- Supervising the work of repairmen

- Deepening methods

- Deepening with rings

- Deepening on quicksand

- Cleaning work in the well

- Video description

- Cleaning work with a bailer

- Cleaning work with a vibration pump

- Cleaning work with two pumps

- Preparing for a long downtime and pumping after it

- Typical malfunctions of water wells

- Where to drill a well outside or inside the house?

- Insoluble impurities in water

- Problems of a natural nature

- Preparing for work 2

- How to repair a well?

- Silting system

- WAYS TO SOLVING THE PROBLEM

- What to do in the event of a water well failure?

- What is maintenance and what services can repair services provide you with?

- Employee Mistakes

- Well deepening methods

- Filter cavity

- Deepening with repair rings

Supervising the work of repairmen

Having entrusted repair work to professionals, the owners are unlikely to be able to relax. After all, they will be interested in whether the money spent will pay off - whether the repair will be done efficiently.

A professional approach to repair includes several stages:

- Depth measurement and determination of the water level - that is, a visual inspection.

- Checking all connections and condition of pipes with a special probe - the use of the so-called geophysical diagnostic method.

- Re-examination with a video camera (lowered on a special cable) is carried out in order to clarify the results of geophysical diagnostics.

- Cleaning and washing is carried out using several types of ruffs and scrapers of different diameters, as well as traps for collecting dirt.

Deepening methods

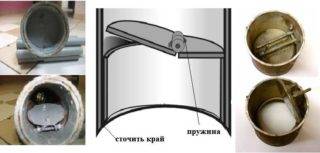

One of the most common methods of resuming the work of the source is the use of a bailer. It is a metal pipe with a valve at the bottom. In order for the bailer to freely cut under its own weight into the ground during manual drilling, you can sharpen its lower edges or cut teeth. The principle of deepening the well here is as follows:

- The source shaft is completely freed from liquid residues.

- The casing string is cleared of silt.

- The bailer is attached to the winch and lowered down into the source.

- From a height of 1-1.5 meters, a metal pipe is thrown so that it crashes into the ground by several centimeters. At the moment of its sharp lowering, the damper opens to take soil from the mine shaft.

- When the bailer is raised, the valve closes, preventing the soil from crumbling down.

- On the surface, the pipe is freed from sand and the steps are repeated with a recess until a result is obtained.

According to the same method, experts work with drilling rigs. The difference lies in the fact that special equipment functions faster and can deepen the well for a longer distance.

Deepening with rings

Bailer with flap valve

Bailer with flap valve

An old well can be drilled with rings. Here they also work with a bailer. To lengthen the casing string, segments of rings or pipes are used, similar in diameter to those already available. Work looks like this:

- With the help of a metal pipe deepen the source.

- As the depth of the shaft increases, new segments of the tube are installed on top of the casing string. Under their weight, they lower the existing trunk down. The main thing is to carefully seal the joints of the elements.

- With each new meter of deepening, the well shaft is finished.

Deepening on quicksand

This is a special type of soil, characterized by its constant movement. To properly drill the source, you need to act quickly. To do this, prepare a longer bailer so that it absorbs more soil. Also, when working on quicksand, you need to use more powerful equipment, since wet soil has an impressive weight.

The finished deep well in the lower part is provided with a filter. To do this, take a plastic pipe of a slightly smaller section than the casing. Holes of 3-4 mm in increments of 3-5 cm are made over its entire surface. The outer part of the tube is wrapped with a fine mesh. It remains to lower the homemade filter into the lower part of the well and close up the joints with the main shaft.

An in-depth source needs to be pumped well.

Cleaning work in the well

If the location of the well is supposed to be in a summer cottage, used only for weekends in the summer, then it is not worth it. Too laborious and costly. It will be quite enough to have imported (brought) water for a couple of days.

It is quite another matter if agricultural work on growing vegetables is carried out on the site, there is an orchard or a flower garden. Or it is used for long-term residence. In this case, the presence of a constant source of fresh water is simply necessary, because. it is supposed to water the beds, cook food and use it for hygienic purposes.

Own well allows the owner to:

- do not depend on the central water supply;

- always have an uninterrupted supply of water in the required volume;

- use clean water that has passed through natural filters and is saturated with essential trace elements.

