- Well silting

- Multilateral method

- Work technology and equipment

- The principle of the column technique

- Machine tools and drilling rigs

- Procedure for percussion drilling

- Do-it-yourself bailer

- Do-it-yourself bailer with a ball valve (without turning)

- How to make a bailer yourself at home

- Disadvantages and advantages of the process

- Advantages of hydrodrilling wells

- How to make a bailer bearing: the traditional way

- Equipment

- Manual settings

- Light self-propelled units

- Heavy installations

- Drilling rigs LBU

- Installation of CO-2

- Cost of equipment

- Defining conditions for offshore drilling

- Winch manufacturing

- Assembling a spoon drill

- The main methods of drilling wells

- Mechanical methods of drilling aquifers

- Features of the column method

- Features of the mechanical rotary method

- Features of the screw method

- Offshore drilling equipment

Well silting

Very often, during operation, sandy wells silt up. Large fractions of sand accumulate on the outside of the filter. Inside, due to vibrations, fine, silty sand settles inside the intake pipe. As a result, the volume of water supplied to the house is reduced.

As you can see, sand wells are an affordable water supply option for a garden plot or one or two private houses with little water consumption. With a limited budget, it is quite possible to do it yourself. However, when drilling, one should take into account not only the advantages of such a source, but also its disadvantages.

Multilateral method

This method consists in conducting two shafts from the main bottomhole glass, while the main shaft is used more than once.

In this case, the working area and the filtration surface increase, but the volume of drilling work in the surface formation decreases.

Depending on the auxiliary shafts, the following types of multilateral design are possible:

- Radial - horizontal main shaft and radial - auxiliary.

- Branched - consists of two inclined trunks and an inclined main.

- Horizontally branched - similar to the previous type, but the angle of the auxiliary trunks is ninety degrees.

The choice of the type of multilateral design is determined by the shape of the auxiliary wellbores and their placement in space.

Work technology and equipment

Two methods of using a core drill are known: work with liquid supply to the bottom or dry, that is, without drilling fluid.

Drilling without the use of drilling fluid is used if non-cohesive soils are saturated with natural moisture in sufficient quantities for penetration and extraction. Water is also not supplied to the mine shaft when driving through fluid-plastic, soft-plastic and hard-plastic loams/clays, hard and plastic sandy loams.

The liquid is necessarily used when drilling rocky and semi-rocky rocks.In the absence of water in this case, the deepening is much slower. In addition, the probability of premature failure of the bit increases significantly, and therefore dry drilling is considered more expensive.

When drilling with drilling fluid, the penetration rate increases significantly. Most often, this method is used when drilling wells of considerable depth. This allows you to complete the work in the shortest possible time with minimal risk of damage to the crown.

Still water under high pressure is fed to the bottom during the development of a well in loose non-cohesive soils, if core sampling is not a task. In this case, the face is simply washed with a jet of water, freeing the shaft from the destroyed soil.

The principle of the column technique

The main element in core drilling is a destructive cutting part installed on the base of the core pipe. They call it a crown. For penetration of rocks, special crowns equipped with diamond cutters are used.

It is the diamond crown that ensures the almost unhindered passage of the drill to a great depth when driving water intake workings on limestone. That is, during the development of wells buried in bedrock, in the cracks of which, as a result of centuries of condensation, reserves of the purest underground water were formed.

The rock is cut with a crown rotating at high speeds. The speed of rotation of the drill can be adjusted depending on the density of the developed soil. The crown "cuts" the soil only along the edge of a kind of cylinder, the central part of which is pressed into the core barrel.

To extract the core, the drilling tool is raised to the surface.The soil captured by it is literally blown out of the core drill with a jet of air supplied to the upper part of the pipe. The blowing process is accelerated by tapping the projectile with a sledgehammer.

Core drills in the passage of strong rocks have greater productivity than matrix and cone bits. This is due to the high speed of rotation of the drill, which reduces the degree of effort applied to the development.

