- Well drilling methods ↑

- Popular Models

- Advantages and disadvantages of wells

- Disadvantages and advantages

- Division by type of work performed

- Installation types

- Types of work performed

- How to drill wells?

- Manual well drilling

- Percussion drilling

- percussive drilling

- How to make a rotary drilling rig

- Features of pneumatic percussion drilling

- Advantages and Disadvantages of Hammer Drilling

- Diamond drill bits

Well drilling methods ↑

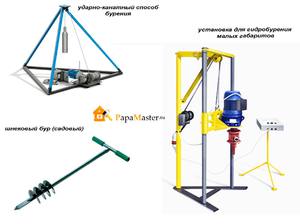

The drilling method is chosen depending on the type of soil on the site. There are two types of tool movements that allow you to select the ground - impact and rotation. The blow allows you to "bite" into the ground, after which the tool is removed and cleaned. Rotation removes the soil gradually. The drill is immersed in the ground, and it pushes the soil out. Drilling methods can be based on the principle of impact, rotation, or a combination of both types of movement. There are some of the most common methods:

Auger

The most common drilling method. The blades of the auger loosen the soil and bring it to the surface. The blades themselves are welded to the pipe at an angle of 90 degrees. Such a tool is not very convenient, because. part of the crushed soil is poured down. If the angle of inclination of the blades is 30-70 degrees, then the extracted soil is not crushed and does not pour back into the well.

Kolinsky

The core drilling tool is a pipe with a special crown equipped with sharp cutting elements. The principle of operation is based on breaking up the soil and lifting the sludge through the pipe. This method is well suited for drilling in hard ground. The diameter of the well corresponds to the diameter of the pipe. Sludge, raised in a metal "glass", is knocked out with a sledgehammer. So that the walls of the well do not collapse, water is supplied with clay. The pipe is lengthened as it goes deeper into the ground, increasing additional rods of 1.2-1.5 m each.

Shock rope

The device for this type of drilling is a two-meter tripod, on which a block is installed with a cable thrown over it. A bailer is attached to the end of the cable - a cutting and gripping tool. The bailer "scoops out" the earth, then it is lifted with a cable and cleaned through a special technological hole. To simplify the process, water is poured into the well, which is later removed.

Shock-rotational

The device for rotary percussion drilling is almost the same as for percussion-rope. In addition to percussion movements, the installation also performs rotational ones. This allows you to get the job done much faster. For hard soils, the shock-rotational method is considered the most effective.

For wells, you can use a conventional ice drill. The only problem that may arise is the insufficient length of the rod. As it goes deeper into the ground, it can be built up with home-made additional elements.

Popular Models

A small-sized drilling rig, the price and quality of which are perfectly correlated, allows users to solve the issue of arranging a well. Installations of domestic production are very popular among consumers.

For drilling a well up to 70 m deep, users choose the RB-50/220 unit. This is piston equipment, the cost of which is from 80 thousand rubles. If you want to create wells up to 100 m deep, you should give preference to the RB100/380 model. The motor power is 4.2 kW. This is professional grade equipment. The price of this unit is about 120 thousand rubles.

For small wells up to 15 m deep, you can purchase auger drill UBK-12/25. The price of new equipment is from 200 thousand rubles.

If you want to use the installation not only for creating water wells, but also for installing piles, arranging the foundation, you should purchase the PM-23 equipment. The cost of the equipment is 110 thousand rubles.

Advantages and disadvantages of wells

A well in the sand has a number of advantages, including:

- insignificant cash costs due to the shallow occurrence of the sandy aquifer;

- installation does not require a long time (collection and preparation for operation 1-2 days);

- a small amount of dissolved iron, which significantly improves its properties;

- there is no need to obtain special documentation, which is necessary when drilling artesian wells;

- productivity is greater than that of wells (1-1.5 m3/hour);

- the expediency of using MBU in a limited space, as well as in basements and rooms where there is no access to a car;

- no serious damage to the backyard landscape;

Sand wells also have disadvantages:

- it happens that when developing a well, a sandy aquifer is absent;

- the service life is 6-10 years subject to periodic cleaning;

- not always high-quality water, when used, there is a need for filtration;

- with a casing string gauge of 135 mm, the water supply is limited to 500 liters.

