- Possibility to connect a boiler

- Heater power

- Features of layer-by-layer heating of a liquid

- Advantages and disadvantages

- So what to choose anyway?

- Power supply type: non-volatile or not

- Heating principle: flow or storage

- Rating TOP-5 wall-mounted single-circuit boilers

- MORA-TOP Meteor Plus PK24SK

- BAXI ECO Four 1.14 F

- Viessmann Vitopend 100-W A1HB001

- Buderus Logamax U072-24

- Protherm Panther 25 KTO

- Double-circuit gas boiler: operating modes

- About combustion chambers of thermal devices

- Kinds

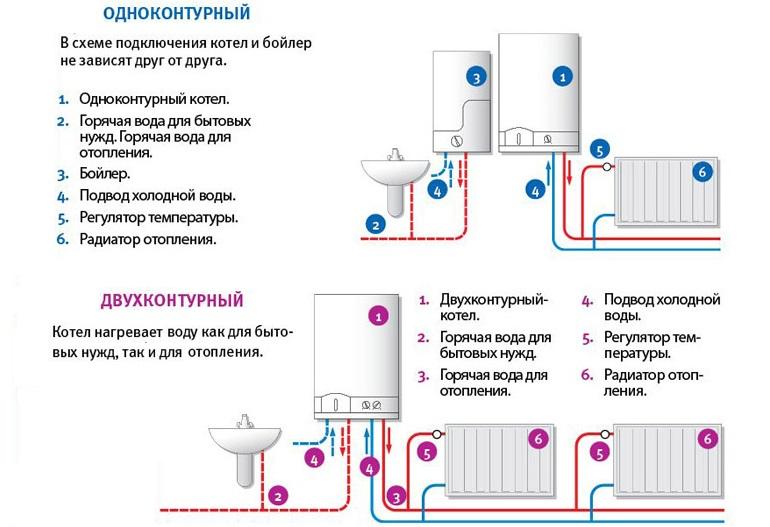

- Features of a single-circuit boiler

- How to choose a boiler?

- Criteria for a competent choice

- Installation requirements

- Advantages of single-circuit boilers

- Connecting gas equipment

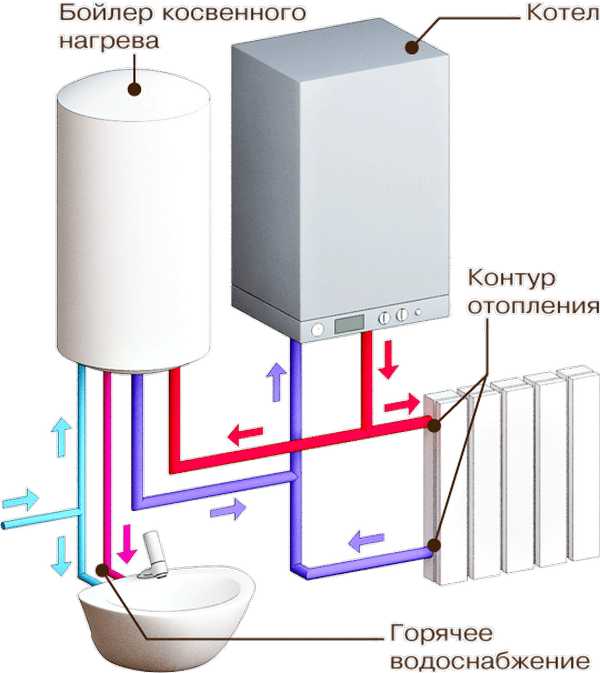

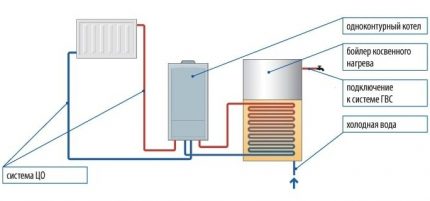

Possibility to connect a boiler

A boiler for a gas boiler is a storage tank, inside of which a heat exchanger is placed. This model, in fact, is a double-circuit, as it has a connection for both the heating system and the hot water supply.

Double-circuit models have a built-in flow-type water heater, which single-circuit models cannot boast of. The advantage of a gas boiler with a built-in storage tank is that there is no need to create an indirect heating boiler.In addition, water is heated much faster than in single-circuit versions and does not reduce the efficiency of the heat carrier for heating.

A separate boiler can also be connected to double-circuit boilers to provide more hot water. Such equipment belongs to the technique of layer-by-layer heating. You can also buy a double-circuit gas boiler with a built-in indirect heating boiler. Such devices are combined with the boiler, although separate devices can be purchased. Depending on what is best for you: ease of transport and installation or compact placement, you can choose a separate or adjacent model.