Video description

Which option of a well for water to choose can be found here:

However, the presence of these advantages will require the owner of the site to carry out periodic preventive maintenance to clean the clogged device. As a rule, this cleaning is carried out in several ways:

- with the help of a bailer;

- pumping the well with a vibration pump;

- using two pumps (deep and rotary).

The use of these methods presupposes both their separate use and their joint use in turn. It all depends on the weediness and depth of the well.

Cleaning work with a bailer

The bailer (metal pipe) is fixed with a strong iron cable or rope and smoothly lowers to the bottom. When it reaches the bottom, it rises (up to half a meter) and drops sharply. The blow of the bailer under the influence of its weight is able to lift up to half a kilogram of clay rock. Such a well cleaning technique is quite laborious and long-term, but inexpensive and effective.

Cleaning the well with a bailer

Cleaning work with a vibration pump

This option for cleaning the well will be the simplest and fastest. That is why it is considered the most common and has found application even in mines with a narrowed receiver, which is why the use of a conventional deep pump is not possible.

Vibration pump cleaning

Cleaning work with two pumps

This method is characterized by the fact that it does not actually require human participation in the process.The flushing of the well takes place using two pumps that do all the work themselves, but the time spent on this is simply enormous.

Preparing for a long downtime and pumping after it

If a visit to the summer cottage in the winter (or for another long period) is not expected, and the well will not be used either, then you should take care of this in advance. It is necessary to consider preparing the device for inactivity and how to pump the well after a winter or a long downtime.

Preparation comes down to installing a heating cable inside or using any materials at hand to insulate the device.

Well pumping after winter is carried out by standard methods, which are described above, and are used only if necessary.

An example of well insulation for the winter

A private well on your own site is a useful and absolutely necessary thing. However, it will require some periodic maintenance work on cleaning and buildup. The above describes what buildup is, why it is used, which pump to pump well after drillinghow to do it correctly and in what way, and what are the features of using one or another option. The issues of preparing the device for a long downtime (wintering) and restoring performance after this period are also mentioned.