The main pros and cons of a well for limestone:

- greater productivity compared to a sand well;

- the service life is 50-60 years;

- does not silt, so constant cleaning is not required;

- the location of the well on the plot is not important, since the aquifer is everywhere;

- the depth of the aquifer is significant, so the development of the well is expensive;

- installation requires a longer time (collection and preparation for operation at least 3 days);

- high content of dissolved iron, which worsens the properties of drinking water.

With a small-sized installation, it is most practical to drill a well into the sand, but it is also possible to perform deeper drilling. A water well on a sandy aquifer can be at a depth of no more than 40 meters and a caliber of 125-135 mm. It does not have strong differences from the artesian source, except that the inside of the sand well is always made of one pipe (usually plastic, PVC). In order to protect the PVC sheath from ground pressure at great depths, a metal protective sleeve is made in artesian wells.

Disadvantages and advantages

A homemade water well drilling machine has advantages and disadvantages, like any other technique. The advantages are the following:

-

- High degree of maintainability. Each part is replaceable, which makes the service life quite long.

- Compact dimensions, light weight.

- Homemade devices are much cheaper.

- Versatility and efficiency.Ability to apply in a limited area.

- Quick installation and dismantling, a small-sized DIY drilling machine can be transported in a car trailer.

The main disadvantages are the need to regularly change pipes to longer ones if the immersion depth reaches more than 10 meters, as well as the need to spend time on its manufacture.

The manufacture of a water drilling rig will allow the owner to create an autonomous water supply system without the involvement of specialists. The engineering design is not difficult, so every person can create it without special skills and experience.

Division by type of work performed

In accordance with this criterion, well drilling rigs are:

- Operational. Machines are used at the stage of exploration of rocks in the field. Their main purpose is to take soil samples to clarify data on geology.

- Intelligence. This technique is used to collect soil samples from the field. Based on the results of his research, it is necessary to determine the value of the industrial facility.

- For drilling technical wells. Holes are necessary in the construction of buildings and structures for various purposes, for the construction of foundations. They can also be classified as a type of drilling rigs for oil and gas.

Installation types

Drilling rigs are used not only on land, but also in water. They can often perform several different types of work. For drilling a certain well, a rig is selected according to the permissible load on the hook. The load must not exceed the weight (in air) of the heaviest casing string. When choosing equipment model and size, it is necessary to take into account climatic, geological, traffic and energy conditions.In accordance with these data, the type of drive (electric or diesel) and the installation scheme are selected. There are many approaches to the classification of drilling rigs. They can be subdivided according to:

Dislocations: floating and ground. Floating are:

- PBBU (semi-submersible);

- SME (marine stationary);

- SPBU (self-submersible)

Way of movement: non-self-propelled and self-propelled.

Type of work:

- for the development of deposits: gas, oil and groundwater;

- for deep geological research.

The latter, in turn, are divided into collapsible and non-collapsible. Collapsible (small-block and large-block) are used for the construction of wells up to 10,000 m deep.

The latter, in turn, are divided into collapsible and non-collapsible. Collapsible (small-block and large-block) are used for the construction of wells up to 10,000 m deep.

Drilling structures vary in size. These can be small machines that can be operated and installed by two people, or huge equipment mounted on steel towers and serviced by a team of specialists.

Drilling rigs are also divided according to the type of rock being drilled. In areas covered by a thick sedimentary stratum and hard rocks, well drilling is carried out using the following equipment:

- auger (for soft soil);

- shock-rope (it is used very rarely, only for exploratory drilling);

- rotational (in unproductive deposits);

- machines "Empire" (when exploring bauxite deposits for drilling to a depth of 9-12 m of loose deposits).,

Can be classified according to the method of drilling. But the main classification parameter is the carrying capacity, which determines the design and characteristics of the incoming power and drilling equipment. The lifting capacity depends on the loads when lifting and lowering the drill and casing string and on the loads.