If a single-circuit boiler is already installed, a special layer-by-layer heating boiler can be purchased for it, which is equipped with a flow-through liquid heater. If you need to save space in the apartment, you can opt for a single-circuit boiler with a built-in indirect heating boiler.

Heater power

Depending on the power of the gas burner, the flow rate of the liquid in the instantaneous water heater varies. Also, the rate of water heating depends on the design features of the heat exchanger. A feature of heating the liquid is its short contact with the heat exchanger, therefore, in order to warm the coolant to the desired temperature, a lot of heat is needed. To increase the performance of the heating element, it is necessary to increase the burner power and increase the gas flow.

In order for the water temperature in the shower to be 40 degrees, you will have to adjust the burner to a generated power of 20 kW, but if the burner is not designed for such power, then it is impossible to take a warm shower. The bath also requires a powerful burner, as the water must be heated quickly in large volumes for a normal set.

Most boilers have a capacity of about 20–30 kW, and 10 kW is enough to heat a house. Thus, all the difference can be used to provide domestic hot water. For hot water boilers, modulating burners have been developed that cover a range from 30 to 100 percent of the maximum output.

However, even the weakest boilers have excess power, which leads to frequent switching on and off of the burner. This process leads to rapid wear of equipment and increases fuel consumption. These problems make buying a more powerful boiler model to provide more hot liquid an unprofitable and unjustified solution.

That is why in dual-circuit models a boiler is provided that contains hot water, which allows it to be given in large volume while taking a shower or bath. Thus, layer-by-layer heating of water is optimal: it ensures the normal operation of the equipment and does not lead to burner wear.

Features of layer-by-layer heating of a liquid

Features of layer-by-layer heating of a liquid

In double-circuit models with stratified heating, water is heated using a plate radiator or a tubular water heater. The presence of an additional heat exchanger is beneficial in condensing models, as it provides additional heat from the combustion products. The liquid enters the boiler with layer-by-layer heating already heated, which allows you to quickly prepare the hot liquid in the required volume.

Floor double-circuit gas heating boilers with a boiler have a number of advantages.

- The flow of hot water into the upper layers of the boiler allows you to take a shower 5 minutes after turning on the heat exchanger. In contrast, boilers with an indirect heating boiler provide longer heating of the liquid, since time is spent on the convection of warm water from below the heat source.

- The absence of a heat exchanger inside the storage tank allows you to collect more warm water for domestic needs. The performance of such boilers is 1.5 times higher than in models with indirect heating.

Advantages and disadvantages

Single-circuit boilers are functional devices that provide heating for a house of any size, and the distance from the heat exchanger is unimportant.

The advantages include:

- high reliability due to a simpler design;

- the ability to connect additional equipment;

- ease of installation and maintenance;

- high degree of maintainability;

- availability due to lower price.

However, for heating single-circuit boilers, you have to additionally buy a boiler, which leads to the cost of its maintenance. Devices are standardly produced with relatively low power.

Double-circuit boilers take up less space because they are equipped with a built-in boiler. The advantages of this type of model include:

- economical fuel consumption, so the equipment pays off almost within a year;

- an effective security system, especially in models equipped with electronic filling;

- the presence of a flow heat exchanger, which allows you to provide a large amount of water for domestic needs.

However, aggregates have their drawbacks and limitations. For example, they are not designed for houses that have many points of water consumption.Such devices simply cannot provide them all with liquid of the same high temperature.

So what to choose anyway?

Turbocharged models use air from the street, which enters through a coaxial tube. Unlike atmospheric boilers, they can be installed in the kitchen, bathroom and other residential areas. This is the best option for heating an apartment or an oversized house.

When choosing between a turbocharged and atmospheric boiler, several factors speak in favor of the first:

- no need to allocate an area for a boiler room, which attracts owners of small houses;

- can work completely autonomously;

- Ideal for servicing small objects.

Atmospheric boilers are installed when:

- you need to burn a large building;

- the possibility of using several types of fuel is necessary;

- there is no possibility of connection to the mains.

In private houses equipped with a brick chimney, it must be lined with an acid-resistant pipe. If this is not done, then the resulting condensate will destroy the pipe.

The efficiency of atmospheric units is lower than that of turbocharged ones. They are heavier, often requiring a reinforcement device or an additional foundation in the boiler room. However, they are more reliable in operation and are much less likely to upset breakdowns.

In the atmospheric boiler (convection) for burning gas, an open chamber is provided. This model is connected to a standard chimney. The air is taken from the room where the equipment is installed.

High demands are placed on the installation of equipment with an open combustion chamber. Atmospheric-type boilers are not allowed to be installed in houses whose number of storeys exceeds 9 levels.