Typical malfunctions of water wells

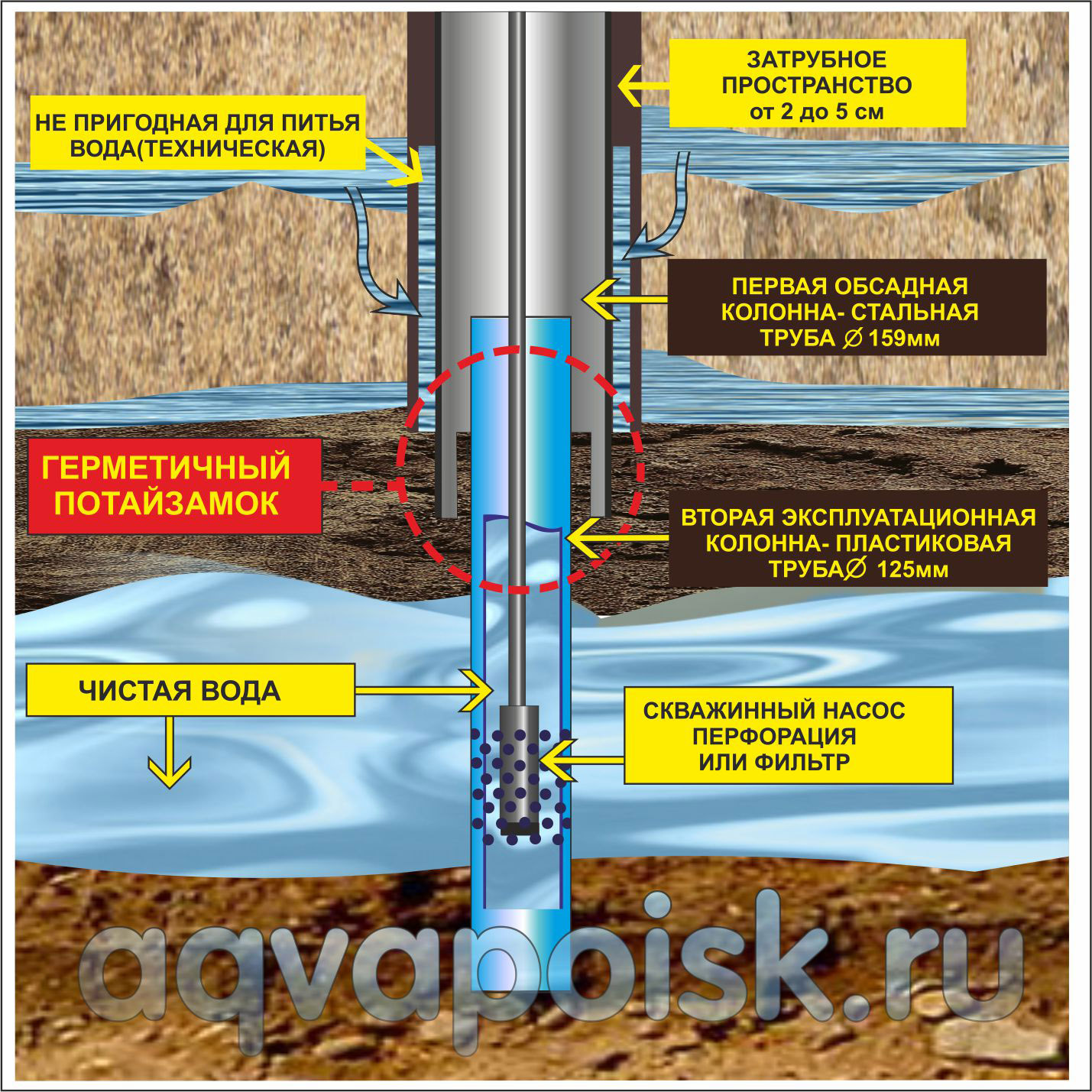

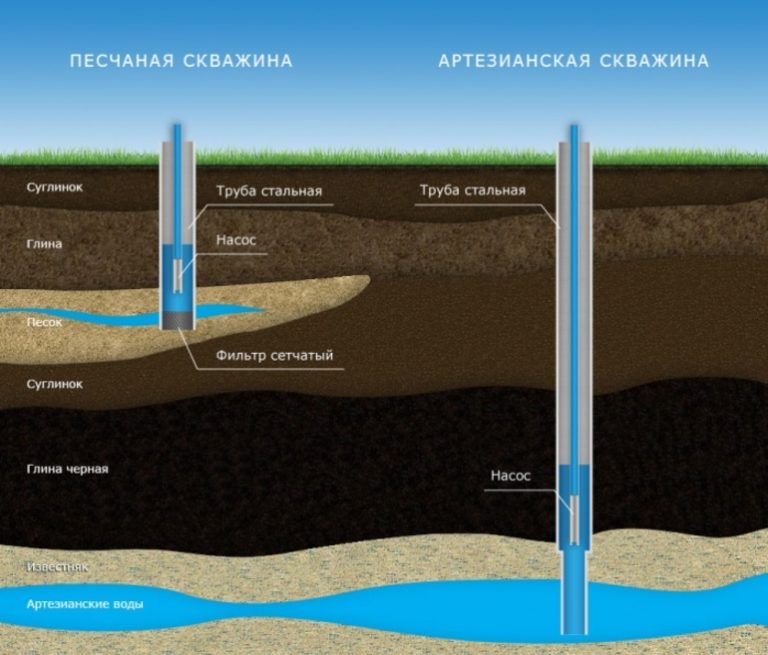

A common problem is the appearance of sand and silt in the water. Impurities cannot come from anywhere, which means they get through an incorrectly selected or damaged filter section. Also, the cause is depressurization or perforation of casing pipes.It is desirable to connect steel pipes with welded seams, and not threaded ones. Sand can enter the well through the casing shoe (due to lack of cementation or damage to it). With the wrong equipment well head debris easily enters the well through the unprotected top.

The decrease in flow rate is caused by overgrowing or clogging of the filter. This happens if it was not manufactured correctly, materials that are subject to electrochemical corrosion were used, or the filter cone was not sprinkled.

Even with serious damage, there is a chance to revive the well. If necessary, during the repair, a complete replacement of the production string is performed. Workover of a finished well is an expensive service, the complexity of which can be higher than drilling a new one.

