- Production of ceramic pipes

- Applications

- Which chimney is better

- Mounting Features

- Requirements for ceramic chimneys

- It's important to know

- Chimneys for a bath: internal or external?

- Mounting Features

- Selection Tips

- brief technology

- By installation

- By independent production

- Useful tips for installation

- Types of chimneys

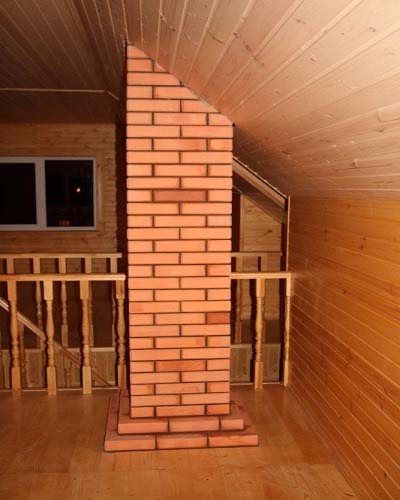

- Brick

- galvanized pipe

- coaxial chimney

- Ceramic

- Stainless steel

- Requirements for the arrangement of chimneys

- brick chimney

- Ceramic chimneys

- Metal chimneys

Production of ceramic pipes

So, in order.

To begin with, we will study the technology for the production of ceramic pipes, so that it is more understandable for you, we will describe the process in stages:

- For the processing and preparation of raw materials, the same equipment is used as in the manufacture of bricks. This process includes: Grinding clay - removal of lumps.

- The introduction of special additives that increase the strength of products.

- Preparation of mass for the formation of products.

On the so-called pug mills, the molding mass is evacuated and compacted. Products are molded on screw vertical vacuum presses in a plastic way. This equipment does:

- Formation of products.

Connecting socket.

Cutting the product to a given length.

This is followed by drying with firing.These processes take place in special:

- tunnel dryers.

The use of such equipment in production can significantly increase the quality of products.

tunnel ovens.

At the end, the ceramic product is glazed from the inside and outside by dipping into a special pool.

Applications

Due to its excellent quality and performance characteristics, ceramics are used in various areas of production and in the household sector.

According to the intended purpose, these products are divided into:

At the same time, do not be surprised if you are offered not round pipes at all.

- Ceramic pipes for sewerage. Distinctive features: High wear resistance.

- Not susceptible to corrosion.

- They are not sensitive to temperature changes.

- They are not afraid of the aggressive effects of sewer fecal or chemically saturated industrial effluents.

- Practical and easy to fit.

A separate column can be distinguished ceramic sewer pipes intended for the installation of drainage systems. The features of these products are:

- The presence of holes along the entire length (perforation).

High strength under various loads in the ground.

Sufficient flexibility of ceramic drainage systems due to the connection with special couplings.

Possibility of use on almost any part of the landscape for drainage.

Products of large diameters with increased tightness and strength are used in microtunnelling. This method of laying pipelines allows you to arrange engineering communications without disturbing the pavement of roads and pedestrian sidewalks. In addition to sewerage, they are used in the creation of systems:

- Water supply.

Heating mains.

Gas supply.

