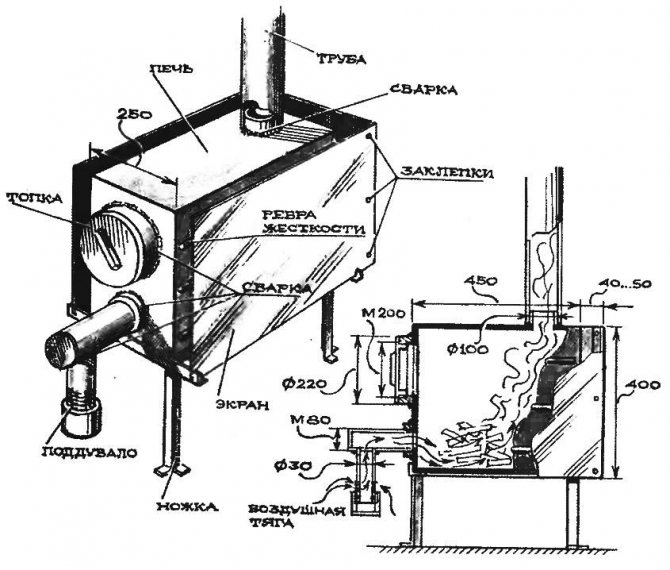

- Creating a potbelly stove from a gas cylinder

- Potbelly stove plus water circuit

- Stove for garage working out

- Design features

- Features of furnaces using waste oil, their advantages and disadvantages

- The principle of operation of the stove

- The principle of operation of the potbelly stove

- Pros and cons of a potbelly stove in oil

- The principle of operation of the potbelly stove

- 6 Assembly of the whole structure

- Do-it-yourself step-by-step instructions for making a waste oil furnace from a cylinder

- Making a pallet for working out and installing a chimney of an oil stove with your own hands

- Overview of Russian-made waste oil boilers

- Expensive domestic waste oil boilers

Creating a potbelly stove from a gas cylinder

Another design option for a mining furnace is a self-made potbelly stove based on a 50-liter gas cylinder. In addition to this main element, you need to prepare 2 steel pipes with a wall of about 4 mm and a diameter of 10 cm. One of them will remove burning gases, and the second will act as a heat exchanger.

To this should be added a 4 mm steel sheet for a canopy above the heat exchanger and a partition separating the evaporator and combustion chamber.For the evaporation chamber itself, you will need a brake disc from a car with such a diameter that it effortlessly enters the cylinder. A piece of 0.5-inch pipe is needed to transport oil to the combustion chamber.

In addition, you should have in stock an equilateral steel angle with a shelf of 50 mm and a length of more than 1 m, a 0.5 inch valve, sealing clamps - 2 pcs., Hose, any cylinder equipped with a needle valve.

The work on creating a potbelly stove is performed in a certain order. First, the balloon is turned upside down and a small hole is drilled in it. A measure such as wetting the drill and the drilling site with oil will protect against sparking.

Free the container from gas condensate

Drain it carefully away from housing, because. its unpleasant smell remains for a long time. Then the billet is filled with water, after which it is drained again, thus removing the remaining gas

Since the mixture is explosive, there should not be a source of open flame nearby.

Then the billet is filled with water, after which it is drained again, thus removing the remaining gas. Since the mixture is explosive, there must be no source of open flame nearby.

Cut out in the cylinder body 2 rectangles of the same width, equal to 1/3 of the diameter of the workpiece. The height of the lower rectangle is 20 cm, the second, located 5 cm higher than the first, 40 cm. To separate the chambers, a circle with a diameter equal to the inner diameter of the vessel is cut out of the sheet.

In its middle, a hole is made for a pipe with a diameter of 10 cm. This part will separate the combustion chamber from the heat exchanger.

A burner is made from a pipe 20 cm long and 10 cm in diameter. Its lower part is perforated, making holes about 2 cm in diameter.They clean the inside of burrs, otherwise they will collect soot on themselves, which will significantly narrow the hole later.

They put a previously cut circle on the burner, placing it exactly in the middle, and weld it. The structure is placed inside the furnace and a weld is made around the circumference of the cylinder.

