- Features of cleaning boilers of different brands

- Baksi

- Navien

- Ariston

- Vaillant

- Beretta

- Arderia

- Causes and consequences of clogging

- How to remove and clean the AOGV burner block

- AKGV series

- Choosing a boiler "Borino"

- Consider the method for finding the above malfunction

- Working with AOGV

- Combustion products and their cause

- Automation for heating gas boilers AOGV

- Automation for gas boilers AOGV

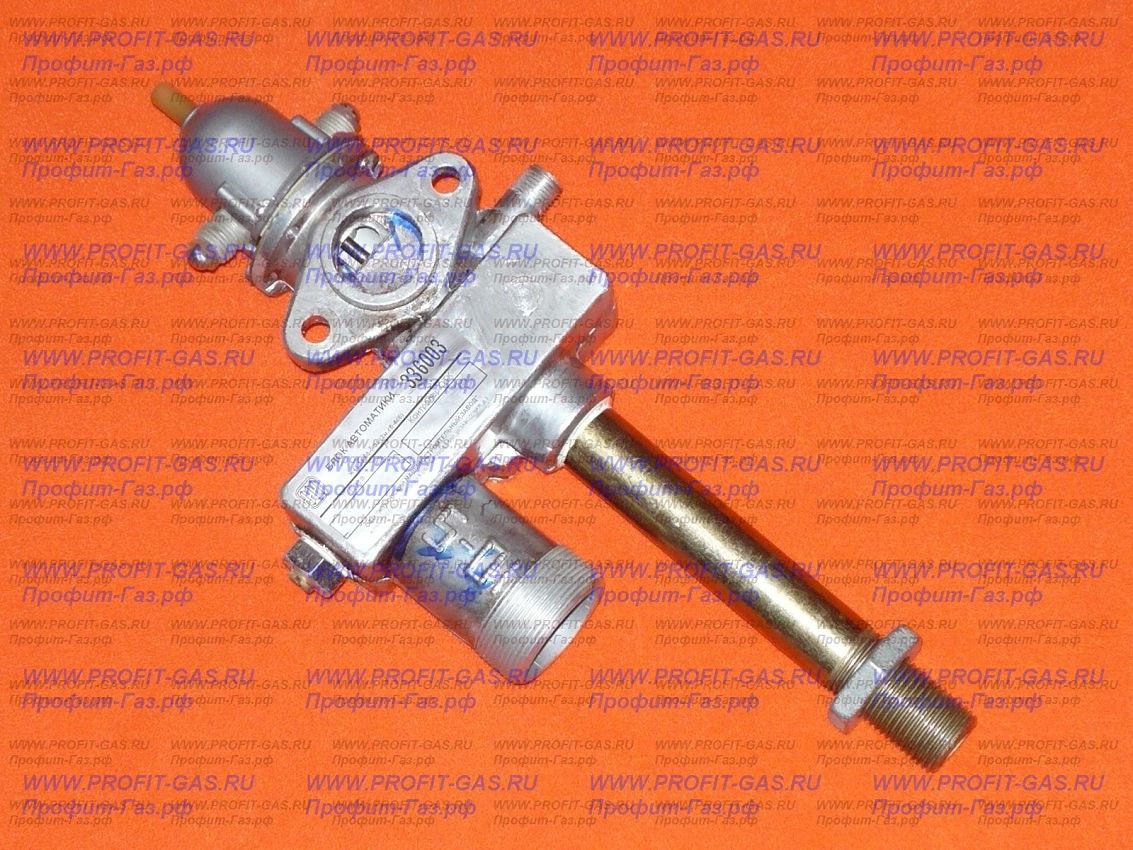

- What does automation for gas heating boilers AOGV consist of?

- The main characteristics of gas boilers AOGV-11.6-3

- Company "VodoGazServis"

- Startup and operation instructions

- How to check the thermocouple of the AOGV boiler

- The device of the gas boiler AOGV - 17.3-3

Features of cleaning boilers of different brands

Depending on the manufacturer of the water heating equipment, cleaning may have a number of nuances that must be considered. Let's look at the most common brands.

Baksi

The main feature of Baksi boilers is the presence of a secondary plate heat exchanger. This should be taken into account when choosing a cleaning agent.

Navien

A South Korean manufacturer that produces water-heating products adapted to Russian conditions. During its flushing, no problems arise, since the system has increased stability and reliability.

