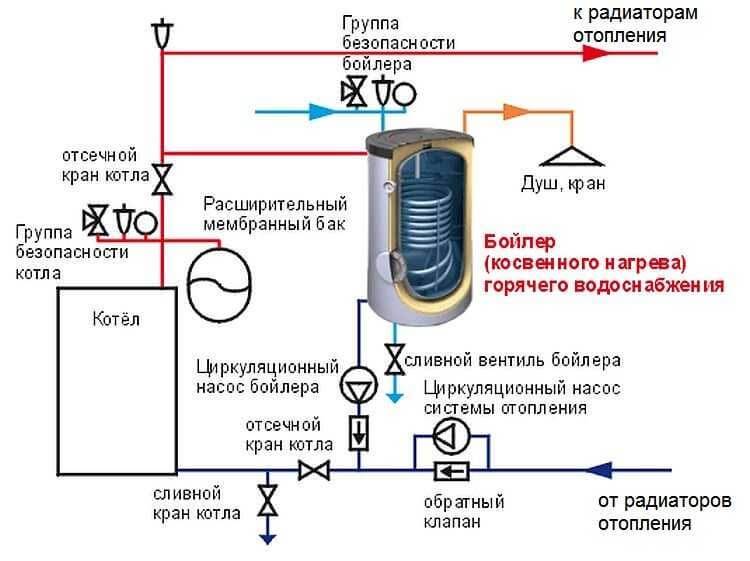

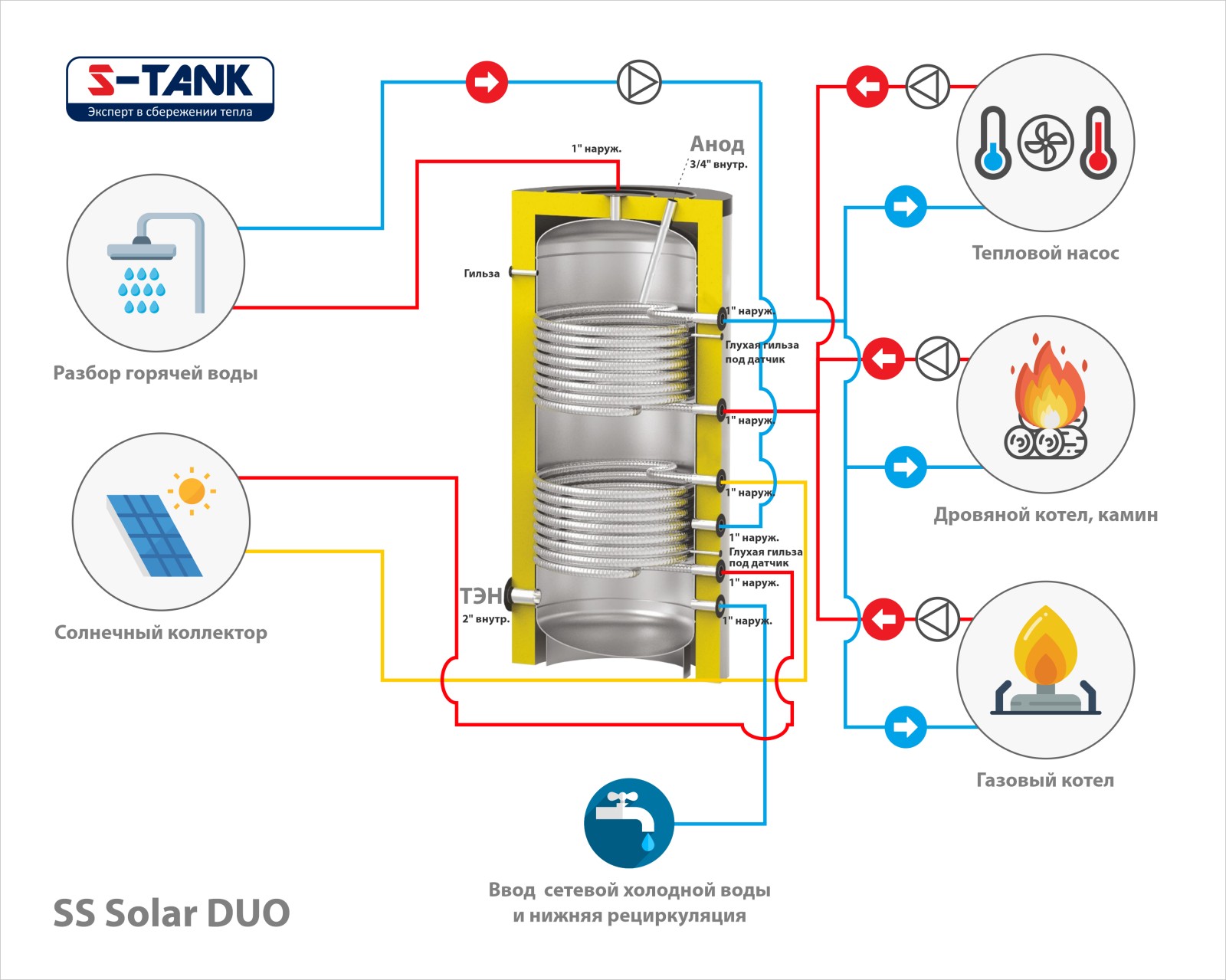

Connection diagrams for the heating system

When choosing a connection scheme for an indirect boiler for heating water, the location of the device in the house, as well as the features of the heating system wiring, are taken into account.

