- Materials for hydro and vapor barrier

- The composition of the roofing cake

- What insulation to choose for the attic

- 2 Overview of the best heaters

- 2.1 Foam insulation

- 2.2 Solid insulation - mineral wool and polystyrene foam

- floors

- A little about the types of heaters

- Mineral wool

- Insulation of the attic floor with penofol

- Penoplex and polystyrene for insulation of the attic floor

- Sawdust and ecowool

- Insulation of the attic floor with polyurethane foam

- Do-it-yourself insulation of the attic from the inside with mineral wool - Procedure for performing work

- Check the evenness of the rafter legs.

- Measure the distance between the rafters.

- Install waterproofing.

- Carry out cutting of thermal insulation boards.

- Install mineral wool between the supporting structures of the roof.

- Insulate gables and exterior walls.

- Seal all passages and crevices.

- Make a vapor barrier structure.

- Material Requirements

- Thickness

- Density

- We warm the attic from the inside with our own hands

- Warming of gables

- We warm the floor in the attic

- Attic ceiling insulation

- Which is better - plates or rolls?

- Attic roof insulation from the inside and useful tips

- Attic and its subtleties as a building object

- General aspects of attic insulation work

- Conclusion

Materials for hydro and vapor barrier

To insulate the roof of the attic from the inside, do-it-yourself mineral wool is mainly used, which tends to accumulate moisture. If you do not protect the material with films for vapor and waterproofing, it will quickly get wet and cease to perform its functions.

To isolate the material for insulation use:

- Izospan is a two-layer membrane for vapor barrier, the rough surface of which allows condensate to be retained.

- Polyethylene - a film that performs a waterproofing function, but does not let steam through - is the cheapest of the materials.

- Waterproofing membrane. Quite often you can find roofing membranes that serve as waterproofing and are vapor-permeable at the same time.

- Penofol. Insulating material with a foil waterproofing layer.