Ariston

Ariston equipment is equipped with additional water purification filters, which is why water enters the system cleaner than usual.This allows you to do without cleaning for a long time and use sparing options when choosing chemistry.

Vaillant

The temperature regime of operation recommended by the manufacturer is in the range of 40-50 o. If you follow it, scale will accumulate in the heat exchanger more slowly.

Beretta

A quality manufacturer that adapts its products to Russian realities. Has no features during cleaning. It is carried out by analogy with most similar products.

Arderia

Another brand from South Korea equipped with two heat exchangers. In case of incorrect operation of the product, it is advisable to clean both parts.

Causes and consequences of clogging

Energy dependent are divided in turn into:

- processing gas;

- electrical installations;

- solid fuel and liquid fuel equipment;

- combined models.

Volatile boilers can turn off for a number of reasons:

- surges and surges in power lines

- lack of electricity

- failure of factory settings.

Often used in homes: AOGV, Zhukovsky boiler, gas "Hearth", Lemax, Signal, Conord.

Do-it-yourself furnace for working out: drawing, scheme of work. Read here.

Connection to the city water supply network: documents, prices:

Mechanical ones can work intermittently due to wind flow entering the chimney. In addition, due to insufficient oxygen, the flame may go out.

You should pay attention to the hood (for cheaper models it is not always present)

When the chimney is contaminated, modern devices have an alert system that will notify you of problems and the need for cleaning.

How to remove and clean the AOGV burner block

To remove the burner block, you need to turn the boiler pan and disconnect the igniter tube, gas pipe and thermocouple contact tube from the automation unit. Then carefully unscrew the nuts on the fittings of the automation unit.

Remove the paronite gasket on the main gas pipe and check its condition. Check the gasket on the flare tube for wear, most likely it will remain on the tee fitting.

After disassembling this assembly, the pallet is easily rotated and through the groove closest to the tubes, the holder is removed from engagement with the casing. Supporting the bottom of the tray, slightly push it towards you and disengage the other two holders. Lower the entire assembly to the floor and carefully pull it out between the legs of the boiler.

- Check the condition of the main burner and clean it if necessary. Then inspect the ignition torch nozzle.

- Unscrew the two screws holding this assembly in the assembled position (wick and thermocouple). To facilitate unscrewing, process the screws with WD-40, the process will go much easier.

- Remove the box housing from the pilot burner to gain access to the nozzle. If necessary, remove plaque from the brass nozzle effortlessly with fine sandpaper.

- Clean the nozzle itself with a thin copper wire and blow under pressure with a pump from the side where the tube is connected to the tee.

- While there is free access, very carefully clean the bend of the thermocouple tube with fine sandpaper, there may be a small layer of oxide.

AKGV series

Floor-standing boilers with a double-circuit heating system are also presented here. Boilers of this series require high-quality ventilation, which will remove combustion products, and a separate room.True, as the reviews of the models of this series show, you can also buy a gas boiler for installation in the kitchen.

- The burner power in these units varies from 11.5 to 29 kW. The most popular model has a power of 17 kW and heats a room of 150 square meters. meters

- The boiler is equipped with a bithermic heat exchanger - a coil is installed inside the tank, which is responsible for heating the water to the desired temperature

- The burner of the device has anti-corrosion properties

- Equipment for heating is equipped with a thermostat, a temperature control system and control of gas supply and draft in the system

Also, the AKGV series is distinguished by the fact that the outer walls do not heat up during operation, and with sudden gusts of wind, the thrust will not disappear due to a special stabilizing element.

You can buy a Borinsky heating boiler of the AKGV series for 250 USD, and you can buy Borinsky gas heating boilers with a higher power of 23 kW for $360. What do reviews say about the powerful model of the AKGV 23 heating boiler?

Anastasia, 32 years old:

I am glad that this model belongs to non-volatile, with constant power outages, parents always have a problem. It also heats the water well, but I won’t say that there is enough pressure for all needs - it’s enough to wash the dishes. ”

3. AOGV series - here are gas single-circuit boilers designed for space heating. The devices of this series are floor-standing units operating on natural gas.

AOGV models are made in a cylindrical body and are represented by several “sub-series” - an economy version with a Russian-made control unit, a universal device with a control unit from Italian brands and a comfortable unit, where the automation is presented by a German manufacturer.