In addition, the bits completely destroy the rock, which will need to be “scooped out” with a bailer or water with pressure to wash the bottomhole. In fact, you will have to go through the same segment twice, or even three times: first destroy, then clear. Core technology allows you to go through and clear the face in one go.

Machine tools and drilling rigs

The choice of machine or drilling rig is determined by the purpose of the well and its diameter. The popularity of the core drilling method leads to the production of drilling rigs and machine tools all over the world. Heavy tractors, trucks and ATVs are suitable for exploration drilling rigs.

Most often, drilling equipment is mounted on classic cars of the MAZ, KAMAZ, Ural brands. However, there are installation options for lighter equipment, which is used for drilling water wells in private construction.

In manual rotary drilling, the core barrel is replaced by its historical predecessor - a glass. This projectile is a shortened version of a core barrel with a sharpened edge on the sole. The glass is twisted into the ground manually or using a motor drill and everything that has been stuffed into it is removed to the surface.

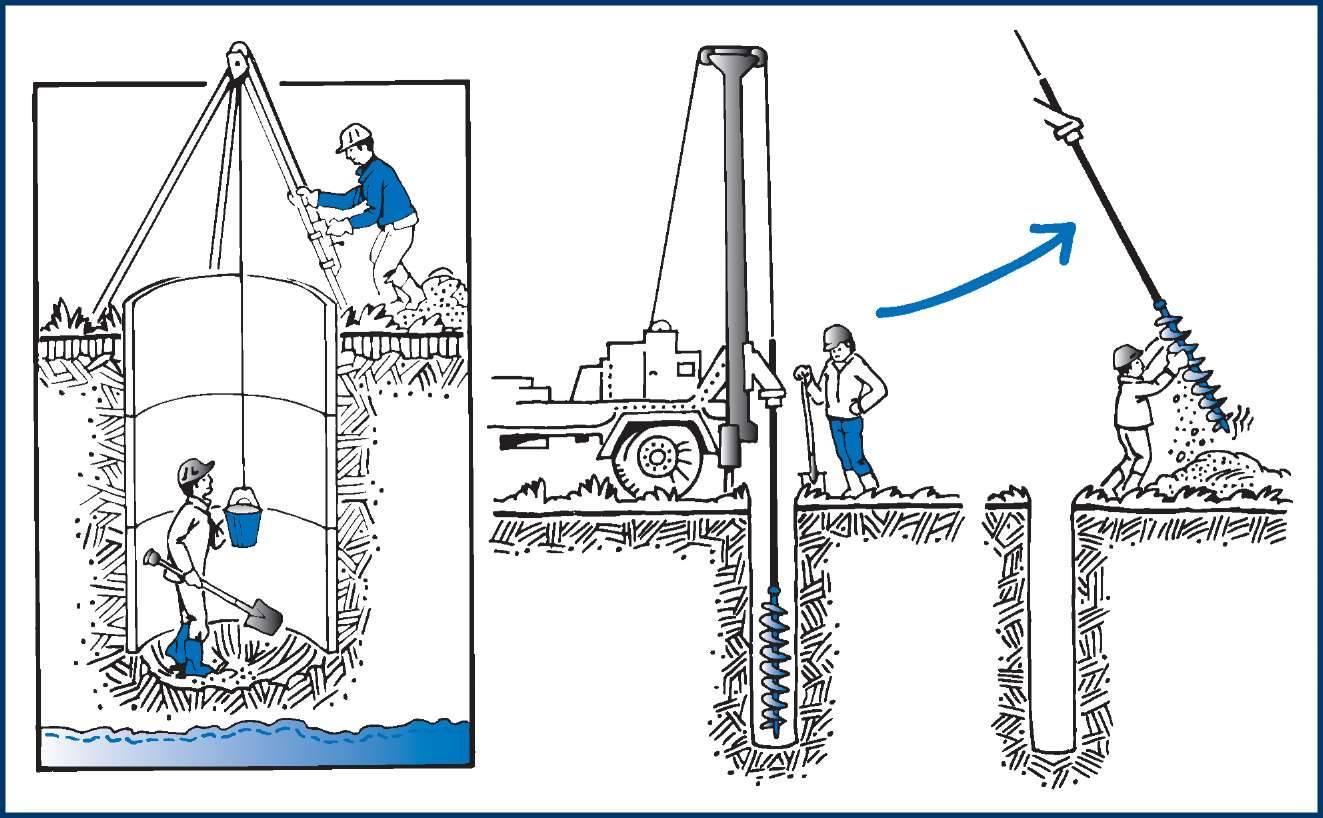

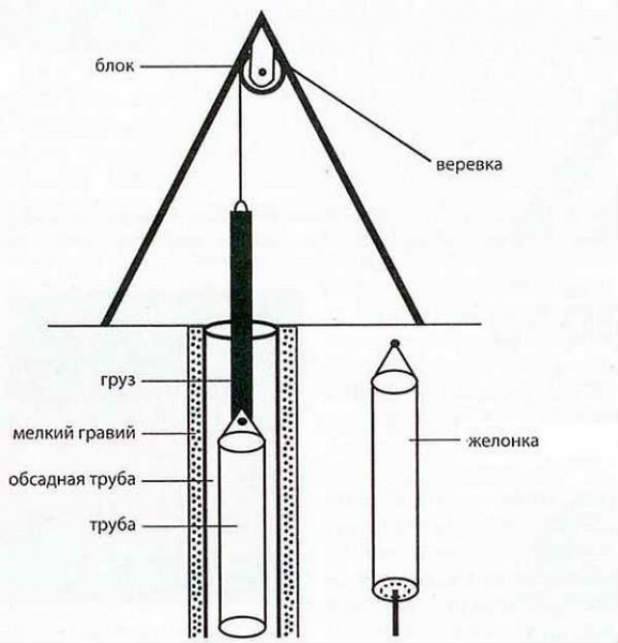

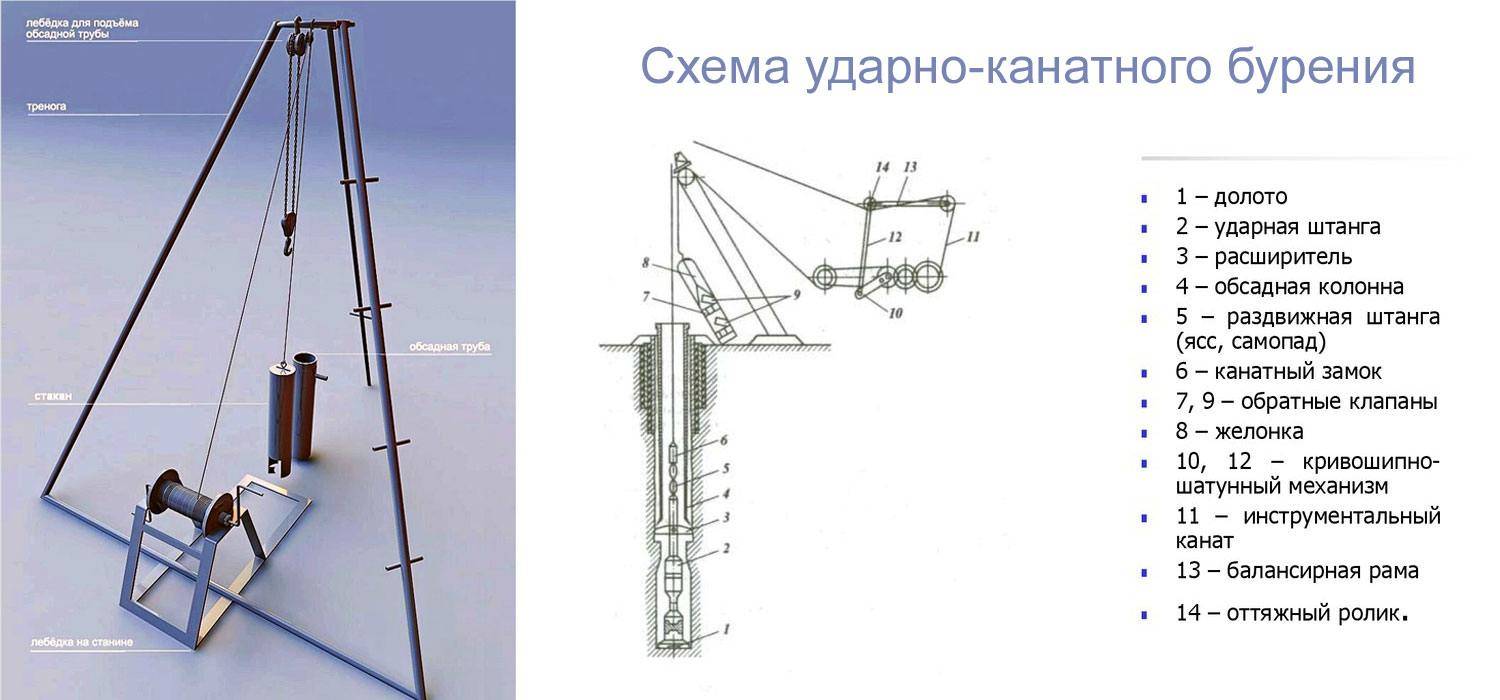

Procedure for percussion drilling

The work of the device consists in lowering and raising a glass filled with earth, and the sequence of creating a well using the shock-rope method is as follows:

- Preparation of a site for the placement of a drilling rig and selection of a site for the wellhead. In most cases, 2.5 m2 of free space is enough for this.

- First drilling. It is performed with a special tool and cannot be done deeper than 1.5 m.

- The rise of the destroyed rock to the surface and the simultaneous installation of the casing pipe.

- Fastening the drill glass (or any of its modifications, depending on the type of land) and then driving it into the soil. Each blow must be of such force that the tool does not go deeper than 0.5 m.

- Raising a glass filled with earth and cleaning it.

The last two operations are repeated many times until an aquifer is found.

Do-it-yourself bailer

With a welding machine and some skills in working with iron, a do-it-yourself bailer is done in a few hours.

Do-it-yourself bailer with a ball valve (without turning)

This version of the ball valve is assembled from spare parts that can be bought in stores. For manufacturing, a water pipe with a diameter of 89 mm was used. I also bought a concentric adapter 89 * 57 mm, and a ball from a bearing with a diameter of 60 mm.

Everything you need to make a ball valve bailer

The ball fits perfectly inside the adapter and gets stuck there. But it doesn't fit snugly. To fit everything better, the inner surface of the adapter is sanded - it fits almost perfectly.

This is what it looks like half assembled.At the bottom right, a ball is photographed in the transition - this is how it will be inside

The narrow part of the transition is inserted into the pipe and welded. The ball is thrown inward, the stopper is welded. And the final touch is to make a mount for a cable or twine. Everything, the do-it-yourself bailer is ready.

You may be interested in reading about how to purify well water.

How to make a bailer yourself at home

If you need to clean the well, but there is no sheet metal and welding for serious work at hand, there is a way out: a bailer with a valve from a plastic bottle.

Homemade bailer with a valve from a plastic bottle

This option is suitable for cleaning the well, but not for drilling. You need a bolt, the length of which is slightly larger than the diameter of the pipe for the bailer and a nut. Stepping back two or three centimeters from the edge of the pipe, one opposite the other, two holes are drilled. Their diameter is the same as the diameter of the bolt.

The valve is cut out of plastic. It is an ellipse. The smaller diameter of the ellipse is equal to the diameter of the pipe. It must be cut very precisely so that when inserted inside it fits snugly against the walls. The cut-out valve in the middle will be attached to the bolt; for this, four holes are made in the plastic through which the wire is threaded. How it all comes together is shown in the photo below on the left.

Only such a mount, as in the photo above, is very unreliable. After a few hits, your projectile may come off and you will have to decide how to get the bailer out of the hole. The best mounting option is one-piece, without seams and twists. How to do this will become clear if you watch the video. By the way, there is an important thing there - how to make hooks so that, if necessary, you can pull the bailer out of the well.