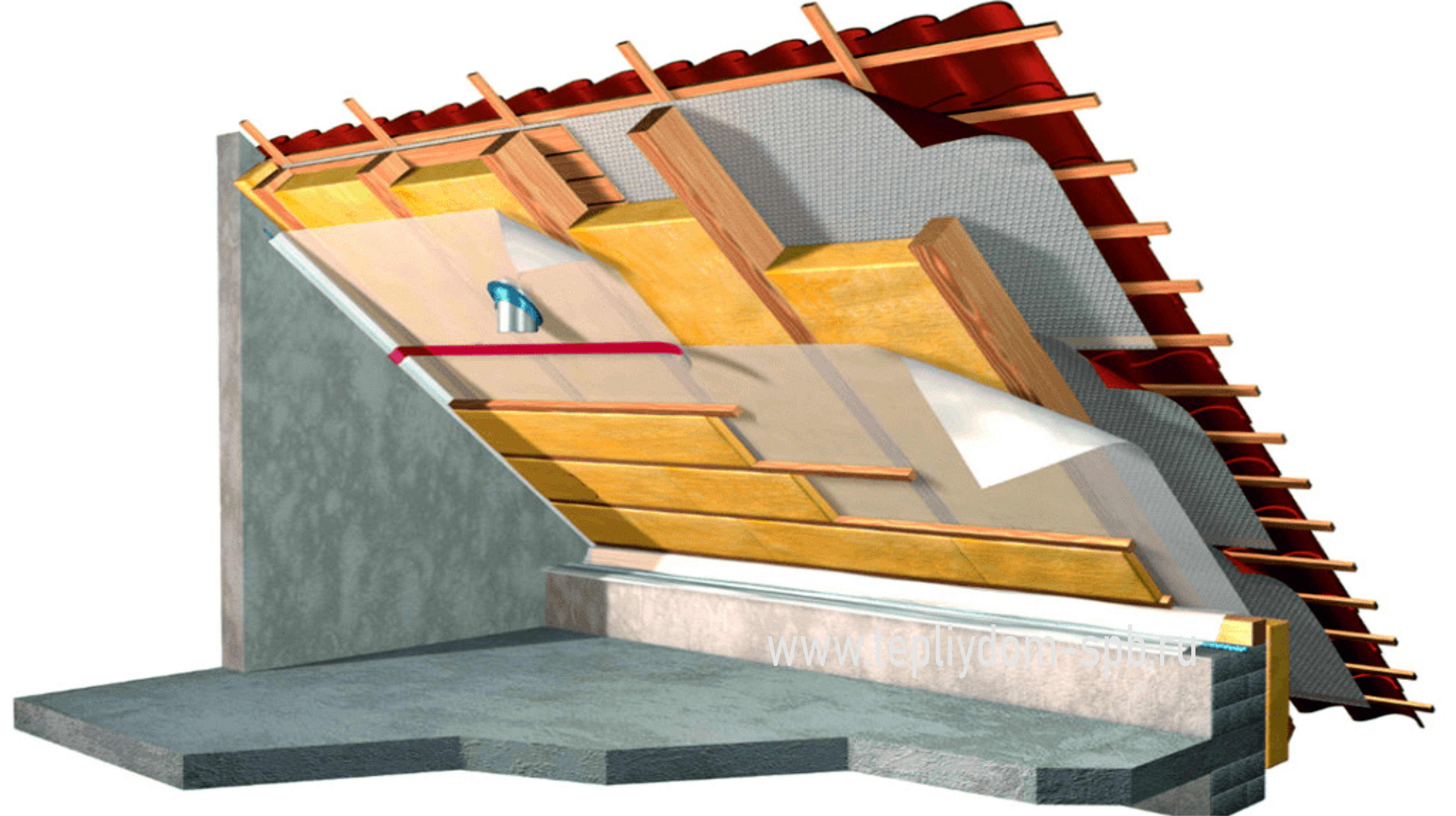

The composition of the roofing cake

Insulation of a residential attic with mineral wool requires mandatory compensation for the weaknesses of this material: the ability to absorb moisture from the room, as well as high airflow and low resistance to precipitation. Therefore, two, and sometimes three membranes are introduced into the composition of the roofing cake, provided that fibrous insulation is used. In the direction from the room to the outside, the layers are arranged in the following order:

Scheme of attic insulation with mineral wool

- Ceiling finish. The warmest material for this layer is drywall and a layer of putty (taken into account separately in the thermal calculation).

- An air gap formed by a crate for fixing the finishing cladding. Equal to the thickness of the laths (or galvanized profiles) of the crate. This gap is not necessary for the operation of the heat-insulating system.

- Vapor barrier film.Protects the insulation from the ingress of steam rising from the room.

- The main insulation (2 - 3 layers of mineral wool).

- High diffusion membrane (waterproofing). Its peculiarity lies in the one-way passage of water. Moisture coming from below (evaporated by mineral wool) should freely penetrate through the membrane, and water entering from above (precipitation and condensate) should drain under the roofing down to the street. Films of this type combine the functions of a hydro-barrier and wind protection. In domestic practice, isospan three-layer membranes have proven themselves well. It is better to use Izospan AQ proff for the attic, which is characterized by high strength and a good steam transmission rate (1000 g / m2 per day). The gap between isospan and mineral wool is not needed.

- Ventilation gap between the membrane and the roof deck. It is formed by battens of lathing, located perpendicular to the rafters in the plan. The thickness of the crate is usually 4 - 6 cm.

- Roof decking.

What insulation to choose for the attic

Having decided on the specifics of choosing a room, it is worth deciding on the choice of materials, namely, how to insulate the attic from the inside. So the choice of material can be influenced by some undeniable factors, namely:

- roof parameters;

- roof structure;

- climatic features.

So, there are several types of materials that can be used to insulate the attic from the inside:

Insulation of the attic with foam

Styrofoam is one of the cheapest and most popular types of insulation material. Easy to install. However, its vapor permeability is significantly reduced.From this it can be seen that during the operation of this type of material, the room may be exposed to dampness, and as the rafters dry out, unwanted gaps may form;

in this material

Styrofoam. An analogue of polystyrene, but with slightly increased physical strength characteristics

It is quite durable, retains its shape perfectly, it is not afraid of high humidity and, very importantly, it does not burn. Special attention should be paid to the fact that for insulation a not very thick layer is required - 5-10 cm.

Mineral wool is an absolutely ideal solution in all its parameters.

It has a high density, moisture resistant, has such a property as fire safety and weakly transmits heat. This material is more durable, and if we consider it as a sound insulator, then it is more effective.

Cotton wool is able to withstand low temperatures

However, when working with it, special precautions must be taken into account;

Cellulose wool (ecowool) refers to a heat insulator made of non-dusty materials. It contains an antiseptic that prevents damage to the insulation layer and the wood in contact with it.

