- Manufacturing Recommendations

- We improve heat dissipation

- We make a long-burning stove with our own hands

- Conclusion

- Do-it-yourself three-way potbelly stove

- Materials and tools

- Step-by-step instruction

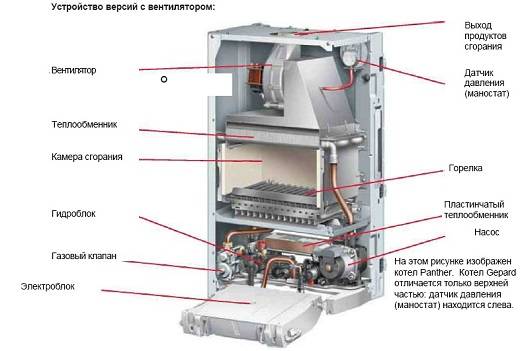

- The device of a potbelly stove for long burning

- Increasing the efficiency of the furnace

- How to make a potbelly stove of long burning?

- Methods and rules of calculation

- exact method

- Swedish method

- The main advantages of pyrolysis ovens:

- Simple and convenient "ash pan"

Manufacturing Recommendations

The topic of making various wood-burning potbelly stoves from gas cylinders is very popular and here's why. Firstly, it is an affordable material that can be found at any scrap metal collection point. Secondly, such a tank is the actual finished furnace body with fairly thick walls. It remains only to refine it on your own and you will get an excellent potbelly stove for heating a garage or a summer house. Moreover, the design can be both vertical and horizontal.

A do-it-yourself vertical potbelly stove from a cylinder is more compact and takes up little space in the room. But the firewood in it will not burn for a long time, no matter how you limit the air flow, since the flame will cover the entire volume of fuel.

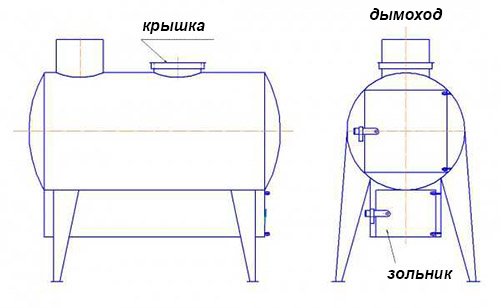

Another thing is a horizontal stove, in which the flame moves from beginning to end, gradually burning wood.But there is more work with it, you need to arrange an ash chamber outside, because inside it will take up too much usable volume. The device of this potbelly stove is shown in the drawing:

Now about how to make a horizontal potbelly stove at home. To do this, you need to carefully cut off the top of the cylinder with a grinder, where the gas valve is screwed. Naturally, the valve must first be unscrewed, and the container filled to the top with water in order to displace all propane vapor that could remain inside the tank.

Otherwise, you risk setting off an explosion, the consequences of which are unpredictable. Then the sequence of actions is as follows:

- cut a strip in the side wall where the ash chamber will be welded. Another option is to drill a lot of holes, as you can see in the photo below.

- make and weld an ash pan from metal 2-3 mm thick to the cylinder. Put a homemade door or damper in front to regulate the air supply;

- in front of the end should be embedded loading door. It can be made in a round or square shape, or you can purchase a finished product;

- in the back, you need to cut a hole for the chimney channel. You shouldn’t make it too big, it’s enough to take a chimney diameter of 100 mm, a maximum of 150;

- weld a pipe;

- make a stand from any metal-roll at hand and also weld it to the body.

A vertical-type furnace from a cylinder is a little easier to make. To make such do-it-yourself potbelly stove, it is necessary to cut openings for doors in the side wall, and the cut pieces of metal themselves can act as flaps. You just need to attach loops to them, for example, from several links of a thick chain, as is done in the photo:

But with the grate you have to tinker.Not only do you need to make a grate (preferably from rebar), it also needs to be somehow installed inside the cylinder. Here you have to cut off its top or bottom part - at your discretion.