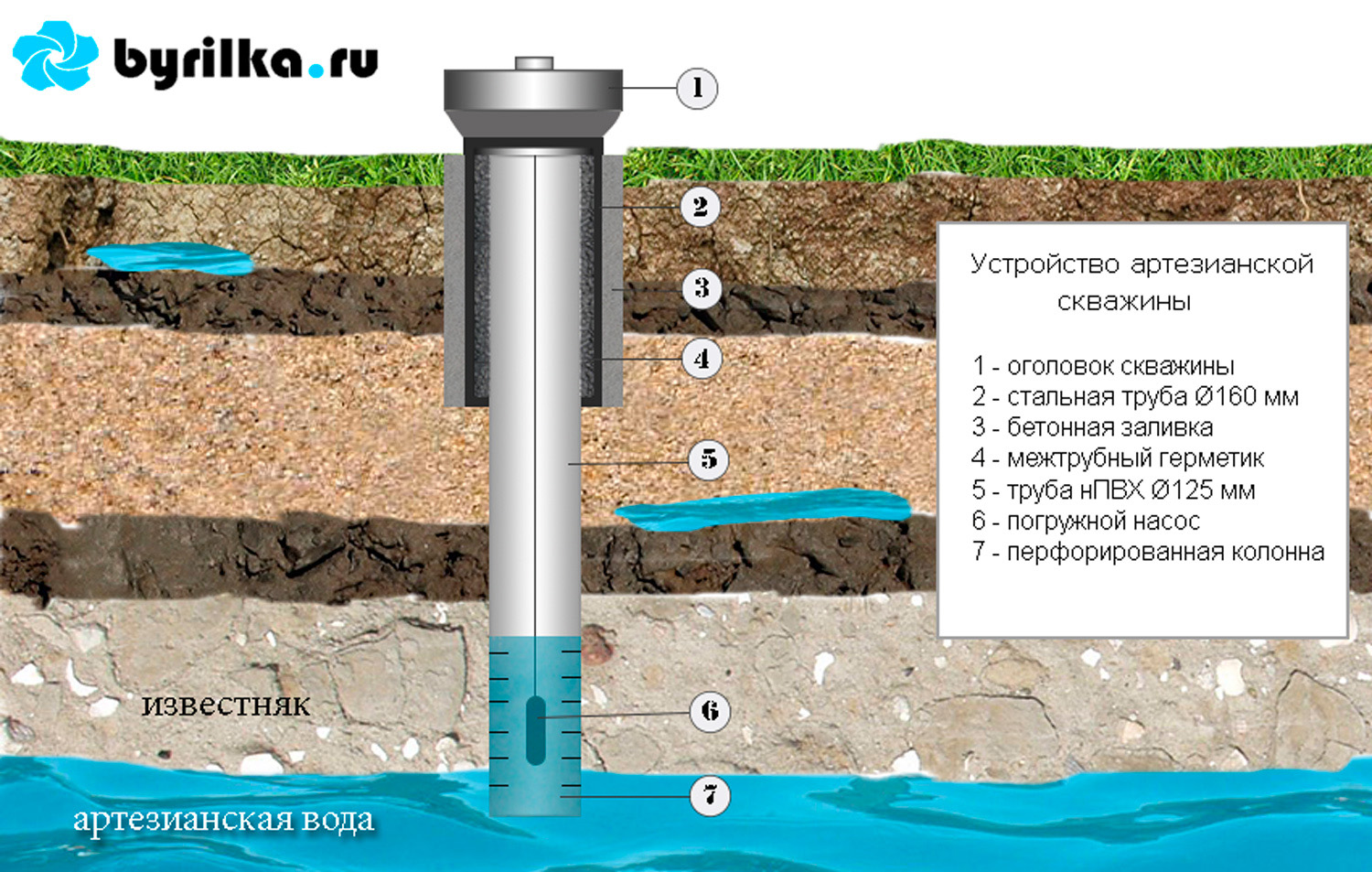

The appearance of water color is due to the fact that the filter or column passes water from unprotected horizons into the mine. Upper groundwater should be cut off with a pipe of larger diameter, and the gap should be cemented to exclude the possibility of annular overflow. It is realistic to replace the filter only when the well consists of two columns: casing and production. If there is only one pipe, then after it is pulled out, the well hole will be pulled in by the surrounding rocks. The only possibility in this case is the insertion of a repair pipe of a smaller diameter.