- Floor-standing gas boilers Borinsky AOGV have a thermal power of 11.5 to 29 kW.

- Are intended for heating of rooms from 40 (at the minimum power) to 250 sq.m. meters (maximum boiler power).

- Gas boilers are equipped with an automatic system for stopping the gas supply in the absence of draft and fuse on the burner.

- Equipped with a thermostat with a temperature range up to +95 degrees.

You can buy a Borinsky boiler of the AOGV series for 220 USD. - such a model will have a minimum power, a unit for a large house with a maximum power will cost 450-490 dollars. Let's look at the reviews of the mid-range model with a power of 23 kW.

Alexander, 37 years old:

In general, I bought a model with Italian automatics for my 150 squares. I want to say that the efficiency is really about 90%, and the gas consumption is small - somewhere around 1.7 kg / hour (balloon). I am satisfied with the device and have not been overjoyed for half a year now.”

4. KOV series are single-circuit floor standing boilers, which have great power and are designed for heating impressive rooms.

- Borinsky boilers KOV have a capacity of 30 to 63 kW;

- Equipped with automation from an Italian manufacturer;

- Are intended for heating of the area from 250 to 750 sq.m. meters;

- Gas boilers are equipped with a protection system in the absence of traction, gas supply interruption and the absence of a fuse on the burner.

You can buy a Borinsky boiler with a capacity of 30 kW for 600-660 USD, a boiler with a capacity of 50 kW for a room of 500 square meters will cost 820-860 dollars.

Choosing a boiler "Borino"

Before you buy a Borinsky gas boiler, decide what you need it for - will it only perform the function of heating, or do you need a double-circuit model.

- Look at the power - if your house is insulated, you can choose a boiler commensurate with the area of \u200b\u200bthe house. If your house is “cold”, take a model with a “power reserve”

- Look at the automation - all floor-standing boilers are equipped with a protection system, but the automation itself can be of domestic or foreign production

- Look at the combustion chamber and air outlet - the chamber can be closed and open, run on natural gas and from a cylinder. Some models may require replacement injectors for LPG operation.

Consider the method for finding the above malfunction

A check during the repair of a gas boiler begins with the “weakest link” of the automation device - the draft sensor. The sensor is not protected by a casing, so after 6 ... 12 months of operation it “acquires” a thick layer of dust. The bimetallic plate (see Fig. 6) quickly oxidizes, which leads to poor contact.

The dust coat is removed with a soft brush. Then the plate is pulled away from contact and cleaned with fine sandpaper. We should not forget that it is necessary to clean the contact itself. Good results are obtained by cleaning these elements with a special spray "Contact". It contains substances that actively destroy the oxide film. After cleaning, a thin layer of liquid lubricant is applied to the plate and contact.

The next step is to check the health of the thermocouple. It works in heavy thermal conditions, as it is constantly in the igniter flame, naturally, its service life is much less than the rest of the boiler elements.

The main defect of a thermocouple is burnout (destruction) of its body.In this case, the transition resistance at the welding site (junction) sharply increases. As a result, the current in the Thermocouple - Electromagnet circuit.

The bimetal plate will be lower than the nominal value, which leads to the fact that the electromagnet will no longer be able to fix the stem (Fig. 5).

Working with AOGV

It starts when the gas supply is blocked - the corresponding valve closes. And this is a general principle for such work with any boilers and columns.

How to clean the burner of a gas boiler AOGV? After shutting off the gas, this element is removed from its position. The burner has a nozzle

It is carefully unscrewed and carefully cleaned with a brush. The burner itself is cleaned by blowing using a special pump

Then the nozzle and burner are returned to their place.

These are general criteria. And the details are presented on the following two models.

First. AOGV 11.6-3. It is a reliable and practical device.

But after a certain operational period, it is thoroughly cleaned. The process goes like this:

Removing the burner block

To do this, the pallet of the apparatus is rotated, and three tubes are disconnected from the automation unit: contact, gas and thermocouples.

Carefully unscrew the nuts located on the fittings of the automation mechanism.

The paronite gasket on the main gas pipe is removed and its condition is studied. If it is damaged, it needs to be replaced.

The designated pallet is taken out through the groove, which is as close as possible to the tubes

Along with it, the casing is also pulled out. Fixing the lower part of the pallet, direct it towards yourself and remove the remaining holders (two pieces) from engagement.

This whole knot falls to the floor.

