- How to fit into the design: general rules

- English

- Chalet

- Provence

- Scandinavian

- Fachwerk

- Baroque

- Basic requirements for cladding materials

- No. 10. New and Undistributed Materials

- Sheathing a house using crates

- Exterior design

- Decking

- Mounting methods

- 4 Porcelain stoneware

- Porcelain stoneware

- Material selection rules

- Brick is a reliable building material

- General properties and characteristics

- What materials are available

- What is the outer casing for?

- Types of decorative trim

- Clinker thermal panels

- Installation of thermal panels

- Facade plaster for exterior cladding

- Value "price-quality" in the selection of material for sheathing

- Wood

- Conclusion

How to fit into the design: general rules

When deciding to create a stylish exterior, you should not rely solely on your own wishes.

It is necessary to take into account the peculiarities of the natural and climatic zone, the specifics of the landscape design of the territory where the house is located, and the appearance of the neighboring cottages. There are several styles that are most often used in the design of facades.

English

Stiffness and impeccability - these concepts are invariably associated with England.That is why they have become the main leitmotif in the creation of the English exterior, Classic rectangular lines, the use of expensive materials, brick or stonework, as well as the unchanging roofing of tiles in discreet shades. Most often, two-story houses with an attic are decorated in this style. In this case, the porch is made small and decorated with semi-columns.

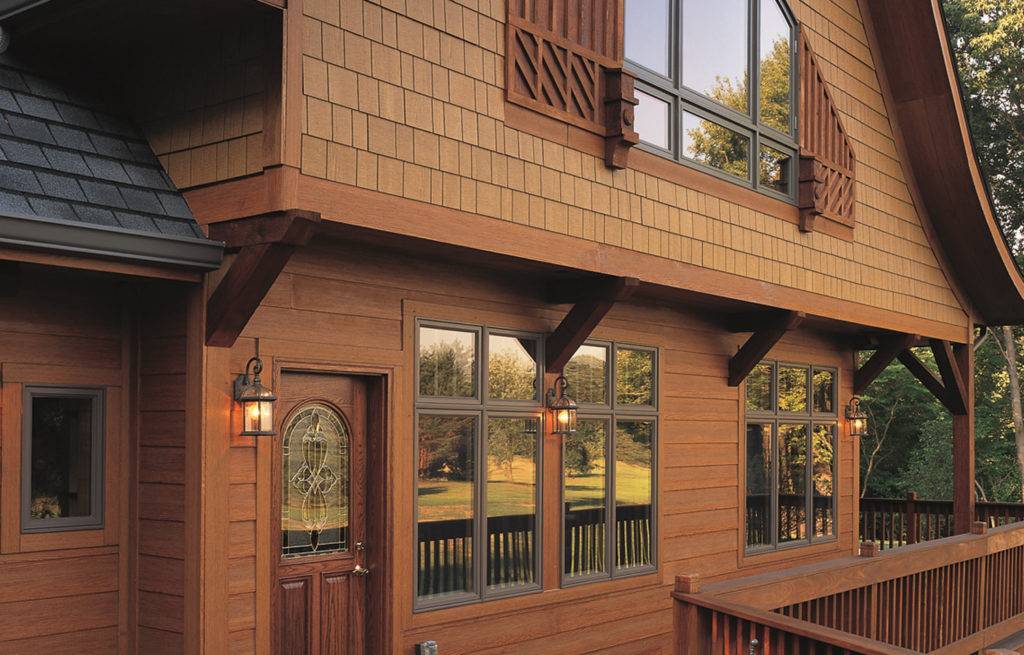

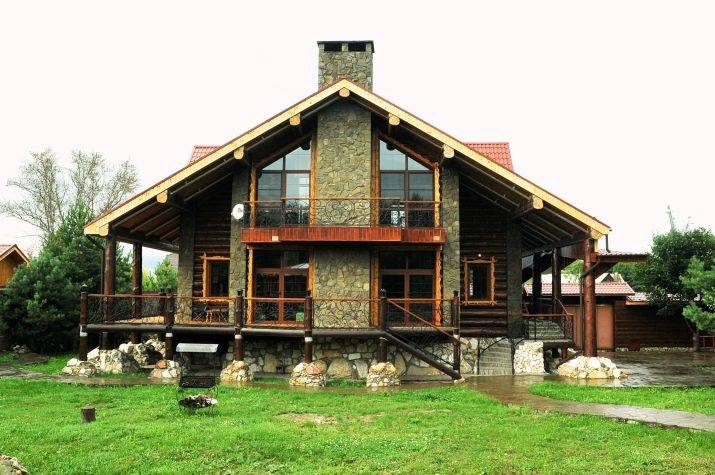

Chalet

This direction in the arrangement of low-rise cottages originates from shepherd's huts in the mountains. Nowadays, it is gaining more and more fans due to originality and comfort. Such houses are built only from wood. In their decor of a one-story log building, arched and doorways abound, as well as balconies, the number of which is quite large. The roof in such houses is made in the form of an attic, so the ceiling often has a slightly sloping appearance.