Construction errors can lead to skew and deformation of the column. In this case, it is very problematic to remove the pump and the pipe itself, it is simply clamped by flattened walls. Repair is possible, but the cost will be high. If the cable breaks, you can try to get the pump with a “cat”.

The simplest repair procedure is to clean the filter from deposits.It is performed in several ways, including using special chemical solutions.

It is important to understand that if the filter becomes clogged in the first year of operation, then there is a high probability that it was chosen incorrectly, and the clogging will be permanent.

Irreversible problems include the destruction of the column, flattening of pipes by soil and changes in the hydrogeological structure of the site. Here the chance of success tends to zero.

To reduce the chances of encountering a well failure, you need to apply for a drilling service only to a specialized company. An announcement on a pole or two lines in a newspaper is not a sign of the seriousness and stability of the company.

This is interesting: Reminder well cleaning: know in order

Where to drill a well outside or inside the house?

Very often, especially before starting a new construction, water well customers ask quite logical questions:

- Where to drill a well outside or inside the house?

- Is it possible to drill a well right under the house?

At first glance, it may seem that this is a really great idea that will solve several problems at once: it is unnecessary to pull the water supply and insulate it, build a separate caisson ... The well itself is reliably protected, since it goes headlong into the basement. Consider in this article all the pros and cons of drilling a well in the house and outside.

In addition to all these advantages, the wells located in the house have a very significant drawback - they are difficult to maintain and almost impossible to flush, in case of silting. In addition, there is a high risk of uneven settlement of the building or even its destruction due to washing out of the soil around the casing filter.The size of the resulting cavity can reach more than three meters in diameter. Its influence on the building immediately depends on many conditions, including such as the depth of the well, the density of passable soils, the distance between the foundation walls, the load on the foundation, etc.

During the operation of the well, it sometimes becomes necessary to raise the pump, and this can only be done together with a hose or pipe through which water is supplied upward. It is extremely inconvenient to perform such work indoors, especially if a polyethylene pipe goes to the pump, which has much less flexibility than a hose.

If the well under the house is drilled into limestone, then we are talking about its significant depth, and therefore a long and, accordingly, heavy supply pipe. For sand wells drilled in the perimeter of the building, the main thing is not even the supply pipe and the difficulty of dismantling it, but the problems that may arise if it is necessary to flush it. It is necessary that easy access be provided to the well, otherwise, special equipment will not be able to get close to it.

As is obvious, on one side of the scale lies a cheaper option for arranging a well under the house, and on the other, the inevitability of problems with its maintenance. And if such problems arise, then the matter will most likely end with the drilling of a new well already outside the perimeter of the building. Analyzing the weight of all the pros and cons, it would be wiser to abandon the well under the house. However, the business of specialists is to warn; but the last word still remains with the customer ...

Insoluble impurities in water

Most often, harmful impurities appear due to a clogged or rotten filter.

Repair should be given careful attention. Sometimes you need to replace a part

Dirty water can cause irreparable damage to health. To purify water, you first need to conduct its chemical analysis. Perhaps the problem is not in the filter, but in the natural composition of the liquid. For example, clay soils often have high iron content. Sand, clay and silt may be present in large quantities. For additional water conditioning from unwanted impurities, various purification systems can be used.

Problems of a natural nature

The most common problems are likely to be avoided by reconnaissance ahead of time. However, even with a qualitative check, nature is capable of presenting unpleasant surprises.

- Search for an aquifer. The most serious most obvious problem. It happens that there is simply no water on the site, it is located extremely inconveniently or difficult to detect. To understand exactly where the aquifers are, most often, small test wells are made in several places, dividing the territory into separate squares for convenience, indicating on the map the coordinates and the depth of the water location. In some cases, echolocation, frames or vines are used.

- Stones and hard rock. Hard mineral deposits are a significant problem that can lead to breakage of drilling equipment. Large deposits are easily detected when examining an area with a sonar, but small stones are not visible on it and can cause serious trouble. With some types of rocks, for example, with granite, the drill may not be able to cope, but a qualified team must have either a special grab to extract the rock, or a diamond drill, which stones are not a hindrance to.The place of drilling is changed only in the most extreme case.