After the installation of the grate, the cut off part should be welded in place, and a branch pipe should be attached on top to remove the combustion products.

We improve heat dissipation

The biggest problem of bourgeois women: inefficient use of heat. Most of it literally flies into the flue gas pipe. This disadvantage is effectively combated in top-burning furnaces with afterburning of flue gases, similar to the Bubafonya furnace (also, by the way, can be made from a gas cylinder) and Slobozhanka.

A variant of a potbelly stove made of propane cylinders with secondary afterburning - the efficiency is higher than that of "ordinary" models.

Another way to improve heat dissipation is to make the chimney longer, thereby increasing the amount of heat that will remain in the room. When designing such a broken chimney, it is better to avoid horizontal sections, and even more so sections with a negative slope.

This gas-fired stove is wood-fired. Increased heat transfer by making a long broken chimney

Another option to use the heat of flue gases is to weld a vertical cylinder-flue pipe to a horizontally located cylinder-body. Due to the larger area, the heat transfer will be higher. It will only be necessary to create good traction so that the smoke does not go into the room.

Such a potbelly stove from a gas cylinder will warm up the room faster

You can do it the way they do in sauna stoves: put a net around a metal pipe into which stones are poured. They will take heat from the pipe, and then give it to the room. But.First, until the stones heat up, the air will warm up slowly. Secondly, not all stones are suitable, but only round ones, which are along the rivers. Moreover, uniformly colored without inclusions. Others cannot be covered: they can explode from high temperatures no worse than a fragmentation projectile, or release radon, which is very harmful in significant concentrations.

The solution can be peeped at the sauna stoves: build a grid for stones on the pipe

But such a solution also has advantages: firstly, the pipe will not burn. Stones emit even heat. Secondly, after the stove goes out, they will maintain the temperature in the room.

Often you need to quickly heat the room. To do this, you can use a conventional fan that will blow around the body and / or pipe of the furnace. But the same idea can be carried out with a stationary version: weld through pipes into the potbelly stove cylinder in the upper part. On the one hand, attach a fan to them (heat-resistant, preferably with several speeds, so that it is possible to regulate the temperature).

Pipes that pass through are welded into the upper part of the cylinder. On one side, a fan is attached to them, which drives air through them, quickly warming up the room.

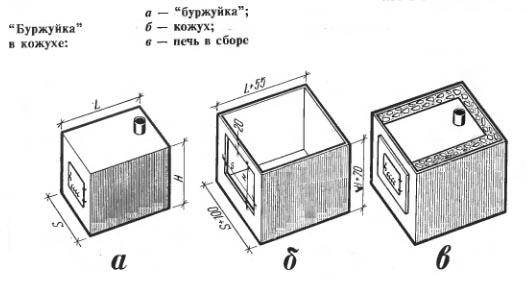

Another option that allows you to achieve active air movement along the walls of the case and not use a fan at the same time: make a casing around the case at a distance of 2-3 cm, but not solid, but with holes at the bottom and top. Buleryan furnaces or metal furnaces work according to this principle. sauna stoves.

One of the options for such a casing around a horizontally located cylinder is visible in the photo below. Through the gaps that are below, cold air is sucked in, located near the floor.Passing along the red-hot body, it heats up, and exits from above.

This is a stove lies on its side: the casing is not solid, there are decent gaps at the bottom and top

The principle is not new, but it is no less effective. What the finished stove looks like with such a casing, see the photo below.

Potbelly stove with improved convection around the body for quick space heating

Here is another implemented casing, around a potbelly stove from a horizontally located cylinder

Pay attention to the non-standard door fastening

This shiny leaf improves room heating

A home-made boiler from a gas cylinder for water heating can be made according to the same principle: weld a water jacket around the cylinder, and connect it to radiators. Just do not forget that the system must have an expansion tank with a volume of 10% of the total displacement.

You now know how to make a potbelly stove from a gas cylinder and how to improve it. Watch another video about an interesting version of a combined stove for a summer residence or a garage made of bricks and a gas cylinder.