Provence

This is a folk style with motives of the French province. Very cozy, warm, but at the same time exceptionally refined. The abundance of white, masonry, imitating ancient coatings, semicircular arches and large rectangular windows - these are the main features of the Provence architectural style. It is noteworthy that there is absolutely no symmetry between the windows - even on the same wall there can be openings of different sizes located at different heights. This style is favorably set off by flower beds and rabatka. They create a unique atmosphere of real France.

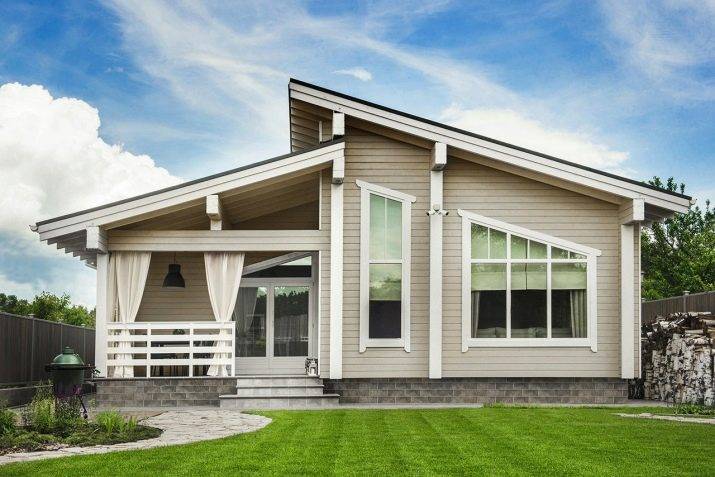

Scandinavian

This style has been very popular in recent years, most modern apartments are decorated using this technique, but recently the outside of buildings has also been decorated in accordance with the traditions of Norwegian settlements.

Fachwerk

This direction originated in Germany, where houses are made according to the model of the designer. The main tone is light beige, cream or ivory, the coating is crossed by dark wooden beams, which can be located in horizontal, vertical and diagonal directions. The roof in such houses is covered with tiles of the same tone with beams. As a rule, it is equipped with tiles and decorated in the same color scheme as the beams.

Baroque

This style is not suitable for every home. Perhaps only luxury real estate - large mansions and even residences can look harmoniously in this pompous and pretentious design. Here the buildings look like real palaces, the verandas are decorated with massive columns, stucco and multi-tiered domes. The design is dominated by gold and silver tones, quite often decorated with artistic painting of the pediment.

Basic requirements for cladding materials

The modern market of building and finishing materials is able to offer the widest range of products of various types and price categories. Often a person who has recently decided to equip his new home has many difficulties associated with the right choice of cladding for a wooden house.

Therefore, it is important to know the basic parameters that finishing materials must comply with.

- The cladding of the house should have low thermal conductivity. This will keep the heat in during the winter and prevent the indoor temperature from rising rapidly in the summer.

-

To protect the insulation layers from the accumulation of condensate, the exterior finish must be vapor-tight. In addition, the sheathing material itself should not absorb and retain moisture, its complete moisture resistance is necessary.

-

Fire resistance, heat resistance, resistance to thermal deformation and the influence of ultraviolet radiation. It is unacceptable to use a casing that can ignite, change shape or other physical characteristics under the influence of the above factors.

- Inertia. The substance of which the finishing elements are composed should not have a predisposition to enter into various chemical reactions.

- Finally, the material must be protected from attack by microorganisms, insects and rodents.