The bottom and cover are welded onto the brake disc. This will be the evaporator tray or bowl. To supply fuel, an opening is left in the lid through which air will enter the potbelly stove. The opening is made quite wide, otherwise the draft will decrease and the oil will not get into the bowl.

Weld a pipe to the top of the lid. A coupling is made from a pipe with a diameter of 10 cm, which will connect the bowl to the burner.

Assemble the fuel supply system, for which:

- make a receiving hole in the pallet;

- insert a 0.5-inch piece of water pipe into it at an angle of about 40⁰;

- weld the pipe to the furnace body;

- an emergency backup valve is screwed to the pipe, the role of which is played by an ordinary water tap.

A heat exchanger is made from a pipe with a cross section of 10 cm. It is cut horizontally into the body of the potbelly stove, and a reflector is mounted at the end. Air is arranged by installing a duct fan at the end of the heat exchanger. The air driven through the heat exchanger with its help has a high speed.

An air swirler is placed inside the heat exchanger, consisting of triangular teeth interconnected by welding. A chimney is made from a pipe with a cross section of 10 cm.

It is welded into a hole located in the upper part of the furnace body and led out through the wall to the roof of the building.

Next, they are engaged in the manufacture of a tank for oil. If there is a freon-free cylinder with a working needle valve, then it is quite suitable for this purpose.The vessel and the potbelly stove are connected by a hose connected to the valve. To fill in the used oil, a hole is made in the tank body.

To provide air access to the burner and the evaporator bowl, a groove is selected in the door of the lower compartment. Thrust plates are attached to the opening of the upper chamber door, which ensures reliable sealing of the combustion chamber. For the same purpose, the door is additionally equipped with a lock.

Now, even if the body of the potbelly stove is deformed as a result of strong heating, the tightness of the combustion chamber will not be violated.

It remains to weld the legs from the pieces of the corner to the body and place the furnace vertically. In addition to vertical stoves, horizontal stoves are also made from a cylinder. Their device is similar.

Potbelly stove plus water circuit

Any home does not interfere with the presence of an emergency source of heat. An ordinary, but slightly modernized, potbelly stove can play its role. There are two ways to improve the stove - put a water jacket on the burner pipe or wrap its body with a coil of copper tubes.

The coils of the coil are placed at a distance of about 5 cm from the perforated body of the potbelly stove and connected to a common heating system. A reflective screen is installed around the coil. For its manufacture using sheet aluminum, galvanized steel, tin.

The water jacket is a tank on the upper chamber of the potbelly stove. There should be 2 fittings in its body - one for supplying and the other for draining water. In general, the design resembles a samovar. The volume of the water jacket depends on the length of the heating system and the way the coolant circulates.

In practice, the issue of the device of the water circuit is solved by installing the tank directly on the potbelly stove.Through the outlet to the heating system, hot water enters the latter. Passing in a circle, she pours heat into the room and returns back to the container.

If a pump is installed in the system, the volume of the tank is small, and with natural circulation it has impressive dimensions. To control the water parameters, a pressure gauge and a thermometer are installed on the tank.