There are two characteristics of drilling machines:

- Rated load capacity, which is determined by the duration of use of the equipment.

- The maximum load capacity is determined by short-term overloads of the installation.

The difference between the maximum and nominal lifting capacity increases with the depth of the well. Due to the fact that short-term overload is possible when drilling a deep well, the equipment must be larger than when working with a shallow well.

According to the lifting capacity of the nominal installation for production and exploration drilling, they are divided into five classes. In the presence of a wide variety of well designs and depths, various purposes and conditions, it is impossible to be satisfied with one standard size of the installation. Therefore, according to GOST, the equipment differs in the permissible load on the hook.

Types of work performed

Depending on the parameters of the tasks performed, the equipment in operation has subcategories:

- operational equipment;

- reconnaissance devices;

- machines for technical and auxiliary processes.

Well types

Well types

Operational complexes are used at preliminary rock sampling for further work and soil research. During engineering work, the well parameter has an insignificant depth.

Reconnaissance vehicles are used for geological prospecting for minerals. In geological exploration, they are used to find oil and gas.

In the same processes for the study of water reservoirs and drilling of artesian wells.

Auxiliary equipment is used for making holes for piles in construction when laying foundations of various depths and purposes.

How to drill wells?

The passage to the aquifer lying in shallow water can be done by hand using one of three types of drilling:

- manual;

- shock-rope;

- shock.

The method of making the well is selected depending on the type of soil and the depth of the passage.