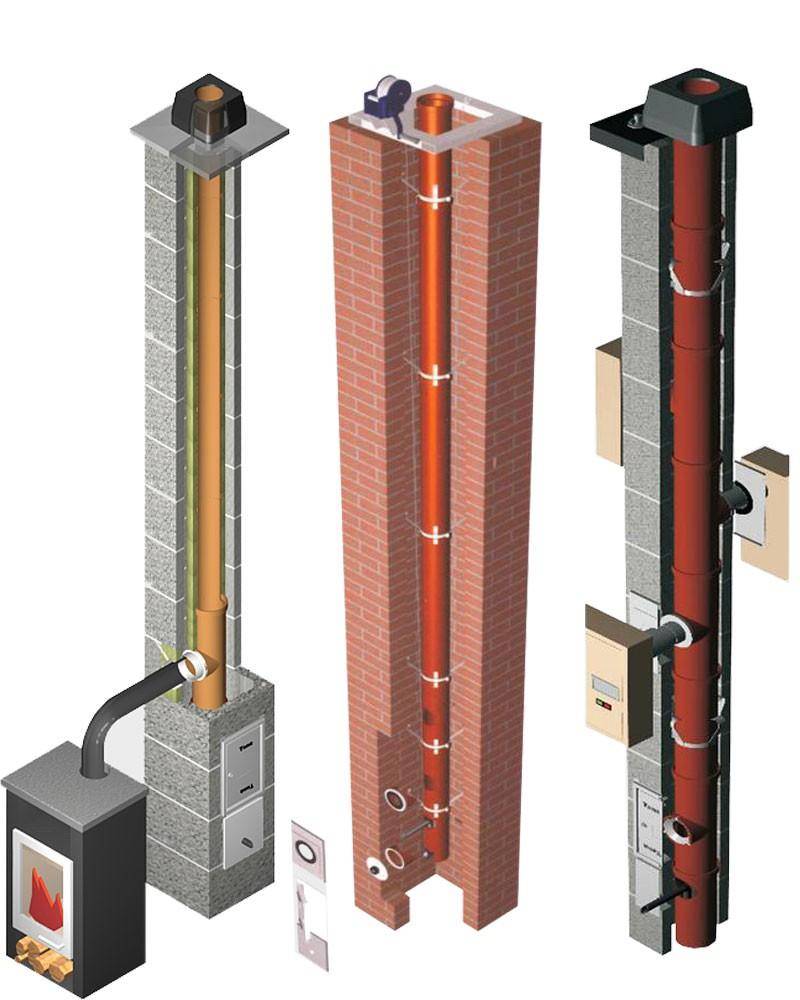

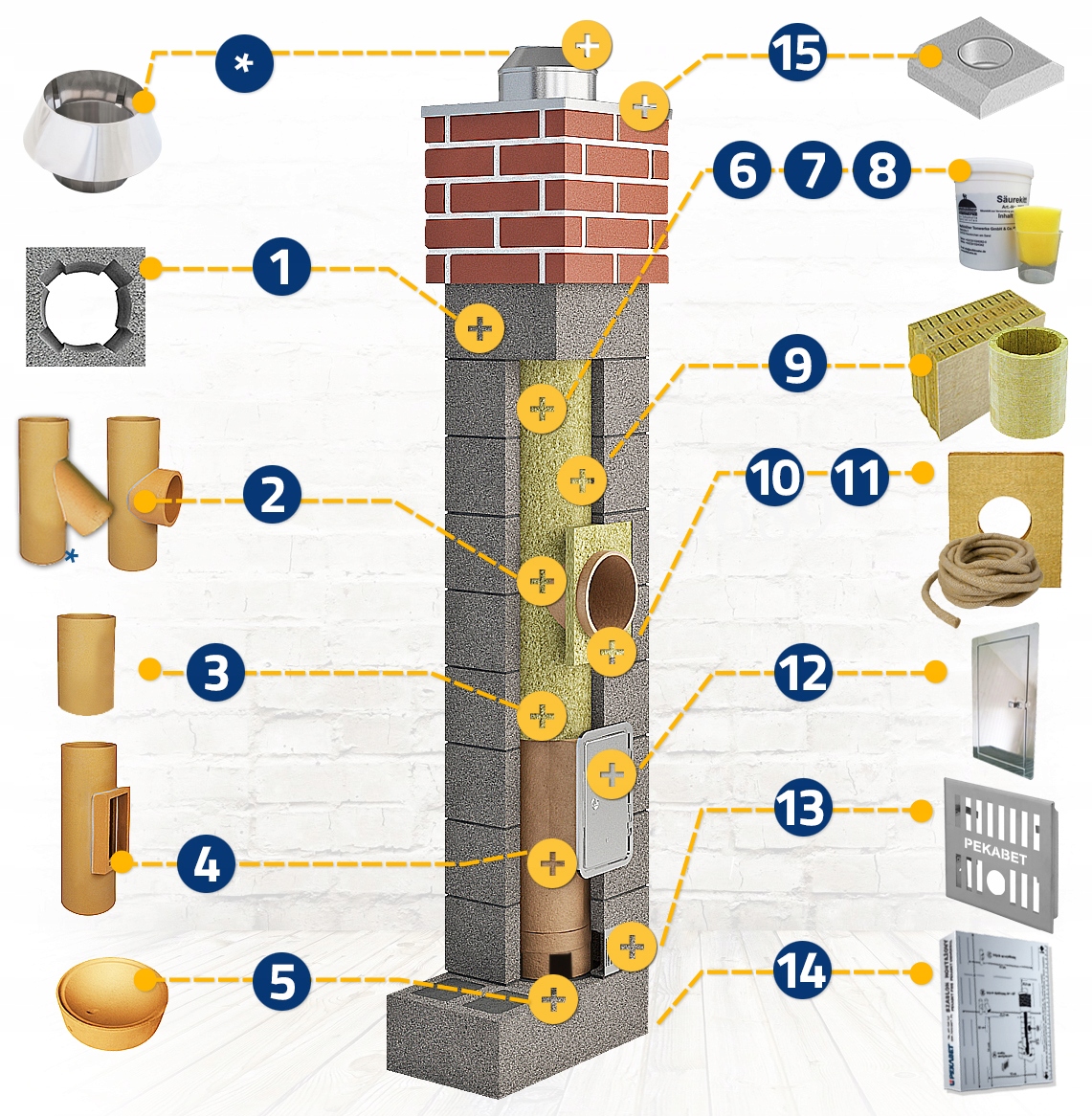

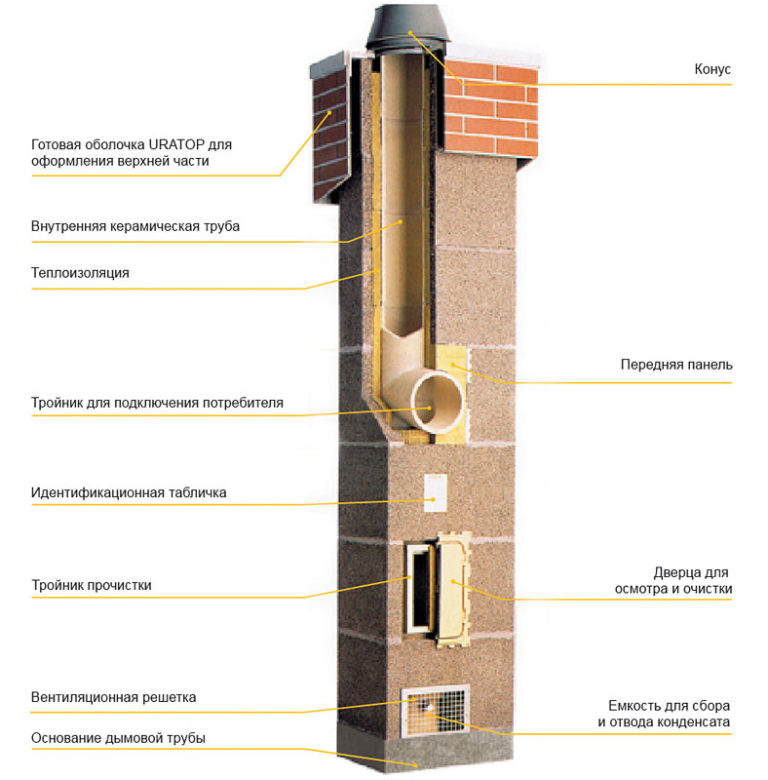

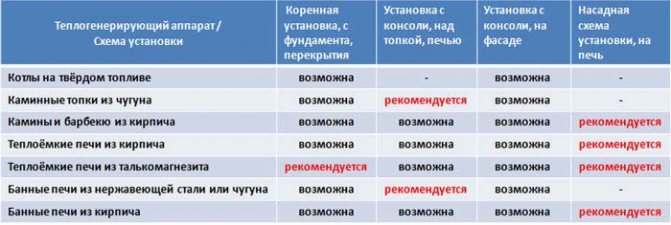

ceramic chimney pipe utilizing combustion products from various equipment, such as, for example, boilers (gas, diesel, wood), stoves, etc. The ceramic chimney is assembled from individual elements, and then covered with a protective layer of steel with an anti-corrosion coating or expanded clay.

Chimneys should be insulated and insulated so as not to lose "precious" heat

Without exception, all ceramic products, regardless of the scope of application, are distinguished from their counterparts by the following:

- Relatively low price of products.

- The durability of the structures created from them (you will not need repairs in the next 5-10 years).

- Environmental safety for human health and the environment - the background is not disturbed.

- Thermo-chemical resistance to various influences.

You can try to cut a damaged product, but, as a rule, this does not help, the element will have to be thrown away

Which chimney is better