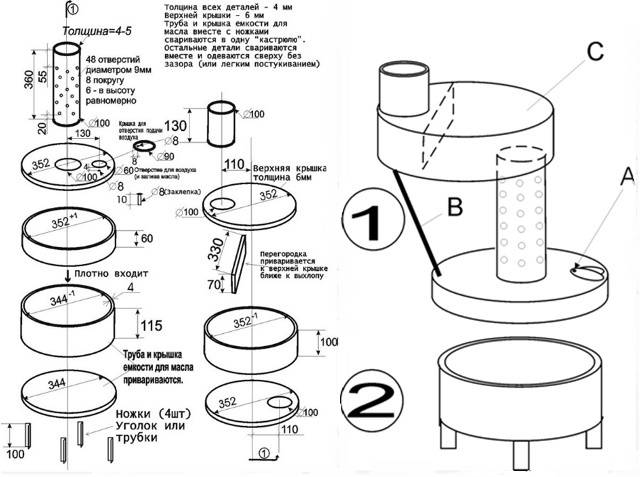

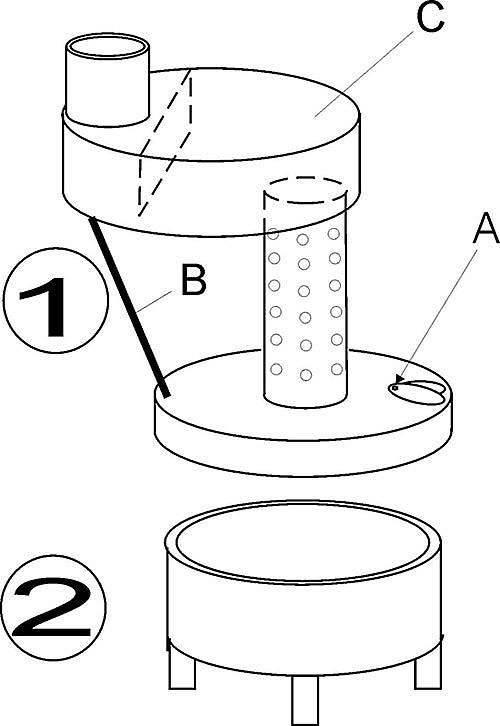

Stove for garage working out

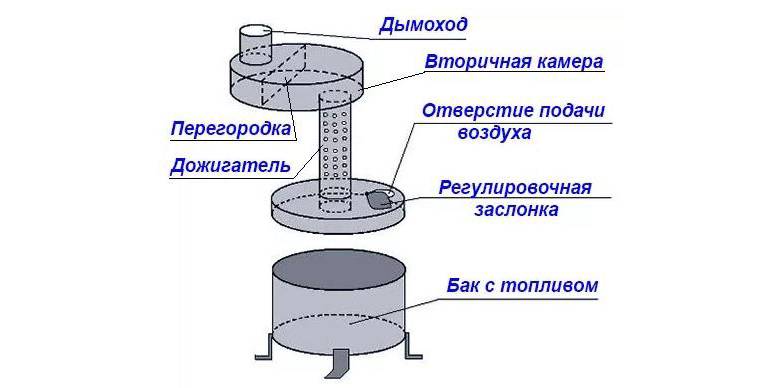

Let's see how to weld a stove in a garage that will work on working off - it will come in handy for those who repair cars and often change oil (for one warm season, you can collect working off for the whole winter). Our stove will consist of three parts:

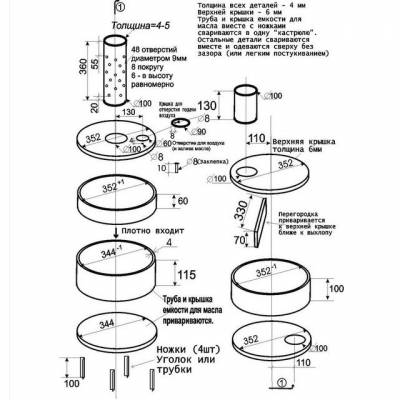

You can get detailed information about the dimensions of individual elements from the drawing.

- Fuel tank - its diameter is 352 mm. We weld the legs to it, in the middle we make a hole with a diameter of 100 mm. Nearby we make another 100 mm hole, with a lid - here we will fill in fuel for heating our garage;

- Combustion chamber - it is a vertical metal pipe with a diameter of 100 mm, in which 48 holes are drilled in 6 rows;

- Afterburner - all unburned gaseous residues are burned here. Its diameter is 352 mm, it has a hole for the combustion chamber and a hole for the chimney (the same 100 mm). A partition is welded inside the chamber.

After the garage stove is assembled, you can start testing. We pour the mining inside, pour a little kerosene on top (in no case, not any other liquid, only kerosene!), Set it on fire, wait until the stove warms up. As soon as a steadily burning, literally buzzing flame appears in the combustion chamber, the experiment can be considered a success.