Disadvantages and advantages of the process

Summer residents who choose the technology of shock-rope drilling for the construction of hydraulic structures in their areas are guided by the advantages of the method. These include:

- the possibility of obtaining separate soil samples during the work for geological examination of the area;

- shortened time for the subsequent well construction, allowing to start activities immediately after the completion of the drilling procedure;

- the technique does not require the use of flushing fluid, which simplifies the drilling technology and reduces the labor intensity of the process;

- the possibility of creating a shaft of large diameter, from 0.5 m and more;

- preservation of the original appearance of the aquifer, expressed by the absence of pollution during the use of equipment;

- the method allows drilling wells in rocks of increased hardness, containing large boulders and pebble inclusions, and in soils that absorb washing fluid;

- simplified technology allows the full scope of work to be done on its own, which reduces the cost of paying for specialized teams;

- the possibility of effective and quick opening with subsequent testing of the aquifer.

With a lot of advantages, the technology of drilling with a shock-rope method has its drawbacks. Among them:

- A mandatory requirement is a vertical orientation when installing equipment. Deviations are unacceptable, as they prevent the correct installation of the casing.

- Low speed of work. If it is necessary to urgently build a well, a different drilling method will have to be used.

- Limited borehole length. With the deepening of the mine, productivity decreases.

- The selectivity of the method. The percussion-rope technology is not available for all rock types.In sandy soils of increased flowability, it is not used.

The list of advantages outweighs the disadvantages. Therefore, in suitable soils, the choice is obvious.

HelpfulUseless

Advantages of hydrodrilling wells

The technology of hydro-drilling for water among the people has gained popularity relatively recently, therefore it has many misinterpretations. First, it is a misconception that the method is only suitable for small wells. This is not true.

If desired, and with appropriate technical support, it is possible to hit wells with more than 250 meters by hydraulic drilling. But the most common depth of domestic wells is 15-35 meters.

The opinion about the high cost of the method is also not supported by calculations. Good speed of work reduces financial costs.

The obvious advantages of the method also include:

- compactness of the equipment;

- the possibility of drilling in an extremely limited area;

- minimum technological operations;

- high speed of work, up to 10 m per day;

- safety for landscape and ecological balance;

- the possibility of self-drilling;

- minimum cost.

Perhaps the most significant advantage of hydrodrilling is still the ability to drill in landscaped areas without significant aesthetic troubles.

The technology of hydraulic drilling on the MBU machine allows you to carry out a cycle of work on a small site and does not violate the landscaping of the site

The advantages of hydrodrilling are also very clear when compared with dry drilling technology, where it is necessary to constantly remove the working tool from the hole for cleaning and load it again.

Most of all, this technology is adapted to work with fine-clastic sedimentary soils, which are most easily removed from the well using a bailer. And the drilling fluid allows you to do without gelling.

Of course, for a good result of the enterprise, it is necessary to purchase the appropriate means of mechanization, because one home-made drill, even at shallow depths, is not enough.

How to make a bailer bearing: the traditional way

A metal ball that plunges into the pipe, immured on both sides and is called a bearing. Sometimes such a device is hard to find, but you can assemble it yourself.

To do this, stock up on lead shot. Ordinary bearings from something are also suitable for this. Now take a baby ball of a suitable diameter and cut it into two halves. After that, fill in the material and grease everything with iron glue (sold in specialized stores), and connect the two halves together.

As soon as the device is dry and securely fixed, remove the rubber and grind the resulting element on the machine. Then it can be used for the bailer. Do not assume that a home-made design will be flimsy. This bearing will last for many years.

Equipment

Screw rigs for drilling wells are divided into three types:

- manual;

- light mobile;

- heavy mobile.

They are designed for different tasks but work on the same principle.

Manual settings

The main advantage of such models is light weight and compactness. Many models are equipped with a motor, which greatly facilitates the process of drilling holes in the ground.

The main characteristics of manual models:

- compactness;

- light weight - the maximum weight of the installation reaches 200 kg, while the average weighs up to 50-80 kg;

- used for drilling drinking wells, as well as other construction work.