When arranging a chimney, the right material plays an important role. It is best to use pipes made of stainless steel. Outside, they are trimmed with bricks, blocks, laying out a pipe that looks like a classic fireplace. In this case, the brick can be used not only heat-resistant. The pipes have a high level of protection against heat, so the brickwork will not get very hot.

When installing a steel pipe in the form of an insert in a smoke exhaust duct, a door must be installed to inspect the system and clean it. Such doors are placed in places of inclination, where decomposition products can give out sediment. The smoke exhaust system is cleaned through the windows.

Ceramic pipes designed for chimney installation have proven themselves well. They are very expensive, which is why they are rarely used. Outside, they are ennobled with hollow expanded clay concrete blocks, bricks. As a result, the pipes of the smoke exhaust system are hidden inside an attractive box.

A headband is put on top of any type of structure. In places where pipes pass through combustible structures, reliable, refractory insulation is mounted.

Mounting Features

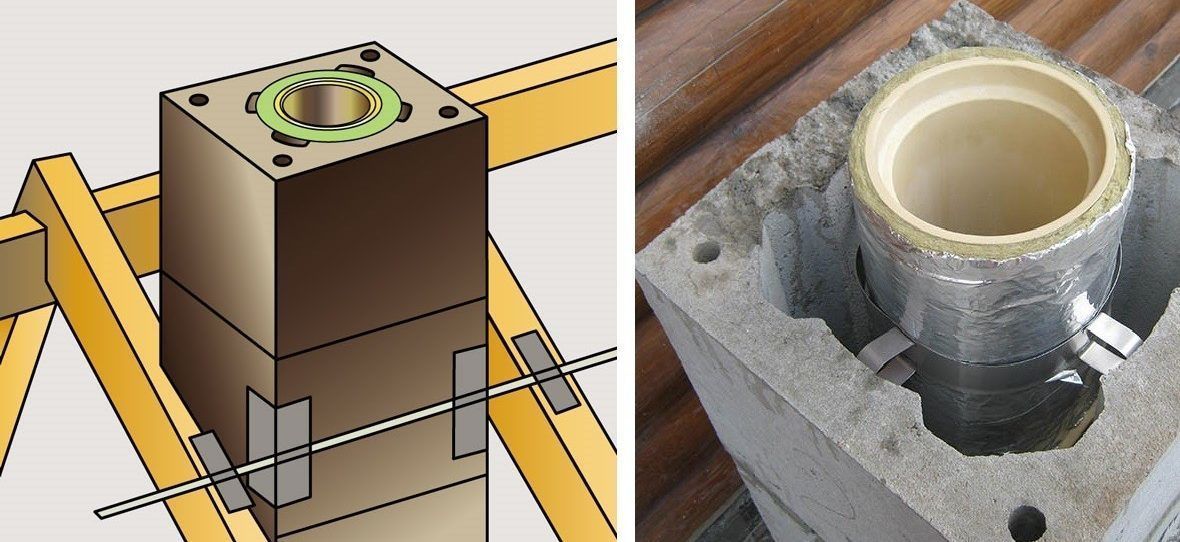

Installation of a ceramic chimney implies several important features. So, keep in mind that you will need to prepare a solid foundation. The "pillow" should be perfectly horizontal and even, without tilt and other things.