We make a long-burning stove with our own hands

The first step is to decide what the body of the stove will be made of. It is advisable to choose a thick metal so that it does not burn out longer. Most often, such a potbelly stove is made from a gas cylinder with a volume of 50 liters. You can use a thick-walled pipe with a large diameter or a steel barrel with a volume of 200 liters, but its walls are thinner.

You will also need:

- steel pipes;

- metal profile;

- a tool for cutting metal (grinder, gas cutter, etc.);

- welding machine with electrodes;

- Sheet steel.

Let's consider in detail how to make a potbelly stove with your own hands.It is preliminary recommended to sketch a design diagram and determine the dimensions of the elements.

Frame. When manufacturing a body from a gas cylinder, it is necessary to carefully cut off the upper part of it (the cut line is 1 cm below the weld). If desired, the body can be extended by welding the cut off part of another cylinder. At the barrel, the upper part with the lid is also cut off. And if a pipe is chosen for the body, a round or square bottom made of thick sheet metal should be welded to it.

Housing options

Housing options

Lid. In the cut off top of the gas cylinder or in the barrel lid in the center, a hole should be cut that matches the size of the pipe from which the piston will be made

The lid is scalded with a steel strip - it is important that it fits snugly on the body. For a pipe housing, the cover will have to be specially made from sheet metal. Chimney pipe

On the side of the stove, a couple of centimeters below the put on cover, a hole is cut and the chimney pipe is welded

Chimney pipe. On the side of the stove, a couple of centimeters below the put on cover, a hole is cut and the chimney pipe is welded

It is important that the removable chimney elbow fits snugly, without a gap.

Chimney. The lower, horizontal section of the chimney must be longer than the diameter of the stove. The chimney can be made broken to increase the surface area that gives off heat to the room

It is important that there are no angles less than 45°. A pipe with a diameter of 10-15 cm is suitable for installing a chimney

Piston. The length of the air duct must exceed the height of the body by 100-150 mm.It is necessary to weld a steel circle with a hole in the center to its lower part and equip it with five or six blades from the bottom side (arranged in a circle, rays from the center).

The blades may be:

- pieces of steel corner;

- segments of the U-shaped profile;

- wave-curved strips of metal (welded with an edge).

In the middle, a small steel circle with a hole in the center is welded onto the blade. If the platform with the blades is made of steel less than 6 mm thick, it deforms over time from overheating. To prevent this from happening, stiffeners are welded on top - a triangle made up of segments of a corner. On the upper cut of the pipe, attach a steel plate with a bolt to adjust the intensity of combustion.

Assembly. Install the top burning stove, check the tightness of the chimney connection. Insert the piston into the oven, put on and close the lid. Make sure the cap fits snugly and that there is minimal clearance between the piston and the hole in the cap.

Commissioning. Homemade potbelly stoves of long burning can be placed on an earthen or concrete floor. If the floor in the room is wooden, lay out a platform of bricks, using mortar for laying stoves, and cover it with steel sheet. Instead of a brick, a sheet of refractory material can be laid and also covered with sheet metal. It is advisable to lay out the walls next to the self-made stove with bricks, which will accumulate heat and give off to the room.

Firewood is placed in the installed stove, filling the firebox by about 2/3 or a little more. Paper is placed on top and set on fire. After making sure that the wood is busy, you can install the piston and put on the lid. The next laying of firewood is possible only after all the fuel has burned out and the stove has cooled down.

Conclusion

"Bubafonya" is not the most efficient long-acting homemade stove. Craftsmen are developing various options for a wood-burning “rocket” stove, but its manufacture requires accurate calculations, hand-made drawings and good skills in working with various tools.

"Bubafonya" can also be upgraded, for example, to mount a device that simplifies the unloading of ash.