Ecowool is able to penetrate into the smallest voids, filling them

It is an eco-friendly material that can “breathe”, moreover, it is not afraid of moisture and does not support combustion. Ecowool is not harmful to health, unlike the same mineral wool, for example;

Polyurethane foam is applied by spraying on absolutely any surface. Using this material for attic insulation, you can create a monolithic layer without existing gaps;

Foil materials that function not only as a heater, but also work as a mirror reflector that prevents heat from escaping to the outside.To create the desired effect, this material should be deployed with an aluminum coating inside the room, while leaving a distance of 5 cm between it and the vapor barrier layer.

Of course, when choosing a material for insulation, the owner of the house has the last word. When working with any insulating material, safety precautions must be observed. Required: gloves, goggles and long sleeves.

2 Overview of the best heaters

Among all the thermal insulation materials on the market, the above requirements are fully met by three types of heaters:

- Thermal insulation from mineral wool;

- Thermal insulation made of extruded polystyrene foam;

- Foam thermal insulation (liquid penoizol, foamed polyurethane foam).

2.1 Foam insulation

The category of foam insulation includes materials made directly at the workplace by foaming raw materials. From the pneumatic unit, the foam insulation is supplied with a hose to the insulated surfaces.

Among foam thermal insulation, the most popular options are liquid penoizol and foamed polyurethane foam. The latter option has an order of magnitude better technical characteristics, but it costs significantly more than penoizol.

The thermal conductivity of thermal insulation made of polyurethane foam is 0.02 W / mk, which is significantly lower than all popular heaters, the density is 25 kg / m3, moisture absorption is not higher than 2%. The thermal conductivity coefficient of liquid penoizol is about 0.04 W / mk, the density is 28 kg / m3, like that of rolled thermal insulation materials.

If you want the most efficient wall and roof insulation, and the prospect of hiring contractors does not stop you, it is recommended to choose insulation with polyurethane foam - this material has no analogues in terms of thermal insulation properties.

