- Natural wood materials used for exterior cladding of a wooden house

- clapboard

- timber imitation

- Block house

- planken

- Material selection rules

- Siding for exterior cladding of a wooden house

- Vinyl siding

- metal siding

- cement siding

- Important options for choosing a skin

- Interesting ideas

- Decor of curved and frame facades

- Provence

- Scandinavian

- High tech

- European style

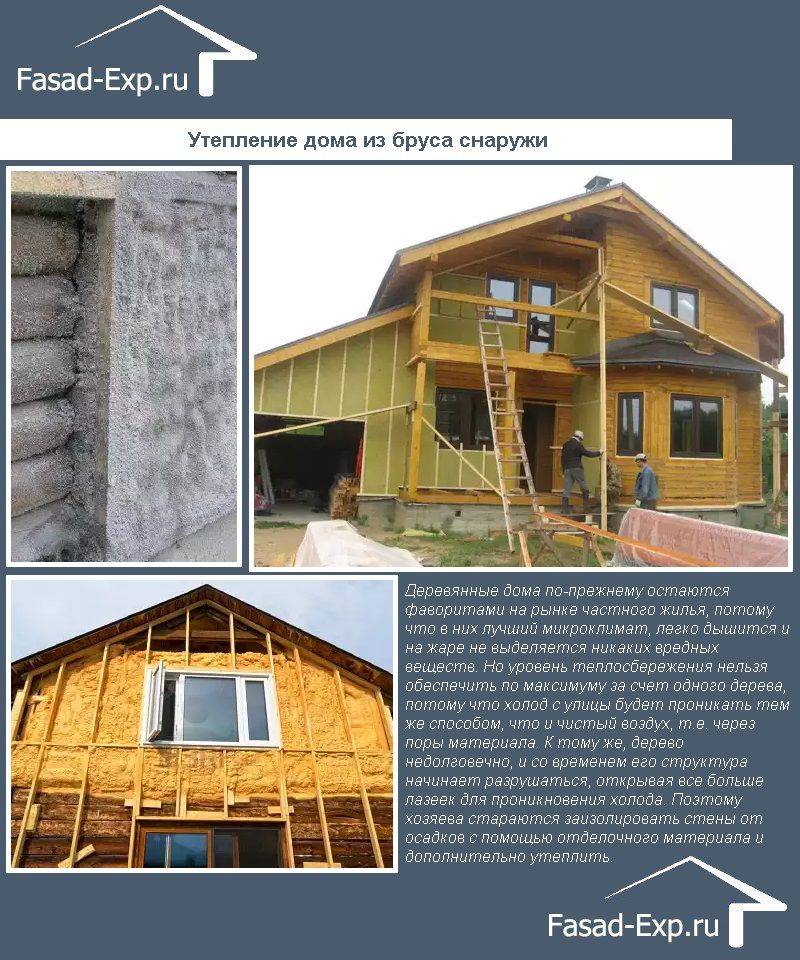

- Features of a wooden house

- Wall cladding with facade bricks

- Photo gallery: brick cladding

- Video: how to brick a wooden house

- What do you usually pay attention to when choosing a finish?

- Requirements for facing facade materials

- Options for the exterior of a wooden house

- What is the outer casing for?

- Conclusions and useful video on the topic

Natural wood materials used for exterior cladding of a wooden house

When choosing than it is better to sheathe a wooden house outside, materials from natural wood inevitably come into view:

- lining;

- block house;

- timber imitation;

- planken.

All of them have obvious advantages as a natural material, but they also have the same disadvantages as any wooden product. This leads to the fact that in addition to the cost of purchasing the material, it is necessary to incur certain costs for finishing with antiseptics and top coats and paints.

clapboard

The cheapest and most technologically advanced type of natural wood sheathing is slats with profiled sides that form a tongue/groove connection. During installation, the lining is firmly and tightly connected and forms an almost monolithic surface.

For finishing, only dry lining is used, with a humidity not higher than 10 - 15%. If you use an insufficiently dried lining, then it will inevitably dry out and cracks will appear along the interface lines.

There are several standards for lining, its average dimensions are as follows:

- thickness - 12 - 40 mm;

- width - 76 - 200 mm;

- spike length - 4 - 5 mm;

- length - 2 - 6 m.