The main burner is being studied and cleaned. The igniter nozzle is examined.

The wick and thermocouple are unscrewed.

A box-shaped casing is separated from the pilot burner. This clears the way to the nozzle. If it is brass and there is a coating on it, it can be removed with fine-grained sandpaper.

Nozzle cleaning. For this, a thin copper wire and a blowing method under strong pressure are used. The second action is carried out by a special pump from the side where the tube is connected to the tee.

The same sandpaper very carefully cleans the bend of the thermocouple tube.

After this work, all the details are assembled in the reverse algorithm. Gently, avoiding distortions, lift this block as a whole. The burner must be inside the housing, and the igniter and thermocouple must not touch the flange of the casing.

From the side of the tubes, the entire assembly should be pushed towards itself with a slight downward slope. The opposite side of the pallet should rise.

Then feed it forward and synchronously put on a pair of distant holds. They should be on the flanging of the casing. The near hook is a cut groove. After it enters there, the entire pallet rotates in the opposite direction to the clockwise movement. The gas pipe must be positioned only under its branch pipe of the automation unit.

Next, it is tested how well the gaskets fit, and all tubes return to their places. The wrench tightens the nuts on two tubes: igniter and gas.

Before reassembling the thermocouple tube, its contact areas are carefully but carefully cleaned. The nut is finger-tight.

The final stage is to check the tightness of all connections for potential leakage. In their absence, the boiler turns on. If available, these places are covered with sealant, the nuts are tightened tighter.

The second model is AOGV-23.2-1 Zhukovsky.

It works like this:

- The nut is unscrewed so that the gas pipe passes.

- The angle, igniter and thermocouple are unscrewed.

- All burners in the kit stretch outward, move out to the side towards the user. If there is difficulty with their movement, loosen and unscrew the studs with pliers. Clean all jets and other components.

- Burner disassembly. To do this, the studs are unscrewed 4 pieces on both sides.

- The slotted plates are removed from the top of the burners, then the springs. Every detail is thoroughly cleaned.

- Assemble all elements in reverse order.

After reassembly, a tightness test is arranged, it is studied how tightly the burners adjoin the body.

Combustion products and their cause

- soot;

- resin;

- tar.

The reasons for the appearance of these substances are the following important points:

- Causes of soot:

- there is not enough oxygen for the combustion process;

- fuel combustion temperature is too low.

- Factors affecting the appearance of resin:

- low-quality fuel is used;

- the fuel material has a high degree of moisture;

- the boiler operates at a low temperature;

- too much fuel is loaded into the furnace.

- Tar appears in the following cases:

- weak injection of air flow into the combustion chamber of the pyrolysis boiler;

- incorrect design of the unit;

- low chimney.

As you can see, the main reasons for the appearance of harmful substances are poor fuel and the technical aspects of the organization of the combustion process.

Experts advise: use only high quality fuel - otherwise the wear of the boiler will increase rapidly.

Automation for heating gas boilers AOGV

Automation for gas heating boilers ensures stable and safe operation of the equipment. These systems greatly simplify the use of heating equipment, increase its efficiency and allow rational use of energy resources.

Automation for gas boilers AOGV

Modern models of heating boilers are equipped with automatic devices in production. Automation should ensure an uninterrupted supply of gas to the burner, but the functions of these devices are not limited to this. Automatic devices close the gas supply valve in potentially dangerous situations:

- The temperature of the water in the boiler tank exceeds the set maximum.

- The igniter goes out.

- The water supply stops.

- There is a failure in the gas system.

- The pressure falls below the established norm.

- With insufficient chimney draft.

What does automation for gas heating boilers AOGV consist of?

A standard automatic system should have several basic elements.

Ignition elements. There is no burning torch in modern systems. The pilot burner is ignited by a piezoelectric element, which produces electrical energy as a result of mechanical pressure on the crystal. There are systems in which you need to open the gas supply valve with one hand, and press the piezo ignition button with the other. In the most modern boilers, one button is responsible for the operation of both processes. Further control of the gas valve is carried out in one of two ways:

- Due to the voltage that occurs when the thermocouple is heated.

- By heating an additional thermal generator (more often used in imported boilers).

Automation of gas boilers AOGV most often works due to the energy of a thermocouple.

In both cases, the generated energy creates a voltage that acts on the gas valve coil. It remains open, providing gas supply, as long as the gas burner is lit.