Attic roof insulation with liquid penoizol

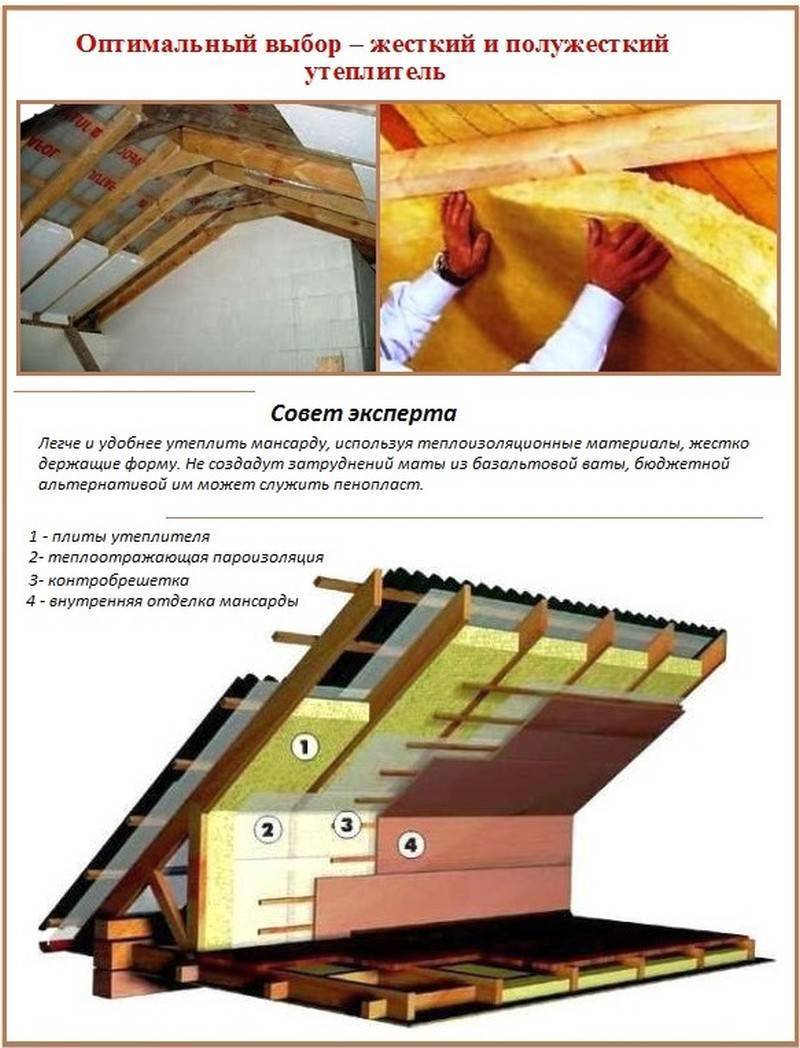

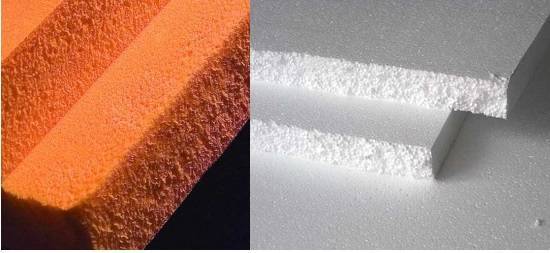

2.2 Solid insulation - mineral wool and polystyrene foam

Mineral wool insulation is one of the most versatile heat-insulating materials; they can be used with equal success both for attic insulation and for insulation of walls, facades, floors and ceilings of a house.

The category of mineral wool insulation includes three types of materials: basalt wool - a material made by remelting basalt rocks and subsequent formation of microscopic basalt fibers from the melt; slag wool - made from waste from the metallurgical industry - blast furnace slag; and fiberglass insulation - made from cullet,

Basalt wool has the best technical characteristics, and, accordingly, the highest price.

If you are not limited in funds, then it is worth choosing this option from mineral wool heaters, but if finances are limited, then it is quite possible to use fiberglass heaters.

In terms of versatility, extruded polystyrene foam is not much inferior to mineral wool. You can insulate not only the roof with your own hands, but also the surface of the walls and floor of the attic.

The advantages of extruded polystyrene foam include low thermal conductivity, due to which even a relatively thin layer of insulation will be quite effective (the optimal thickness of attic insulation made of extruded polystyrene foam is 4-10 mm).

The main manufacturer of basalt wool in the domestic market is Technonikol, extruded polystyrene foam - Penoplex.

Simultaneous use of mineral wool and foam

Among the range of these companies, for attic thermal insulation it is best to use Technolight mineral wool from TechnoNIKOL, and Penoplex Comfort slabs. Let's compare the main technical characteristics of these attic heaters.

- Thermal conductivity coefficient, W / mk: TechnoNIKOL - 0.036, Penoplex - 0.032;

- Vapor permeability, m/hPa: TechnoNIKOL - 0.6, Penoplex - 0.015;

- Combustibility class: TechnoNIKOL - G1 (non-combustible material), Penoplex - G4 (highly combustible material);

- Density, kg/m3: TechnoNIKOL - 35, Penoplex - 30;

- Moisture absorption by volume when fully immersed for 24 hours: TechnoNIKOL - 1.5%, Penoplex - 0.5%.

Mineral wool TechnoNIKOL "Technolight" is produced in the form of plates with dimensions of 120 * 60 centimeters, the thickness of the plates can be 4-20 cm. Penoplex plates have similar dimensions, but their thickness range is somewhat smaller - from 2 to 15 centimeters.

As you can see, the technical characteristics of Penoplex are better than TechnoNIKOL mineral wool, both in terms of thermal conductivity and vapor barrier.

In general, in practice, in most cases, experts combine these two materials - expanded polystyrene is used to insulate the walls and floor of the attic, and it is recommended to choose mineral wool for thermal insulation of the roof.

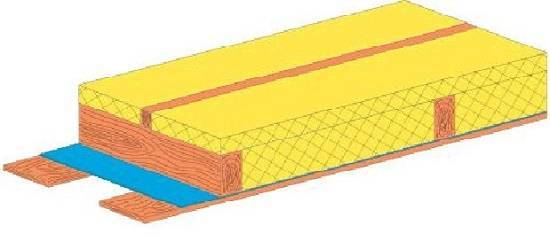

floors

Most of the baths in all rooms have insulated streams, which means that the attic floors do not need such construction activities. If the ceilings of the bath for some reason do not have thermal insulation, you will have to do it.Although there are options here - the uninsulated ceiling of the rooms in the bath automatically makes the floors of the attic room warm. Decide for yourself what to do in your case

Take into account the specific purpose of the attic in the bath, the frequency and time of using these rooms

floor insulation schemes

If you decide to insulate the floor, you can use the same foam or mineral wool. The laying technology has one fundamental difference - the vapor barrier layer must be placed under the thermal insulation, and the waterproofing layer must be placed on top.

A little about the types of heaters

Next, we will consider heaters suitable for insulating the attic floor, its gables and roof. There are a great variety of materials offered to us in stores, and they all have different physical and technical characteristics. Let's figure out which insulation is best for the attic.