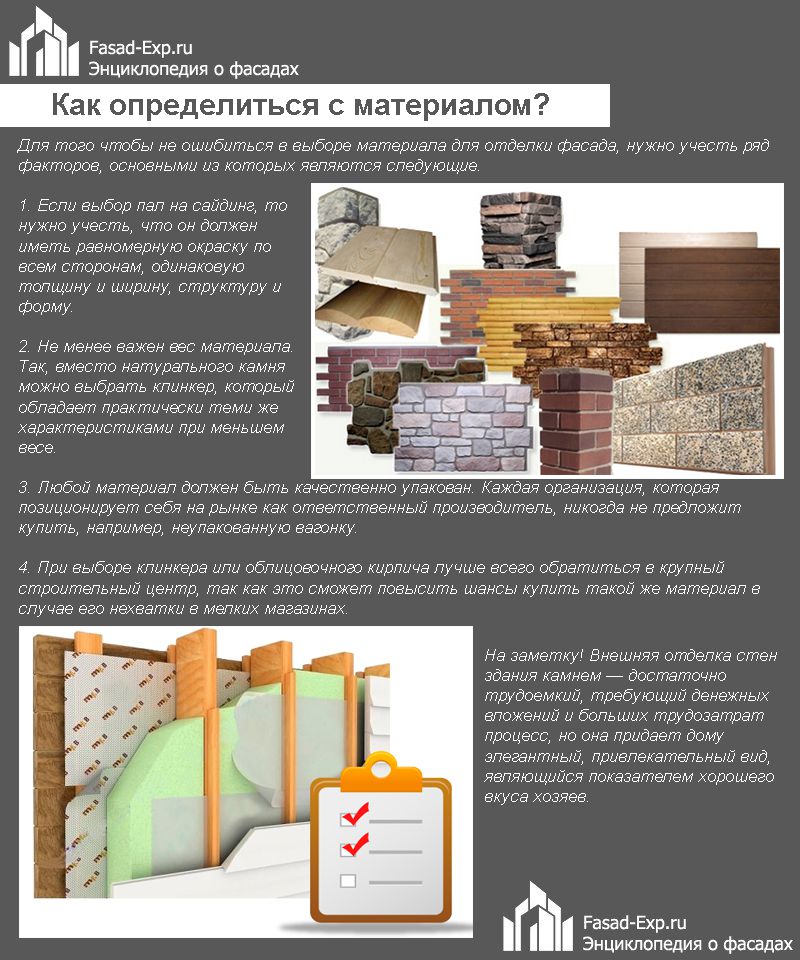

How to decide on the material for sheathing?

No. 10. New and Undistributed Materials

In addition to those materials that have already become traditional in the field of facade cladding, there are more innovative and in some ways even more progressive. The most interesting of them:

-

concrete siding. It is made from cement, sand and dyes. The material has a beautiful appearance and a pleasant rough surface, it is durable, but heavy enough, so it will require strengthening the foundation;

-

clinker thermal panels consist of ordinary clinker tiles and a welded layer of expanded polystyrene, and this is an excellent insulation. With external attractiveness, such a finish becomes an additional heat insulator. The disadvantage is the high price;

-

glass panels are a popular option for shopping malls and office buildings. For arranging a private house, it is suitable only if you like bold decisions.

The choice of finishing material for the facade should be preceded by a multivariate analysis, including the climatic features of the region, the type of house, the particular style of the site, your own preferences, the material of the walls, your own requirements and preferences. Fortunately, there are plenty to choose from.

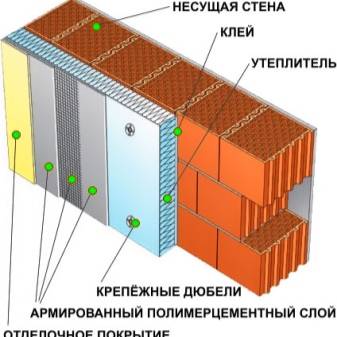

Sheathing a house using crates

Insulating facade system using lathing can be installed in one or two layers. The position of the frame bars will depend on how you plan to install the decorative trim.

Installation of the facade lathing

- To install the crate correctly, it is better to first mark the wall. In this case, it is necessary to take into account the width of the insulation mats.

- Then bars or metal profiles are mounted on the surface of the walls.

- If a wooden wall is sheathed, then before laying the insulation, a vapor barrier film should be fixed to the entire surface of the walls.

- Next, insulation mats are laid between the bars of the crate. If necessary, they are fixed to the wall with fungal anchors.

Insulation is laid between the guides of the crate

- After installing the insulation layer, a superdiffusion membrane is stretched on top of it, fixing it on the bars of the crate with staples of a construction stapler.

- Next, you can install decorative cladding material.

Another option for installing the crate is done in a slightly different way.

Markings are also made on the wall and suspensions are fixed along it at a distance of 40-60 cm from each other. Their edges-holders should protrude from the wall by the thickness of the insulation and wooden bars that will be attached to them.

Scheme of facade insulation with the installation of battens on metal hangers

- These elements will be fasteners not only for the bars, but also for the installed insulation.

- Insulation mats are marked and cut in those places where they will be put on metal elements.

- Then the insulation is mounted on the wall, and a diffuse membrane is stretched and fixed on top of it.

- Next, bars of a wooden crate are installed in the hangers, the insulation is pressed tightly against the wall with them and fixed in metal holders with self-tapping screws.