- Voids and loose soils are the most common problem of a natural nature. They are dangerous, as they can lead to collapse of the walls and subsidence of the soil. If voids are found, the walls of the wells are strengthened with a special composition or special primers of deep action.

Preparing for work 2

The preparatory stage is important when deepening the well under water. The result of secondary drilling depends on how correctly everything is done. The preparation looks like this:

- fluid is pumped out of the well;

- if at this moment a distortion of the barrel rings is detected, eliminate the defect if possible. If the shift is strong, the work will have to stop on this source;

- all joints of the column are carefully fixed with special plates - this will save the mine from breaking during drilling; the plates are placed at an equal distance from each other;

- prepare a shovel, sand containers, an electric or manual winch, a drill, a lantern.

All do-it-yourself deepening actions can only be carried out with an Abyssinian source (no more than 5-6 meters deep). In other cases, deepening the well without drilling will not work.

How to repair a well?

It is far from always possible to independently repair a water well. The correctness of its implementation is largely determined by the accuracy of diagnostics, which no one can do better than professionals (experience and special equipment are required).

When contacting specialists, many owners are alarmed by the high cost of the services offered. However, it will be possible to carry out high-quality repairs on our own only with certain types of breakdowns. And the list is quite small.For example, if there was a break in the pumping equipment and the pump fell to the bottom of the well, it can be lifted using specially emergency equipment or a special cat. If it is not possible to get a downhole pump, and the integrity of the well is not violated, then you can simply install another pump over the old one. If the pump is removed from the wellhead, then before handing it over for repair, it is necessary to look at the integrity of the electrical wiring and rinse the pump impellers from sand so that they rotate freely. Thus, you can independently try to do without a long and expensive repair of the pump.

But you need to remember! Accidental entry into the well of any object (for example, scrap) will cause its final failure.

Silting system

Appears if the water intake is not hermetically closed. Also, if the well is not used for a long time, stagnant water can lead to the formation of sediment.

To eliminate the blockage, it is enough to flush and blow the well. This is done by supplying compressed air to the pipe. It is better to call specialists, otherwise there is a high risk of leaks and holes, which will only increase silting.

In this way, the well is a problematic place for the owner of the dacha. It would be wiser to initially purchase expensive equipment and competently conduct plumbing - then you will not have to redo numerous mistakes at the construction stage.

I like it6 I don't like it9

WAYS TO SOLVING THE PROBLEM

There are three ways to solve the problem of an inactive fund.

First, the use of innovative types of maintenance and repair equipment.

Secondly, the use of innovative technologies for oil production and carrying out the pilot project.

Thirdly, optimization of organizational work. Innovative production equipment includes equipment with intelligent diagnostic systems, packers and shut-off valves, and equipment with anti-flight devices.

Innovative types of PRS equipment include diagnostic equipment (video cameras, thermal imagers), special fishing tools, and coiled tubing equipment.

One of the options for optimizing organizational work can be the path proposed in the letter that Deputy Energy Minister Sergei Kudryashov, on behalf of Deputy Prime Minister Igor Sechin, sent to the management of Soyuzneftegazservis. The document, in particular, notes that "the parameters of the operation of a single well are directly dependent on the functioning of the entire technical and technological complex of the field." The deputy minister also refers to the complexity and "inexpediency" of tax accounting for oil produced at each individual well. According to Mr. Kudryashov, the conclusion of “operator and other agreements” with service companies can become a way out of the situation.

Within the framework of these agreements, it is possible to use the forces and means of service companies that are armed with special methods and special equipment for bringing wells out of inactivity, increasing the profitability of oil production, and increasing THD.

What to do in the event of a water well failure?

Not everyone can repair an autonomous water well, not to mention establishing the real cause of the breakdown.

If you notice changes in water quality or notice a decrease in water pressure, immediately contact specialists who are obliged to first diagnose all equipment to identify the cause of the breakdown, after which they will carry out qualified repairs.

For example, in Moscow and the Moscow region, services for the repair and cleaning of wells are provided by LLC Rodnik (website). They have been performing work for more than 10 years, a very large number of reviews about well workover - it is immediately clear that the company is reliable.

In order for the water well to work smoothly for many years, it is necessary to carry out preventive work once a year. If you have an artesian well - once every 10-15 years, if the well is located in sandy soil - once every 5 years.