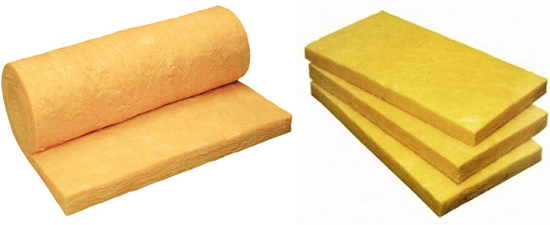

Mineral wool

The most popular material for insulating the attic floor is produced by different companies - Rockwool, Ursa, etc. Mineral wool has a low thermal conductivity and absorbs sound well. It is worth mentioning the fire safety of the material: slag wool begins to smolder at 300C °, stone wool at 600C °, and basalt generally only at 1000C °. There is only one significant disadvantage of mineral wool: it gets wet.

It is produced in rolls - soft, and in plates - more rigid, the density is higher. If the attic has a ceiling, we “insulate” it with a rolled rockwool or similar mineral wool from another company. For gables, slab types of mineral wool are better suited: rolled ones, due to their softness, being installed on a vertical surface, will sag over time.

The better to insulate the attic from the inside: mineral wool

Insulation of the attic floor with penofol

The material has good thermal insulation qualities, but foam insulation as an independent material is impossible, it is too thin. But as an additional insulation and replacement of vapor protection, it can be used, however, due to its vapor tightness, it requires good ventilation.

How to properly insulate the attic from the inside: penofol is suitable only as a vapor barrier

Penoplex and polystyrene for insulation of the attic floor

Penoplex and polystyrene are both derivatives of polystyrene. On the insulation of the attic with foam, the reviews are generally not bad. The same applies to penoplex. Both materials perfectly retain heat, almost do not absorb moisture and have a very low weight. In addition, insulation with extruded polystyrene foam will be quite cheap.

Foam insulation of an attic with a simple roof is possible, but you will have to tinker with a broken one. No matter how exactly you cut the slabs of material, it will not fit 100% tightly to the roof structures, and we have gables adjoining it. And the foaming of cracks, which is usually used in such cases, cannot be used here.

How to insulate the attic floor: foam and polystyrene

An interesting way to insulate the attic with polystyrene foam: a video of filling polystyrene granules under the film.

Sawdust and ecowool

Sawdust is the cheapest and most environmentally friendly material of all. As a heater, the use of the material began a very long time ago, this is, so to speak, an old-fashioned way. Sawdust has good thermal insulation qualities, they will also protect against noise. However, the material is prone to fungal and putrefactive lesions, easily absorbs water, and over time, the sawdust becomes caked.They are not suitable for insulating the roof of the attic and its gables, but the material can be used for the floor.

Warming the attic from the inside with your own hands: sawdust

Ecowool - in terms of environmental friendliness, perhaps, it is not inferior to sawdust. But in terms of technical qualities - much better. Ecowool does not cake, does not rot and is not affected by fungi. The quality of heat and sound insulation is at a height, suitable for mounting on all surfaces. But it’s impossible to do the insulation of the attic with ecowool on your own - the technology requires special equipment.

Insulation of the attic gable: dry blowing of ecowool under the vapor barrier membrane

Ecowool for attic insulation. Video of wet application of the material.

Insulation of the attic floor with polyurethane foam

About the insulation of the attic with polyurethane foam, the reviews, for the most part, are very good. It is universal in application, it is equally suitable for warming gables and ceilings, as well as for a mansard roof. The material does not settle, does not absorb water, during its installation there will be no gaps or joints, which means there will be no heat losses associated with them. Attic insulation with PPU is done very quickly, however, as in the case of ecowool, polyurethane foam is applied to the surface using a special apparatus.

Which insulation to choose for the attic: polyurethane will be an excellent option, but you will have to call in specialists to perform the work.

How to properly insulate the attic: video of the PPU spraying process.

Do-it-yourself insulation of the attic from the inside with mineral wool - Procedure for performing work

In order to carry out the necessary order of work and carry out the insulation of the attic with mineral wool from the inside with your own hands, you should adhere to the following recommendations:

Check the evenness of the rafter legs.

Run, check the evenness of the location of the rafters, you can use the rule - a metal rail. It is usually applied to the beams and determine the degree of unevenness.

Measure the distance between the rafters.

In general, even at the design stage of the roof, for the convenience of working with mineral wool, a rafter pitch should be taken, 580 or 1180 mm. This approach will allow the use of plates with a standard width of 600 mm, without cutting.