Please note that the recommended chimney height for this stove is 4-5 meters

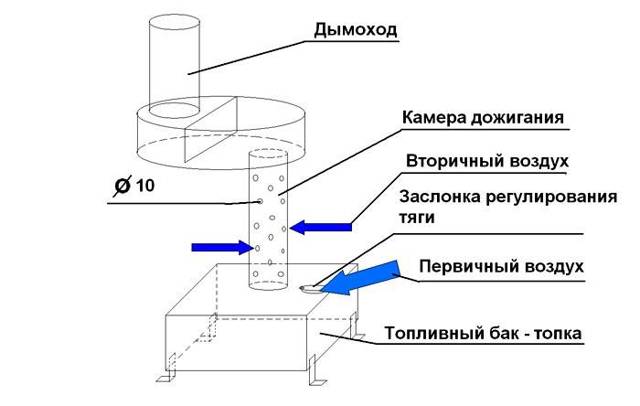

Design features

An oil potbelly stove has a fairly simple design. The device consists of two compartments. In the first of them there is a container into which used oil is poured. The combustion process is carried out at a moderate temperature. Just above it is another compartment in which gases mixed with air are burned. They, in turn, were formed during combustion, but already under the influence of a higher temperature, which can be 800 degrees.

It is very important during installation to provide the necessary amount of air, and it must be in abundance in both compartments. To do this, you need to make a small hole in the lower tank.

Fuel will be poured into it, and it can also be used to adjust the supply of air mass. This passage is covered with a special metal shutter. Secondary air also penetrates into the upper compartment through the holes located on the pipe connecting the container and the second chamber.

The almost free fuel that is used for kindling is not the only plus of such an installation. The fact is that the high temperature allows you to heat the room quickly and efficiently. In addition, if the unit is made taking into account all the rules, then it does not emit an unpleasant odor or harmful substances during operation, which is why home-made equipment is considered environmentally safe.

Although some danger still exists.This is due to the fact that it is strictly forbidden to use flammable substances in the furnace device - gasoline, thinner or kerosene. In addition, do not forget that some types of oils, when heated strongly, can release compounds that are harmful to health, so it is better not to use them as a fuel.

There are several other disadvantages of such heaters:

- in too cold weather, the stove device is not able to warm up a large room, so heating is carried out only in the place where the device is installed, as well as a small area near the chimney;

- incorrect operation and assembly may cause a fire situation;

- when liquid enters the device, the stove shoots splashes of burning oil;

- in the first minutes of operation, acrid smoke is emitted from the device.

Many users of such oil plants try to harvest fuel in the summer. To do this, it is necessary to install a special container in the garage into which the waste material will merge. As a rule, by the beginning of winter, a sufficient amount of oil has already accumulated in the tank, which is enough for the entire heating season. In addition, for a small cost, such fuel can be purchased at a car repair shop.

Features of furnaces using waste oil, their advantages and disadvantages

The mining furnace is a compact, economical unit

Furnaces that use used engine oil as fuel practically do not differ from other bourgeois stoves in terms of simplicity of design and unpretentiousness in manufacturing materials. As for the method of fuel combustion, the processes that take place in this case are associated with the characteristics of the fuel used.

First of all, it should be noted that modern engine oil is a multicomponent substance with a high content of chemical compounds. In the process of use, the lubricating fluid is additionally saturated with decomposition products of automotive fuel, as a result of which it becomes extremely dangerous for the environment.

Simple burning of mining in an open flame is inefficient and unacceptable - it burns unimportantly, forming acrid smoke, in which, in addition to soot, there are also various carcinogenic compounds. A completely different situation occurs with volatile hydrocarbons, into which automobile oil heated to a high temperature decomposes. Gaseous substances are highly flammable and release a large amount of heat energy when burned.

Gaseous substances are highly flammable and release a large amount of heat energy when burned.

Working out can be taken from friends or bought at a car service

Depending on the method of supplying used oil to the combustion zone, potbelly stoves are divided into several types:

- with pyrolysis combustion;

- using pressurization and fuel spraying;

- with drip feed.

The potbelly stove should not be taken as an oven designed exclusively for installation in small technical and utility rooms. With the help of heating devices equipped with an air collector or a water jacket, it is possible to build full-fledged heating systems for residential buildings.

Scheme of a furnace with a drip supply of waste oil

A wide range of home-made liquid-fuel stoves, which starts with simple mobile stoves and ends with stationary heat generators, determines their use both in the household and in production.Today, equipment operating on used lubricants is heated by:

- residential buildings;

- car repair shops and garages;

- workshops of small industries;

- workshops;

- warehouses;

- vegetable stores and greenhouses.

Of course, the ideal option is the installation of liquid heat generators in car repair shops. This will allow not only to heat the premises for free, but also to additionally save money on the disposal of drained oil. Nevertheless, such a potbelly stove will also be useful in a small private garage - the cost of mining is much cheaper than other types of fuel.