Thermoregulation system. These elements control the temperature of the water. They consist of a temperature sensor and a system of valves that shut off the flow of gas when the set temperature is reached. In the most modern models of boilers, a room thermostat has been added to the control circuit, which, depending on the temperature in the room, gives a signal and the need to close or open the gas supply valve.

In the mechanical thermoregulation system, there is a thermometer on the control panel, and the temperature controller is located at the outlet of the coolant from the boiler.

Control elements for efficient and safe removal of combustion products. This is a draft sensor that is mounted in the chimney. Wires connect the thrust sensor with gas valve. In the absence of optimal traction, a signal is given to the valve, it closes and stops the gas supply.

Automation for gas heating boilers does not allow you to turn on the gas supply, if the performance indicators of the equipment go astray, the slightest breakdown or depressurization of pipes occurs.

Additional elements and possibilities of automation

In some models, automation for gas boilers AOGV is equipped with a thermostat that provides regulation of gas flow. The reason for reducing the intensity of work may be an increase in the temperature outside or a thermostat signal in one of the rooms that the maximum allowable temperature has been exceeded.

Models that are mounted in the "Smart Home" system suggest the possibility of remote control of heating modes.

A modern, correctly installed and adjusted automatic system on heating equipment helps to reduce heating costs by 40%.

The main characteristics of gas boilers AOGV-11.6-3

Floor standing gas boilers AOGV-11.6-3 are single-circuit units with a rated power of 11.6 kW. The device is able to operate both from natural and liquefied gas with a very economical consumption. To date, this is the best option for heating a house up to 110 square meters. m. At the same time, the unit has acceptable dimensions (850x310x412 mm), which makes it easy to find a place for it in the house and facilitates the installation of the boiler.

In general, AOGV-11.6-3 are reliable and practical, these heating devices are time-tested and ideal for operation in Russia. Boilers AOGV do not require any special conditions for operation. However, after several years of operation, it may be necessary to clean the unit with all components from soot and other contaminants.

How quickly soot will accumulate in your AOGV depends on several reasons, including the initial correct installation of the device. The AOGV cleaning process is not so complicated, so it is advisable to carry it out regularly, at least for prevention, before the start of each heating season.

Starting the procedure for cleaning a gas boiler, be more attentive to the little things of any design in the unit. Everything has its purpose, and ill-conceived actions can lead to emergency situations.

Company "VodoGazServis"

LLC "VodoGazService" is a wholesale and retail company organized by qualified specialists in the water and gas industry who have many years of experience in this industry.During its work, the company has established itself as a reliable partner, ready to serve the most demanding client in all corners of our countries from Kaliningrad to Yuzhno-Sakhalinsk. LLC "VodoGazService" opened branches in Krasnoznamensk, Vladimir, Volgograd and Krasnodar. Based on the knowledge of the consumer market in its field and the experience of employees, the company in its work regularly studies new products, monitors the modern market of domestic and imported water and gas equipment and is ready to offer the buyer only high-quality and reliable goods that meet modern quality and safety requirements.

The warehouse always has gas meters, bimetallic and aluminum heating radiators, plumbing and gas shut-off and control valves, sanitary ware, electrics. The range includes accumulative water heaters (boilers) with a capacity of 10 to 500 liters, as well as safe modern gas and electric instantaneous water heaters of various capacities, imported and domestically produced. All products sold by us have the necessary certificates and licenses.

The products offered by our company are of good quality, have the latest release dates and are provided with warranty cards.

The retail store "VodoGazService" is open seven days a week, phone, location map and opening hours in the "Contacts" section

more about the company

Startup and operation instructions

The boiler is started after installation on a flat horizontal surface and connecting all communications:

- Gas supply.

- Direct and reverse lines of the heating system.

After installation, the system should be filled with coolant.The filling level is monitored using a signal pipe. The boiler is ignited using a piezo ignition unit or a lit match (Economy series).

IMPORTANT!

To start the boiler, first ventilate the room for 15 minutes. After that, open the gas cock, turn the handle to the “igniter on” position and drown it until it stops. Wait in this position for 10-15 seconds, then press the piezo ignition button.

When the flame appears on the igniter, wait another 20-30 seconds, then release the handle. The igniter should continue to burn. After that, you can set the desired temperature of the coolant.

During operation, no specific actions are required from the user, except for periodic cleaning from dust and soot.