- A decorative sheathing material is also installed on top of this system, using the installed sheathing bars as guides.

Exterior design

The material used for finishing determines the methods of its installation, in connection with which the following cladding options are distinguished:

- wet (building mixtures are used);

- dry (finishing materials are fastened with bolts, dowels and other fasteners).

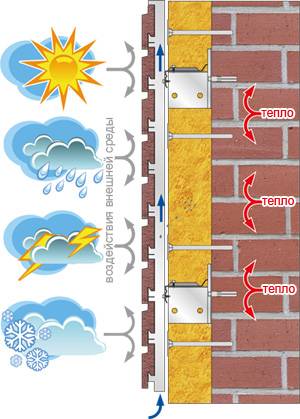

Depending on whether there is a small air space between the facade and the wall, facades are distinguished:

- ventilated (assume a gap between the material and the wall or insulation, necessary for air circulation and removal of excess moisture);

- non-ventilated (the material is attached directly to the wall).

The material for external processing, as well as the type of facade, is determined by the features of the structure. For example, for a house made of foam blocks, brick, stone or facade tiles, in other words, hinged systems, composite material and traditional cladding, will be the best facing materials.

For frame country houses, it is better to use sheet cladding options. Galvanized corrugated sheet will provide additional support for the structure, but it will not require additional strengthening of the foundation.

It is important to correctly combine insulating and facing materials. The main rule is that one of the components must be non-flammable

So, for fiber cement non-combustible slabs, you can use mineral wool insulation.It is not recommended to use them in combination with vinyl siding.

Decking

Initially, corrugated board was used as a material for finishing non-residential premises. Along with the improvement of its characteristics, it moved into the category of finishing materials used for cladding residential buildings made of wood. The use of corrugated board finishes can significantly increase the life of the building, and the diverse design of the material gives it a great appearance.

There are several options for profiled sheets, differing in their thickness and wave size. For finishing the facades of the house, a material labeled C10 is used. Its strength and low weight allow you to install the material in a vertical position, which is very convenient for installation. You should be aware that in order to use all the positive qualities of corrugated board, it is usually used in conjunction with insulating soundproofing material as the top layer of the finish.

An important factor for the popularity of corrugated board in the decoration of buildings was its affordable cost (the material belongs to the middle price category), as well as ease of installation. Buyers are also attracted by the variety of colors, the offered range of material, and its quality.

With the help of inexpensive material, the old house takes on an original look.

Mounting methods

Any installation begins with the creation of a drawing and a project, the necessary markup, a plan necessary for an accurate representation of all further construction work. The preparation process begins with such preliminary work as leveling the walls, removing defects and various existing roughness on the surface.This is directly related to the creation of the crate, whereby a distance of 5–7 cm is formed.

Thus, all unwanted defects and irregularities will be hidden and will not remain noticeable. After creating the project, one should, focusing on it, mark the walls, install existing profiles and beacons.

One of the most important aspects of high-quality work on the installation of the facade is good thermal insulation, because this is a very significant thing that helps to significantly save money and not go broke on heating a country house. Directly for these purposes, special insulation boards are used, which are attached to the wall using the necessary fasteners.

It is important that there is not even the smallest distance between the wall and the insulation itself. For the most part, the fastening of the insulation layer is carried out by means of screws with a wide head or dowels.

The distance from the insulation layer to the future coating varies within 50 mm.

For this purpose, a special windproof membrane is used, which is installed on top of the insulation layer itself. A significant aspect is the need to cover the bearing profiles

For this, a plumb line is used, and it is important to control the distance between them. Profiles are often fastened by using self-tapping screws for metal with a press washer

Next, is the fastening of the panels themselves, the selected material for decoration facade of a private house. To fasten the panels to the supporting profiles, special clamps or other devices are required. Their choice depends on the material used.The complexity of the installation of the facade of the house or the reconstruction of the old building depends on the facing material itself.

4 Porcelain stoneware

The most durable finishing material for facade decoration is porcelain stoneware. It is made by semi-dry pressing of a mixture of natural ingredients such as clay, feldspars and quartz. Manufacturers offer homeowners porcelain stoneware in the form of tiles with a thickness of 12-16 mm. Experts attribute absolute moisture resistance, durability, long-term preservation of the original appearance, a wide range of textures and colors to the strengths of the cladding. Depending on the preferences of the consumer, you can choose a matte or polished surface, give preference to a homogeneous or mosaic structure.

In Russia, many owners of houses and cottages finished the facade with porcelain stoneware. They are satisfied with the practicality of the coating, durability and moisture resistance. Of the minuses, there is a lot of weight, decent cost and specific installation.