The installation of the lining is carried out in a horizontal position, starting from the bottom, with the spike up. If you install it upwards with a groove, then the water flowing down the wall will enter the lock and eventually destroy it and the lining itself. With proper installation and proper care, lining from the lining will last 10 - 15 years, and if it is impregnated with modern antiseptics, then even longer.

The advantage of this cladding is that it is cheap and easy to install. Any person who can hold a hammer and use a building level can cope with the installation.

timber imitation

It is the same prefabricated surface as the lining, but slightly different in appearance. It is also installed horizontally, only visible joints are practically invisible. After the final installation, it looks like a wall made of profiled timber. It is made from spruce, pine, cedar or larch, due to the resinous nature of these species, it is quite durable.

The material is produced in the form of boards with a length of 2 - 4 m, a thickness of 20 - 35 mm and a width of 105 - 175 mm.You can buy a solid board, cut from a single log, or spliced, glued under pressure from narrower slats. In terms of performance, both types are about the same.

Pros and cons are similar to lining. Imitation of timber wins only in appearance - the material is more modern and decorative.

Block house

Excellent finishing material, made in the form of boards with a semicircular outer side. In the assembled state, the material creates the appearance of a log cabin. Very decorative, durable and installation is not more complicated than lining. Compared to clapboard and imitation timber, a block house is more durable, holds heat better and is much more durable.

For the manufacture of lamellas, coniferous woods are used, in most cases pine and spruce. Impregnation with various stains, azures and glazing materials allows you to give the finish the look of any valuable wood species. When painting with oil or alkyd paints, most of the effect of using a block house disappears (in the case of imitation timber, this does not happen).

The block house is also distinguished by good thermal properties. Compared to previous materials, it keeps the heat in the house better and lets the cold inside worse. But the cost of sheathing this material is higher.

planken

Relatively new material in our latitudes. It is a facade board with beveled or rounded side edges. It is made from pine, larch or wood-polymer materials. The width of the board is in the range of 70 - 140 mm with a thickness of 15 - 20 mm, the bevel angle of the faces is 45 - 70. It is mounted on special fasteners in a spike or overlap.

Very suitable for installation of ventilated facades.As a rule, it is sold in the form treated with flame retardants and antiseptics, therefore it is resistant to biological pests and is safe in a fire sense.

In most cases, high-quality planken is impregnated with environmentally friendly products, but it will not be superfluous to check the certificate when buying. Cheap materials can be processed with toxic chemicals.

Material selection rules

When using insulating materials, it is important to maintain normal humidity in the room. To do this, there must be a decrease in vapor permeability from the inside to the outside.

Thus, moisture will leave the dwelling in a natural way. Failure to follow this rule can lead to serious problems. The appearance of condensation between the layers will create excellent conditions for the development of fungus and mold. The destruction will begin. And in cold weather, this condensate will freeze and expand, deforming your home.

Proper sheathing of the house will help maintain the optimum level of humidity in the house.

This rule only applies to wood. The rest of the materials have not very good vapor conductivity. This can be fixed in two ways.

- The first way is to fix the cladding directly to the facade wall. In this case, the inside of the wall must be equipped with vapor barrier material. Through it, moisture will not penetrate into the house, but will come out with the help of ventilation.

- The second way is to install a ventilated facade. This is a unique separating layer between the inner wall of the house and the exterior. Thanks to it, the air inside circulates freely, providing natural ventilation.

Ventilated facade reduces the negative impact of the environment on the walls of the house

Wait for the house to completely shrink before you start facing work. For each material from which the house is built, its own term:

- felled trees are planted for at least two years;

- rounded log - from 6 to 12 months;

- glued and profiled beams do not need shrinkage.

Siding for exterior cladding of a wooden house

Material specially created for finishing facades. It is produced in the form of lamellas of a special profile (“herringbone” or “ship”), with locks on the long side and special perforation for nail fastenings. The lamellas are interconnected by special latches and form a dense coating.

Siding is made from various materials:

- polymers;

- metal;

- cement chip materials.

The width of the slats ranges from 10 to 30 cm, and the length is 2 - 6 m. Like wooden facing materials, the siding is installed in a horizontal position with the profile arranged in such a way that rainwater will certainly flow down without getting inside the wall.

A variety of color schemes and ease of installation determined the exceptional popularity of siding in the cladding of various types of buildings - from residential buildings to industrial, commercial and public buildings. In addition to the lamellas themselves, a wide range of profile parts is produced - internal and external corners, cornices, connecting strips, etc.