Due to their compactness, these small units can be used in any environment. You can also work indoors, such as in the basement.

Light self-propelled units

These are more powerful units that are installed on the base of trucks. This makes it easier to transport them. In addition, they can use the vehicle's chassis as a drilling platform.

Peculiarities:

- the weight of installations can reach 1 ton;

- ease of movement;

- high performance.

Naturally, such units win manual ones, but this is already industrial equipment.

Heavy installations

They are also mounted on the basis of the chassis of a heavy freight transport. However, unlike lungs, they are already a drilling complex, because. integrated with vehicle systems.

Peculiarities:

- control of the installation from the car;

- the possibility of drilling wells of large diameters and depths;

- autonomous operation - no additional equipment is required.

Thus, installations for this type of drilling are quite widely represented on the construction market. And they allow you to perform different types of work, and are also focused on all consumer groups - from homeowners to large industrial enterprises.

Drilling rigs LBU

One of the most popular mobile auger drilling rigs is the LBU 50 model. It is mounted on the chassis of such trucks:

- KamAZ;

- ZIL;

- Ural.

These drilling units are characterized by high power and reliability. They are used both for the manufacture of drinking wells, and for general construction and exploration work.

LBU installation

The machine can carry out different types of work:

- auger drilling;

- shock-rope;

- with washing;

- with purge;

- core.

Thus, it is quite versatile and can be used on various types of soil. Also, in the process of drilling with forehead-type machines, casing pipes can be installed.

Main characteristics:

- belongs to the class of self-propelled units;

- maximum well diameter – 850 mm;

- maximum penetration depth - 200 m;

- depth of drilling with augers - 50 m.

In the basic configuration, the unit is equipped with all the necessary elements for drilling operations.

Installation of CO-2

This is another popular industrial model. Auger drilling machines type co 2 is mainly used for arranging piles. The basis for the installation are cranes or excavators.

The main characteristics of the model:

- the ability to expand the base of the well;

- maximum drilling depth - 30 meters;

- maximum diameter - 60 cm;

- type of drilling - auger.

Installation of CO-2

Cost of equipment

The average price of drilling equipment can vary from several thousand rubles to millions. This is due to the fact that there are many models on the market that are aimed at different consumers.

For example:

- installation of LBU-50 - the average cost, depending on the base and configuration, varies from 3 to 4 million rubles;

- small units are much cheaper. For example, the UKB-12/25 model costs about 200 thousand, and the PM-23 is around 100 thousand;

- kits for manual drilling will cost even less - the average cost will be in the range of 20-30 thousand;

- a simple auger drill can be purchased for 2-3 thousand.

Among the equipment, the model range of small-sized installations is the most popular and diverse. Since for relatively little money the buyer receives a full-fledged drilling unit.

Defining conditions for offshore drilling

The specific technology of underwater drilling is determined by various factors. Among them stand out:

- natural;

- technical;

- technological.

The main will be natural factors due to hydrometeorological, geomorphological, mining and geological conditions.

The first group of conditions will include all the characteristics of the marine environment (waves, temperature, presence of ice cover, level fluctuations, water flow rate, visibility). The greatest difficulty is caused by temperatures below zero, which lead to icing of equipment, and poor visibility.

The complexity of geomorphological conditions is determined by the structure of the shores, the composition of the bottom soil, its topography, and the depth of the water.

Mining and geological conditions include the geological structure of the deposit, the physical and mechanical properties of rocks at the drilling site, the morphological features of productive deposits at the development sites.

Winch manufacturing

The winch is a lifting block through which a cable passes, to which a glass or bailer is attached. If desired, it can be made by hand. For manufacturing, you can use logs, in the center of which a metal pipe or steel bar is clogged from the end side to give greater strength.Before hammering a metal part, you can drill holes on the ends of the log with a smaller diameter than the diameter of the part. This will make it easier to drive the axle and make it more secure. To prevent turning, special ears are welded to one of the ends of the axis emerging from the log. A handle is welded to the other end, which can be made from a piece of pipe, giving it the shape of the letter "G". The gate is fixed between the racks of the frame, a cable is wound around it when lowering or raising the tool from the well, hitting the glass and its subsequent extraction filled with soil.