Once a year, a foreman should be invited to perform maintenance. For all problems, please contact the warranty or service workshop.

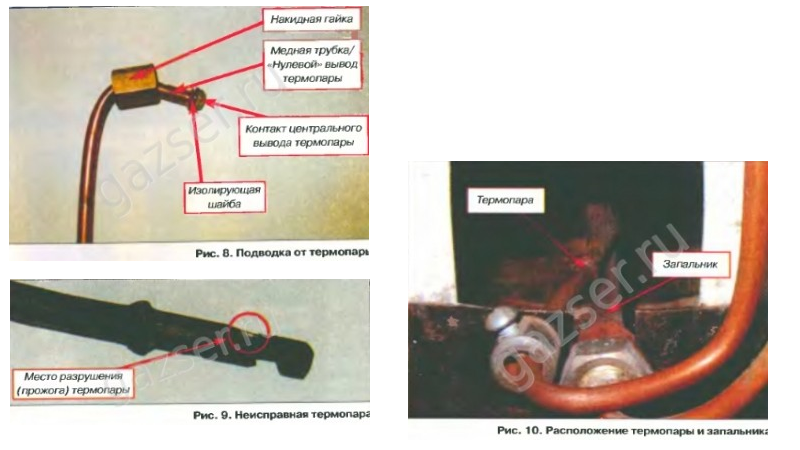

How to check the thermocouple of the AOGV boiler

To check the thermocouple, unscrew the union nut (Fig. 7), located on the left side of the electromagnet. Then the igniter is turned on and the constant voltage (thermo-EMF) at the thermocouple contacts is measured with a voltmeter (Fig. 8). A heated serviceable thermocouple generates an EMF of about 25 ... 30 mV. If this value is less, the thermocouple is faulty. For its final check, the tube is undocked from the casing of the electromagnet and the resistance of the thermocouple is measured. The resistance of the heated thermocouple is less than 1 ohm. If the resistance of the thermocouple is hundreds of ohms or more, it must be replaced. The appearance of a thermocouple that failed as a result of burnout is shown in Fig. 9. The price of a new thermocouple (complete with tube and nut) is about 300 rubles.It is better to purchase them in a store at the manufacturer or use the services of an authorized service center. The fact is that the manufacturer is constantly improving its products. This is reflected in the parameters of self-made parts. For example, in the boiler AOGV-17.4-3 of the Zhukovsky plant, since 1996, the length of the thermocouple connection has been increased by about 5 cm (that is, similar parts manufactured before or after 1996 are not interchangeable). This kind of information can only be obtained from a shop (authorized service center).

The low value of thermo-EMF generated by a thermocouple can be caused by the following reasons:

- clogging of the igniter nozzle (as a result, the heating temperature of the thermocouple may be lower than the nominal one). A similar defect is “treated” by cleaning the igniter hole with any soft wire of a suitable diameter;

- shifting the position of the thermocouple (naturally, it can also not heat up enough). Eliminate the defect in the following way - loosen the screw securing the eyeliner near the igniter and adjust the position of the thermocouple (Fig. 10);

- low gas pressure at the boiler inlet.

If the EMF at the thermocouple leads is normal (while maintaining the symptoms of the malfunction indicated above), then the following elements are checked:

- the integrity of the contacts at the connection points of the thermocouple and the draft sensor.

Oxidized contacts must be cleaned. Union nuts are tightened, as they say, "by hand". In this case, it is undesirable to use a wrench, since it is easy to break the wires suitable for the contacts;

- the integrity of the electromagnet winding and, if necessary, solder its conclusions.

The performance of the electromagnet can be checked as follows. Disconnect the thermocouple lead.Press and hold the start button, then ignite the igniter. From a separate source of direct voltage to the released contact of the electromagnet (from the thermocouple), a voltage of about 1 V is applied relative to the housing (at a current of up to 2 A). To do this, you can use a regular battery (1.5 V), as long as it provides the necessary operating current. Now the button can be released. If the igniter does not go out, the electromagnet and draft sensor are working;

- thrust sensor

First, the force of pressing the contact to the bimetallic plate is checked (with the indicated signs of a malfunction, it is often insufficient). To increase the clamping force, loosen the lock nut and move the contact closer to the plate, then tighten the nut. In this case, no additional adjustments are required - the pressure force does not affect the temperature of the sensor response. The sensor has a large margin for the angle of deflection of the plate, ensuring reliable breaking of the electrical circuit in the event of an accident.