The external texture of siding, regardless of the material of manufacture, usually imitates the natural pattern of wood. The slats are covered with a polymer coating or weather-resistant paint, which also have high strength - it is quite difficult to accidentally scratch the siding. All materials used for the manufacture of siding are highly weather resistant and practically unaffected by moisture.The service life of siding is several decades.

Compared to wood sheathing, siding has the advantage of being maintenance-free. From time to time it is enough just to wash it with clean water or any of the household detergents without abrasive additives.

When considering what material to sheathe a wooden house on the outside, this feature must be paid attention to. Varnishes and paints are not required

Having once paid for the material and installation, you can be calm for 15-20 years about the appearance and condition of the facades.

Vinyl siding

Vinyl siding is lightweight and does not require heavy support frames. It can be installed on any frame or panel house - it is enough to fix the rack frame on the walls.

Since this material is not capable of passing steam, its installation must be carried out only on a ventilated facade.

metal siding

Galvanized steel siding has become widespread only over the past few years. Profiled strips with locking joints with a width of 120 - 550 mm are covered with a layer of powder paint and polymer protection and are not inferior in strength and durability to roofing corrugated board.

The service life of such a coating exceeds 50 years. Metal sheathing is installed only on ventilated facades.

cement siding

Cement siding has also recently become widespread. It consists of wood fiber boards mixed with cement mortar and pressed into profiled panels. Production takes place at a high temperature, at which the cement is sintered and acquires some of the properties of ceramics.

Such siding is unusually durable, but it is heavy and requires a strong frame. The panels are produced in the form of primed products with different surface textures. They are designed for painting with special paints.

Important options for choosing a skin

It is necessary to make a decision on one or another method of sheathing a house with your own hands, based on its following parameters:

- The difference in the linear expansion of the building itself and the outer sheathing material. If they expand with different intensity during temperature changes, sooner or later the internal or external panels will crack. This will lead to destruction of the house.

- The level of vapor permeability of the outer material. It should be higher than that of the wall material. In this case, the vapors will come out. Otherwise, they will begin to settle on the walls of the house, which sooner or later will provoke fungus and destruction.

Between the casing and the walls of the house, it is desirable to lay a heater. It will increase the energy efficiency of decoration and the house as a whole.

Interesting: How to insulate walls so that there is no condensation

Interesting ideas

Facade decor is far from the last thing in the conditions of modern construction. It is necessary in order to hide existing defects and imperfections in construction work. The decor is also often used to update the appearance of a country house, its restoration and to achieve greater attractiveness. The structure can be given a Gothic, Scandinavian, Byzantine look. It all depends on the desires and design imagination. An important argument in favor of decorating the facade are some practical aspects. For example, insulation.

Currently, there are several of the most popular preferences for decorating the facades of private houses.

Decor of curved and frame facades

Due to the past years, there has been a noticeable increase in the demand for various curved and frame facades, for the manufacture of which high quality MDF is used. These materials can be well decorated as the walls of the building, and the corners of a country house. In addition, there are some developed technologies, following which you can install the facade of the house in accordance with any style and architectural direction that will emphasize individuality.

Provence

This style is the most preferred for adherents of such natural facing materials as brick, ceramics, stone. Predominantly the presence of light shades, in which the decor of the facade of the house is carried out. This finish is refreshed by some colorful, eye-catching panel with a ceramic tile base. You can also finish the facade using decorative plaster, overhead elements or paintings.

Scandinavian

The founders of this style are lovers of conciseness, the predominant absence of eye-catching decor and the presence of uniformity. Thus, the Scandinavian style of installation is aimed at visually increasing the space in size. This style is characterized by cladding materials such as wood, brick or stonework. Light and warm shades of colors and lack of contrasts suit the Scandinavian style.

High tech

This style is characterized by a modern origin, focuses on the use of various modern building technologies, suggesting maximum convenience. High-tech style is characterized by extensive use of glazing in combination with different geometric shapes.

European style

The world architectural art is dominated by a considerable number of very different styles of decoration, including characteristic features from the Gothic and Byzantine trends. Both in Western countries and in Russia, Gothic styles and decorations that came from the Middle Ages are especially popular and in demand. Popular is the tendency to combine the Gothic style with any other. This style is characterized by difficulties in the installation of the facade.

In addition to the above styles, there are others, each of which has its own characteristics and practical aspects, namely:

- avant-garde;

- country;

- colonial;

- classic;

- minimalism.