Assembling a spoon drill

It is necessary to prepare a pipe with a wall thickness of at least 5 mm. An incision is made on the side wall. Its width depends on the type of soil: the looser it is, the smaller the gap. The lower edge of the pipe is rounded with a hammer. This edge is bent so that a helical coil is formed. On the same side, a large drill is fixed. On the other hand, attach the handle.

The spoon drill includes a long metal rod with a cylinder at the end. The cylinder has 2 components, which are located along or in the form of a spiral. A sharp cutting edge is located along the bottom of the cylinder.

The main methods of drilling wells

Depending on the type and condition of rocks in the near-surface layer, the diameter and type of the rock cutting tool, the drilling method, the type of cleaning agent and the drill string, the following main methods of well drilling are used.

- 1. Installing the pipe-direction of the well into the hole, previously dug by hand. After installation in the pit, the pipe-direction is either cemented or buried.This method is used when drilling large-diameter wells with roller bits with mud flushing (mainly oil and gas wells) and when drilling geological exploration wells using the shock-cable method.

- 2. Drilling the well "dry", i.e. without flushing or blowing. This option is used when drilling from the surface of the earth in cases where the upper interval of the geological section is represented by sedimentary rocks using conventional projectiles (without a removable core receiver). For drilling, the core set is equipped with a SM or SA type carbide bit, and drilling is carried out with slow rotation of the column and increased loads to a depth of 2-3 m to bedrock. If the bedrock lies deeper, then “dry” drilling is carried out to the maximum possible depth, and then a directional pipe is installed and drilling is carried out to the bedrock already with flushing with a smaller tool.

It is possible to dry-drill by landing a casing string equipped with a bit or shoe into loose loose rocks with rotation and under the action of increased axial load to the maximum possible depth. After that, the casing string is not extracted, and the rock inside the string is drilled out already with flushing with a smaller core barrel set.

3. Drilling with purge air hammer or cone bit can be used on any, including hard, weathered rocks, rocks saturated with large debris and at considerable depths. This method is recommended for various drilling conditions, but only if no core is required in the drilling interval.For drilling, for example, a P-105 pneumatic hammer (bit diameter 105 mm) and a compressor providing an air pressure of 0.2-0.5 MPa can be used. For operational drilling, it is advisable to have a mobile compressor in the organization with a set of drilling tools specifically for drilling operations.

When drilling in unstable, alluvial, loose rocks, drilling with a pneumatic hammer can be carried out from the surface with advanced wellbore fastening, when the destruction rocks at the bottom accompanied by clogging and casing, equipped with a shoe or a special bit. According to this scheme, drilling is carried out in accordance with Atlas Copco's OD, ODEX and DEPS methods.

4. Drilling with flushing with diamond or carbide tools is carried out when drilling from underground mine workings without installing casing pipes, if the rocks are stable and not prone to swelling and collapse.

In this case, technical water is removed from the well by a spout and enters the sump along the groove.

The wellhead when drilling horizontal or rising wells drilled from underground mine workings is necessarily equipped with a special wellhead-sealing nozzle when using the SSK projectile for drilling. Then the delivery and extraction of the core receiver and overshot is carried out due to the adjustable hydraulic head in the sealed space of the wellbore.

The option of drilling with flushing is also practiced when drilling wells from the surface of the SSC.In this case, drilling is carried out with flushing with water using an SSC core set with a hard-alloy or diamond crown to the maximum depth and a core receiver with a core is removed to the surface. Technical water, at the initial stage, pours out of the well and is removed outside the drilling rig along the groove. Next, the casing pipe of a larger size left in the well and emerging on the surface of the core pipe is drilled, equipped with a reinforced shoe. After drilling with the casing pipe, drilling with the SSK projectile continues, and drilling with the casing string is carried out until the casing string enters the dense bedrock.