Like any other home-made heat generator, a mining furnace has its advantages and disadvantages. The advantages of these structures include:

- low cost of fuel. Mining can be drained from your own car, borrowed from friends, or literally bought for next to nothing at car service stations;

- high heat transfer, which contributes to the rapid heating of the room immediately after ignition;

- Efficiency up to 90%;

- autonomy;

- work for a long time when installing volumetric fuel tanks;

- undemanding to the materials of manufacture;

- possibility of equipping with a water circuit or an air heat exchanger;

- ease of operation;

- disposal of fuel without the danger of environmental pollution.

If we talk about the minuses of the units working on mining, then they are inherent in all stoves. Firstly, it is the low heat capacity of the structure. The temperature in the room will begin to drop immediately after the flame goes out. Secondly, you will need to install a long chimney, which means that you will need to clean it much more often.Thirdly, the hot walls of the diffuser and heat exchanger do not allow you to install the device directly in the house - you will need a special extension. It should also be noted that the use of liquid fuel increases the requirements for operational safety - you will need to be extremely careful and attentive.

The principle of operation of the stove

Potbelly stove - a primitive version of a metal wood-burning stove. Such a device works extremely simply: firewood is laid in the furnace, they burn out, the furnace body heats up and gives off heat to the surrounding air. Smoke gases are removed through the chimney, and the ash is poured through the grate into the ash pan, which should be cleaned periodically.

One of the main advantages of a potbelly stove is the simplicity of design. There are no strict dimensions here, the main thing is that the body can withstand heat, and the chimney works properly. An experienced craftsman will make such a stove in just a couple of hours. And you can burn almost any dry tree in it: both logs and sawdust. On our website there is an article with a detailed description of the process of making a potbelly stove with your own hands.

They heat a potbelly stove with other combustible materials: diesel fuel, coal, peat, household waste, etc. If desired, on such a stove you can cook quite successfully. This point should be considered even before the start of the manufacture of the structure in order to make a flat hob.

The potbelly stove is a combustion chamber made of thick metal with a loading door, a chimney, a grate and a blower. You can use an old gas cylinder as a housing

But one should also take into account the disadvantages of such a heating solution. For starters, this is a high risk of burns and fires.

For a potbelly stove, you need to choose a special place, finished with fire-resistant materials. It is desirable that she stand to the side, where no one accidentally touches the body and does not burn herself.

If desired, the upper part of the vertical potbelly stove from an old gas cylinder can be turned into a hob of modest size

Such a metal structure weighs a lot, so there is no question of any mobility of the device. It will be difficult to move the potbelly stove to heat different rooms.

Such stoves are usually used to heat utility rooms in which there is no electricity or where it is supplied intermittently: a garage, a barn, a workshop, etc.

From two gas cylinders connected perpendicularly, you can make an improved version of the potbelly stove, which allows you to save more heat and get high returns when burning fuel

Another problem is the low efficiency, since part of the thermal energy during the combustion of wood literally flies into the chimney. There are various ways to keep warm and modify the potbelly stove a little to make it work more efficiently.

Finally, you need to take care of good ventilation of the room in which the potbelly stove is installed, since such a device burns a large amount of oxygen during operation.

So, a potbelly stove consists of a metal case, the role of which is usually “invited” to an old gas cylinder. In the case it is necessary to make two doors: large and small. The first serves to load fuel, the second is needed as a blower through which air enters the combustion chamber to ensure the combustion process and traction.

A drawing of a potbelly stove from a gas cylinder allows you to make a device with specific parameters and calculated power, but such accuracy is not necessary

Below, at some distance from the bottom of the structure, a grate should be welded. It can be made from thick wire or just take a sheet of thick metal and cut long slots in it. The distance between the bars of the grate should be such that the furnace material does not spill down into the ash pan.

If the potbelly stove will be heated only with firewood, the grate gaps are made large, but when wood chips are supposed to be used, the grate should be made more frequent.

A curved metal chimney mounted on a potbelly stove from a gas cylinder allows you to keep more heat in the room and increase the efficiency of the design

The ash box can be welded from sheet metal or you can take a ready-made metal container of a suitable size and resistant to strong heat. Some people prefer to do without an ash pan at all, they simply scoop out the ash from the lower section as needed, although this is not very convenient. As a rule, the chimney for a potbelly stove is brought up to provide the necessary traction.