Very interesting and original design solutions can be obtained as a result of the correct combination of two or more styles of facade decoration. Today, there is an opinion among designers that the most original and unusual design can be obtained by combining a modern "chalet" with some additions to the classic style.

For information on how to make a wooden house sheathing with siding, see the video below.

Features of a wooden house

With all its wonderful qualities, a wooden house has drawbacks that are caused solely by the properties of the wood itself.

Wood is the only basic building material that is combustible.Therefore, the rules for laying internal electrical networks are very strict. Cables or wires can be mounted either in an open way, using non-combustible gaskets or mounting on insulators, or inside metal pipes that reliably locate the wiring from the wooden walls. Therefore, the second method is the only one that allows you to carry out hidden laying of electrical circuits inside the cavities of the frame or in the free space that forms the crate between the main wall and the skin.

Open wiring looks good only in a retro-style interior. Source sv.decoratex.biz

The walls in a wooden house, unlike brick or building blocks, are characterized by significant shrinkage, which is caused by changes in the size of the material itself during the drying process. Of course, for glued laminated timber, it is insignificant, but in other cases it is recommended to start interior decoration after a year.

This factor, plus the susceptibility of wooden structures to changes in air humidity, does not allow "directly" cladding walls with stone or ceramic tiles. Therefore, before finishing the walls in a wooden house inside, it is necessary to prepare an even base that would be stable under any humidity conditions.

The same need arises if they want to use decorative plaster or wallpaper in the interior of a wooden house. Therefore, for such a finish, sheathing of internal walls with sheet materials that are resistant to changes in humidity is used.

Wall cladding with facade bricks

Brick cladding of a wooden house is carried out only after strengthening its foundation. However, it is also necessary to take into account the size of the cornice overhangs available on the house.If they have a width of more than 35 centimeters, then you can proceed to facing the building with bricks. If the overhangs are smaller, then such work does not make sense, since the facade brick wall will constantly be exposed to moisture.

Brick cladding will give the old house a modern look and keep it warm.

- Facade decoration of a wooden house is made in the form of a brick wall, which has some distance from the main surface of the building. The finishing wall must be connected to the main wall with flexible joints. They are made in the form of anchors made of polymers or galvanized wire. This allows the finishing masonry to maintain its position during seasonal ground movements.

- Anchors are installed evenly over the area of \u200b\u200bthe walls in the amount of 4 pcs. per sq. meter. In places of windows and doorways, additional anchors are installed along their perimeter. The anchor is fastened to a wooden wall by driving its hard end into a tree, and the other end is fixed with mortar in a brick lining.

- Before starting the laying of the facing wall, it is necessary to cover the foundation with a layer of roofing material. Laying of facade bricks starts from the corner of the building. To ensure the evenness of the masonry, a cord is stretched, and the horizontal laying of the bricks is checked by a level on each of its rows. The further quality of the wall depends on the quality of the construction of the first row.

Photo gallery: brick cladding

Important! It should be borne in mind that for free circulation of air between the walls in the lower part of the masonry, vertical seams through two bricks are not filled with mortar. Holes are obtained, called "vents"

A gap of about a centimeter in size is also left under the roof. So way the facade becomes ventilated.

Video: how to brick a wooden house

Finishing materials decorate a wooden house, preserve it, protect it from adverse effects. Manufacturers are constantly developing finishing materials of even higher quality. However, even the latest finish will not protect the house if the installation technology is not followed exactly.

What do you usually pay attention to when choosing a finish?

It's nice when the owners of wooden houses have a choice of materials for its decoration. However, the wide range of options offered by manufacturers makes it difficult for buyers to choose the most suitable finishing material.

First of all, the owner of the house must decide - for what purpose he will perform the decoration. It will only decorate the house, hiding the shortcomings of its appearance, or at the same time perform the function of an insulating element. It is also necessary to take into account the climate of the region where the house is located. How often does it rain there, how much snow falls, what are the minimum and maximum air temperatures.

All these factors should be decisive when choosing a material.

It is equally important what means the owner of the house has. It must be borne in mind that high-quality home decoration cannot be cheap, but choosing the right option from the materials offered by manufacturers is quite realistic.

Here is what the owners of the houses who completed their decoration write about the selected materials.

Requirements for facing facade materials

So that dampness does not appear in the house, it is comfortable and warm, and the house looks aesthetically pleasing from the outside, the cladding materials must meet certain requirements.