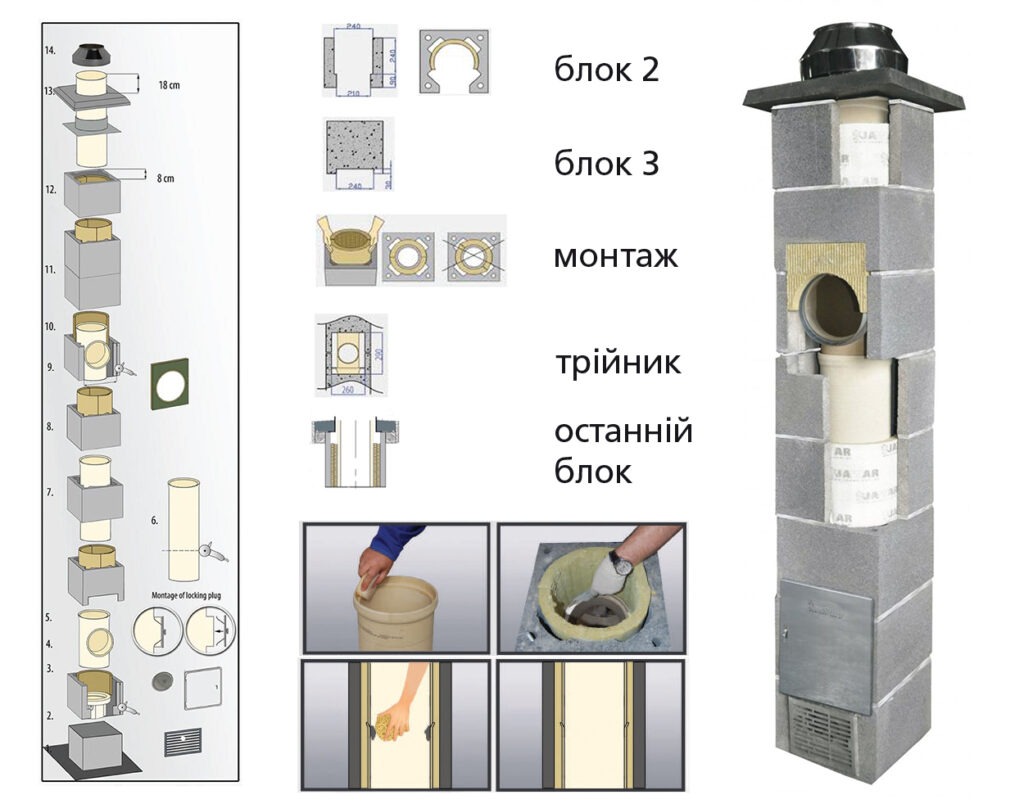

Here is the main work plan:

- The solution is laid out on the finished “pillow” in the right amount, in each individual case, calculate independently based on the weight of the structure and the diameter of the chimney. So, a module is installed on the solution, which can combine not only the connection pipe to the boiler, but also a special condensate receiver. By the way, do not forget to install a hatch for preventive cleaning with a "cesspool".

- We are preparing a special solution on which the chimney will “sit down”. Please note that it must be acid-resistant. It is necessary to dilute the solution according to the manufacturer's recommendations, but often be guided by a similar calculation: 1 part of water to 7 parts of powder. In addition, remember that mixing must be done at a temperature not lower than 17-20 degrees, but the solution must be used in 1.5 hours.

- Install the tee module, be sure to coat the place with a solution.

- Install the rest of the pipe, but do not forget to put the mortar in plenty and level it after shrinkage. By the way, be sure to remove excess mixture from the inner walls.

Assembled ceramic chimney

Assembled ceramic chimney

An important tip, do not place the junctions of two different segments at the overlap points. As you can see, the features of a ceramic pipe are quite acceptable for the construction of such a structure on their own

It is important to pay attention to the rules and recommendations above.

Requirements for ceramic chimneys

Ceramic chimney pipe must necessarily comply with certain operating rules, which are prescribed in building codes for the use of such material

Attention to these rules and regulations must be paid without fail, otherwise, due to non-compliance with certain points, the system of operation and outflow of gases may be disrupted, which will lead to the destruction of the seams and the ingress of exhaust gases into the room. What such problems threaten, everyone understands perfectly well.

Therefore, we list the basic requirements for blocks of expanded clay concrete:

- They must necessarily rise above the roof (flat) by at least 1.20 - 1.25 cm.

- Elevation above the parapet, ridge, not less than 50 cm.

- It is forbidden to install the pipe below the ridge mark.

- It is forbidden to place below the ridge and at an angle of more than 10 degrees.

- The minimum height calculated for such a pipe should correspond to 5 meters, the segment from the grate to the head is taken into account.

In addition, do not forget about the most important rule prescribed in SNiPs.Namely, the diameter, the cross section of the pipe itself cannot be more or less than the outlet of the branch pipe

Scope and installation schemes of ceramic chimneys

It's important to know

Before starting the installation, it is worth familiarizing yourself with some subtleties

For example, it is important to know that the larger the area of \u200b\u200bthe structure will be inside the room, the less heat loss will be. When creating a detailed diagram, consider the fact that even horizontal sections should be up to one meter

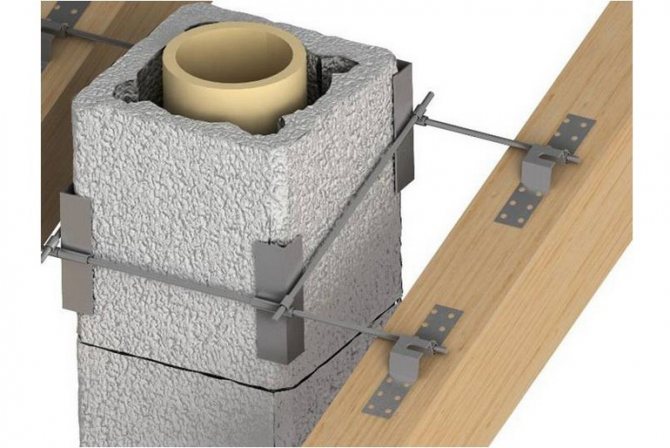

Please note that the contact of the system with any communications, such as gas and electricity, is unacceptable. And if wooden parts come across in the way of placing the chimney, then the pipe must be moved away from them using special steel brackets. The distance between the fasteners should not exceed one meter.