Related videos:

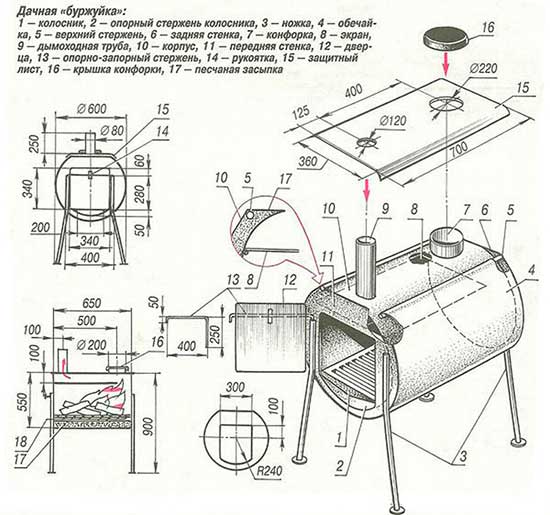

Do-it-yourself three-way potbelly stove

Three-way potbelly stove

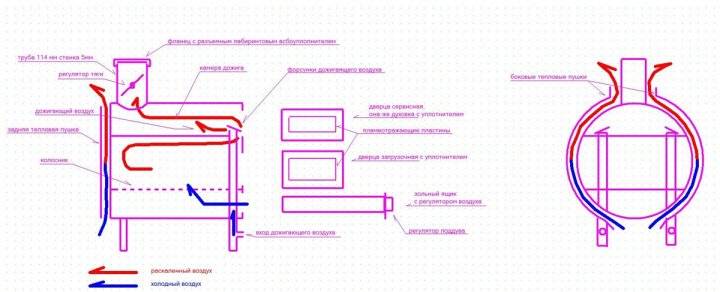

A three-way potbelly stove (pictured above) is two gas vessels of 50 liters welded to each other at a right angle. The principle of operation is as follows:

- The first is actually a horizontal potbelly stove from a gas cylinder on wood. It is equipped with all the details that are typical for a stove: a blower, a loading chamber for firewood, grates. Firewood is loaded here and fired up.

- The second vessel is a unique design in its simplicity and genius. It is divided by internal partitions in such a way that the smoke from the combustion of fuel, passing through it, changes the trajectory of movement three times. The speed slows down and the furnace body gives off more heat. In the end, through the outlet pipe, the smoke comes out.

- Additional ribs are used to increase the heating surface.

- As in a traditional oven, the air supply is regulated through a blower.

Expert opinion

Pavel Kruglov

Baker with 25 years of experience

Such a wood-burning stove from a gas cylinder is quite capable of delivering about 10 kW of heat. This is enough to heat a room of 100 m2. It can be a warehouse, a barn, a greenhouse or a garage. Such a simple design of the furnace is capable of producing an efficiency of up to 55%.

On such a potbelly stove from two gas cylinders, it is quite possible to cook food.

Before proceeding with the manufacture, we will figure out what materials and tools we will need and prepare the necessary drawings. Very good if you have the skills of a welder. If not, then any specialist in ready-made drawings will bring your project to life. A video that is easy to find on the Internet can also help.

Materials and tools

We will need the following tools:

- portable welding machine

- "Bulgarian"

- drill

- drill

- other tool.

The maintenance of the welding machine is not profitable, so it can be rented if necessary. The rest can always be found at the home master.

There are also few materials:

- electrodes

- cutting wheels

- 2 gas cylinders for 50 liters

- sheet 2 mm thick

- corner for the manufacture of "legs"

- fittings with a diameter of 20 mm

- others

Step-by-step instruction

Scheme of a three-way potbelly stove

- We make blanks from metal according to the drawing above.

- We cut out the necessary holes in the balloon. One is for the stove, the second is for the smoke outlet.

- Cut off the bottom of the second bottle. At the end, we cut a hole for a pipe with a diameter of 100 mm. We cut the balloon so that it fits snugly on the first one, as shown in the drawing above.

- Make a grate.

- We make a blower. We weld the legs, hinges and frames of the doors.