In a turbocharged boiler, the combustion chamber is hermetically sealed. The collection of waste is forced, the pressure is pumped by a turbine or a fan. The air from the room where the equipment is installed is not burned.

According to the data sheet, the boiler can be located in the bathroom, kitchen, bedroom, next to the meter. It can even be hidden in a specially equipped niche. Smoke extraction is carried out through a coaxial chimney.

Conclusion: the main difference between an atmospheric gas boiler and a turbocharged one is the forced intake and exhaust of exhaust air, which is required as a source of oxygen for the burner to operate.

Power supply type: non-volatile or not

The principle of operation of a volatile boiler is as follows: the installed automation detects, using sensors, the activation of the DHW equipment or a decrease in temperature in the heating circuit and turns on the heating.

The coolant, passing through the heat exchanger, is heated to the required temperature and is fed into the heating or hot water circuit using a circulation pump.

It is clear that a volatile device will consume electricity. To reduce its consumption, it is better to choose models with an A ++ energy class. But, in addition to energy consumption, it is necessary to take into account the cost of repairs, replacement of spare parts, automation.

For example, breakdown of electronic boards is a fairly common occurrence, repairs are expensive, and replacing a part with a new one will cost almost half the cost of the boiler itself.

Volatile boilers are more technologically advanced, they maintain the temperature in a certain mode, allow you to save more gas

But non-volatile models can be called the most adapted to the conditions when the electricity is turned off, and energy fluctuations make you worry about the integrity of the automation.

Heating principle: flow or storage

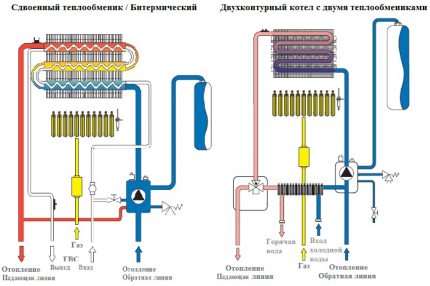

The flow principle of heating can be carried out by two types of heat exchangers:

- separate;

- bithermic.

Both of them have advantages and disadvantages, so the choice may depend only on the equipment buyer and his preferences.

A boiler with a separate heat exchanger has a primary (intended for heating) and a secondary (used for heating water) heat exchanger. The secondary heat exchanger has a built-in circuit that serves to heat water, which is heated by taking heat from the heating circuit coolant.

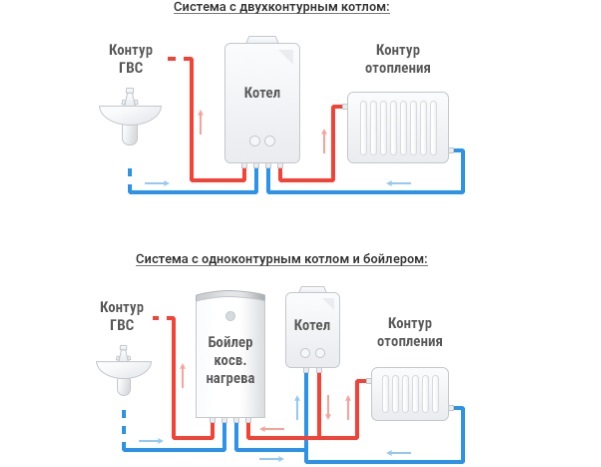

This type of boiler cannot simultaneously operate in heating and water heating modes: as soon as one system is put into operation, the work of the second one is suspended.

The disadvantage of flow-through double-circuit floor-standing boilers is the overuse of cold water, which will have to drain before warm water begins to flow into the tap. In addition, when using water from two or more points at the same time, the pressure in the hot water system will be uneven, as well as the temperature of the water in the taps (+)

In bithermic heat exchangers, water is heated by a burner located in a tube that runs inside the main heat exchanger. In such equipment, water heats up much faster. Such boilers are more compact and cheaper.

A significant disadvantage of bithermic boilers is the temperature drop in the hot water supply. This leads to the fact that immediately after opening the tap, very hot water can flow.

For those houses where consumption is not so high, the operation of double-circuit boilers is quite capable of providing the minimum need for warm water. But if consumption is planned in large quantities, it is better to provide a more powerful option - a boiler with a boiler connected, in which a certain supply of hot water will be accumulated (+)

Double-circuit floor-standing gas boilers with a built-in tank, unlike flow models, can provide water to the fullest. The volume of tanks varies from 25 to 60 liters. For heating large volumes, devices with high power are used. You can increase productivity even more with the help of boilers combined in cascades.