Porcelain stoneware

Porcelain stoneware is a pressed and fired clay mixture with the addition of quartz, feldspar and natural dyes.

The main quality of the material is durability.

Porcelain stoneware is made in the form of slabs of various thicknesses, textures and colors. It has properties that are not inferior to natural stone.

The main indicator of the color, structure and texture of the material is its composition, which includes manganese, chromium, iron, zirconium or cobalt salt. The surface is matte, polished, embossed, polished or glazed.

Features of porcelain stoneware are:

- high strength;

- durability;

- independence from weather changes;

- environmental friendliness;

- no fading;

- soundproofing;

- thermal insulation;

- fire safety and protection of walls from fire;

- resistance to microorganisms;

- ease of installation;

- with a ventilated facade, a comfortable microclimate is provided.

The aesthetic appearance of a building made of porcelain stoneware is ensured by the textured color of the material, it is easy to maintain and easy to repair.

The disadvantages of porcelain stoneware are the heavy weight of the plates, which requires a solid foundation of the building and load-bearing walls and high cost.

Porcelain stoneware

Material selection rules

When using insulating materials, it is important to maintain normal humidity in the room. To do this, there must be a decrease in vapor permeability from the inside to the outside.

Thus, moisture will leave the dwelling in a natural way. Failure to follow this rule can lead to serious problems. The appearance of condensation between the layers will create excellent conditions for the development of fungus and mold. The destruction will begin. And in cold weather, this condensate will freeze and expand, deforming your home.

Proper sheathing of the house will help maintain the optimum level of humidity in the house.

This rule only applies to wood. The rest of the materials have not very good vapor conductivity. This can be fixed in two ways.

- The first way is to fix the cladding directly to the facade wall. In this case, the inside of the wall must be equipped with vapor barrier material. Through it, moisture will not penetrate into the house, but will come out with the help of ventilation.

- The second way is to install a ventilated facade. This is a unique separating layer between the inner wall of the house and the exterior. Thanks to it, the air inside circulates freely, providing natural ventilation.

Ventilated facade reduces the negative impact of the environment on the walls of the house

Wait for the house to completely shrink before you start facing work. For each material from which the house is built, its own term:

- felled trees are planted for at least two years;

- rounded log - from 6 to 12 months;

- glued and profiled beams do not need shrinkage.

Brick is a reliable building material

The brick performs a decorative function and protects the walls from the negative influence of the external environment. The use of brick allows you to protect the structure from excess moisture and ignition of a flammable wooden surface.

Before finishing the facade of a wooden house with bricks, it is worth calculating the load on the foundation and assessing the possibility of using the material.

Brick is rarely used for facing a new wooden house. More often this happens in one of the cases:

-

a wooden house is made of poor quality material or has an unsightly appearance;

-

the house is being built according to the frame-panel version, the cladding is carried out in conjunction with the erection of walls;

-

an old house that requires high-quality insulation, strengthening the rigidity of the walls and improving the appearance.

Facing an old house effectively transforms the appearance

Facing a new house is performed after the final shrinkage of the structure. Facing an old wooden house requires a solid foundation and a ledge of suitable size. If there is none, it becomes necessary to build up the foundation.

The design features of the roof are also of no small importance when facing the facade with bricks: the length of the hanging cornices is desirable about 30 cm.A ventilation gap of about 2-2.5 cm is left between the layer of brick and wood

Silicate brick in the decorative finish of the house

Decorative finishing of a wooden house is performed by one of the types of bricks:

-

Ceramic facing brick It is made from high quality clay using various additives and color pigments. The texture, shape and variety of colors of ceramic facing bricks allow you to implement any design project.

-

silicate facing brick consists of lime, quartz sand and various additives. It is much cheaper than ceramic bricks. It is used very rarely in facade decoration, as it is afraid of high humidity and has a heavy weight. The technology of facade cladding with silicate brick requires surface treatment with various water-repellent compositions and the presence of large cornices.

-

Hyper-pressed facing brick made using crushed limestone, cement, and pigment dyes. Differs in the high durability and frost resistance. Attractive appearance, imitation of natural stone and versatile use make hyperpressed brick popular.