- We make doors. We seal all junctions.

- Scraps from the cylinder should be used for partitions in a vertical cylinder.

- Weld one cylinder to another, weld the chimney.

- Weld additional fins to increase the heating area.

The device of a potbelly stove for long burning

There is no difference what section this stove will be. It can be round or rectangular.There are several requirements that will affect the efficiency of the device:

- Chimney diameter 85-150 mm. These are the optimal dimensions suitable for the power of the furnace. The more power, the larger the diameter.

- Blower installation. This device must be made according to certain standards. First, an L-shaped pipe is attached to it. Secondly, the end of the pipe must be perforated with a large number of holes with a diameter of 5-7 mm. Thirdly, the same end must have an external thread on which a blind plug will be screwed. By unscrewing the plug, we open some of the holes, thereby increasing the supply of fresh air to the furnace.

Vertical option

I would like to dwell on the blower. Everyone knows that the supply of oxygen to the combustion zone of the fuel is a fundamental effect of proper combustion of firewood. So, in order to determine how efficiently firewood burns due to the correct air supply, it is necessary to conduct one simple experiment.

To do this, pay attention to the red-hot ring around the chimney. The farther it is from the stove, the worse. That is, when opening the plug or closing it, it is necessary to lower the location of the ring

That is, when opening the plug or closing it, it is necessary to lower the location of the ring.

And another important element of a long-burning wood-burning stove is a protective screen. It would seem not the most important thing, but this is an erroneous opinion. Why?

- First, the screen protects against burns.

- Secondly, it is installed at a distance of 5-6 cm from the potbelly stove itself, thereby creating a certain thermal zone around the heater. And this is an additional buffer that restrains heat loss.

- Thirdly, this element protects the room from overheating by infrared radiation.

Increasing the efficiency of the furnace

The potbelly stove is able to heat the room in just a few minutes. Moreover, you can throw everything that comes to hand into the furnace: since it does not have an extensive network of chimneys, and the smoke in it comes out “directly”, you can not be afraid that they will clog.

But if a conventional heating stove installed in premises for permanent residence has an extensive network of chimneys that trap heat, in a potbelly stove it goes directly into the pipe, so its efficiency is not too high. That is why it is too "gluttonous" and requires a lot of fuel.

To reduce fuel consumption, you can use the following tips from experienced stove builders: • firebox door and blower in such an oven should be as tight as possible; otherwise, the air supply to the potbelly stove will increase, and the fuel will burn out too quickly; • to regulate the output of warm smoke in the chimney it is desirable to provide a gate valve ;• next to the stove it is possible to provide side metal screens at a distance of 5-6 cm from the stove, in which case it will heat the room not only due to heat radiation, but also with the help of convection (warm air circulation);

• to retain heat in the room, it is necessary to build up elbows in the pipe; however, at the same time, soot will linger in them, therefore it is desirable to create a collapsible structure; • the pipe can also be given a stepped shape: place the knees in stages, with each step making a turn of 30°; at the same time, each of the knees must be securely attached with bars to the wall;

• chimney capacity it should be less than the productivity of the furnace itself, in which case hot gases will not go into the pipe immediately; its diameter should be only 2.7 times larger than the furnace volume, for example, with a furnace volume of 40 l, the diameter should be 110 mm; blowing the chimney with a fan – this will turn the stove into a kind of smoke gun; • to reduce air circulation firewood in the oven should fit as tightly as possible; if it is heated with coal, it is necessary to stir up the resulting ash as little as possible; • to regulate the air flow, the door to the blower can be made adjustable by providing it with vertical slots and shutter. which will cover these slots; • to increase the heating area, it can be ribbed, that is, welded onto its body perpendicular to the furnace metal strips ;• if you put steam on the stove buckets or metal box with sand. then they will accumulate heat and store it even after the furnace is extinguished; sand backfill or heat accumulator made of stones can be sewn inside the metal body of the furnace;

• bake, lined with 1-2 layers of brick. will keep warm much longer;

• the volume of the furnace also matters: the larger the area of its walls. the more heat they will give to the room; • bricks or sheet metal. on which the stove is installed, will help not only to protect the room from fire, but also to keep warm.