Rating TOP-5 wall-mounted single-circuit boilers

Consider the most popular and popular models of wall-mounted single-circuit boilers:

MORA-TOP Meteor Plus PK24SK

Convection type gas boiler designed and manufactured by Czech engineers.

The power of the unit is 24 kW, which corresponds to 240 square meters. m. of serviced area. The boiler has electronic control, multi-stage protection against external influences or failures in the operation mode.

Main parameters:

- Efficiency - 90%;

- coolant temperature (max) - 80 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.6 m3/hour;

- dimensions - 400x750x380 mm;

- weight - 27.5 kg.

Models of this power are the most in demand, since they roughly correspond to the needs of medium-sized private houses.

BAXI ECO Four 1.14 F

Italian convection gas boiler. The power of the unit is 14 kW, which is suitable for rooms up to 140 sq.m.

It can be apartments, offices, small houses. The unit has a closed combustion chamber that allows you to install it in the kitchen.

Consider its characteristics:

- Efficiency - 92.5%;

- coolant temperature (max) - 85 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 1.7 m3 / hour;

- dimensions - 400x730x299 mm;

- weight - 31 kg.

Italian heating engineering is famous for its quality, but the prices cannot be called too affordable.

Viessmann Vitopend 100-W A1HB001

The quality of German technology has long been the benchmark for all manufacturers. The Vitopend 100-W A1HB001 boiler confirms the prevailing opinion.

Its power is 24 kW, the most demanded value for heating a house of 240 square meters. m. The turbocharged burner does not spread smoke odors, so installation in the kitchen or other interior areas of the house is possible.

Options:

- Efficiency - 91%;

- coolant temperature (max) - 80 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.77 m3/hour;

- dimensions - 400x725x340 mm;

- weight - 31 kg.

The unit can be switched to liquefied gas, for which you will have to change the set of nozzles and change the settings a little.

Buderus Logamax U072-24

High-quality heating boiler from a well-known German manufacturer.

The company is a "daughter" of the Bosh concern, which eloquently indicates the quality and capabilities of the unit. The power is 24 kW, the heated area is 240 square meters. m.

Main characteristics:

- Efficiency - 92%;

- coolant temperature (max) - 82 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.8 m3/hour;

- dimensions - 400x700x299 mm;

- weight - 31 kg.

The unit is equipped with a copper heat exchanger in the form of a coil. This increases heat transfer and makes the boiler more durable and stable.

Protherm Panther 25 KTO

There are two modifications of this model - from 2010 and 2015.

They differ little from each other. in a more recent design, some shortcomings have been eliminated and power has been slightly increased. It is 25 kW, allowing you to heat houses of 250 square meters. m.

Boiler parameters:

- Efficiency - 92.8%;

- coolant temperature (max) - 85 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.8 m3/hour;

- dimensions - 440x800x338 mm;

- weight - 41 kg.

Equipment from Slovakia enjoys well-deserved success with buyers.

A distinctive feature are the names of the series. For example, all series of wall-mounted boilers bear the names of animals from the cat family.