The standard design of a gas cylinder stove can be improved by increasing productivity by turning a solid fuel heater into a heater or hob:

The principle of operation of the potbelly stove

The work of the potbelly stove is based on the phenomenon of pyrolysis. Such a furnace, where oil is used as fuel, has 2 main compartments: a tank and a combustion chamber located at different levels. The first is intended for pouring mining and its combustion.

In another compartment, located above, the afterburning of the combustion products of mining, mixed with air, takes place.At the first stage, the temperature is relatively moderate, and at the second stage it is much higher - up to 800⁰.

In the manufacture of such a furnace, the main task is to make sure that air enters both compartments. It enters the first chamber through an opening designed to load liquid fuel. The hole is equipped with a special damper, through which the volume of air supply is regulated.

Despite the fact that the design of the furnace is very simple, increased requirements are placed on the chimney of the potbelly stove. For effective removal of combustion products, it is necessary to prepare a straight pipe with a diameter of more than 10 cm and a length of more than 400 cm. Bends and horizontal sections are highly undesirable. In addition to its intended purpose, the pipe also acts as a residual heat exchanger

Air access to the second tank is provided by holes with a diameter of about 9 mm. The efficiency of a properly assembled potbelly stove reaches 90%. Visually, different potbelly stoves can differ from each other in both shape and size, but the principle of operation is the same.

The power of the potbelly stove is proportional to the volume of the lower tank. The larger it is, the less often you have to add mining. Sometimes this container is made very massive, containing about 30 liters of used oil.

The improvement of the simple design of the stove at work out made it possible to invent a unit for arranging a garage, in which it would be nice to wash your hands with hot water, or a small private bathhouse:

Image gallery

Photo from

Enlarged mining afterburner chamber

Lower chamber in the form of a drawer

Convenient scheme for pouring mining

Practical hot water tank

Pros and cons of a potbelly stove in oil

The potbelly stove will require recycled oil. It is an inexpensive but efficient fuel.In this case, flammable substances such as gasoline, diesel, thinner and kerosene cannot be used.

The principle of operation is to directly heat the air that is in the furnace. The design consists of two chambers. In the first, oil burns, and in the second, vapors that mix with air. The combustion temperature of the vapors is quite high, and this heat is transferred to the stove and the room.

The potbelly stove works due to the influx of air. The first chamber contains a special damper that controls the oxygen supply. The connections between the chambers are made by a pipe with holes.

Advantages of oil ovens:

- Safe operation due to combustion of steam, not oils;

- Available installation;

- Simple use;

- Cheap cost of equipment and fuel.

The disadvantages relate to fuel requirements. So fuel must be stored in a heated room. When cold, the oil loses its properties and becomes unusable. Mining must be purchased separately, as the fuel must be filtered. It is impossible to do this at home.

The principle of operation of the potbelly stove

The work of the potbelly stove is based on the phenomenon of pyrolysis. Such a furnace, where oil is used as fuel, has 2 main compartments: a tank and a combustion chamber located at different levels. The first is intended for pouring mining and its combustion.

In another compartment, located above, the afterburning of the combustion products of mining, mixed with air, takes place. At the first stage, the temperature is relatively moderate, and at the second stage it is much higher - up to 800⁰.

In the manufacture of such a furnace, the main task is to make sure that air enters both compartments.It enters the first chamber through an opening designed to load liquid fuel. The hole is equipped with a special damper, through which the volume of air supply is regulated.

Despite the fact that the design of the furnace is very simple, increased requirements are placed on the chimney of the potbelly stove. For effective removal of combustion products, it is necessary to prepare a straight pipe with a diameter of more than 10 cm and a length of more than 400 cm. Bends and horizontal sections are highly undesirable. In addition to its intended purpose, the pipe also acts as a residual heat exchanger

Air access to the second tank is provided by holes with a diameter of about 9 mm. The efficiency of a properly assembled potbelly stove reaches 90%. Visually, different potbelly stoves can differ from each other in both shape and size, but the principle of operation is the same.