Related video: Do-it-yourself potbelly stove

How to make a potbelly stove of long burning?

In order for the potbelly stove to radiate heat for as long as possible without throwing another portion of firewood, not to burn out quickly, you can make a long-burning stove, while the fuel will not burn, but smolder, the heating process without laying firewood can be extended for several hours.

The manufacture of a furnace for long burning is somewhat different from the usual design.

A balloon is best suited for the furnace:

- Cut off the top of it, this will be the lid on the stove.

- Make a hole at the top and side of the stove, this will be the hood.

- Make a hole in the center so that you can easily insert the balloon.

- Weld a pipe to the cut hole of the pancake, a little longer than the cylinder. The pipe will serve as a blower, and oxygen will flow into the furnace, the fuel will not smolder, but will not burn.

- Cut off part of the balloon in the center, insert a pipe into the hole as a blower. The principle of operation of a potbelly stove for long burning is to create pressure inside the chamber. After the firewood flares up, a heavy metal circle sinks inside, begins to put pressure on the fuel, creates pressure on it, the fuel begins to experience a lack of oxygen and slowly smolder. The smoke, heading up, goes out through the chimney, the room will not be smoky.

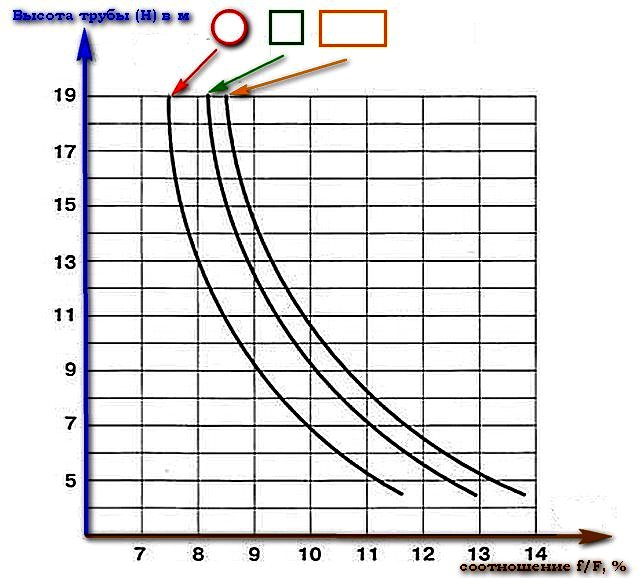

Methods and rules of calculation

The calculation rules have their own tolerances, you need to know them before calculating the pipe diameter. There are several calculation methods, they depend on who and for what conditions they will be executed:

- High-precision, they are used in the manufacture of boilers and are carried out by the design departments of equipment manufacturers.

- Approximate calculations performed by non-experts based on graphs, charts and tables.

- Automatic, obtained on the basis of online calculation.

Accurate calculations are understood as those in which many factors are taken into account:

flue gas temperature at the outlet of the boiler and from the pipe, the speed of movement of gases in the furnace and in sections of the smoke exhaust system, loss gas pressure according to movement in the gas-air path. Most of these parameters are obtained experimentally by manufacturers of boiler equipment and depend on the brand of the boiler, so this type of calculation is practically not available to users.

With regard to the approximate method, before calculating the diameter of the chimney, the characteristics of the volume of the combustion chamber are taken into account. To determine the geometric parameters of pipes, there are various tables and graphs. For example, with a firebox with dimensions of 500x400 mm, you will need a round pipe from 180 to 190 mm

For example, with a firebox with dimensions of 500x400 mm, a round pipe from 180 to 190 mm is required.