It is much easier to carry out installation with a step of 580 mm. Since, in this case, only one plate needs to be laid in width. Consequently, its fixing is noticeably simplified. A margin of 20 mm allows the insulation to be held during installation, due to friction forces, without additional fixing devices. In addition, installation in a spacer minimizes the occurrence, between beams and insulation slabs, of various gaps and crevices.

Install waterproofing.

Insulation work, as a rule, begins only after the waterproofing and roofing have already been installed. To carry out the installation of waterproofing, allows you to reliably, efficiently protect the heat material from external moisture.

Carry out cutting of thermal insulation boards.

If, nevertheless, the proper distance between the rafters was not foreseen in advance and it strongly does not correspond to the values \u200b\u200bgiven above, then the thermal insulation boards are cut. At the same time, the margin of 20 mm indicated above must be provided. The width of the thermal insulation product should not be much larger than the distance between the rafters.

Install mineral wool between the supporting structures of the roof.

To quickly install mineral wool in the design position, the product is slightly compressed and mounted between the supporting structures of the roof. Further, crumpling and wrinkles on the surface of the insulation are removed

It is also very important to control the quality of the fit of the heat-material in the places where skylights are installed. To do this, you will need to cut out several non-standard elements of the heat product and install it along the frame, the same as for the entire roof plane.

Laying mineral wool slabs between rafters

Insulate gables and exterior walls.

Thermal insulation of the attic from the inside with mineral wool, includes not only the insulation of the roof, but also the walls. Such thermal protection actions are important if on the previous floors, it was not carried out from the outside. In order to qualitatively insulate the gables or external walls on which the slopes rest, it is required to build a frame. Accept the distance between the racks, based on the recommendations above, in paragraph No. 2. It is also necessary to take into account that for walls and roofs, the requirements for heat engineering are slightly different. Therefore, it will be necessary to perform two completely different thickness calculations. If you use the Teremok program, the time for calculation will be noticeably reduced.

Seal all passages and crevices.

After the installation of mineral wool slabs, it is required to eliminate all paths and cracks that allow cold air to penetrate. To eliminate, as a rule, use a sealant or mounting foam. With these chemicals, they fill all the joints between the extreme rafters and the wall, while not forgetting to seal other weak points.

Sealing joints and seams

Make a vapor barrier structure.

When insulating the attic from the inside with mineral wool, in order to prevent unauthorized wetting of the heat product from the inside of the room, a vapor barrier of the structure is made. Basically, polyethylene film is used as a protective material. But a more effective solution is the use of vapor barrier membranes.

The protective material is smoothed and attached to the rafters on a construction stapler. As a rule, the step of the staples is 15-20 cm. The film is mainly mounted with an overlap of 10-15 cm. After fixing the structure, the joints of the film strips are glued with tape. It will ensure the quality and proper reliability of the structure. Further, on top of the vapor barrier film, the lower crate is attached. It will allow you to keep the heat insulator in the design position and will become a worthy basis for the construction of a beautiful ceiling.

Installing a vapor barrier film

Material Requirements

Requirements for insulation may vary depending on the type of roofing device, but the basic characteristics should remain unchanged:

- thermal conductivity not more than 0.045 W/mK;

- material density in the range of 30 - 50 kg per cubic meter;

- rigid or semi-rigid structure of the heat insulator.

Thickness

The thickness of the insulation layer directly depends on the purpose of the attic floor. When arranging living rooms and a bathroom within this space, it is necessary to protect the structure as much as possible from heat loss and freezing.

That is why experts advise using a layer of insulation of at least 100 - 150 mm. Moreover, the material is laid in 2 layers for more effective protection against heat loss.

Density

It is also worth remembering that the lower the density of the material, the greater its thermal insulation capacity and the less impact on the truss system.We must not forget that the weighting of the roof can adversely affect the state of the entire structure of the house, because the pressure of the rafters on the walls increases, and this can lead to their deformation.

That is why, before choosing the optimal insulation for the attic, it is necessary to carefully study its properties and calculate the approximate load on the truss system.

We warm the attic from the inside with our own hands

So, now let's decide what material we will choose for self-insulation of the attic floor. Ecowool and polyurethane foam disappear, as we do not have the necessary equipment. Styrofoam or foam plastic is best used only when it comes to insulating brick gables from the outside. We will use combined insulation with rolled and slab mineral wool. You can calculate the thickness of the attic insulation using any online calculator. Next - the phased insulation of the attic.

Warming of gables

The walls are vertical, so here we will use medium density mineral wool boards. We attach a layer of waterproofing to the gables, install a crate on top of it in increments of 50 cm, cut the insulation to a width of 52 cm. This difference will allow the material to stand up between the slats of the crate

When laying the insulation, we pay special attention to places near the windows, there should not be a single gap left.