Manual well drilling

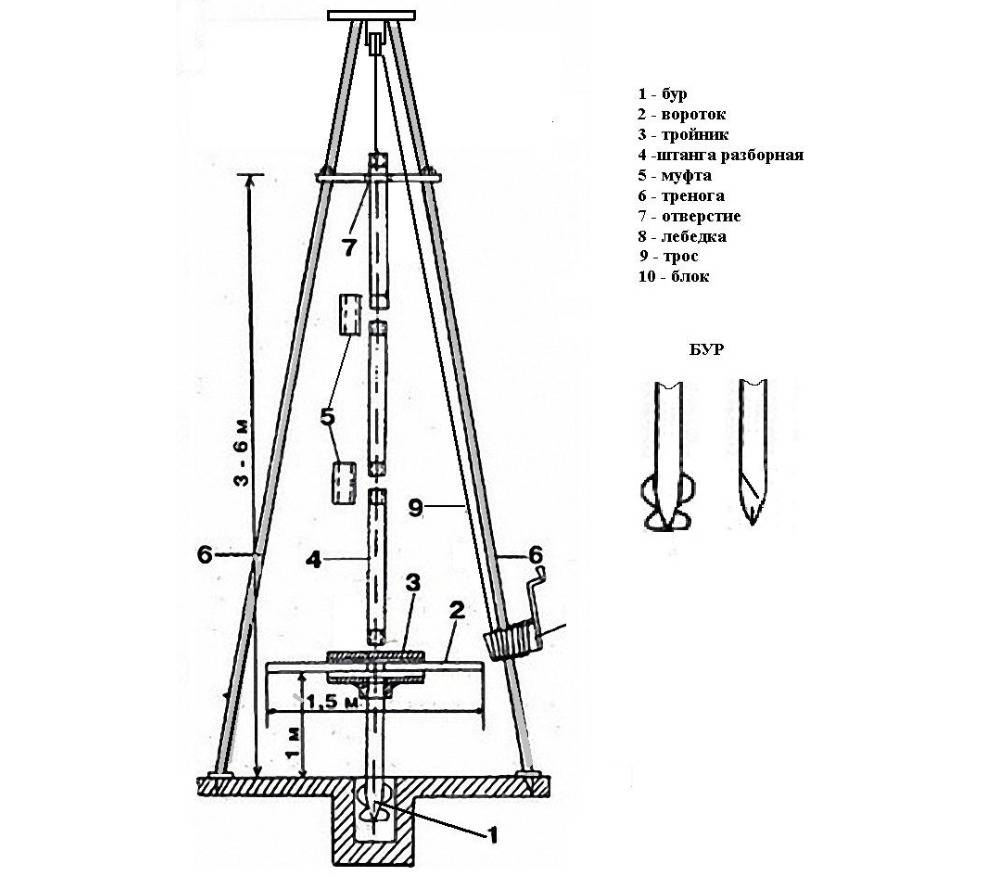

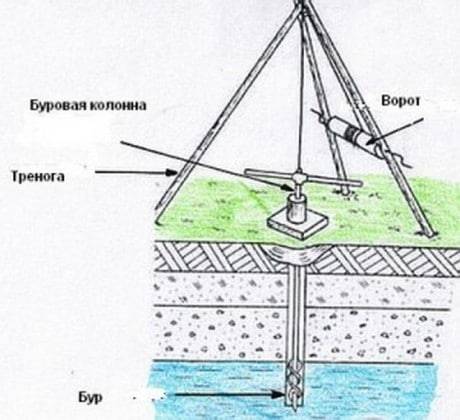

If additional equipment, a drilling tripod (tower) and a system of blocks are not used, a “well” can be drilled to a depth of up to 20 m.

Drilling technology:

- A tripod is installed on the selected passage area. The height of the tower should be 1-2 m higher than the length of the drill rod section.

- A shovel makes a recess for one or two bayonets for centering and guiding the passage of the cutting edge of the drill.

- To deepen the drill at a depth of more than one meter, you will need the help of a partner. One person is not able to continue drilling under the piles.

- If there are difficulties with the removal of the drill from the hole, it is necessary to turn it in the opposite direction of drilling by 2 - 3 turns and remove it.

- Every 500 mm of deepening, it is necessary to remove the drill and clean it from the soil.

- The drilling process is repeated until the handle of the drilling rig reaches ground level.

- The drill rod is taken along with the drill and extended with an additional section.

- All operations are repeated until you break through to the aquifer. This is determined by the type of soil being extracted.

- After reaching the reservoir with water, you need to continue drilling to a solid (water-resistant) layer. This will fill the well with the maximum volume of water.

- Pumping of water containing soil can be carried out using a pump of a manual or submersible type.

- After pumping out 3 - 4 buckets of muddy water, clean water should appear. If clear water has not gone, then it is necessary to increase the depth of the working by 1.5 - 2 meters.

Tip: Use the rig's design options to excavate as much soil as possible, as this is a time-consuming operation.

Tools:

- tripod;

- Boer;

- hoses for pumping water;

- composite drill rod;

- pump or pump.

Percussion drilling

A well made by this drilling method has a long service life of 80 years or more, an increased supply and inflow of water. The process of work consists in the destruction and grinding of the rock in a closed cycle with a special impactor.

Drilling process:

- The drilling rig is placed above the point for deepening the driving glass (chute, drill bit).

- A guide recess is made for the passage of the slope.

- The punching of the first meter of the well can be done manually.

- Next, a guide is installed, in the form of a steel pipe of a larger diameter than the diameter of the glass.

- The slope is thrown into the pipe by releasing the winch upon impact, the soil is destroyed and crushed, thereby filling the glass. The presence of a special valve prevents the soil from spilling out of the projectile.

- After that, the glass rises and the broken soil is excavated.

- The cycle repeats again until you reach the aquifer.

This method of drilling is laborious and lasts up to several weeks. Therefore, it is better to use it for drilling wells on the following types of soil:

- clay;

- on loams;

- on soft (watered) soil;

percussive drilling

The principle of shock passage as shock-rope. The difference is that the bits for drilling are in the face and the blow is carried out on them with the help of a striker.In this way, you can go to depths of more than 100 m.