The third method is based on the use of special online calculators. They take into account almost all important parameters, so they give very accurate results. In order to use them, the operator will need to know a lot of starting data.

exact method

Accurate calculations are based on a rather laborious mathematical base. To do this, you will need to know the fundamental geometric characteristics of the pipe, the heat generator and the fuel used. For such a calculation, you can use the following method for determining the diameter of a round pipe for a wood stove.

Input calculation parameters:

- Indications of T gases at the outlet of the boiler t - 151 C.

- The average velocity of the flue gases is 2.0 m/s.

- The estimated length of the pipe, which is standardly used for stoves, is 5 m.

- The mass of burned firewood B= 10.0 kg/hour.

Based on these data, the volume of exhaust gases is first calculated:

V=[B*V*(1+t/272)]/3600 m3/s

Where V is air mass volume, which is necessary for the completeness of fuel combustion - 10 m3 / kg.

V=10*10*1.55/3600=0.043 m3/s

d=√4*V/3.14*2=0.166 mm

Swedish method

Chimney calculations are often performed using this method, although it is more accurate when calculating the flue systems of fireplaces with open fireboxes.

According to this method, the size of the combustion chamber and its gas volume are used for calculation. For example, for a fireplace with a portal 8 masonry high and 3 masonry wide, which corresponds to the size F = 75.0 x 58.0 cm = 4350 cm2. The ratio F / f = 7.6% is calculated and it is determined from the graph that a rectangular chimney with this size cannot work, perhaps the use of a circular section design, but its length must be at least 17 meters, which is not really high. In this case, it is better to make a choice from the reverse, according to the minimum required diameter section. It is easy to find it by the height of the building, for example, for a 2-storey house, the height from the fireplace to the chimney cap is 11 m.

F/f ratio= 8.4%. f = Fх 0.085 = 370.0 cm2

D= √4 x 370 / 3.14 = 21.7 cm.

The main advantages of pyrolysis ovens:

- High efficiency - from 90% or more.

- Fuel efficiency - one bookmark is enough for 12-24 hours.

- Modern models of factory-made pyro ovens work on one fuel tab for more than 48 hours.

- Minimum human intervention, simplified operation. Night shifts are excluded.

- From an environmental point of view, the less combustion products go into the atmosphere, the better.The pyrolysis oven produces a minimum of carbon monoxide and particulate matter. Almost all CO is burned.

- If you have competent drawings for making a pyro oven with your own hands and high-quality precise execution, it is really possible to get a unit that works with almost complete combustion of dry fuel. There is very little ash and soot, everything burns without residue, and there is no need to clean the stove and chimney.

- You can use cheap fuel - dried wood waste, light plant biomass, foliage, branches, straw, etc.

Simple and convenient "ash pan"

In a potbelly stove for long burning, an ash pan is not needed, a small amount of light ash after combustion remains directly in the furnace. But it is still possible to adapt the stove for easier cleaning, especially if you plan to add coal to the firewood.

1. Stops from the corner. 2. Grate above the "ash pan"

With a horizontal position of the potbelly stove, you need to cut out the same plate that was used to form the upper chamber. Instead of a partition, it has the usual 35 mm corner welded transversely. In the front part, a handle is made from a thin rod. The plate is mounted on two guide angles welded along the body. To tightly adjoin the plate and exclude strong air leaks, it is recommended to do this:

- weld the corners under the bottom of the plate with the shelves up on small tacks that are easy to beat off;

- insert the plate into the body and weld the corners to the walls, filling the thick weld well;

- insert scrap into the lower chamber and undermine the plate, if possible, clean up traces of welding.

Through small gaps, the minimum of oxygen necessary for combustion will enter the chamber.

1. Disk. 2. Reinforcement holder. 3.Side "ash pan"

For a vertical potbelly stove, you need to cut out another flat disk and weld a piece of thick steel reinforcement to it in the center. Along the perimeter of the circle, a side of a steel strip is bent and welded. In both cases, the removal of ash is carried out after the potbelly stove has cooled down: the ash pan is removed, cleaned and installed in place before a new bookmark.