The power of the potbelly stove is proportional to the volume of the lower tank. The larger it is, the less often you have to add mining. Sometimes this container is made very massive, containing about 30 liters of used oil.

The improvement of the simple design of the stove at work out made it possible to invent a unit for arranging a garage, in which it would be nice to wash your hands with hot water, or a small private bathhouse:

6 Assembly of the whole structure

The container can be made from three parts. To begin with, a steel strip of the desired size is cut out, which must be bent into a circle and welded. The same diameter is required to cut two steel circles (one for the bottom of the case, the second for the top cover).

Make 2 holes in the lid. One of them will serve to fill the oil and air into the primary chamber, and the second should correspond to the diameter of the pipe.The first hole must be made with a plug installed on a bolted connection, which will make it possible to regulate the air supply to the chamber.

The second container (secondary combustion chamber) is made in the same way, but here you need to install a partition (the diameter is slightly smaller than the chamber itself), dividing it in half. In one part, the chimney will exit, and the other will serve to burn a mixture of air and gases. In the second chamber, a hole is made in the bottom for the connecting pipe, and on top - for the chimney.

When both containers are made, you need to take care of the pipe for the burner. To do this, you need to drill a lot of holes in it. But one should take into account the fact that if there are too many holes, a strong air flow is formed, and the fuel will quickly burn out, and if there are not enough of them, the necessary thrust will not be created.

Finally, you need to carefully collect all the details together. The quality of the seams in this case must be high, since the tightness of the structure is a prerequisite. The only removable part is the cover of the device. The rest of the components must be tightly welded.

The chimney is installed last. It is not recommended to install it in a horizontal position. It is better to keep a small angle. Often, legs are also welded to such a unit. On them, he will be a little off the ground.

Do-it-yourself step-by-step instructions for making a waste oil furnace from a cylinder

The device can be made from old items using the provided drawings of the waste oil furnace. For this process, you will need a gas cylinder with a capacity of 50 liters.You should also prepare:

- a pipe with a diameter of 80-100 mm and a length of 4 m;

- steel corner for the manufacture of the stand and internal elements of the heat exchanger;

- sheet steel for making the bottom of the upper chamber and the plug;

For the process of manufacturing a waste oil furnace, you will need a gas cylinder with a capacity of 50 liters

- brake disk;

- fuel hose;

- clamps;

- half-inch valve;

- loops;

- half inch oil supply pipe.

An empty gas cylinder is used to make the case. It is necessary to unscrew the valve on it, after which it should be left overnight on the street to ventilate the remaining gas. A hole is drilled in the bottom of the product. To prevent the formation of a spark, the drill must be moistened with oil. Through the hole, the balloon is filled with water, which then drains, washing off the remaining gas.

Two openings are cut in the balloon. The top one will be used for the combustion chamber, where the heat exchanger will be installed. The lower one acts as a burner with a tray. The upper part of the chamber is specially made large. If necessary, it can be filled with other fuel options in the form of firewood or pressed briquettes.

A gas cylinder stove will be more economical and efficient than other materials

Further, the bottom for the upper compartment of the apparatus is made from sheet metal with a thickness of 4 mm. A burner is made from a piece of pipe 200 mm long, as shown in the drawing of a waste oil stove. A lot of holes are made around the circumference of the product, which are necessary for air to enter the fuel. Next, grind the inside of the burner. This will eliminate the possibility of soot accumulation on the ends and uneven surfaces.

Furnace burner in operation from a gas cylinder is welded to the bottom of the upper chamber. In the absence of mining reserves, wood can be laid on the formed shelf.

Making a pallet for working out and installing a chimney of an oil stove with your own hands

According to the drawing of the stove, for the manufacture of a waste oil pan, cast iron car brake disk, which has good heat-resistant characteristics. In its lower part, a steel circle is welded, which forms the bottom. A cover is made in the upper part, through the opening of which air enters the furnace.

For the manufacture of the pallet, a cast-iron automobile brake disc is used.

The next step in the manufacture of a waste oil stove from a gas cylinder is to make a coupling from a 10 cm long pipe that connects the burner and the pan. Thanks to this element, it will be much easier to maintain the stove. You can remove the pan and clean the bottom of the burner. To ensure oil supply a metal tube is inserted into the hole in the body, which is seized by welding. An emergency valve is installed on the pipe.