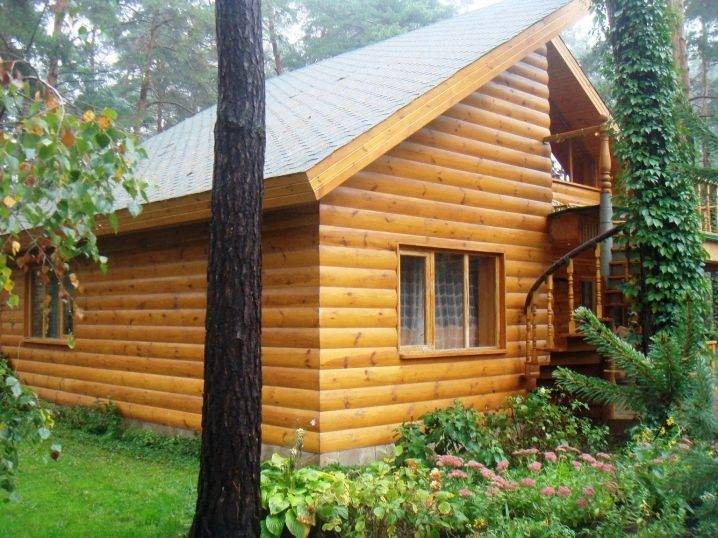

General properties and characteristics

The construction industry and the introduction of the latest innovations into it are moving forward. Natural wood as a material for cladding country houses and cottages still remains one of the most popular and sought-after building materials.

Often, builders, using wood as a sheathing material, can resort to facing the house from the outside. This allows you to achieve a beautiful, prominent result, create the appearance of a “Russian hut” and sheathe the house with the highest quality.There are many reasons, referring to which we can say with confidence that the cladding of the house is desirable, and sometimes a mandatory construction procedure.

In addition, there are a number of factors and necessary conditions that you should pay attention to when choosing a sheathing material:

- Unfavorable climatic factors can always contribute to breakdowns and any destruction. To avoid this, it is recommended to resort to house cladding, mainly with additional protection against impregnation by sedimentary moisture and condensate.

- Thermal conductivity and vapor permeability must be excluded, thereby ensuring that the house is sheathed with a material that implies high-quality thermal and waterproofing.

- Noise can also often interfere, so you should choose a material with good sound insulation.

- It happens that over time, the skin often loses its former attractive appearance due to fading. To prevent an undesirable situation, it is recommended to choose a sheathing material that will steadfastly respond to the influence of sunlight and ultraviolet rays.

- A fire can strike at any moment. To avoid this, there are materials for cladding home, the use of which will secure and protect the home from open fire.

- Specialists often put forward material requirements that ensure ease of installation, as a result of which the use of special equipment is optional.

However, home owners often have to choose between reliability and aesthetics, as it is quite difficult to find a material that meets both characteristics.

What materials are available

To begin with, we list the common methods of exterior wall decoration, and then we highlight the options that will cost relatively inexpensively:

- smooth or textured plaster with and without insulation;

- vinyl or metal siding, corrugated board;

- decorative elements made of wood - lining, block house and the so-called shingle (boards that form a coating in the form of scales);

- panels made of fiber cement and foam plastic with imitation of brick and other types of facade cladding;

- artificial and natural stone;

- various types of sheathing bricks - torn, figured, bassoon and so on.

Sheathing the walls of the house with artificial stone is not the cheapest option.

If you choose the right colors and sheathe the walls in any of the above ways, then your country house will look beautiful, but it’s not a fact that the work will be cheap. It is not difficult to make sure of this: find out how much it costs in your city to finish the facades with stone or overlay with clinker bricks. Since we are interested in inexpensive finishes, we will not consider the last two.

A little about how it is better to sheathe different types of buildings. If any house can be upholstered with siding, wood and various panels, then wet-applied external plaster or fur coat is not suitable for wooden walls of timber and log dwellings. Plastering is appropriate to do in cottages made of stone, slabs and blocks, and even in old adobe houses. You can get more visual information about the methods of cladding private houses by watching the video:

Since wood, plaster and fiber cement do not impede the passage of moisture (it has good vapor permeability), products made from these materials can be fixed directly to the walls.Another thing is upholstery with panels made of plastic or metal, which absolutely does not allow water vapor to pass through. In order for it to freely go outside, such a skin is mounted using a new technology - on a wooden or steel frame - a subsystem. The latter provides a ventilation gap (air) between the structure and the cladding.

So that the structure is not saturated with moisture, all its layers must be permeable to steam.

What is the outer casing for?

Wooden house cladding outside is not only a way to make it more attractive in appearance. It is also carried out for practical purposes and also serves as protection for the wooden base of the house.

Sheathing protects the walls of a wooden house from direct moisture.

Insulation, which is usually located under sheathing materials, helps keep the house in excellent condition for a long time.

In some cases, the outer skin increases the sound insulation of the walls of a wooden house. This is necessary so that every street noise does not disturb you while you are inside the house.

Finishing the house on the outside will allow it to stand longer without major repairs and makes the overall look of the house beautiful and attractive.

New wooden houses are not recommended to be used without external cladding.