Laying mineral wool in the crate of the gables

If the pediments are brick, then we limit ourselves to one layer of insulation, if they are made of boards or other thin material, then we make the second layer. To do this, we fasten slats across our crate, between which we also lay mineral wool. We arrange its plates so that they overlap the joints of the previous layer.This is how the warming cake will look like:

Layout of the first and second layers of insulation

Now you need to sew up the surface with a vapor barrier. The canvases are attached to the crate with staples of a construction stapler. At the joints of the canvases there must be an overlap of at least 10 cm, the seams are glued with special adhesive tape.

Vapor barrier installation

As you can see in the photo above, on the crate, over the vapor barrier, boards are sewn that fix the insulation boards. Now look down: the boards are nailed through the mineral wool slabs right to the wall. You can’t do this, each nail or self-tapping screw in this case turns into a bridge of cold.

Incorrect fixation of insulation boards

We warm the floor in the attic

Since there is a living room below and the attic itself will be warm, then, in addition to retaining heat, the material must have good soundproofing qualities. Mineral wool slabs of low density, or rolled mineral wool, are suitable. We lay a layer of vapor barrier membrane on the floor, fasten it with a stapler to the logs.

Laying vapor barrier on the attic floor

We measure the distance between the lags, cut the insulation plates so that they are 1.5-2 cm wider. Now we put the insulation in the space between the lags. Next, the insulation must be covered with a vapor barrier layer. We lay the canvases, overlap the joints (from 10 cm) and seal them with adhesive tape, as on the gables. Now you can proceed to the device of the subfloor and finishing the attic.

Laying thermal insulation between the lags

Insulation of the attic with your own hands: a video about the device of the subfloor in the attic.

Please note: if we lay insulation between the roof rafters flush with their edge, then here there should be an air gap of 50 mm to the edge of the log. This is necessary for good ventilation of the floors.

Attic ceiling insulation

Soft rolled mineral wool is well suited here. Just as in the case of the floor, first we lay the vapor barrier, then we lay a layer of insulation on top of it. From above we cover the material with a vapor barrier and sew everything up with drywall or boards.

Ceiling insulation in the attic

Which is better - plates or rolls?

Another important parameter is the form of insulation release. Some people like to work only with plates, while others prefer rolled materials. In principle, in practice, roll insulation is more convenient and easy to install. The process is nothing complicated: you need to measure, roll out a roll, cut and lay. It is especially comfortable to work if the rafter pitch is 61 cm - in this case, the roll is simply cut in half, and the resulting parts fit easily and tightly into the space between the beams.

As for the plates, it is more difficult to work with them, and more cold bridges appear. It is also worth mentioning the large amount of waste remaining after trimming. But in terms of transportation, slab insulation is more convenient. In any case, you will have to personally choose which insulation to give preference to.

Insulation in rolls is more convenient in laying slab insulation

Attic roof insulation from the inside and useful tips

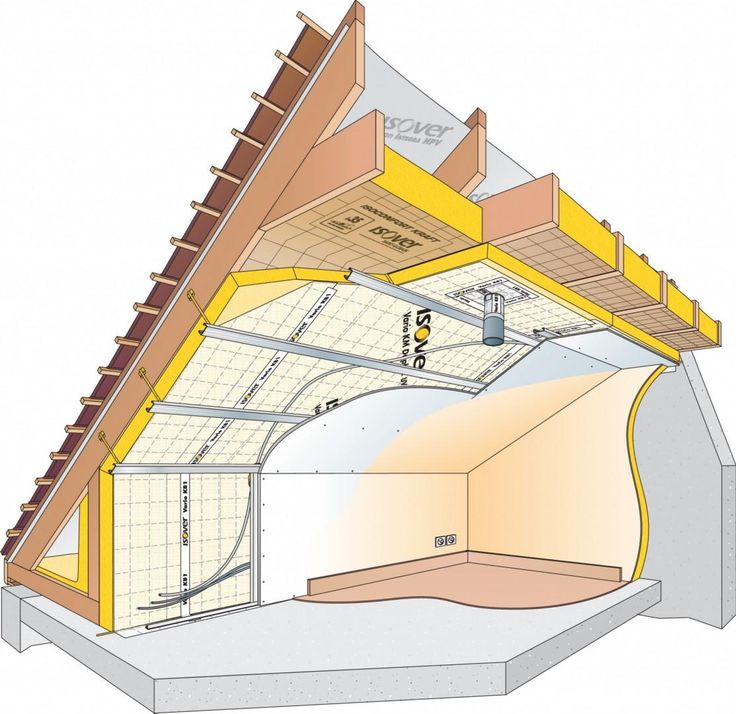

Comprehensive insulation of the room will help to avoid heat loss and save a lot of money on heating not only the second floor, but also the first one. Now we will consider how to make good insulation of the attic ceiling and roof without large overpayments.