The chimney structure is made of a pipe with a diameter of 100 mm. One of its ends is welded to the hole in the central upper part of the body, and the other is brought out into the street.

After watching the video "Furnace for working out from a gas cylinder", you can familiarize yourself with the sequence of actions in the manufacture of the apparatus.

Overview of Russian-made waste oil boilers

Boilers of domestic production using waste oil are manufactured mainly in Voronezh, where the manufacturer has all the necessary documents related to the production of products. There are other small businesses as well.However, most of them do not have a state certificate for the manufacture of heating equipment.

This should be taken into account when buying a boiler.

Powerful boiler Stavpech STV1 is characterized by high efficiency

The double-circuit waste oil boiler Teploterm GMB 30-50 kW is characterized by the high quality of every detail. It, thanks to the multifunctional microprocessor, is equipped with an automatic control system. The device has many options that simplify the operation of the device, making it safe. Fuel consumption - 3-5.5 l / hour. The cost of the model is 95 thousand rubles.

A popular model is the Gecko 50 pyrolysis boiler. The device can work not only on mining, but also on crude oil, diesel fuel, fuel oil of all brands, kerosene, fats and various types of oil. The boiler is undemanding to the quality and viscosity of the fuel. There is no need for its pre-filtering and heating.

The design has small dimensions (46x66x95 cm) and a weight of 160 kg. The device is characterized by high efficiency, reliability of all elements and connecting nodes, ease of maintenance and repair. The maximum temperature in the device reaches 95 °C. The fuel consumption is 2-5 l/h. The power consumption is 100 W. The price of a waste oil heating boiler is 108 thousand rubles.

Combined boiler KChM 5K has a cast-iron reliable body

The Stavpech STV1 boiler is characterized by high efficiency. The power of the device is 50 kW. The flow rate of the fuel mixture is 1.5-4.5 l/h. Housing dimensions - 60x100x50 cm. The device is equipped with a reliable modulated burner for a waste oil boiler, which has a high emission rate.The device is equipped with a fuel filter, a pump and a water tank. Various types of oil, diesel fuel and kerosene can be used as fuel. The price of the boiler is 100 thousand rubles.

Combined apparatus KChM 5K has a cast-iron body. It can work not only on mining, but also on gas, as well as on solid fuel. The power of the device is 96 kW. The model differs in high quality of production of details, safety in operation and durability. You can buy a boiler for 180 thousand rubles.

Expensive domestic waste oil boilers

The domestic automatic waste oil boiler Teplamos NT-100 is characterized by an expanded configuration. A double-circuit boiler can be used not only for heating, but also for providing hot water in the house. The model is characterized by high quality workmanship of all components. The exterior parts are powder coated to protect them from corrosion. The case has an internal heat-insulating coating in the form of high-density glass wool.

The exhaust boiler Ecoboil-30/36 can be used to heat a room up to 300 sq. m

For convenience of management the device is equipped with the remote control that allows it to work in the automatic mode. It consists of a switch, a thermostat, a thermohygrometer and an emergency thermostat.

The boiler measures 114x75x118 cm and weighs 257 kg. The maximum power consumption reaches 99 kW. The consumption of combustible substance fluctuates within 5-6 l/hour. The price of a waste oil boiler is 268 thousand rubles.

Ecoboil-30/36 single-circuit heating apparatus for mining can be used to heat a room up to 300 sq. m.It has dimensions of 58x60x110 cm. The power of the device is 28 kW. Fuel consumption can vary from 0.9 to 1.6 l/h. The boiler works on any type of oil, regardless of its quality. You can also use kerosene and alcohol for it. The cost of the boiler is 460 thousand rubles.

Hot water fire-tube boiler Belamos NT 325, having a capacity of 150 kW, is able to heat a room with an area of more than 500 square meters. m. Fuel consumption reaches 1.8-3.3 l / h. Due to the presence of a heat exchanger, it has a high efficiency. Equipped with a control unit with a smooth adjustment function and the ability to maintain the set temperature of the coolant. It can work on any type of liquid fuel that does not need filtration and heating. The price of the boiler is 500 thousand rubles.

The double-circuit boiler Teplamos NT 100 can be used not only for heating, but also for providing hot water in the house