A simple and commonly used scheme is based on connecting an indirect device through a three-way valve. As a result, two heating circuits are formed: heating and hot water. After the boiler, a circulation pump crashes in front of the valve.

If the need for hot water is small, a system diagram with two pumps is suitable. The indirect water heater and the boiler form two parallel heating circuits. Each line has its own pump. The scheme is suitable for country houses where hot water is rarely used.

The connection diagram is more complicated if the house has a “warm floor” system installed along with radiators. To distribute pressure across all lines, and together with an indirect boiler they will get three, a hydraulic distributor is installed. The node normalizes the circulation of water through the "warm floor", water heater and radiators. Without a distributor, pumping equipment will fail.

In indirect water heaters with recirculation, three nozzles come out of the body. Traditionally, two outputs are used to connect to the heating system. A looped circuit is led from the third branch pipe.

If the indirect water heating device does not have a third branch pipe, and recirculation must be done, then the return line circuit is connected to the cold water pipe and the recirculation pump is additionally inserted.

Recirculation allows you to get hot water at the outlet of the tap even before the liquid in the storage tank of the boiler is completely heated.

Details

Cleaning the heating element of the water heater from scale without disassembly

It is not always possible to disassemble the water heater in order to carry out its deep mechanical cleaning. This process is time consuming and complex. To disassemble a large boiler, the help of another person is needed. As a preventive treatment or first aid, you can use special products that can dissolve scale and clean the heating element from contamination.

How to remove scale in a water heater using professional tools

Water that passes through a rusty water supply should be used with products containing phosphoric acid. According to the recommendations of experts, it is better to use the following tools:

— Aipacon;

— Cillit ZN/I;

— Thermagent Active;

— Alphaphos.

REFERENCE! Equipment that has been in operation for more than 2-3 years should not be cleaned with products based on other acids.

The inside of the boiler can be cleaned with surfactant-based products. The most effective are Alumtex and Steeltex.

Before using the products, it is necessary to carefully study the instructions for cleaning the boiler from scale. The manufacturer usually indicates the exposure time on the packaging.

Usually the solution still needs to be prepared, that is, mixed with water in the required proportions.Then you need to open the cold water supply on the water heater and drain the hot water by 60-70 percent. Using the reverse connection of the boiler, you need to pour the prepared solution into the tank. Then you need to leave the product for 5-6 hours and drain through the hot water flow tap.

Cleaning the water heater from scale at home using folk remedies

If it was not possible to buy a specialized tool for some reason, then you can try using improvised means. You can clean the heater from scale with vinegar or citric acid.

To prepare an active solution, you need to dissolve 0.5 kg of citric acid in two liters of water. Release the tank by 1/3, and pour acid inside. In this state, the tank must be left overnight. During this time, lime deposits and rust should dissolve.

REFERENCE! Inside the boiler is protected by thin enamel, which can be easily damaged by aggressive chemical compounds.

Boiler disassembly and heating element cleaning

Experts advise to completely disassemble small units to clean them from scale. Thus, you can return them to their original performance indicators.

To clean the water heater from the scale layer, it must first be disconnected from the power supply and shut off the cold water supply. Then you need to wait 2-3 hours so that the water temperature decreases and the person does not get burned. Then you need to open the hot water tap and empty the tank.

Then the scale should be removed as follows:

- The hot water inlet hose must be disconnected and the corresponding tap on the mixers must be opened so that the residues drain off.

- Disconnect the power cable from the thermostat and heating element, proceeding carefully.

- Gradually unscrew the flange to which the heating elements fit, allow the remaining water to drain. After which it must be completely removed.

REFERENCE! Now is the time to take a picture of the internal connection of the boiler, so as not to get confused later in its electrical circuit.

A heating element that has been successfully removed must be descaled. This must be done with a sharp object. A knife, chisel or other object with an abrasive surface will do

Be careful not to damage the tube

The storage tank must be cleaned of mucus and other contaminants with a brush or plastic scraper. In this case, do not put pressure on the case or rub it hard, as this can lead to a breach of tightness or damage to the walls.

After the descaling work has been carried out, you need to assemble the boiler in the reverse order of its disassembly.

Before installing the boiler in place, it is recommended to clean the rubber parts of the boiler and treat them with sealant. With this technique, you can avoid the flow of water during the operation of the water heater and reduce the risk of scale.