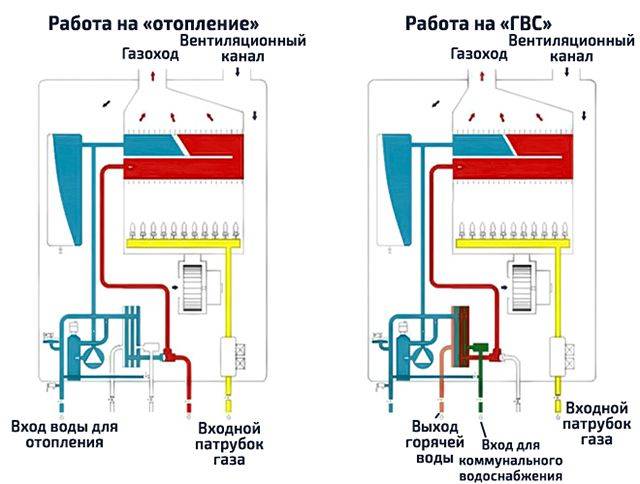

Double-circuit gas boiler: operating modes

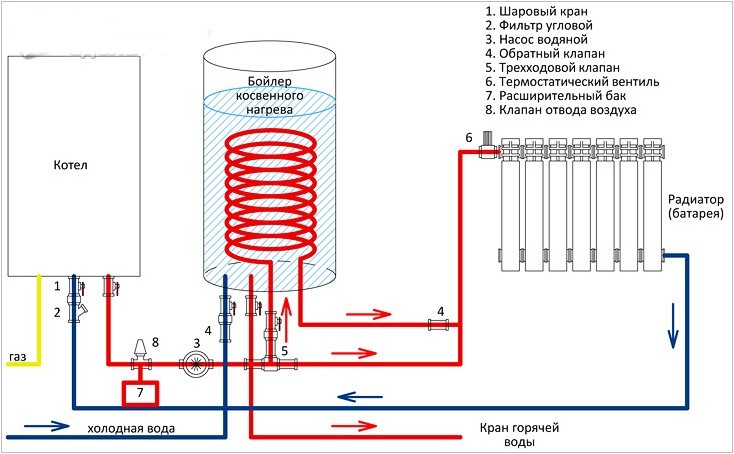

Image 4. Space heating work: A - heating supply line, B - cold water inlet, C - hot water outlet, D - heating return line, 1 - heat exchanger, 2 - shut-off screws, 3 - three-way valve.

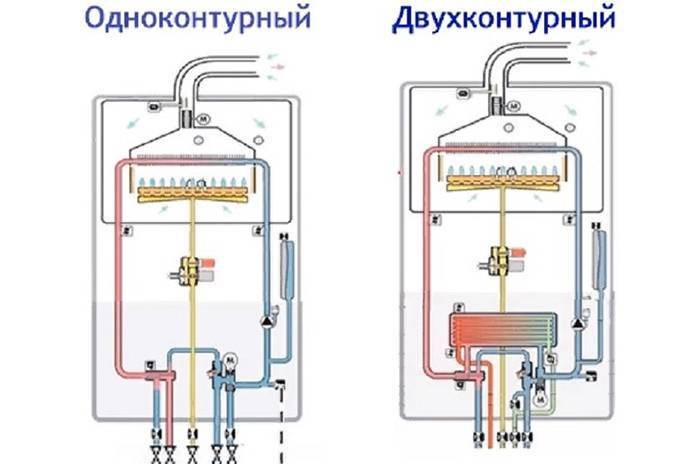

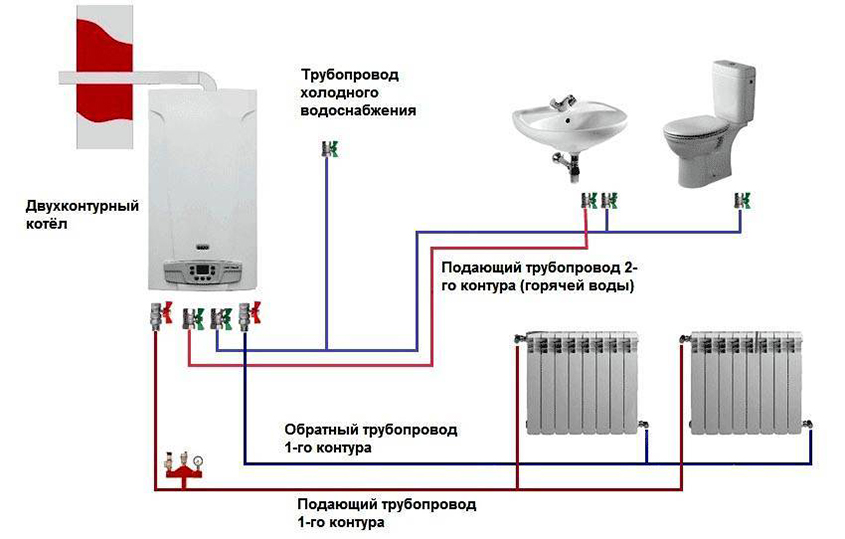

This type was originally designed for space heating and heating sanitary water. Structurally, they differ in the number of heat exchangers.

In one of the options, the boiler has one heat exchanger, through which either the heat carrier of the heating system or sanitary water can be pumped. Work on space heating is shown in image 4, and in DHW mode on image 5. In these diagrams, the heating supply and return lines (A and D, respectively), the inlet of cold and hot DHW water (C and B, respectively) are indicated.

The heat exchanger in this scheme is called biothermal. Sanitary water circulates through its inner pipe, and the heat carrier of the heating system circulates through its outer pipe.The pump constantly pumps the coolant, but during the withdrawal of sanitary water by any consumer, the main circuit is disconnected from the heating system, and the coolant circulates only inside the boiler, heating the sanitary water.