Drilling with flushing is also carried out when drilling with a double column of KGK (hydrotransport of the core). In this case, water circulates through the gaps in the string and enters the sump without pouring out and without contacting the well walls.

Mechanical methods of drilling aquifers

Mechanical drilling is performed using nozzles made of hard alloys. They are located on the drilling munition. In addition, heavy equipment is needed for this.

Wells made by this method are characterized by high productivity and a good level of water quality. This category of method of drilling sources for the extraction of water, for its part, is divided into subtypes.

Thus, the following main 3 types, which are used in modern engineering hydrogeology, can be attributed to mechanical methods:

- mechanical rotary subtype;

- columnar subtype;

- screw subtype.

Features of the column method

Core drilling of wells is considered a good viable option from the category of mechanical method, in which the worked out soil is an integral rod called a "core". It is expedient to use this method for bottomhole wells with a huge depth indicator (up to 1000 m) in areas dominated by rocks.

Core drilling technology is performed by rotating the drilling rig, which has a high-strength nozzle that looks like a diamond crown.

In addition to these advantages, the method has a couple more important advantages:

- good drilling speed;

- core drilling rigs are characterized by compactness and good maneuverability;

- due to the fact that the destruction of the rock occurs not by a continuous method of slaughter, but by the ring method, the efficiency of drilling increases.

The disadvantages of this method include the fact that with the help of it it is possible to make wells with only a small (up to 15-16 cm) diameter. In addition, when they are formed just by this method, the wear of drill bits occurs quite quickly.

Features of the mechanical rotary method

The technology of rotary drilling of wells involves the use of a bit, which is fixed on a drilling rig, capable of making rotation. He, for his part, is driven by a deliberately built-in device called a "rotor".

This drilling method is considered one of the most productive, since it allows you to reach deep aquifers, where there is the purest water without various compounds, as well as iron.In addition, drilling of wells by the rotary method makes it possible to achieve a large stable flow rate of the source on virtually any soil.

Perhaps, the disadvantages of this method include the high consumption of both clay and water, which are necessary for the manufacture of the flushing mixture, and the fact that during the flushing of the trunk itself, clay elements enter the aquifer. All this, of course, makes this method of well formation more laborious.

In addition, in winter there are certain difficulties when choosing this method. This is explained by the fact that in this case it is useful to heat the flushing mixture, which is not at all easy to do in such volumes.

Features of the screw method

This method is considered the most optimal for shallow sources in areas where loose soils are located. With the use of the auger drilling option, work on the formation of a well for the extraction of drinking water is carried out quite quickly.

Moreover, this method does not require the employment of highly skilled workers and the use of heavy special equipment. That's why it is usually chosen for aquifers just in private land ownership.

All work with this type of drilling is performed using an auger. This device is a rod with blades and cutters. With the help of these elements, rocks are removed from the borehole channel.

The screw method has the following additional advantages:

- providing enormous mechanical speed;

- in the course of work, the cleaning of the bottom hole occurs continuously, in other words, in parallel with the process of rock destruction;

- it is possible at the same time with drilling to make and lay the walls of the well from concrete or steel, which are needed to hold the rock in order to prevent its collapse.

Offshore drilling equipment

Offshore drilling of wells is carried out from floating drilling facilities located on the surface of the water. Complexes of special underwater wellhead equipment are installed at the bottom of the sea. They are less susceptible to damage even when the floating platform is displaced.

Underwater complexes allow you to combine equipment located on the surface of the water and at the bottom of the sea into a single whole, ensuring the efficiency of work.

Offshore well drilling blowout preventer

When using subsea equipment, a greater accuracy of guiding the drilling tool into the well is achieved, and a closed circulation of the drilling fluid is also provided. In addition, a closed technological connection allows you to more accurately control the drilling process.

Wellhead equipment reliably closes a drilling well, preventing blowouts in case of accidents or heavy seas.

Subsea wellhead equipment has several modifications, the use of which allows drilling wells at different depths.

They all meet the requirements that apply to this equipment:

- durable;

- vibration-resistant;

- withstand strong external pressure;

- sealed;

- controlled remotely.