Also include in the plan a part of a collapsible pipe or an insert with a door through which it will be possible to inspect and clean soot. Of course, installing a chimney sandwich is a serious and responsible matter, so if you decide to do it without specialists, then understand the degree of responsibility and strictly follow the step-by-step instructions.

Chimneys for a bath: internal or external?

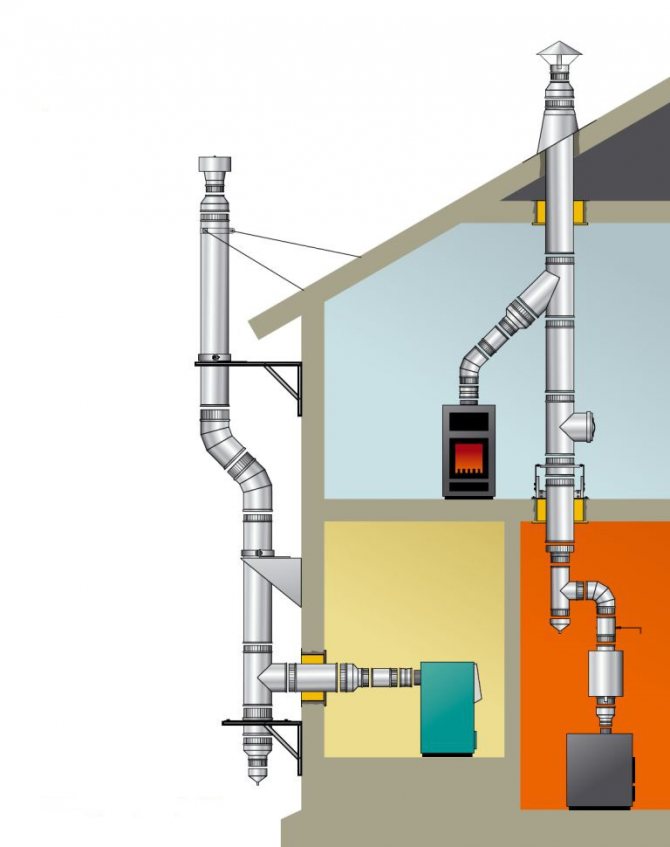

All chimneys for wood burning stoves It is customary to subdivide according to the principle of their installation into internal and external. In Russia, internal systems are more popular. They allow you to significantly save heat inside the room, while the external ones are more typical of Western-style baths and have an aesthetic function.

Each of the models has a number of advantages and disadvantages:

- Interior. Differs in the increased internal draft which considerably exceeds draft of an external flue.When installing it, there is no need for additional insulation and the presence of a door for cleaning the pipe from soot. In general, caring for it is much easier than for the outside and requires almost no significant action. Another plus is the fact that the internal chimney retains heat indoors for a long time. The only drawback is the complex design.

- External. When installing it, you do not have to make holes in the walls and roof, however, the natural draft of such a chimney is much lower. In general, as already mentioned, its installation is more of an aesthetic nature.

Mounting Features

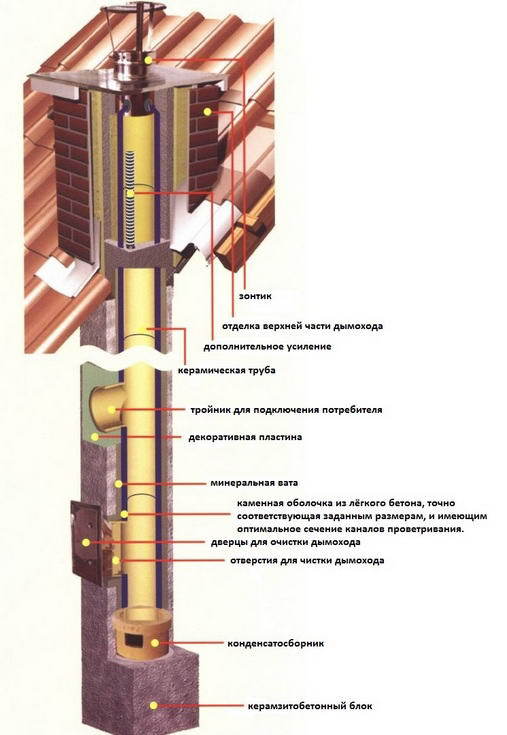

Step-by-step instructions for installing a ceramic chimney:

- the base for installing the pipe (foundation) must be perfectly flat - no distortions during installation are allowed; the top of the foundation is leveled with cement mortar;

- a special acid-resistant solution is used to seal the seams between the modules. It is diluted in accordance with the instructions on the package immediately before use, it is advisable not to knead the entire amount of the mixture at once - otherwise the solution will harden during the assembly process;