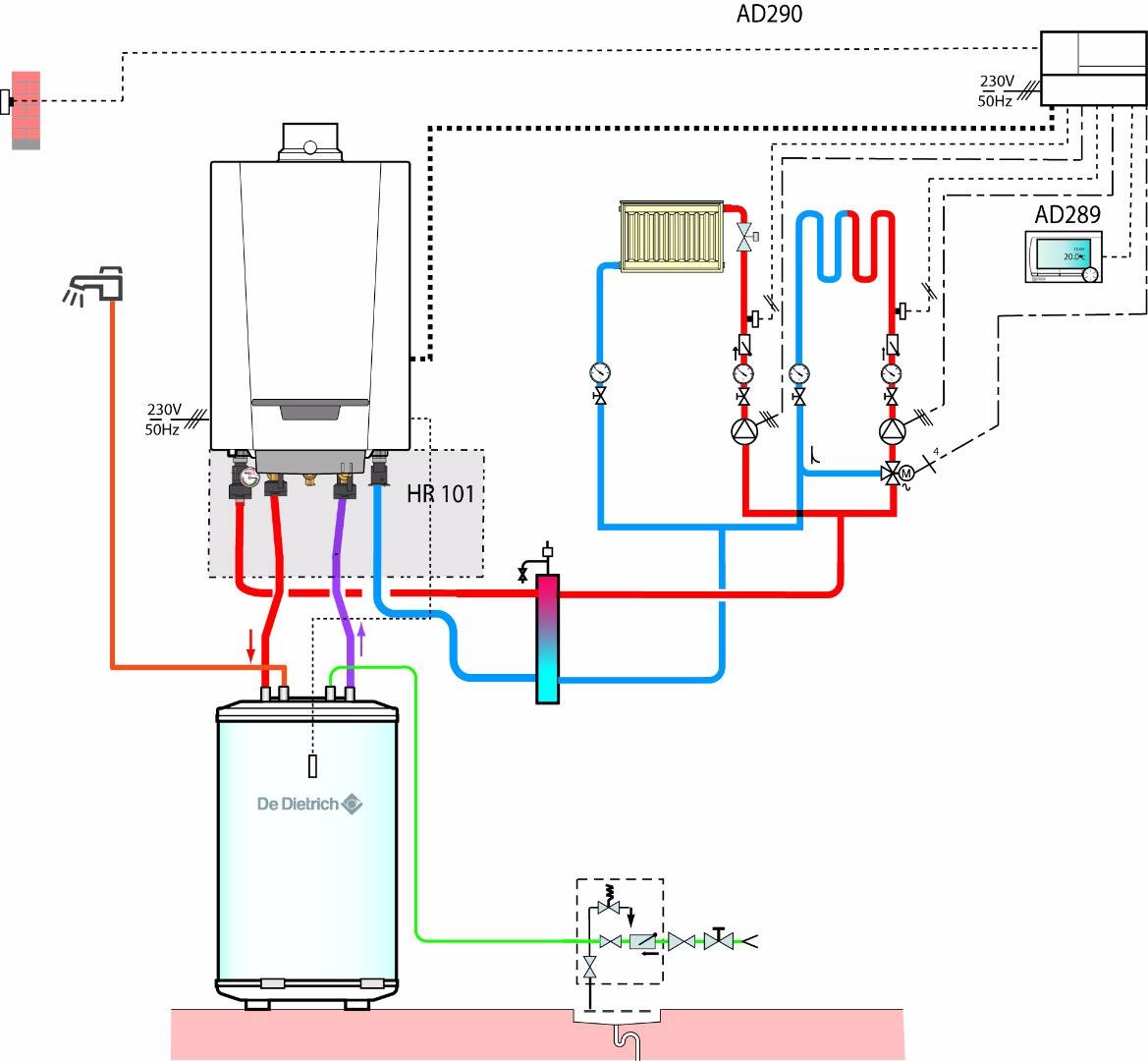

In another embodiment, the apparatus has two heat exchangers, primary and secondary. This option is shown in figure 6. The primary heat exchanger (5) can be connected via a three-way cock (3) to the heating system (inlet D, outlet A) or to a secondary heat exchanger (4), inside which the DHW circuit passes (inlet C, outlet B) .

Image 5. Work on space heating in DHW mode: A - heating supply line, B - cold water inlet, C - hot water outlet, D - heating return line, 1 - heat exchanger, 2 - shut-off screws, 3 - three-way valve, 4 - secondary heat exchanger.

What is the advantage of two heat exchangers?

If in the first variant, hard water initially circulated in the main circuit, then scale will form in the entire system, including in the external pipes of the bimetallic heat exchanger, but over time it will not increase.

Hard plumbing water, flowing through the internal pipes of the heat exchanger, will eventually bring the hot water supply out of working condition. To replace the heat exchanger, you will either have to turn off the heating system, or refuse to use hot water until the end of the heating season, when it will be possible to turn off the gas and start repairs.

If there are two heat exchangers, it is possible to replace the DHW heat exchanger without interrupting the heating of the room, that is, having two nights of heat transfer is better than one.

After analyzing the design features of floor and wall double-circuit and single-circuit boilers, you can decide which boiler to choose for arranging your own home.