Facing the house is most often carried out in parallel with its insulation.

Based on them, and it is worth choosing the right option. So, the lining should have the following qualities:

- have low thermal conductivity to keep warm inside the house;

- have vapor permeability - no condensation should form inside the insulation layers;

- differ in moisture resistance - do not absorb or retain moisture inside the material;

- have absolute or increased heat resistance - the skin must withstand high temperatures, under their influence not be deformed and not ignite;

- have inertness to chemical influences - do not change their characteristics when such substances get on it;

- be protected from the influence of microorganisms, not serve as a breeding ground for insects and rodents;

- do not decompose and do not lose physical qualities under the influence of ultraviolet rays.

In order for the sheathing to be effective in all matters, it is necessary not only to securely attach decorative material to the walls, but, following the technology, cover them with a whole system of layers, each of which will play its role.

Requirements for facing facade materials

There are two main systems for home insulation, and the choice will depend on what material is planned to be used for decorative finishing and on the insulation used. In one of their systems, the insulation is attached directly to the wall with glue, in the other - along the created crate.

Options for the exterior of a wooden house

The choice of finishing material depends entirely on the taste preferences of the owner of the house and the aesthetic goals pursued. There are two ways in which you can move forward. The first is to preserve the appearance of a real wooden house and give it a well-groomed appearance. The second implies more modern exterior and finishing solutions, both color and texture, which will not be connected with wood in any way. So, let's look at the most popular ways to give this or that appearance to the house:

-

Wooden lining. Such material is well suited for recreating the wooden essence of the house. In appearance, it is a wooden flat board, which can be betrayed in various shades. Such a finishing material is easily mounted using special spikes that connect the boards along the length. It is environmentally friendly, durable, has heat and sound insulating properties. The disadvantage of wooden lining can be called susceptibility to various insects, which makes it necessary to cover this material with a special protective agent. Also, this finish must be tinted at intervals of about once every three years;

- Block house. A very beautiful finish, which can be called a kind of wooden lining, imitating a rounded log from the outside, and having a flat surface on the inside. It is made only from coniferous breeds. This material is durable, protected from the negative influence of the external environment in the form of weather conditions and insects, and is also easily mounted using a spike-phase. The disadvantage can be called, perhaps, only the high cost of this material;

- Vinyl siding. Such material is durable, has an affordable price, light both in weight and in installation.Available in various colors, which allows you to make the decoration of the house modern and unusual. It is easy to care for, as it does not require periodic painting and washes well. Vinyl panels can be either screwed or nailed down. The disadvantage of siding is low strength and unnatural appearance. Therefore, this type of finish will appeal to those who want to transform a wooden house and give it a modern look;

- PVC panels. According to its technical characteristics, it is almost identical to vinyl siding and is its variety. The main difference is in an interesting appearance, which imitates surfaces such as marble, brick and stone. Looks very interesting and effective. This material is often combined with vinyl siding to create interesting design solutions.

There are many more different finishing materials, but as practice shows, the options described above are the most suitable for sheathing a wooden house. The main thing is to decide whether you want to keep the wooden look of the tree or bring something new and interesting. We hope that our advice and recommendations on carrying out all stages of work on sheathing a wooden house will help you in this difficult, but at the same time pleasant business.

What is the outer casing for?

Sheathing a wooden house from the outside is not only a way to make it more attractive in appearance. It is also carried out for practical purposes and also serves as protection for the wooden base of the house.

Sheathing protects the walls of a wooden house from direct moisture.

Insulation, which is usually located under sheathing materials, helps keep the house in excellent condition for a long time.

In some cases, the outer skin increases the sound insulation of the walls of a wooden house. This is necessary so that every street noise does not disturb you while you are inside the house.

Finishing the house on the outside will allow it to stand longer without major repairs and makes the overall look of the house beautiful and attractive.

New wooden houses are not recommended to be used without external cladding.

Conclusions and useful video on the topic

The cheapest option for sheathing a country house:

Informative video about the installation of facade panels, analysis of the nuances and details:

Subject to the technology of facing works, subsequent proper care of materials, the facade of the building will be in operation for at least ten years. Therefore, before deciding on the best way to sheathe a residential building, analyze the advantages and disadvantages of each type of finishing material.

Do you want to talk about how you selected the material for finishing the facade of your own house or cottage? Do you have your own opinion and strong arguments that justified your choice personally? Please write comments in the block below, ask questions and post photos on the topic of the article.