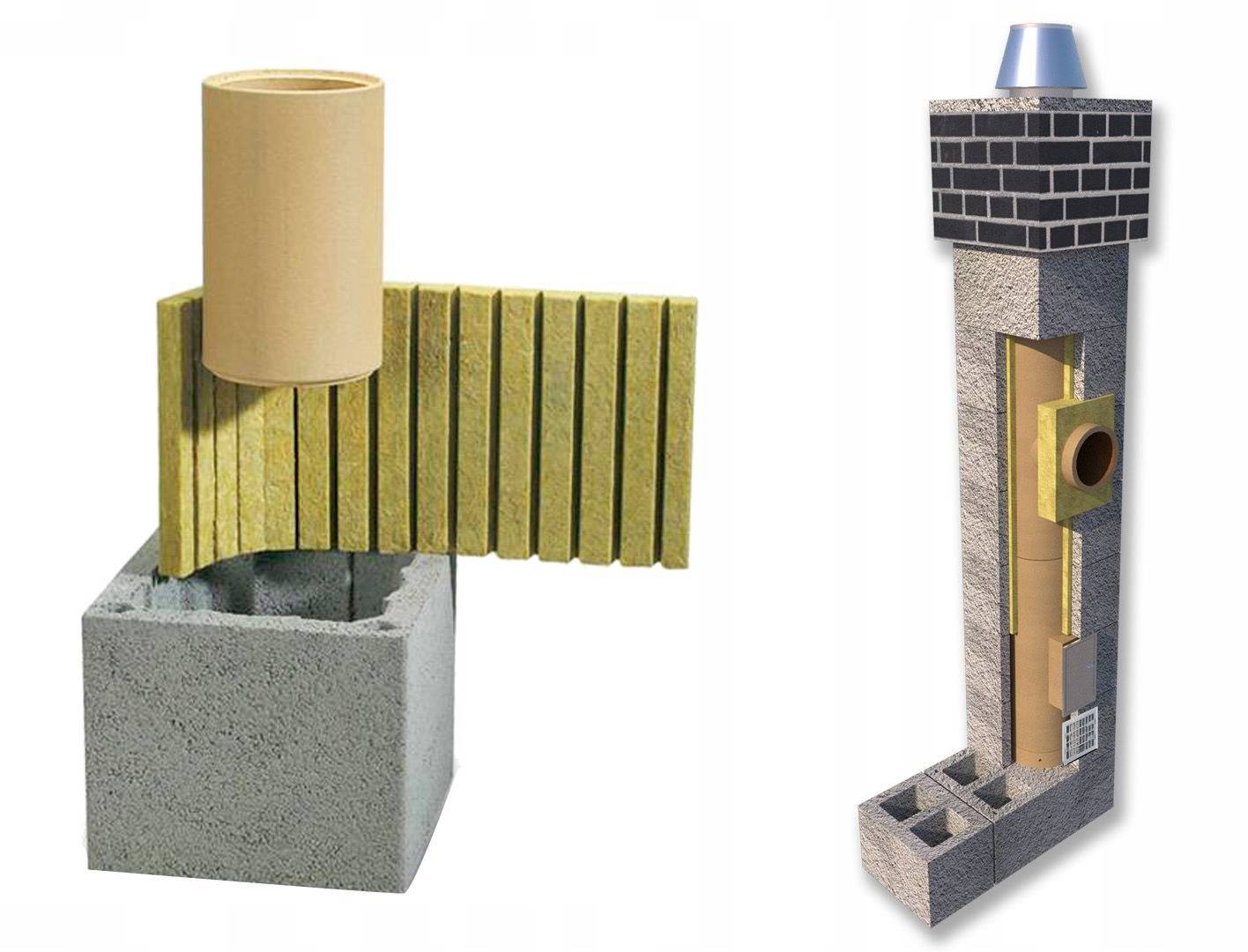

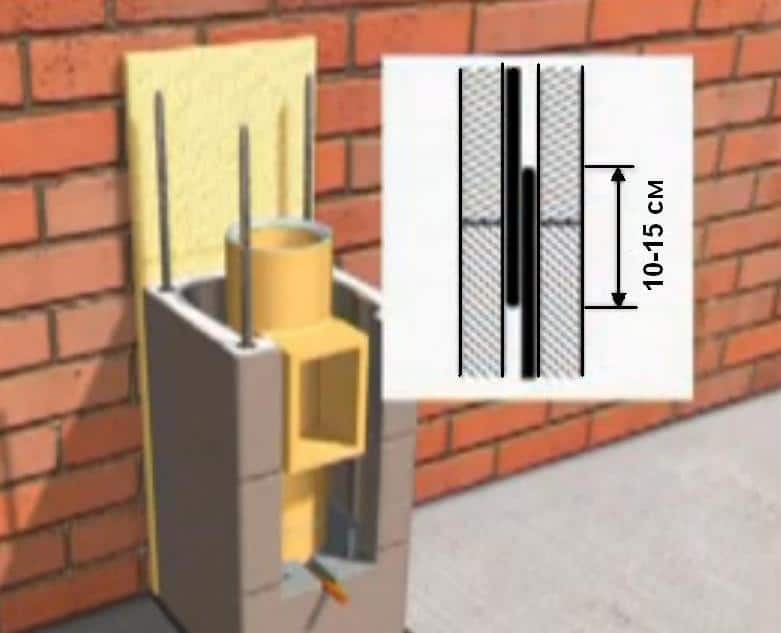

- an external expanded clay concrete body is installed on the foundation;

- insulation and reinforcing elements are inserted into it; it is convenient to cut them into pieces of 1.5 m each. if it is necessary to connect two reinforcing rods, they are simply inserted into the holes in the body blocks with an overlap of at least 100 mm. Holes with reinforcing bars must be filled with cement mortar;

- the joints of the hull blocks are also fastened with cement mortar;

- a module with a condensate tank and a pipe for its removal is installed;

- in the future, the pipe elements are mounted in the same order - body, insulation, ceramics;

- if necessary, holes are cut in expanded clay concrete elements with the help of a grinder;

- then a module with an inspection door or a tee for cleaning is mounted;

- then a tee is mounted to connect the boiler or fireplace;

- then the pipes are mounted;

- excess solution should be wiped with a wet sponge;

- when passing through the roof, the pipe is fastened with special clamps.

After installation of all structures, decorative finishing of the outer expanded clay concrete body and installation of the deflector are carried out.