STEP 1: under the floor beams (which are set clearly in level), you need to fix a sheet of drywall, which will become the ceiling of the future room. It will be enough to screw the screws with a frequency of 30-40 centimeters. Only insulation for the roof will lie on the ceiling, there will not be much weight there, so it makes no sense to spend a lot of screws.

STEP 2: we put a vapor barrier under the drywall. It should protect the insulation from increased moisture, which can accumulate in the room and rise up when the air is heated. Without vapor barrier, the effectiveness of the insulation will be reduced by 5-65% (depending on the type of material). For example, mineral wool increases its thermal conductivity with increased moisture by 50%, and polyurethane coating by only 5%.

STEP 3: attic insulation with mineral wool and polyurethane. Why? Because that's the best way to do it. At least 10 centimeters of cotton wool must be laid on the ceiling in order to get at least 3-4 W / m2 * K. If funds allow, it is best to spray the polyurethane layer on the roof from the inside, since when it hardens it does not form cold bridges and protects against moisture. 2 cm will be enough - in combination this will give an excellent result.

STEP 4: laying the diffusion membrane on top of the insulation. It keeps it dry and reduces heat loss. But it may not be laid if the attic is very dry and the insulation of the roof itself is of high quality.

Many builders advise insulating the attic floor with ecowool or bulk building materials (for example, expanded clay), but here we must understand that we will lose about 20-25 centimeters of room height and will not “close” the heat of the first floor.It is better to use such insulation when insulating the floor in a house or garage, where there will be earth or bedding under the logs.

We suggest watching a detailed video of the attic roof insulation with your own hands, because it is better to see once than to read 10 times:

Attic and its subtleties as a building object

A bit of interesting history to make it easier for you to understand why attics are such problematic in terms of heat.

For the first time, the concept of an attic was introduced into this world by the French architect Francois Mansart, in the 17th century, who proposed using the attic space for household and residential purposes. And from the beginning of the next century, the poorest people began to live under the usually uninsulated roof. And only much later - bohemia, i.e. wealthy youth, free artists and poets.

The joy of the Parisians can be understood: at that time, the tax for a house was taken based on the number of floors, but the attic was not considered a floor. Those. it made sense to equip this nice room because of the economy, and therefore the fashion for a residential attic came to Russia much later. And only since the 1990s, the attic has come to grips with: the market has sharply become inundated with a variety of heaters and new building materials.

And today, the attic as a living space is recognized by modern building codes and regulations (SNiP), which state that this term can be called the attic, where the line of intersection of the facade and the roof plane is not lower than 1.5 m from the floor level. But with all confidence we will tell you that the attic insulation and waterproofing technology is the most complex and demanding of all existing ones.

General aspects of attic insulation work

When performing various repairs, in particular, warming the attic from the inside, you should decide what this room will be equipped for. It should be understood that due to the lack of a “thermal cushion” in the upper part, which was replaced by skylights, the room is rather cold by nature. Based on this, the insulation must be of high quality.

Attic insulation scheme

And here some difficulties arise. Each building has its own individual architecture, it is necessary to take into account the shape of the roof and the physical characteristics of the material of the roof and walls. Difficulties often arise in the fact that the surfaces are uneven. And for the implementation of the discharge of condensate, it is necessary to make waterproofing. You should also take into account the fact that more heat passes through the end walls of the attic, which is why they also require insulation.

Conclusion

Never save on the thickness of the insulation layer. If it gets too hot, you can always open the windows to ventilate the rooms. And if it is too cold, you will have to spend additional significant money on heating to comfortable temperature values.

We did not consider options with "ecowool" and liquid polyurethane foam for several reasons.

- Firstly, state sanitary authorities recommend using these insulation options only for external work.

-

Secondly, it is impossible to make such insulation on your own; you have to use the services of specialized construction companies. How much such “pleasure” will cost, you can guess on your own.

- Thirdly, "ecowool" for thermal insulation of vertical surfaces is a very bad option.It will definitely shrink over time, the effectiveness of the money invested in thermal insulation work will approach zero.

An example of a warm operated attic bath

Bath with insulated attic