Types of decorative trim

Modern materials allow you to make on a wooden wall imitation brickwork or vice versa - to transform a brick house into a wooden frame. To do this, use linings such as siding made of different materials, wooden lining, block house, thermal panels, ceramic or stone tiles, and others.It is necessary to find out in advance how each of the skins is attached and how it looks in the end - this will largely determine which insulation system to choose for it.

Clinker thermal panels

Clinker thermal panels are one of the modern materials for insulation and facade design.

House sheathed with clinker thermal panels

They relatively recently appeared on the construction market, and have already gained wide popularity. This is not at all surprising, since they have many positive qualities.

- One of the main advantages is that this material immediately performs two functions: it is insulation and decorative trim.

- The panels perfectly imitate brickwork, and are produced in various colors, so they can be matched to any style and taste.

- They give the surface absolute accuracy and aesthetics.

- This type of sheathing is convenient and relatively easy to mount on the wall.

- Thermal panels can be used for covering any wooden or brick surface.

- The light weight of the panels makes it possible to do without additional strengthening of the foundation of the old building.

- Since the materials have a low percentage of water absorption, the facade can be washed from the hose with water under high pressure.

- The density of the connection of the panels on the wall does not allow cold air to penetrate to the wall of the house.

Thermal panels have a polyurethane foam or polystyrene foam base, on which clinker tiles are pressed.A warm substrate increases the thermal insulation qualities of the panels by two to four times, and creates an optimal vapor-permeable microclimate for the walls, which allows you to save the material from which the house is built for a longer period.

The structure of the panels - a layer of insulation and decorative tiles "under the brick"

- Clinker tiles protect the insulation base from external factors such as wind, precipitation, direct solar ultraviolet rays.

- Clinker panels are very securely attached to the wall and can last 45-60 years without repair work, without losing their original appearance.

- The panels are assembled in a single plane using the existing locking joints (ridges and grooves), which ensures tight adhesion.

Installation of panels is quite simple and intuitive.

Straight, wall thermal panels and corner elements for them are produced, which facilitate the task of decorating the corners of the building, making them absolutely neat, not differing from the general appearance of the walls.

Thermal panels are completed with the necessary additional profile elements

Thermal panels are reinforced with plastic guides that prevent deformation and mechanical stresses of the facing material.

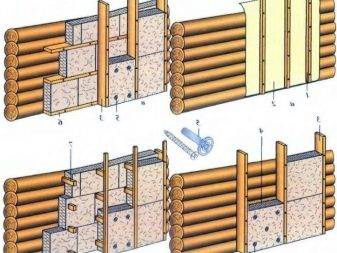

Installation of thermal panels

Before starting the installation of panels on the wall, it is necessary to revise it for various bulges, significant recesses and chips, which can greatly interfere with quick installation. Therefore, it is necessary to bring the surface of the walls in a perfectly even state.

Revision of walls before installation of thermal panels

When installing panels on surfaces that have large irregularities, for example, the walls of a log cabin, they are laid on a crate of wooden beams.

Installation of clinker thermal panels can be carried out directly on the walls or on the crate

In this case, it is very important to correctly calculate the location of the elements of the crate so that the fastening of the panels is successful. Each of the panels to be fixed must have at least three battens to create the necessary rigidity of the cladding.

Dimensions of thermal panels, places of attachment to walls

The diagram clearly shows the attachment points to the wall or crate and the dimensions of the panel itself and the protruding locking ridges.

Facade plaster for exterior cladding

Facade plaster for building cladding has a different composition, texture and connecting element. Components for plaster are selected depending on climatic conditions, frequency of precipitation and type of primer.

Before plastering, the wall must be prepared with a surface sandblaster or wire brush. All irregularities are removed with a chisel, and in the presence of greasy stains, contamination is treated with a solvent

Before plastering, the wall must be prepared with a surface sandblaster or wire brush. All irregularities are removed with a chisel, and in the presence of greasy stains, contamination is treated with a solvent

Applying plaster on a substrate that tends to expand/contract with changes in moisture levels requires measures to be taken to prevent cracking of the finish. Therefore, a plastic binder is added to the solution.

In this regard, in the process of preparing the components for the mortar, it is necessary to familiarize yourself with the characteristics of the finish and the climatic conditions of the region. Then properly selected plaster will last for several decades.

In addition, facade plaster when facing a house has the following advantages:

- protects walls from precipitation and mechanical influences;

- gives the building a unique look, as it can be applied in the form of decorative textures of various colors;

- has high adhesion, elasticity and safe composition;

- resistant to UV rays, temperature extremes.

A high-quality composition applied to the walls of a building has many advantages. But if during the mixing process the proportions of raw materials were not respected or second-rate materials were used, then the plaster in the first season will partially lag behind the wall, crumble and it will be necessary to renew the facade of the building.