What is maintenance and what services can repair services provide you with?

If the customer has concluded a contract with a certain warranty period for the maintenance of equipment, drilling organizations/companies are obliged to provide scheduled and workover wells. Namely, the following types of work:

1) Water lifting equipment:

— determination of extraneous noise and vibrations,

- determination of the current strength of the consumed pump,

- checking the insulation resistance of the windings,

- pumping up pressure in the hydroaccumulator tank,

– cleaning the hydroaccumulator tank from mechanical impurities (as needed, not more than 1 time per year)

– revision: pump (dismantling / installation), submersible cable, cable (as needed, no more than 1 time per year)

2) Plumbing and valves:

— visual inspection to determine water leaks,

– mechanical check of shut-off valves performance, replacement of gaskets, seals

- checking the operation of the pressure sensor (pressure gauge)

3) Hydraulic parameters of the water well:

– measuring the flow rate of the well and subsequent adjustment of the pump performance

4) Well pavilion:

– sealing concrete seams and joints, cleaning the premises from dirt and dust,

– painting/priming of oxidized surfaces

5) Sampling for chemical analysis of water for macrocomponents (as agreed with the Customer)

6) Maintenance log entry

7) Recommendations for equipment upgrades

Employee Mistakes

It must also be remembered that most of the problems arise due to the fault of the drillers themselves, and if so, then you should not pay them extra. If employees begin to make excuses and sin on bad ground, the horizon that has gone, and so on, while not taking any measures, then this indicates unprofessionalism. Further cooperation with such employees is impossible. If the masters do not have a map of the area, then they must do test drilling. This is the only way to understand what is underground.

It must also be remembered that the equipment and materials must be of high quality and properly selected. Otherwise, the layers can move, and the well is deformed. Water will leave it, or it will simply deteriorate, since perch water will get into it.

Drilling wells for water in the districts of the Leningrad region

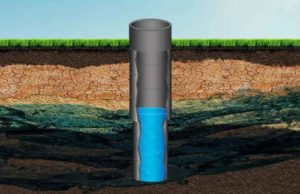

Well deepening methods

There are 2 main ways to deepen:

- Filter.

- With repair rings.

With method 1, holes are made in a plastic or metal pipe and a mesh is attached. This is a homemade filter, which is installed so that water is not poured through the top hole, but only flows through the bottom one.Repair rings are also an effective way to deepen, but their use requires the use of special equipment.

Filter cavity

The filter recess of the well implies that you need to make holes directly in the very bottom of the well and install a new filter in it. Drilling work in this case is carried out using a bailer. This method is considered the simplest and most effective.

The bailer is a piece of steel pipe. Its diameter should be 1-2 cm smaller than the diameter of the casing string. There is a valve at the bottom end. It can be either ball or petal (spring version in the form of a plate).

Well filter deepening.

Both types of valve are activated when the bailer hits the ground. In this case, the valve opens, soil enters the pipe, and when the projectile rises, it closes. To deepening works wells were carried out more efficiently, such a projectile should be heavy. In addition, its lower edge is sharpened so that the bailer enters the ground better.

Work is performed in the following sequence:

- Install a frame structure equipped with a winch or a gate.

- Hang the projectile on a strong cable.

- The bailer is placed in the casing string and dropped with force.

- Having activated the gate, the projectile is raised to a height of 2-3 m above the bottom and lowered again.

- The bailer is raised to the surface, cleaned.

- The algorithm is repeated.

At the final stage, a filter with a pump is installed. Moreover, they are mounted so that water does not flood it. Be sure to clean the structure from sand.

Deepening with repair rings

Deepening the well with rings.

An effective way to deepen an existing well is to install repair rings of smaller diameter compared to the main elements. With such dimensions, they easily pass inside the column.

On average, 3-4 rings are enough to deepen. Work is carried out in the summer, in dry weather, to simplify the procedure. The technology is simple:

- Water is pumped out of the well as much as possible and the filter is taken out.

- Inspect the sections of the column, it should not have defects.

- The column is reinforced with steel plates.

- Undermining at the bottom.

- Lower the column, installing new rings at the same time.

Upon completion of the work, the new sections are fastened to the main column.