Drilling can be carried out on many types of soils:

- soft ground - a wedge-shaped chisel is used;

- viscous soil - an I-shaped chisel;

- hard rocks - cross shape of the bit;

- boulders - a pyramidal shape of a chisel.

How drilling works:

- a drilling rig is installed;

- a chisel is inserted into the face, selected for a certain soil;

- a projectile descends, weight from 500 to 2500 kg, from a height of 300 to 1000 mm;

- after the impact, the soil splits, the chisel burrows into the soil;

- the projectile rises and the cycle repeats;

- cycle frequency - 45 - 60 beats / min.;

- after passing every 200 - 600 mm, the bit is removed from the face and cleared of the ground.

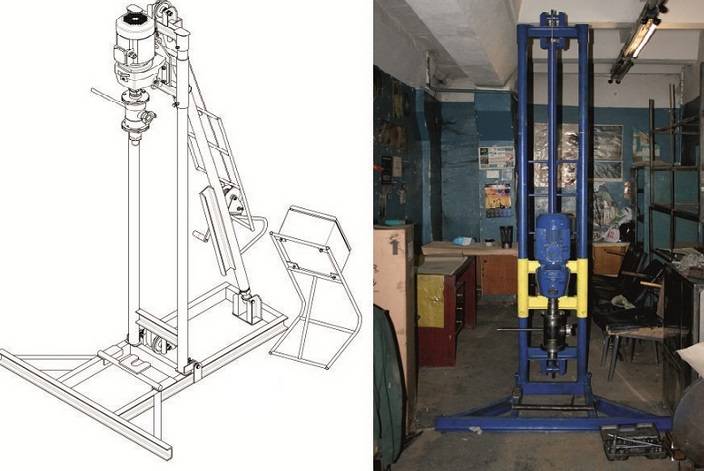

How to make a rotary drilling rig

The hydraulic drilling rig must have a frame that allows you to move up / down the motor, to which the drill is connected through a swivel. Water is also supplied through the swivel into the column.

Principles of building a drill

When making a drilling rig with your own hands, the following procedure is recommended:

- First there must be a swivel and rods. If you are not a qualified turner or you do not have one in mind, then these parts are better to buy. In their manufacture, high precision is required, which can be achieved with high qualifications. Moreover, the threads on the swivel and rods must be the same, or an adapter will be required. The thread on the rods is better - a trapezoid, since then few of the turners can make a conical one.

- Buy motor reducer. If the power is from 220 V, then its characteristics are as follows: power 2.2 kW, revolutions - 60-70 per minute (the best: 3MP 31.5 or 3MP 40 or 3MP 50).More powerful ones can only be supplied if there is a power supply of 380 V, and more powerful ones are rarely needed.

- Buy a winch, it can be manual or electric. The carrying capacity is preferably at least 1 ton (if possible, more is better).

-

When all these components are on hand, you can cook the frame and make a drill. After all, all this equipment is attached to it, and the types of attachment can be different, it is impossible to guess.

The frame of the mini drilling rig consists of three parts:

- horizontal platform;

- vertical frame;

- movable frame (carriage) on which the motor is fixed.

The base is cooked from a thick-walled pipe - wall thickness 4 mm, minimum - 3.5 mm. Better - from a profiled section of 40 * 40 mm, 50 * 50 mm or so, but a round one is also suitable. In the manufacture of the frame of a small drilling rig, accuracy is not important

It is important to observe the geometry: verticality and horizontality, the same angles of inclination, if necessary. And the sizes are "customized" in fact

First, the lower frame is cooked, measured. Under the available dimensions, a vertical frame is made, and according to its dimensions - a carriage.

You can make a simple drill fort yourself - they are made from ordinary steel (drawing in the photo below). If you take high-alloy steel, it is difficult to weld it to the rods. For complex and rocky soils, it is better to buy a drill in a specialized campaign - they have a complex shape, there are many different types.