Selection Tips

There is no fundamental difference in quality and design between the products of different companies. No one makes junk from ceramics - this is a new product, it is produced by companies that sufficiently value their reputation. Therefore, evaluate your financial capabilities and listen to those who have already installed ceramics. If you do not do it yourself, listen to the opinion of installers. We advise you to buy all components in large stores or construction hypermarkets, with a receipt and a guarantee. In addition, it is easier to pick up all the necessary details at once (and hear the advice of a sales assistant).

Do not get hung up on buying imported products. The quality of Russian ones is not worse, but the price differs for the better.

Before buying, you need to make a calculation power of the heating unit and choose the unit itself - then the diameter of the outlet pipe of the unit and, accordingly, the chimney will be known exactly.

brief technology

By installation

- To install a pipe from blocks, arrange a lightweight foundation, since the mass of the future structure allows it to be placed on a less massive slab than with a brick or concrete chimney. To do this, you can simply fill in a slab 20-25 cm thick, which will have dimensions larger than the base of the chimney, about twice. It is necessary to ensure the protrusion of the slab on each side of the base by at least 15 cm. For 10-meter or more chimneys, the foundations are deepened by 50 cm or more, but the slab does not need to be poured.

- To ensure sufficient draft in the chimney, pipes are immediately placed, preferably metal, if you plan to power the heating system of the upper floors from the chimney. You can also use ceramic pipes, but they will not provide heat transfer, so your second floor will not be heated from the chimney. In the upper part of the pipe it is necessary to insulate to prevent the formation of condensate. When installing the structure, use small pipe sections to make it convenient to work. The chimney is assembled together with the chimney, ahead of it by a maximum of a meter. It is advisable to prepare pipes in advance by cutting them with angle grinders or in other ways.

- Lay the blocks on cement mortars or on special glue, which is designed for long-term operation at high temperatures (about 1000 degrees). In the instructions for such adhesives, everything should be described in detail whether they can be used for laying stoves and chimneys. Masonry is carried out in the same way as in the case of standard bricks: dressing in the corners, running up vertical seams, and so on. During work, use a plumb line and a building level to align the elements horizontally.If you still decide to use not glue, but a cement-sand mortar, then it must correspond to grades not lower than M50 - M75

- Assemble the inner pipes according to the technology developed by the manufacturer. If this is a sandwich chimney, be sure to ensure that both pipes are connected qualitatively, both external and internal. The pipes are attached to the blocks with the help of special embedded brackets, they are laid in the seams, and are not mounted after the installation of the next block. It is not recommended to use an anchor (and it is inconvenient, since you have to drill blocks from the inside).

- For high-quality thermal insulation of pipes inside the chimney (see Chimney insulation), it is best to use mineral wool insulation, in particular, basalt. They are heat-resistant, easy to install and provide a low level of thermal conductivity.

- All fittings that are required during the installation of chimney blocks must be fastened to the body of the block with a tie-in. To do this, use a manual mechanized tool. You can also fix some elements on the solution on the pins.

By independent production

Abroad, blocks have long been produced industrially. It is convenient that the elements have different dimensions: you can make any design at your own discretion. But not everything is so rosy.

For example, in Czechoslovakia, baked clay is used as a raw material for their production - already during the manufacture of such products, many cracks form. In Switzerland and Germany, some companies produce reinforced concrete blocks for chimneys - they are very heavy and inconvenient to install. In the USA, fired clay is present in the interior of the blocks, and it also does not always withstand high temperatures very well.

Useful tips for installation

One of the main rules for the installation of ceramic chimneys: only whole elements are suitable for installation. Chips, cracks or any other damage is unacceptable. Do not try to repair the damaged area with a sealant or something similar.

This is a dangerous decision, since damage hidden inside the structure can fail at any time and cause a fire.

Therefore, each element must be checked at the time of purchase, as well as immediately before installation. If even slight damage is found, a replacement should be made. The base for the adapter must be perfectly flat and horizontal.

Maintenance of a ceramic chimney must be carried out regularly twice a year: inspect, clean from soot and check the level of draft

Maintenance of this type of chimney is not difficult to perform. It is necessary to check the presence of traction, clean soot pipes, to control the integrity of all structural elements.

Usually these operations are performed twice a year, but if there is reason to doubt the normal functioning of the chimney, maintenance activities can be performed unscheduled. Although with proper installation, problems with such structures practically do not arise.

Types of chimneys

Pipes are made from different materials, which we will consider in more detail.

Brick

Classic brick chimneys for a gas boiler are still in demand, regardless of their many disadvantages and poor thermal performance. At the same time, they comply with sanitary standards and rules, which state:

- The pipe is made of fireclay bricks.

- For the construction of walls, a solution of clay or special glue is used.

- To improve draft, the chimney rises above the level of the roof ridge.

Standards regulate the height of the pipe in relation to the roof ridge, depending on the distance between them

- The masonry provides tightness.

- At the inner hole, the deviation is no more than 3 mm per 1 m.

- To protect against precipitation, a deflector is installed on the head of the pipe.

And also the chimney can have a mono design, which, due to low thermal characteristics, is repaired every 5-7 years.

galvanized pipe

A sandwich device is today the most effective chimney design option. The undoubted advantage of these chimneys is their resistance to aggressive environments and various mechanical influences.

The product consists of two pipes of different sizes, with one inserted into the other. Basalt wool is usually used as a filler between them.

coaxial chimney

Currently, gas boilers use closed-type combustion chambers. Here, air intake and smoke removal are produced by a coaxial pipe. This is an original device, relatively recently introduced, but already very popular among users.