After installing the heating element in place, you need to do the following:

- Hang the boiler in place.

- Connect it to the pipeline.

- Turn on the cold water supply and open the hot tap.

- Wait until the boiler is filled with water and check the tank for integrity.

- Put the thermostat in place and connect the wires.

- Install the relief valve in place.

- Plug the boiler into an outlet.

REFERENCE! If the boiler is regularly cleaned of rust and scale, then this process will not take much time, so that the life of the device will be extended.

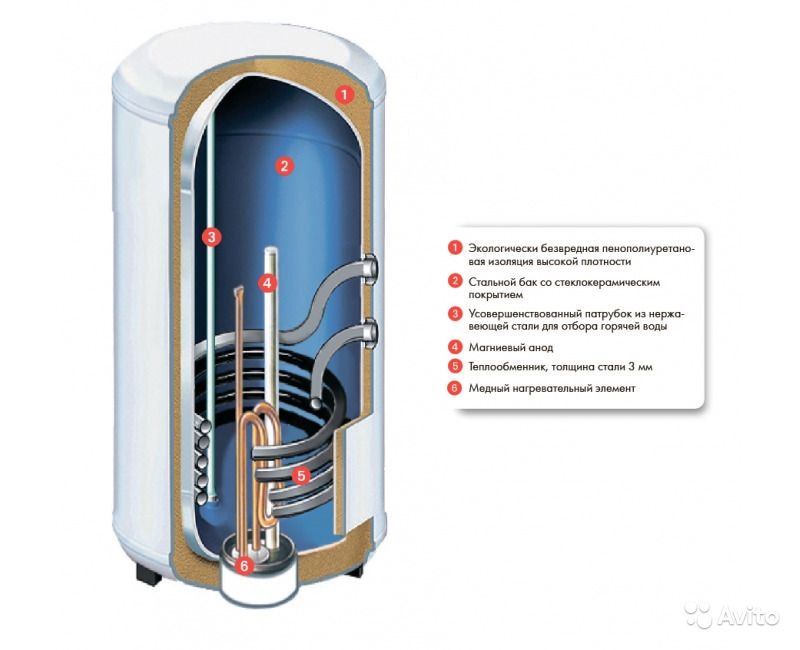

Assembly technology

We will describe in stages how to make an indirect heating boiler with your own hands - the whole range of work will consist of a sequential assembly of different parts of the structure.

Water heater tank

The volume of the tank where water will flow for subsequent heating depends on the needs of the homeowner: the standard consumption is up to 70 liters per household per day, so 200 liters will be enough for a family of 4 people.

The material of the tank should be chosen from aluminum alloy, as well as other non-ferrous metals that are not subject to corrosion, if finances allow - stainless steel. A gas cylinder is a good alternative, but the inner walls must be treated with a special primer, otherwise the hot water will have an unpleasant rotten smell.

At least 5 holes must be cut out in the tank body with your own hands: two from any side - they are designed for inserting the coil, at the bottom there are also 2 - for supplying water and a drain tap, at the top there is only one - hot water extraction.

Making a coil

This element, made of a copper pipe of small diameter, but thick-walled, can necessarily have different dimensions - it depends on the volume and height of the container. Experts say that for every 10 liters. water needs 1.5 kW of heat output of the coil.

You can use pipes from a different material to save money from your home budget, but always with excellent heat dissipation. In the manufacture, it is necessary to carefully monitor the formation of turns:

- in no case do they touch - there must be a gap between the turns;

- excessive efforts should not be made - this will make it very difficult to remove the finished product from a special mandrel;

- the number of turns is strictly calculated and depends on the dimensions of the tank.

For the mandrel, use a pipe of the required diameter or a round wooden log without knots. After manufacturing, the spiral is carefully covered with a protective heat-resistant varnish.

We insulate the structure

The tank from the outside is necessarily covered with thermal insulation to reduce losses and increase the efficiency of the product - this can be a special foam for mounting or another material with excellent thermal insulation properties, for example, foam.

It is fastened with wire, special ties or put on glue. On top of the insulation, the masters recommend strengthening foil sheets or using insulation with one foil side. For insulation, some craftsmen insert the boiler into a larger container, and fill the space between it and the inner walls with any kind of insulation.

final assembly

When all the details of the future design are prepared, then its assembly begins.

- The coil is installed in the center or along the inner surface of the tank, pipes are attached to the ends (soldering or welding).

- With a vertical arrangement, we weld the legs to the container, with a wall arrangement - special fastening loops.

- A heating element is welded to the bottom of the tank.

- A cover is installed on top and welded to the body.

- The coil is connected to the circuit of the autonomous system according to the selected scheme.

- We connect the cold water supply pipes and the hot water outlet line.

- We connect the water heater to the domestic water supply system.

For consultation, so that there are fewer questions, we advise you to watch this video:

Then you just have to enjoy the abundance of hot water without significant financial investments.