If before performing facade cladding you decided to insulate the house, pay attention to the technological and practically waterproof Penoplex. The article recommended by us will acquaint you with its characteristics, varieties and advantages of application.

Value "price-quality" in the selection of material for sheathing

When choosing a specific option, the degree of vapor permeability of the material is carefully considered, since the tree must “breathe”. It is impossible to carry out hermetic finishing at home - you need to maintain gas exchange. In addition, the vapor permeability of the finishing agent must be higher than that of the solid wall. This contributes to the release of excess moisture outside, and not inside the building.

When the vapor permeability rule is not respected, excess water collects at the contact line between wood and planking. This leads to the formation of a zone of increased humidity. This area is excellent conditions for the development of mold, rot and other phenomena that adversely affect the structure of natural material. At sub-zero temperatures, when there is a lot of water in the zone of increased humidity, it freezes and expands, which can lead to damage to the facing material.

When a wooden structure is sheathed with vapor-tight building materials, a ventilated facade must be made.This design implies that the outer relatively or completely vapor-tight layer is located at a distance of 60-150 mm from the tree. Openings are kept at the top and bottom - for natural air circulation, and excess water leaves with convection currents. Choose cladding options depending on the type of wood processing:

- Log houses need sheathing, although many believe otherwise. They finish the walls to protect the tree and so that the structure does not subside. Finishing is especially important when round logs are used. In this case, it is better to sheathe a wooden house on the outside with a euroboard or clapboard.

- SIP panels - PVC panels and siding are suitable for finishing. Lining and euroboard are not the best options.

- Timber - such houses can be sheathed with any material. But, it is recommended not to use natural stone or facing tiles for decoration - the timber will rot, and the house will be damp.

- Frame - you need light material. Suitable rounded board (block house), lining. A good option is siding. It can be sheathed with other plastic or wooden panels. But, it is not recommended to use fire hazardous plastic, since the already low fire resistance of the structure decreases.

For reference!

It is necessary to sheathe a wooden house - to prevent premature degradation of the material. Sheathing reduces the cost of regular wood treatment with protective preparations.

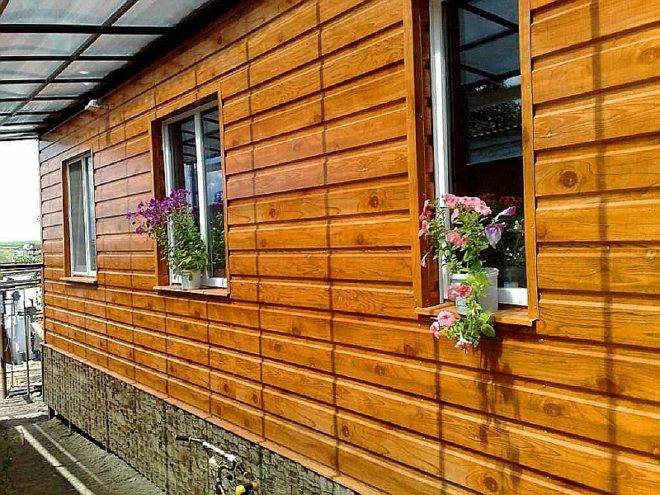

Wood

Wood is used as cladding to give the house a natural look.

Under the tree, you can use modern types of cladding:

- lining;

- block house;

- facade board (planken);

- beam imitation.

The lining is a solid board. It has a different quality class. Differs in ease, availability and low cost.

Block house is a high-strength material, which is a coating in the form of a bar. Classified by color, texture.

IMPORTANT!

Facade board is a profile material resembling siding panels. The peculiarity of the installation lies in the technology of the allowable distance between the boards to ensure ventilation.. The imitation of the beam looks like a board

Mounted using tongue-and-groove technology

Imitation of a bar looks like a board. Mounted using tongue-and-groove technology.

The advantages of wood are environmental friendliness, non-toxicity and good thermal and sound insulation properties.

A significant disadvantage of wood is its susceptibility to decay and fragility. However, with regular processing of a wooden facade, its service life is significantly increased.

Wood

Conclusion

We have considered the 6 most attractive finishing materials that can beautifully, quickly and not at all expensively sheathe walls in a wooden house. With the exception of cork, of course, because this material cannot be called cheap, but due to its targeted use, costs can be significantly reduced. In most modern wooden houses, the usual lining and ceramic tiles are often used, but who said that you have to follow the opinion of the majority? A creative approach does not at all imply significant material costs - it involves, first of all, a non-standard vision of the interior, and the decorative qualities of the finishing materials used often do not depend on their cost.