Unable to ignite the igniter - the flame flares up and immediately goes out.

There may be the following possible reasons for such a defect:

- the gas valve at the boiler inlet is closed or defective; - the hole in the igniter nozzle is clogged; in this case, it is enough to clean the nozzle hole with a soft wire; - the igniter flame is blown out due to strong air draft;

The gas supply is turned off during boiler operation:

- actuation of the draft sensor due to clogging of the chimney, in this case it is necessary to check, clean the chimney; - the electromagnet is faulty, in this case, the electromagnet is checked according to the above method; - low gas pressure at the boiler inlet.

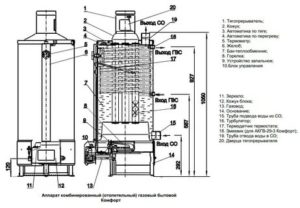

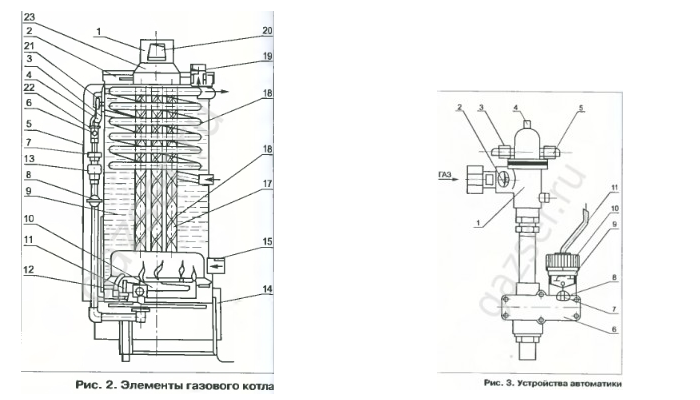

The device of the gas boiler AOGV - 17.3-3

Its main elements are shown in Fig. 2.The numbers in the figure indicate: 1-tractor; 2-thrust sensor; 3-wire thrust sensor; 4-start button; 5-door; 6-gas solenoid valve; 7-adjusting nut; 8-faucet; 9-reservoir; 10-burner; 11-thermocouple; 12-igniter; 13-thermostat; 14-base; 15-water supply pipe; 16-heat exchanger; 17-turbulator; 18-knot-bellows; 19-water drainage pipe; 20-door of the traction breaker; 21-thermometer; 22-filter; 23-cap.

The boiler is made in the form of a cylindrical tank. On the front side are the controls, which are covered with a protective cover. Gas valve 6 (Fig. 2) consists of an electromagnet and a valve. The valve is used to control the gas supply to the igniter and burner. In the event of an emergency, the valve automatically turns off the gas. The draft breaker 1 is used to automatically maintain the vacuum value in the boiler furnace when measuring the draft in the chimney. For its normal operation, the door 20 must freely, without jamming, rotate on the axis. The thermostat 13 is designed to maintain a constant temperature of the water in the tank.

The automation device is shown in fig. 3. Let us dwell in more detail on the meaning of its elements. The gas passing through the cleaning filter 2, 9 (Fig. 3) enters the electromagnetic gas valve 1. Thrust temperature sensors are connected to the valve using union nuts 3, 5. The igniter is ignited when the start button 4 is pressed. There is a setting scale 9 on the body of the thermostat 6. Its divisions are graduated in degrees Celsius.

The value of the desired water temperature in the boiler is set by the user using the adjusting nut 10. The rotation of the nut leads to a linear movement of the bellows 11 and the rod 7.The thermostat consists of a bellows-thermobalon assembly installed inside the tank, as well as a system of levers and a valve located in the thermostat housing. When the water is heated to the temperature indicated on the adjuster, the thermostat is activated, and the gas supply to the burner stops, while the igniter continues to work. When the water in the boiler cools down by 10 ... 15 degrees, the gas supply will resume. The burner is ignited by the flame of the igniter. During operation of the boiler, it is strictly forbidden to regulate (reduce) the temperature with nut 10 - this can lead to breakage of the bellows. You can reduce the temperature on the adjuster only after the water in the tank has cooled down to 30 degrees. It is forbidden to set the temperature on the sensor above 90 degrees - this will lead to the operation of the automation device and turn off the gas supply. The appearance of the thermostat is shown in (Fig. 4).