Drill drawing 159 mm

To make it easier to work, connect two remote controls with the possibility of reverse running. One is put on the motor, the second on the winch. That, in fact, is all.

In the design of a drilling rig for rotary or auger drilling, the main thing is a swivel, but it is unrealistic to manufacture it without experience. For those who want to make it themselves, we will post a photo and its drawing.

Swivel device for rubble installation

Drawing of a swivel for a small drilling rig

Features of pneumatic percussion drilling

Hammer drilling belongs to rotary percussion drilling technologies and is most widely used in the field of engineering and geological surveys, as well as for drilling water wells. With the help of drilling with a pneumatic tool, it is possible to carry out mine workings of vertical and directional wells in the soil up to the 10th category of drillability.

The main distinguishing feature of the technique is to destroy the rock

used simultaneously impact and rotational action performed

respectively with a pneumatic hammer and a drilling rig rotator.

The working body of the machine is a downhole hammer. With the help of a valve device, compressed air flowing through the drill rod sets the hammer in forward-and-return motion, striking the drill bit shank. At the same time, the air hammer rotates together with the rod; the rotator is located outside the well. Drill chips are removed from the well with compressed air.

Advantages and disadvantages of drilling with

hammer

The main advantages of pneumatic hammer drilling are high speed

creation of wells, effective cleaning from cuttings, the ability to work on

fractured rock and eliminate the cost of bentonite and shipping

water for washing.

We also include the following benefits:

- The drilling cycle is several times shorter than those previously considered.Hammer drilling technology makes it possible to create wells much faster than drilling with drilling fluid. The main reason is that the speed of the air flow is much higher than the speed of the washing solution;

- Associated cleaning of the well during drilling. Cuttings removal is achieved by the movement of a powerful ascending air flow in the gap between the drill string and the borehole wall;

- There is no need to use a washing solution, for the manufacture of which it is necessary to purchase bentonite and organize the transportation of water to the place of work;

- Fast and convenient change of the drilling tool.

The disadvantages of drilling by pneumatic percussion method include the need for a large volume of compressed air, it is possible to stick the drill string when drilling aquifers and rocks with increased fracturing. The stability of the borehole walls should be ensured.

Diamond drill bits

The diamond drilling tool is a hard-alloy diamond-bearing working matrix in a steel case, which is equipped with an internal connecting cone-type locking thread.

Such drilling tools differ in the shape of the working matrix, in the quality characteristics of the diamonds used, as well as in the flushing systems used.

Such metal-containing powders hold diamonds well and make it possible to produce working dies with different hardness and wear resistance. Tungsten-based diamond matrices have the best performance in terms of such qualitative characteristics as strength, wear resistance and thermal conductivity.

In the manufacture of drill heads for diamond drilling tools, so-called industrial diamonds weighing from 0.05 to 0.34 carats are used. In the production of such a bit, for example, with a diameter of 188 millimeters, from 400 to 650 carats are consumed (from two to two and a half thousand diamond grains).

Drilling heads of diamond bits are manufactured in two modifications:

- single-layer (types KR. KT, DR, DT t DK), on which diamond grains are placed in the surface layer of the working edges of metal matrices according to certain schemes;

- impregnated (DI type) Yu on which fine diamond grains are distributed evenly throughout the matrix.

Diamond drilling tool

Diamond chisels are of the following types:

- with a surface arrangement of diamonds;

- impregnated (diamonds are placed on the surface up to 8 millimeters);

- tools of special designs;

- with a radial arrangement of channels and with an outer surface of a biconical type (DR);

- with a pressure channel and with toroidal protrusions (DK);

- with a synthetic type of placement of diamond grains (C);

- with impregnated diamond grains (I);

- bladed (DL);

- with an internal cone (DV);

- impregnated with pointed ends of the blades (DI);

- universal (DU).

Such a rock cutting tool is used when drilling deep (more than three kilometers) wells. The durability of a diamond tool is 20-30 times higher than that of a cone tool.