The non-standard solution lies in the intake of air through a pipe that removes combustion products. It turns out that one pipe performs two functions due to the design features.

A coaxial chimney is a pipe in a pipe

And its characteristic difference from ordinary pipes is as follows ... A smaller pipe (60-110mm) is located in a pipe of a larger diameter (100-160mm) in such a way that they do not touch each other.

At the same time, the structure is a single whole due to the jumpers along the entire length and is a rigid element. The inner pipe serves as a chimney, and the outer pipe serves as fresh air.

Air exchange at different temperatures creates traction and sets the air mass in a directed motion. The air in the room is not used during the operation of the boiler, thus maintaining the microclimate in the room.

Ceramic

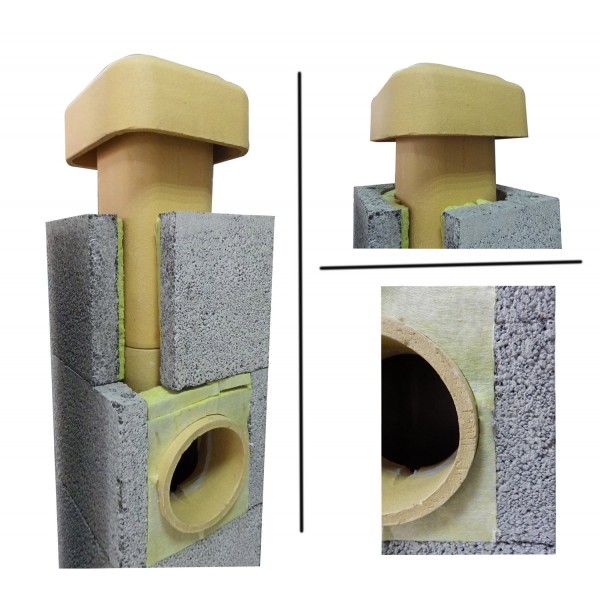

Such a chimney is a composite structure, including:

- Smoke duct made of ceramic material.

- Insulation layer or air space.

- Claydite concrete outer surface.

This complex design is due to several reasons. First, the chimney pipe is too fragile to be left unprotected.

A ceramic pipe is always located inside a solid block.

Secondly, ceramics has a high thermal conductivity, and therefore it needs reliable insulation. The inner tube of a circular cross section has a smooth surface, while on the outer tube, roughnesses are allowed that do not affect the integrity of the product.

Typically, such chimneys are available in lengths from 0.35 to 1 m, depending on the manufacturer. The connection of the inner and outer pipes occurs by means of a lock, which is a thinning in external size from one end and an expansion of the inner pipe from the other side.

The expanded clay concrete outer surface is made of a square shape with a round hole inside. In addition, this product provides a place for a heater, which is held by metal jumpers. At the same time, they are fixed on the outer surface and make a reliable fastening for this pipe.

Stainless steel

A gas chimney made of steel seems to be more reliable than a brick one. They are resistant to corrosion, immune to temperature fluctuations, they are not affected by increased air humidity and aggressive environments.

Stainless steel chimney

In addition, such stainless steel pipes have a number of advantages:

- Long period of operation.

- Multifunctionality.

- Relatively low cost.

- Great strength.

- Probable realization of a product of any complexity.

For chimneys made of this material, an assembly of modules is characteristic, which allows the replacement of a damaged segment if necessary. The installation of chimneys is made with the help of special bends, which allow them to harmoniously fit into certain elements of the roof.

Requirements for the arrangement of chimneys

The main norms for installing a chimney are the distance to wooden structures and other flammable elements. So the information is as follows:

- The distance to the tree must be at least 15 cm if the pipe is made of brick or concrete.

- The distance increases to 25 cm if the pipe material is ceramic.

Important! Be sure to remember that not only wooden structures, but also most finishing materials also light up easily, so the distance to them must also be taken into account

brick chimney

Chimneys made of refractory bricks continue to be popular for wooden houses. The important rules for its laying are as follows:

- Make a chimney from the floor to the ceiling, that is, indoors you need to use limestone or cement-limestone mortar, laying on the roof is carried out with cement mortar.

- The surface of the pipe inside must not be plastered.

- It is necessary to lay a chimney from solid red brick, the seam of which is not more than 10 mm.

- With a large weight of the structure, it must be strengthened with a foundation.

- The destruction of the brickwork occurs due to acid condensate, as a result of which the fragments get inside, thereby reducing the cross section of the channel.

Soot accumulates inside brick chimneys due to the roughness of the surface.

It is recommended to carry out such an event as a sleeve. It consists in filling the space between the brick and the pipe with concrete to eliminate some of the negative points.

Ceramic chimneys

Chimneys made of ceramics are gaining more and more popularity in wooden houses. This is due to the following benefits:

- The modular system is sold already assembled.

- Ceramics are durable, heat-resistant and resistant to acids.

- Unlike brick, soot does not accumulate here due to the smooth surface.

- With all this, such chimneys are very heavy and require a solid foundation. Moreover, the distance from the chimney to the wooden wall must be at least 25 cm.

Metal chimneys

No less popular are chimneys from sandwich pipes thanks to the following benefits:

- Simplicity and ease of installation.

- Light weight design when no additional foundation is needed.

- Thanks to the smooth surface, there is no soot settling, the continuous circulation of the air flow draft is not disturbed.

- During installation, it is filled with basalt wool for thermal insulation.

- It is characterized by durability and safety due to the use of stainless steel inside.

- Interfloor overlap in this case is solved by factory cutting.An important point is the articulation of the chimney pipes, in which they must be outside the structure and not fall into the ceiling.