About combustion chambers of thermal devices

Image 1. The chimney only works if there is a fan that provides it with artificial air exchange.

Combustion chambers are of open and closed type.

The air (more precisely, oxygen) necessary to maintain combustion enters the open chamber from the room, and the combustion products are removed from it through the chimney. This process occurs naturally due to draft in the chimney.

Therefore, in the room where the boiler is installed, it is necessary to provide natural ventilation, ensuring a continuous supply of sufficient air for combustion. Failure to comply with this requirement can lead to a lack of oxygen in the room and even poisoning people with carbon monoxide.

Therefore, to ensure safe operation, it is advisable to install such a boiler in a separate room (boiler room) equipped in accordance with safety requirements.

Basic requirements for ventilation and chimney.

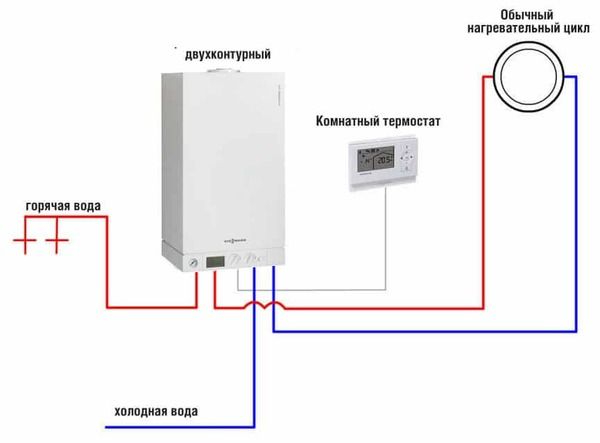

Image 2. Connection diagram for a double-circuit heating boiler.

- For the chimney, two holes must be provided in the wall: one (upper) for the outlet pipe, and the second, at least 25 cm lower, for cleaning it.

- The room must be equipped with a ventilation grill mounted in the wall or in the front door. The grate in the outer wall must have an area of 8 cm2 per 1 kW of boiler power, and if air is supplied from the interior, then at the rate of 30 cm2 / kW.

- The room must necessarily have communication with the general ventilation system of the building.

- The chimney must be completely isolated from the boiler room.

- The cross-sectional area of the chimney must in no case be smaller than its outlet from the boiler.

- The chimney must rise above the roof ridge.

The closed-type chamber is connected to a specially designed chimney, consisting of two pipes inserted one into the other (coaxial type). Through the inner pipe, the combustion products are removed to the outside, and through the outer pipe, fresh air enters the combustion chamber. Image 1 shows the arrangement of such a chimney. This design works only if there is a fan that provides artificial air exchange, that is, the system turns out to be dependent on electricity. This is its essential shortcoming. But there is also an advantage: as a result of heating the air with the heat of the combustion products, the efficiency of the boiler increases, and the temperature of the exhaust gases decreases. Since an increase in efficiency is possible only due to more efficient combustion of fuel, such a boiler pollutes the environment less.

Kinds

There are several design options for floor single-circuit boilers. They differ from each other in various ways.

Combustion chamber type:

- atmospheric (open). The air directly surrounding the boiler is used, and the smoke is removed by natural draft. Such models are connected only to the central vertical chimney;

- turbocharged (closed).To supply air and remove smoke, a coaxial type chimney is used (a pipe in a pipe), or two separate pipelines that perform the functions of air intake and supply to the boiler and flue gases.

According to the material of the heat exchanger:

- steel. The most common option used on inexpensive models.

- copper. The serpentine design increases the path of the liquid passing through the heating zone. Such nodes are installed in expensive models of top manufacturers;

- cast iron. Are established on powerful and massive units. Cast iron heat exchangers demonstrate high performance, efficiency, and are capable of developing large unit power values. They are used for units from 40 kW and above.

Heat transfer method:

- convection. Conventional heating of the coolant in the flame of a gas burner;

- parapet. Able to do without a heating circuit, being a kind of analogue of a conventional stove;

- condensation. The coolant is heated in two stages - first in the condensation chamber, from the heat from the condensing flue gases, and then in the usual way.

NOTE!

Condensing boilers are able to fully work only with low-temperature systems (warm floor), or with a temperature difference in the street and in the room of no more than 20 °. For Russia, these conditions are not suitable.

Features of a single-circuit boiler

Based on the name of the model, it can be understood that we will be talking about the heating device that operates due to one coolant circuit. Of course, if there is a desire, then you can easily attach an additional device that allows you to exchange heat to heat water.As for the very principle of operation, these are easy-to-understand actions. To begin with, the fuel enters the furnace, where it is heated due to the heat carrier. It, in turn, provides circulation directly inside the structure. Such manipulations arise due to the temperature difference and the capabilities of the pump intended for this.

How to choose a boiler?

When choosing a gas boiler, three main parameters are analyzed: all technical characteristics, a reliable and trusted manufacturer, and cost. Be sure to analyze the room in which the equipment will be installed

First of all, you should pay attention to the power and functionality of the equipment.

Criteria for a competent choice

Important Features:

- Performance. The calculation is made after analyzing the area of \u200b\u200bthe room and possible heat loss.

- The number of circuits served. If space heating and hot water supply are required, a double-circuit boiler with a pair of heat exchangers is chosen. If hot water is not needed, then a single-circuit boiler is sufficient. The new double-circuit heaters have a Winter/Summer mode.

- The material from which the heat exchanger is made. For the primary circuit, steel or cast iron is used, and for the secondary circuit, copper and aluminum. The service life, thermal conductivity and cost depend on the material.

- Automation. It is provided in a double-circuit turbocharged boiler. There are two types: standard and weather-dependent. The new models have a built-in remote control unit. The model can be additionally equipped with a remote notification. Gas consumption depends on the number of automation functions.

The best models of gas boilers are produced by German companies.In second place in popularity are Italian and French products. Russia has also begun to supply competitive low-cost boilers.

The most reliable boilers are from Baxi, as well as Vaillant Turbo TEC, Viessmann, Vaillant Atmo TEC. In second and third place are models from Neva Lux and Arderia. Korean products from Navien, Hydrosta, Daewoo and Kiturami have low reliability and build quality.

Installation requirements

The highest requirements are placed on the installation of atmospheric boilers. Installation and connection is carried out only by representatives of the gas company, with which an agreement is concluded for further maintenance and inspection of equipment. All connecting nodes must be made perfectly, extremely tight.

Installation of a turbocharged boiler can be done independently. But keep in mind that the slightest violation will lead to a decrease in performance, and the manufacturer will refuse warranty service.

Turbocharged models are not so demanding, but hand-wiring is also not particularly recommended. Especially if, through the fault of an inexperienced performer, water enters the gas pipeline

There is an important condition - the flawless removal of chimney channels to the street

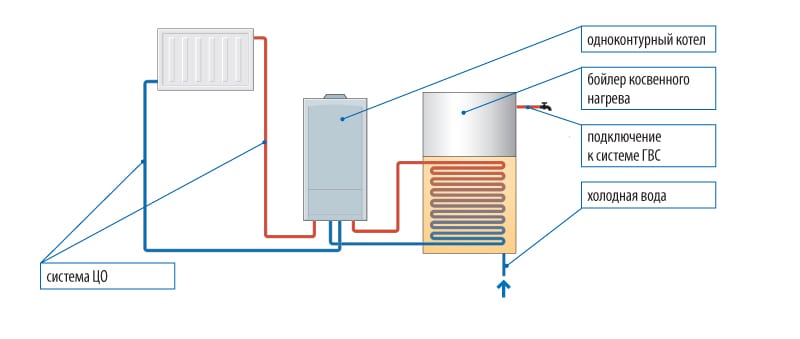

Advantages of single-circuit boilers

Its main advantage is that the price of one unit without additional elements is much less than the cost of the second type. This is due to the simplicity of the structure. True, this plus turns into considerable difficulties, because you need to buy additional elements for strapping and look for a specialist who can connect them.

If we consider the advantages of the boiler only in terms of the heating system, then it no longer has any advantages.They appear when an indirect heating boiler is connected to it. The additional knot becomes part of the harness. At the same time, it is turned on so that, if necessary, the coolant can move around it. The positive aspects of a single-circuit boiler with a boiler:

- Independence of work from pressure in a water supply system.

- Constant supply of warm water. The good news is that the boiler allows you to circulate heated water: after opening the tap, hot liquid immediately flows.

- You can use hot water without restrictions (especially when the taps in the kitchen, bathroom and other rooms open at the same time).

Connecting gas equipment

Gas service specialist at work.

First you need to contact the BTI and make changes to the plan of the house with the appropriate notes and designation of the boiler room. Changes are also made to the technical passport of the object.

We contact the bureau of technical inventory at the place of residence.

Then you need to contact the gas service and apply for connecting the boiler. You will need to provide a technical passport of the device.

After that, it is necessary to install the equipment and install the entire system, except for connecting the gas line. The gas meter must also be installed and sealed.

The connection is made by a gas service specialist.

Now we invite a gas service specialist who connects the boiler to the main. At the same time, we submit an application to the inspector for putting the equipment into operation.

Finally, the inspector checks the correctness of the connection, draws up permits and, if there are no complaints, lets gas into the system.

The inspector checks and puts the boiler into operation.